Preparation method of pericarpium citri reticulatae absolute oil and application of pericarpium citri reticulatae absolute oil in cigarettes

A technology of tangerine peel and tobacco materials, applied in the fields of application, tobacco, and tobacco treatment, to achieve the effects of improving quality, high yield, solution state, and solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

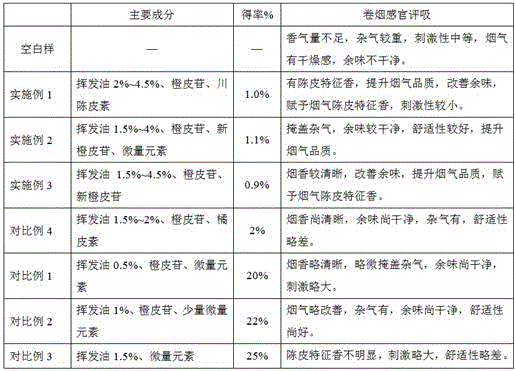

Examples

Embodiment 1

[0029] (1) Crush tangerine peel: crush tangerine peel with a water content of 10% to 5mm tangerine peel grains;

[0030] (2) Fermentation of tangerine peel: take pectinase according to 1.5% of the mass of tangerine peel grains, and take cellulase according to 1.5% of the mass of tangerine peel grains; place the tangerine peel grains obtained in step (1) at a temperature of 301°C and a humidity of 65%. In a constant temperature and humidity environment, add pectinase and cellulase to ferment for 3 days by spraying, and turn the pile every 1 to 2 days to fully decompose the pectin and cellulose in the tangerine peel;

[0031] (3) Dried tangerine peel: Add 10 times the volume of petroleum ether to the fermented tangerine peel grains obtained in step (2) and mix well to obtain a mixed material;

[0032] (4) Extraction and filtration: Heat the mixed material obtained in step (3) to 100°C and keep it warm for 5 hours, then filter with a 100-mesh filter to obtain the extract;

[003...

Embodiment 2

[0038] (1) Crush tangerine peel: crush tangerine peel with a water content of 20% to tangerine peel grains with a particle size of 4mm;

[0039] (2) Fermentation of tangerine peel: take pectinase according to 5% of the weight of tangerine peel grains, and take cellulase according to 5% of the weight of tangerine peel grains; place the dried tangerine peel grains obtained in step (1) at a temperature of 40°C and a humidity of 90%. In a constant temperature and humidity environment, add pectinase and cellulase to ferment for 10 days by spraying, and turn the pile every 1 to 2 days to fully decompose the pectin and cellulose in the tangerine peel;

[0040] (3) Dried tangerine peel: Add 2 times the volume of petroleum ether to the fermented tangerine peel grains obtained in step (2) and mix well to obtain a mixed material;

[0041] (4) Extraction and filtration: Heat the mixed material obtained in step (3) to 30°C and keep it warm for 12 hours, then filter with a 10-mesh filter to...

Embodiment 3

[0047] (1) Crush tangerine peel: crush tangerine peel with a water content of 7% to 0.1mm tangerine peel grains;

[0048](2) Fermentation of tangerine peel: take pectinase according to 0.1% of the mass of tangerine peel grains, and take cellulase according to 0.1% of the mass of tangerine peel grains; place the tangerine peel grains obtained in step (1) in a room with a temperature of 60°C and a humidity of 60%. In a constant temperature and humidity environment, add pectinase and cellulase to ferment for 1 day by spraying, and turn the pile every 1 to 2 days to fully decompose the pectin and cellulose in the tangerine peel;

[0049] (3) Dried tangerine peel: Add 15 times the volume of petroleum ether to the fermented tangerine peel grains obtained in step (2) and mix well to obtain a mixed material;

[0050] (4) Extraction and filtration: Heat the mixed material obtained in step (3) to 150°C and keep it warm for 0.5h, then filter with a 1000-mesh filter to obtain the extract;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com