Patents

Literature

44 results about "Nickel boride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel borides are inorganic compounds with the chemical formula NiₓBy, where x and y vary. A common formula is Ni₂B, which is available in two forms, known as P−1 and P−2. Other less common borides of nickel are NiB, Ni₃B, o-Ni₄B₃ and m-Ni₄B₃ (o for orthogonal, m for metastable).

C5/C6 alkane isomerization catalyst loaded with nickel boride as well as preparation method and application method thereof

The invention relates to a C5 / C6 alkane isomerization catalyst loaded with nickel boride as well as a preparation method and an application method thereof. The catalyst comprises a carrier and the nickel boride the weight of which is 1-5% of that of the carrier, wherein the carrier is formed by aluminium oxide and an H beta molecular sieve; the weight ratio of the aluminium oxide to the H beta molecular sieve is (1:9)-(9:1). According to the catalyst provided by the invention, halogen components are not needed to be added, and noble metals are not used, so that the environmental pollution is avoided and the catalyst cost is reduced; besides, the catalyst can be directly used for isomerization process without requiring pre-hydrogenation for reduction. Tests prove that when the catalyst is used for isomerization reaction for catalyzing n-hexane and n-pentane, the activity of the catalyst is higher, and the isoalkane selectivity and the catalyst stability are better.

Owner:BC P INC CHINA NAT PETROLEUM CORP

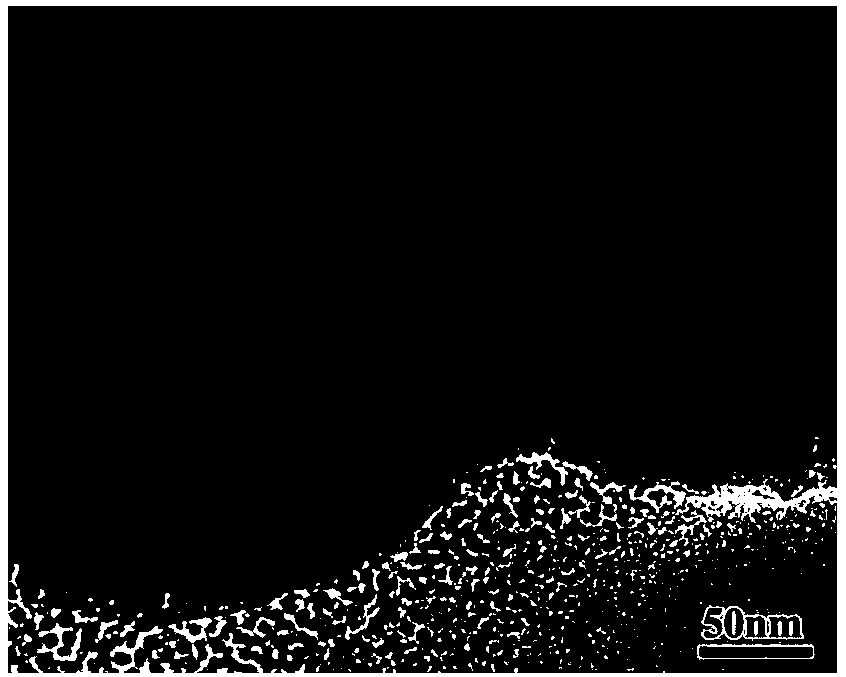

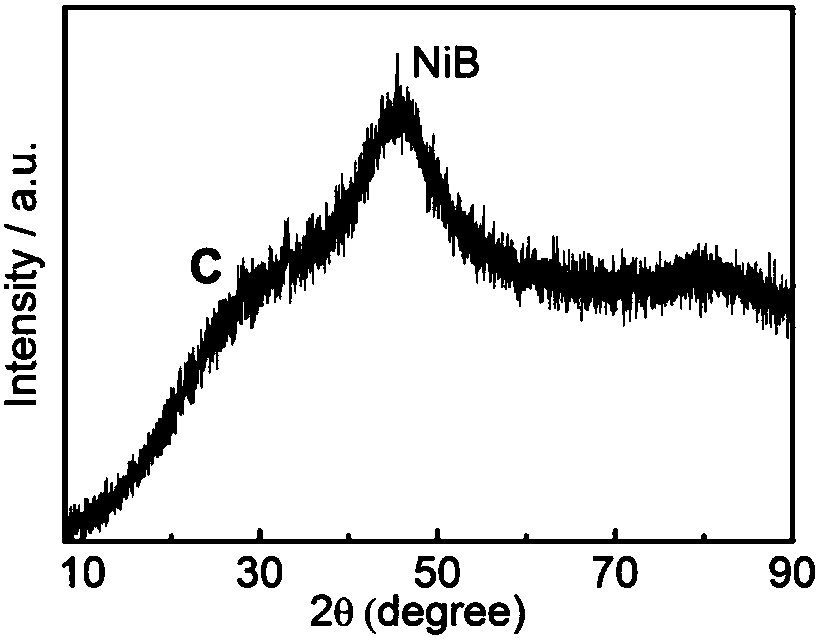

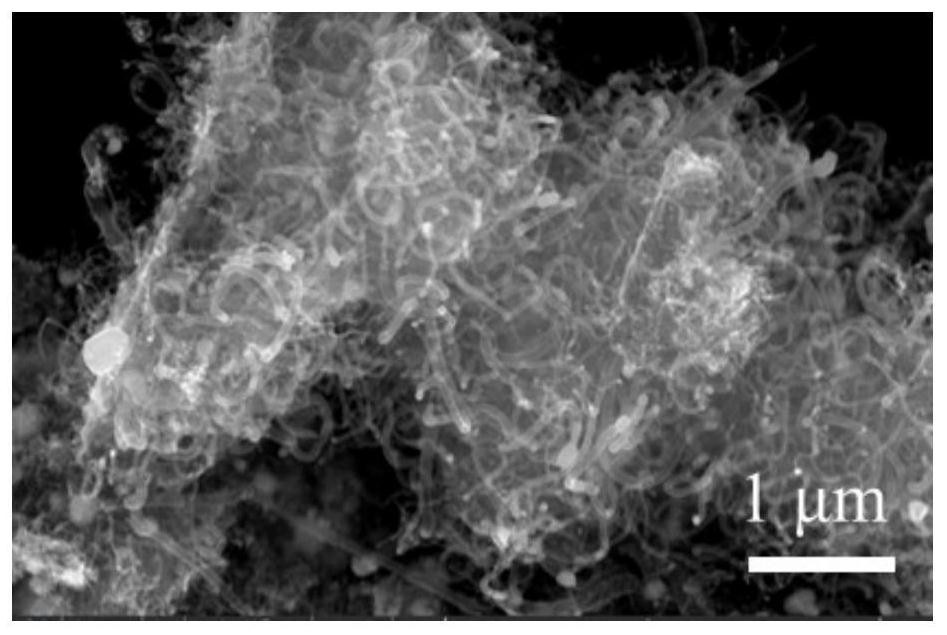

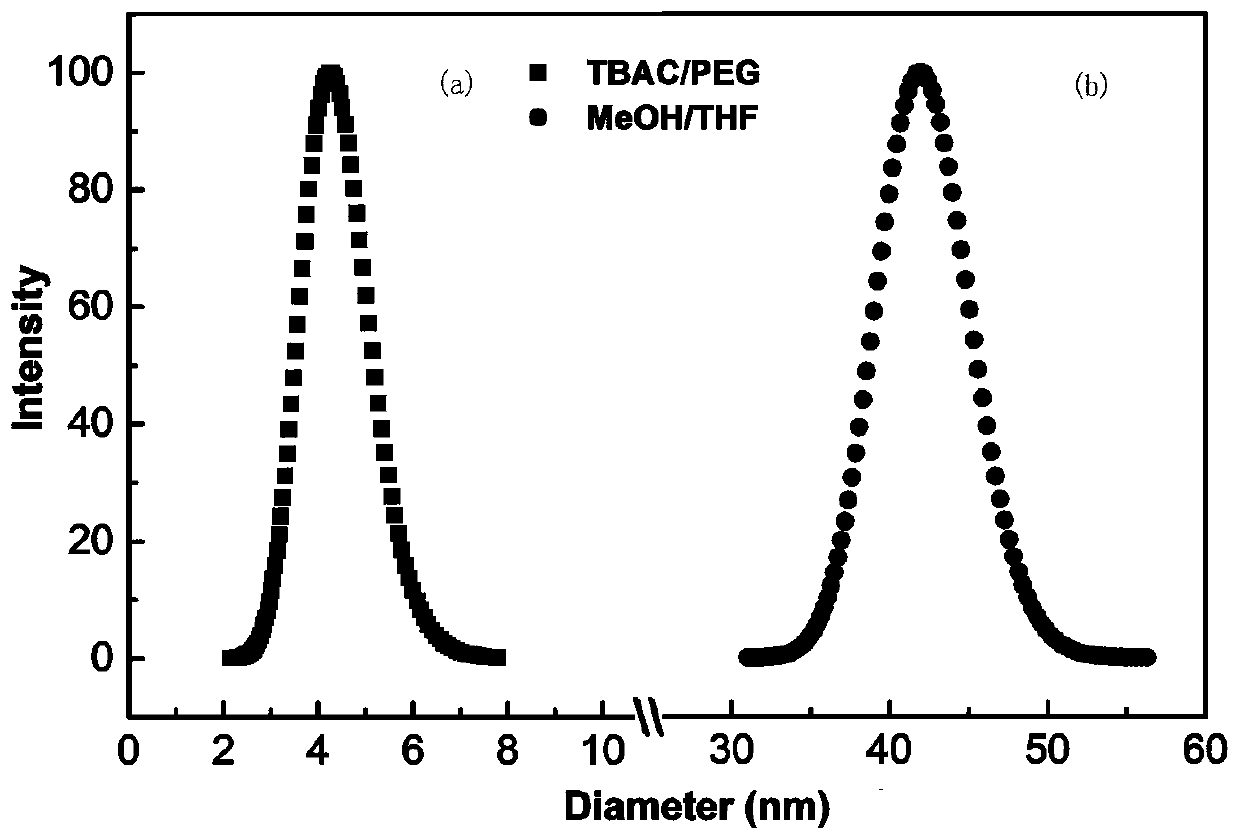

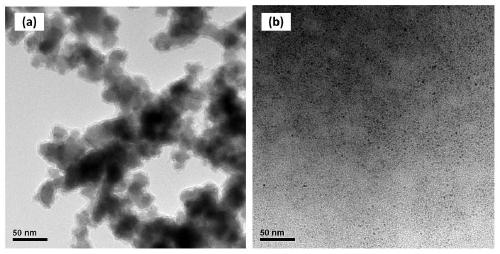

Nano nickel boride (NiB) amorphous alloy and preparation method thereof

The invention discloses a nano nickel boride (NiB) amorphous alloy and a preparation method thereof. According to the preparation method, the nano NiB amorphous alloy with small particle size and large specific surface area is prepared by adopting a liquid phase reduction method, wherein the mass percent of Ni is 10-80 percent, and the mass percent of B is 20-90 percent. The preparation method comprises the steps of: 1, preparing a solution; 2, generating a sediment; and 3, washing the sediment and storing. The invention has the advantages that the NiB amorphous alloy has small particle size of particles and large specific surface area; and the preparation method is simple, is beneficial to massive production, and is suitable for a catalytic hydrogenation reaction.

Owner:CHINA NAT ACAD NANOTECH & ENG

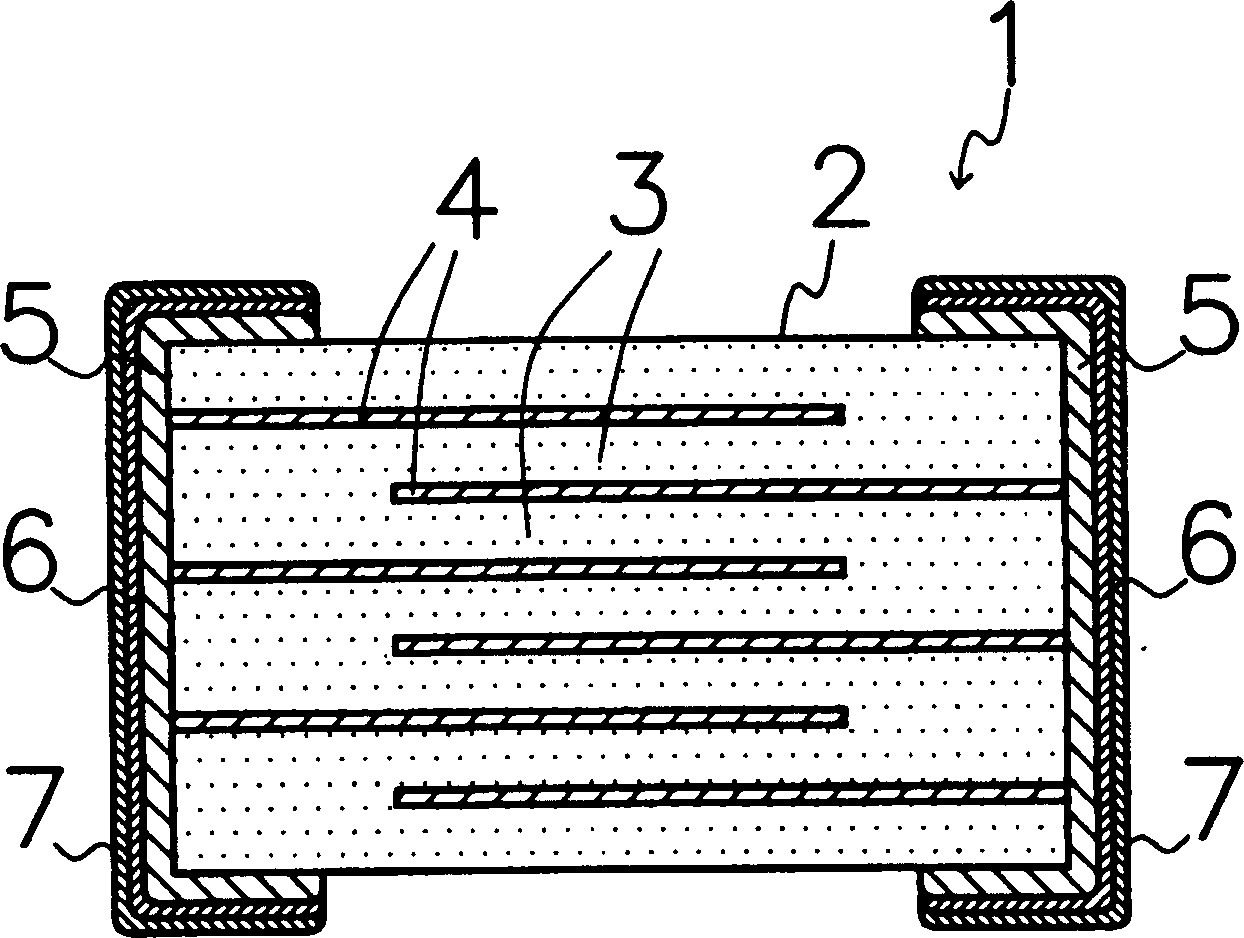

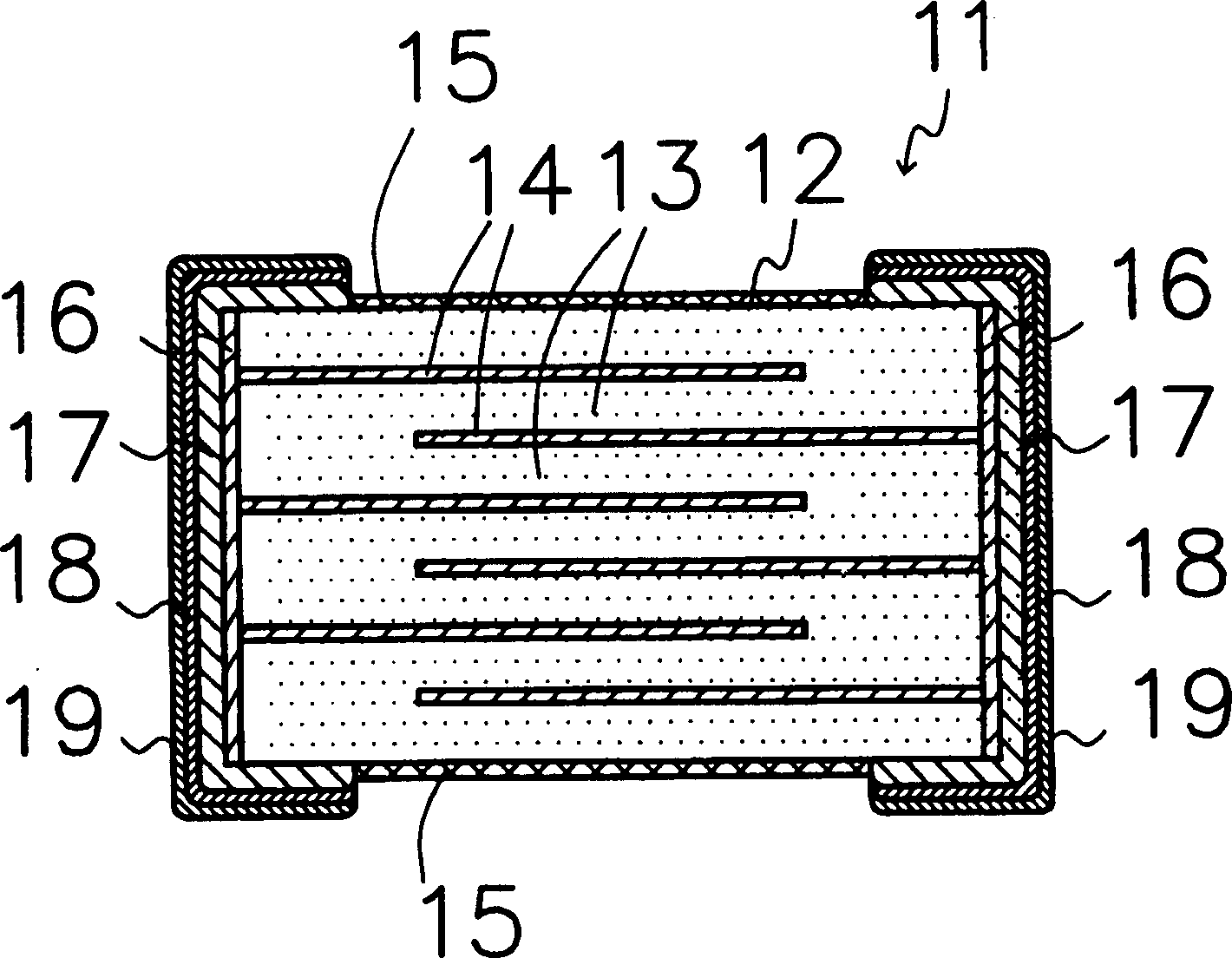

Conductive paste, lamina ceramic electronic element producing method and lamina ceramic electronic element

InactiveCN1405791APrevent surface oxidationFixed capacitor dielectricStacked capacitorsConductive pasteAlloy

Provided is a Ag-based conductive paste for a terminal electrode which suppresses oxidation of the Ni surface of an internal conductor and therefore brings about excellent joining with Ni even when baking is performed in the atmosphere in the case where Ni is used as the internal conductor of a laminated ceramic electronic component. The conductive paste includes at least one of an Ag powder and an Ag alloy powder, a nickel boride powder, an inorganic binder and an organic vehicle, wherein the quantity of the nickel boride powder is within the range of about 5% by weight or more, but less than about 60% by weight of the total paste.

Owner:MURATA MFG CO LTD

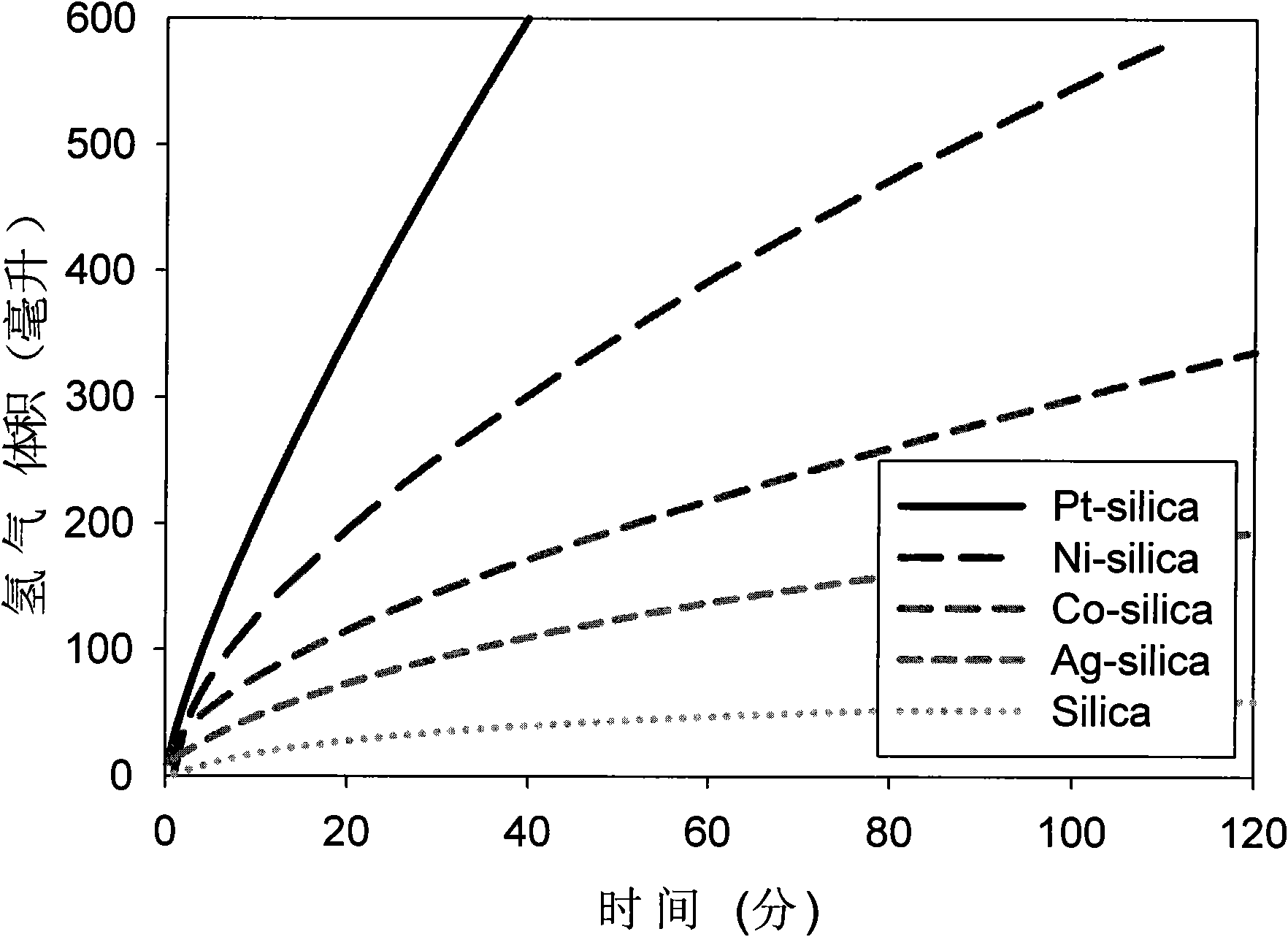

Catalyst for catalytically hydrolyzing sodium borohydride to prepare hydrogen and preparation method thereof

ActiveCN102029159AFulfil requirementsMeet the requirements), suitable for industrial implementationHydrogen productionMetal/metal-oxides/metal-hydroxide catalystsSilicon oxideReducing agent

The invention discloses a catalyst for catalytically hydrolyzing sodium borohydride to prepare hydrogen and a preparation method thereof. The catalyst is characterized in that the catalyst is a composite catalyst formed by taking silicon oxide as the carrier and coating more than one metal nanoparticle layers on the carrier; the diameter of the silicon oxide particle is 100-1000nm; the metal nanoparticle is nickel or nickel boride; the diameter of the metal nanoparticle is 10-200nm; and the mass of the metal nanoparticle is 5-50% that of the carrier. The preparation method comprises the following steps: 1, preparing the silicon oxide carrier: firstly preparing defined amount of ammonia water and ethanol into mixed liquor, then adding tetraethoxysilane to the mixed liquor and stirring the mixture to react to prepare silicon oxide carrier particle suspension; and 2, coating the nickel or nickel boride metal nanoparticle: taking 100ml of silicon oxide suspension, adding defined amount ofmetal salt solution to the suspension, after stirring and uniform mixing, adding excessive reducing agents for reaction, thus obtaining nickel or nickel boride-silicon oxide catalyst suspension.

Owner:TIANJIN POLYTECHNIC UNIV

Termination electrode for multilayer sheet-type temperature-sensitive ceramic resistor and preparation method thereof

InactiveCN102522169AGood electrical conductivityHigh bonding strengthResistor terminals/electrodesNegative temperature coefficient thermistorsElectrical resistance and conductanceSlurry

The invention provides a termination electrode for a multilayer sheet-type temperature-sensitive ceramic resistor and a preparation method thereof. The termination electrode comprises components of, by weight, 40-70% of silver powder, 5-35% of nickel boride, 2-5% of inorganic binder and 25-28% of organic binder. The preparation process comprises steps of: adding the organic binder into the inorganic binder to prepare a fluid suspension; dipping a multilayer sheet-type temperature-sensitive ceramic body in the fluid suspension; drying and sintering to obtain a cladding body with a glass coating formed on a surface thereof; coating a termination electrode slurry on two end faces of the cladding body; and sintering the cladding body to form a Ag termination electrode. The termination electrode of the invention has high conductivity, can fuse well with the glass coating, formed in an early stage, for resisting erosion by a plating liquid, and eliminates unfavorable influences of the glass coating on great fluctuation of resistance of the sheet-type element.

Owner:HUAZHONG UNIV OF SCI & TECH

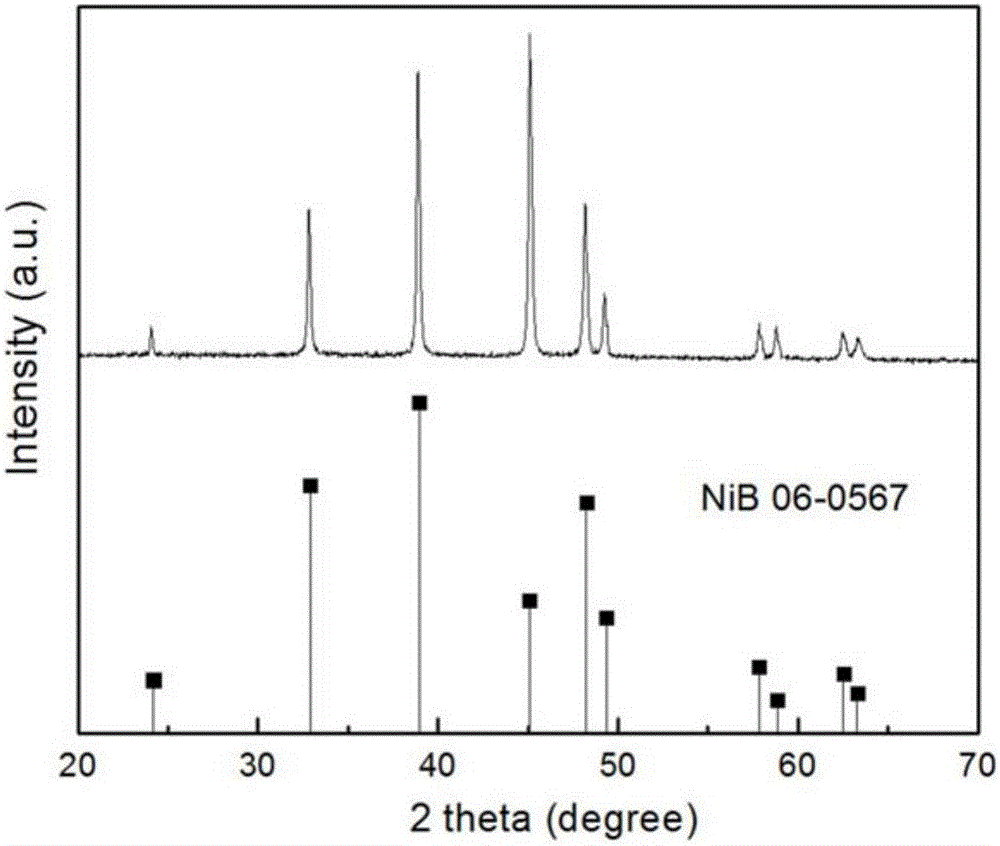

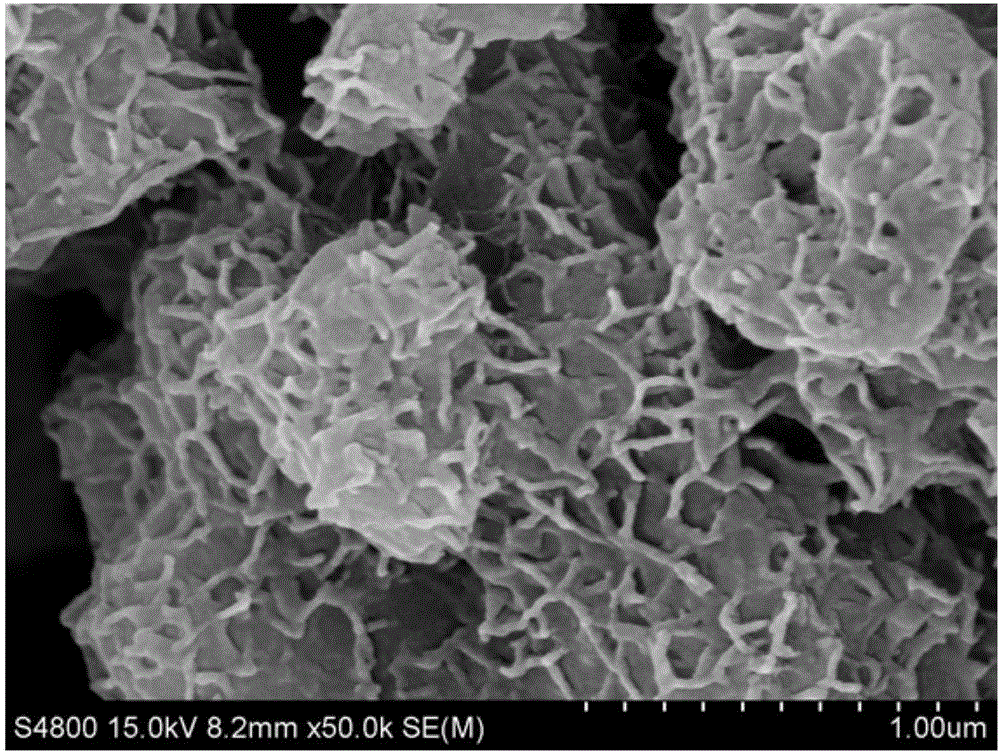

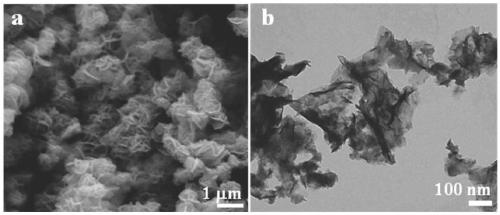

Flaky porous nickel boride powder and preparation method thereof

The invention discloses flaky porous nickel boride powder and a preparation method thereof and belongs to the technical field of inorganic powder preparation. The powder is crystalline-state NiB and is composed of nanosheets with the average thickness of 20 nm and the plane view size of 200-300 nm. The nanosheets are connected in a staggered mode to form an open porous structure. The powder is prepared through the steps that micron-order metallic nickel powder, amorphous boron powder and alkali chloride powder are mixed; the mixed powder is put in a corundum crucible and heated to 1,000 DEG C or above under argon protection, and natural cooling is carried out after heat preservation is carried out for 0.5-2 h; the obtained product is soaked with water for 1-3 h, filtered, washed multiple times with water and ethyl alcohol respectively and dried, and the flaky porous NiB powder is obtained. The obtained nickel boride powder is in a crystalline state, has a flaky porous structure, can serve as a catalyst carrier material and also is a potential inorganic functional material.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

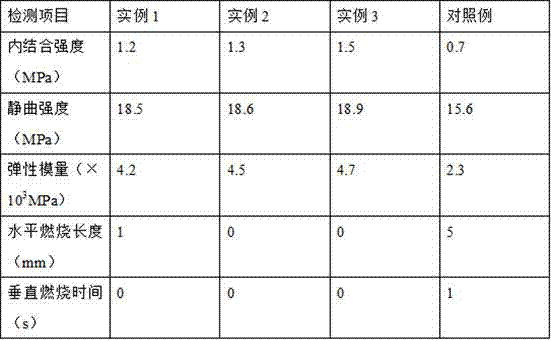

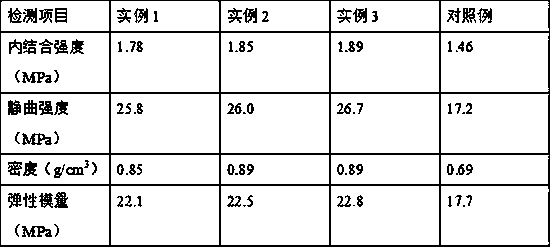

Preparation method for biomass adhesive-free plate

InactiveCN107984590AHigh adsorption activityImprove mechanical propertiesWood working apparatusFlat articlesFiberFurfural

The invention relates to a preparation method for a biomass adhesive-free plate, and belongs to the technical field of artificial board preparation. The preparation method includes the steps that nanoscale hydrotalcite is obtained through a hydrothermal method, organic acid and nickel boride are added while a hydrothermal reaction is made, the nickel boride is used as a catalyzer, the chelating property of the organic acid enables parts of metal ions in the hydrotalcite to leave original crystal lattices to enter the organic acid, cavities are generated in the original crystal lattices of thehydrotalcite, the generated cavities enable adsorption activity of the hydrotalcite to be greatly improved, a self-made inflaming retarding fortifier is obtained, bagasse and alkali liquor are mixed to be subject to soda boiling, in the process, a large number of active groups are increased in the fiber surfaces, through increase of the active groups, the chemical bonding force of the bagasse fibers is increased, furfural generated in the hydrolytic process can be soaked into the hydrotalcite under the hot pressing effect, a physical anchoring structure is formed after curing is carried out, and the mechanical property of the adhesive-free plate is improved again.

Owner:CHANGZHOU OPTICAL MATERIAL

Preparation method of high-strength bamboo shoot shell packing materials

InactiveCN108214725AHigh adsorption activityHigh bonding strengthFlexible coversWrappersAdhesiveCorona discharge

The invention relates to a preparation method of high-strength bamboo shoot shell packing materials and belongs to the technical field of packing material preparation. According to the preparation method, firstly through a molecular sieve dewaxing principle, the surface of a bamboo shoot shell is subjected to dewaxing treatment, molecular sieve powder absorbing bamboo wax, lemon juice and bacterial suspension liquid are mixed for fermentation, then fermentation products and nickel boride are mixed and react in a high-pressure reaction kettle to obtain a reinforced material, and then the reinforcing material, urea resin and starch paste are utilized to prepare an adhesive. Then the surface of the dewaxed bamboo shoot shell is subjected to corona treatment, after the adhesive is applied, hotpressing is conducted, and thus the high-strength bamboo shoot shell packing paper is obtained. According to the preparation method, the surface of the bamboo shoot shell is subjected to corona treatment, corona discharge is utilized, low-temperature plasma is generated, thus free radicals are generated on the surface of the bamboo shoot shell, so that crosslinking occurs, the surface of the bamboo shoot shell is coarsened, the wettability to the modified adhesive is improved, the free radicals generated on the surface of the bamboo shoot shell can generate intermolecular adsorption and hydrogen bond adsorption with active groups in the modified adhesive, and the mechanical strength of a plate is improved.

Owner:黄旭东

Thermal electron reinforced ionic boronizing device and process

InactiveCN1632159AEasy to operateNo pollution in the processSolid state diffusion coatingBorideSource material

A thermal electron enhanced ion boronizing device and process, belonging to the category of metal material surface chemical heat treatment technology, is to use the hollow cathode effect and thermionic emission effect on the surface of ferrous metals and nonferrous metals to perform ion boronizing and boron-metal Co-infiltration techniques and devices. An ion boronizing device and method using solid metal boride as a boron supply source are provided. The hollow cathode effect and thermionic emission effect enhance the infiltration and controllability of boron. Boron-iron, boron-titanium, boron-chromium, boron-nickel, etc. are used as boride source materials to realize boronizing and boron-titanium, boron-chromium, boron-nickel co-infiltration. It is a glow discharge technology and device with convenient, fast, pollution-free, fast infiltration speed, uniform infiltration layer, controllable composition, simple equipment, low cost, and no hydrogen boronizing for the formation of boron atoms.

Owner:TAIYUAN UNIV OF TECH

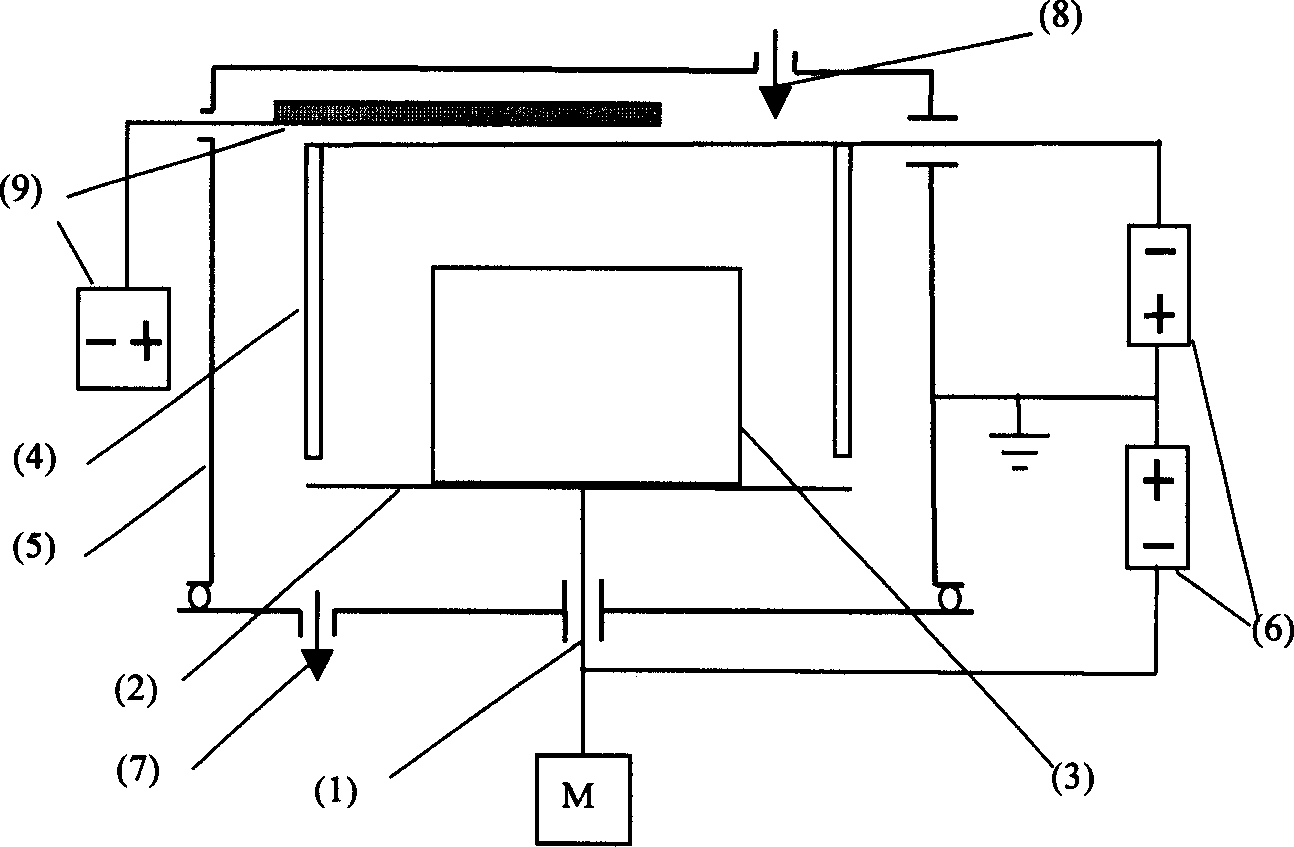

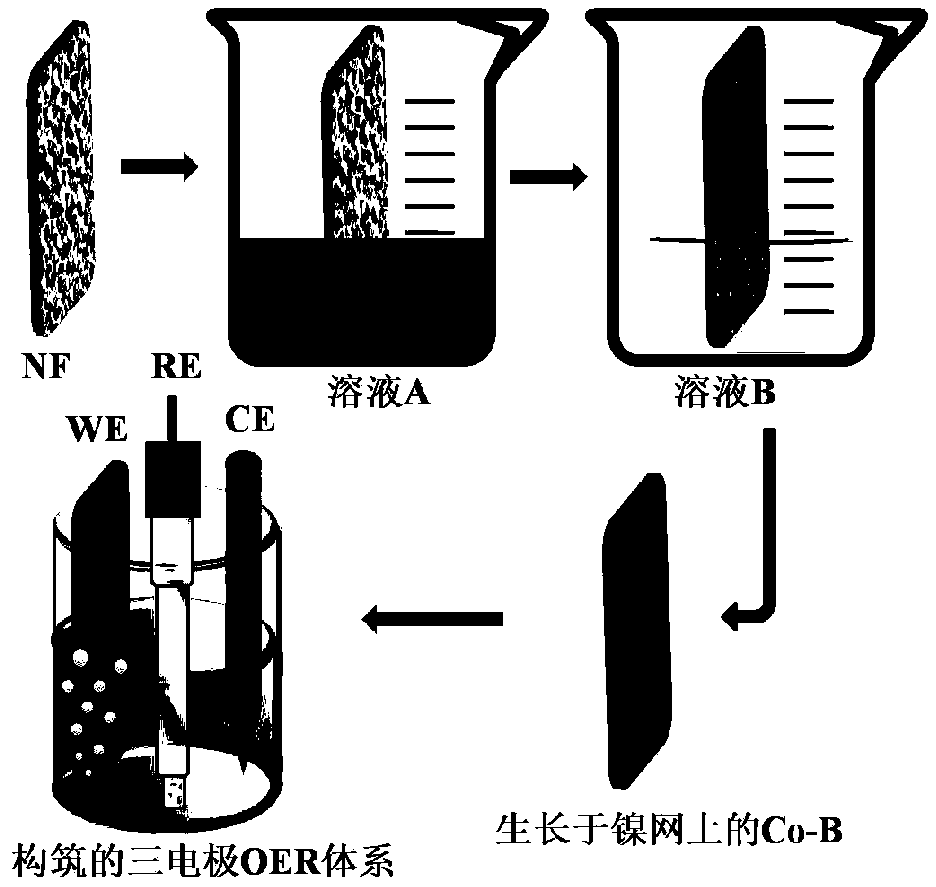

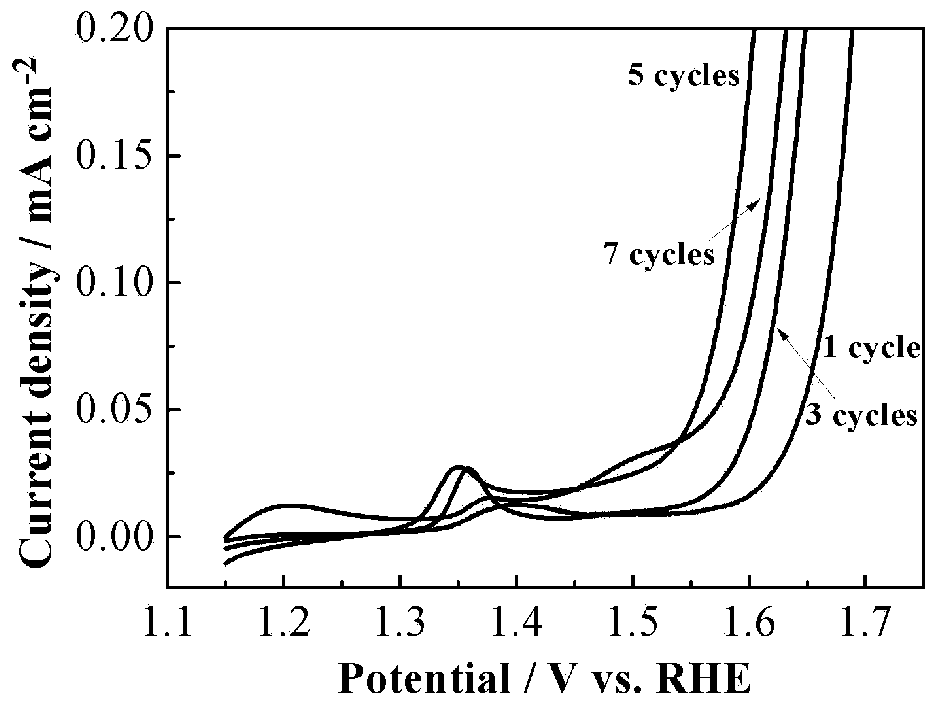

Preparation method of nickel boride base oxygen evolution catalyst

PendingCN109518217AImprove electrochemical stabilityImprove electrochemical activityElectrode shape/formsBorideAlcohol

The invention provides a preparation method of a nickel boride base oxygen evolution catalyst. The method comprises the following steps that a nickel net used for an afflux base is soaked in diluted hydrochloric acid to remove an oxidation layer, then ultrasonically washed with ethyl alcohol and redistilled water in sequence, and dried on the vacuum condition for standby application; a cobalt nitrate water solution and a sodium hydroxide solution of sodium borohydride are prepared respectively, and dissolved oxygen in the cobalt nitrate water solution and the sodium hydroxide solution of the sodium borohydride are removed for standby application; the nickel net is sequentially soaked in the cobalt nitrate water solution and the sodium hydroxide solution of the sodium borohydride, one-timesoaking in the cobalt nitrate water solution and the sodium hydroxide solution of the sodium borohydride is taken as one circulation, the circulation is repeated for a plurality of times, and a cobaltboride nanometer layer is generated on the surface of the nickel net and dried to obtain the nickel boride base oxygen evolution catalyst. The preparation method has the following beneficial effectsthat in comparison with a conventional method of synthesizing boride powder firstly and then dripping and spraying the solution to the afflux base, higher electrochemical stability and activity are possessed.

Owner:UNIV OF JINAN

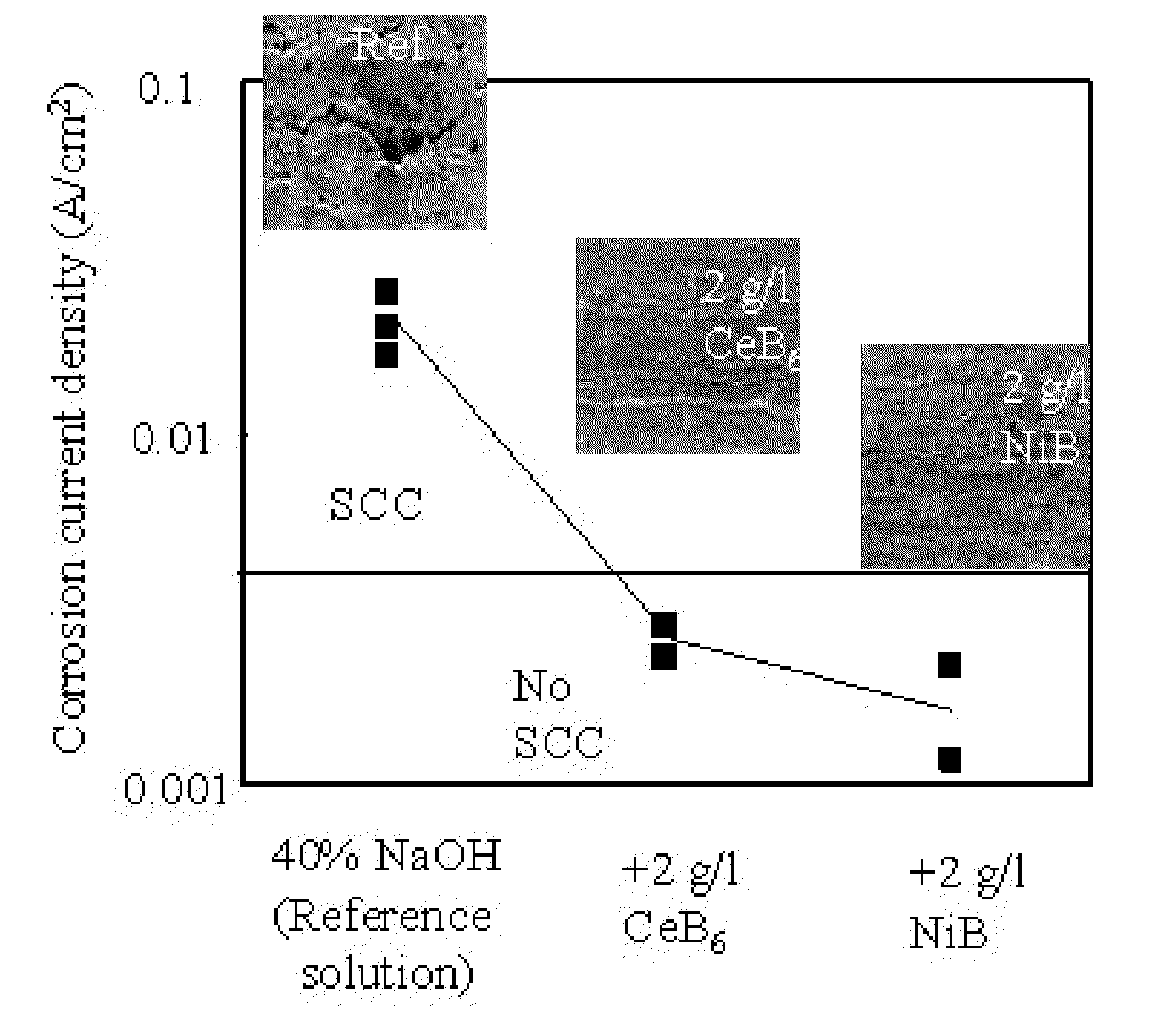

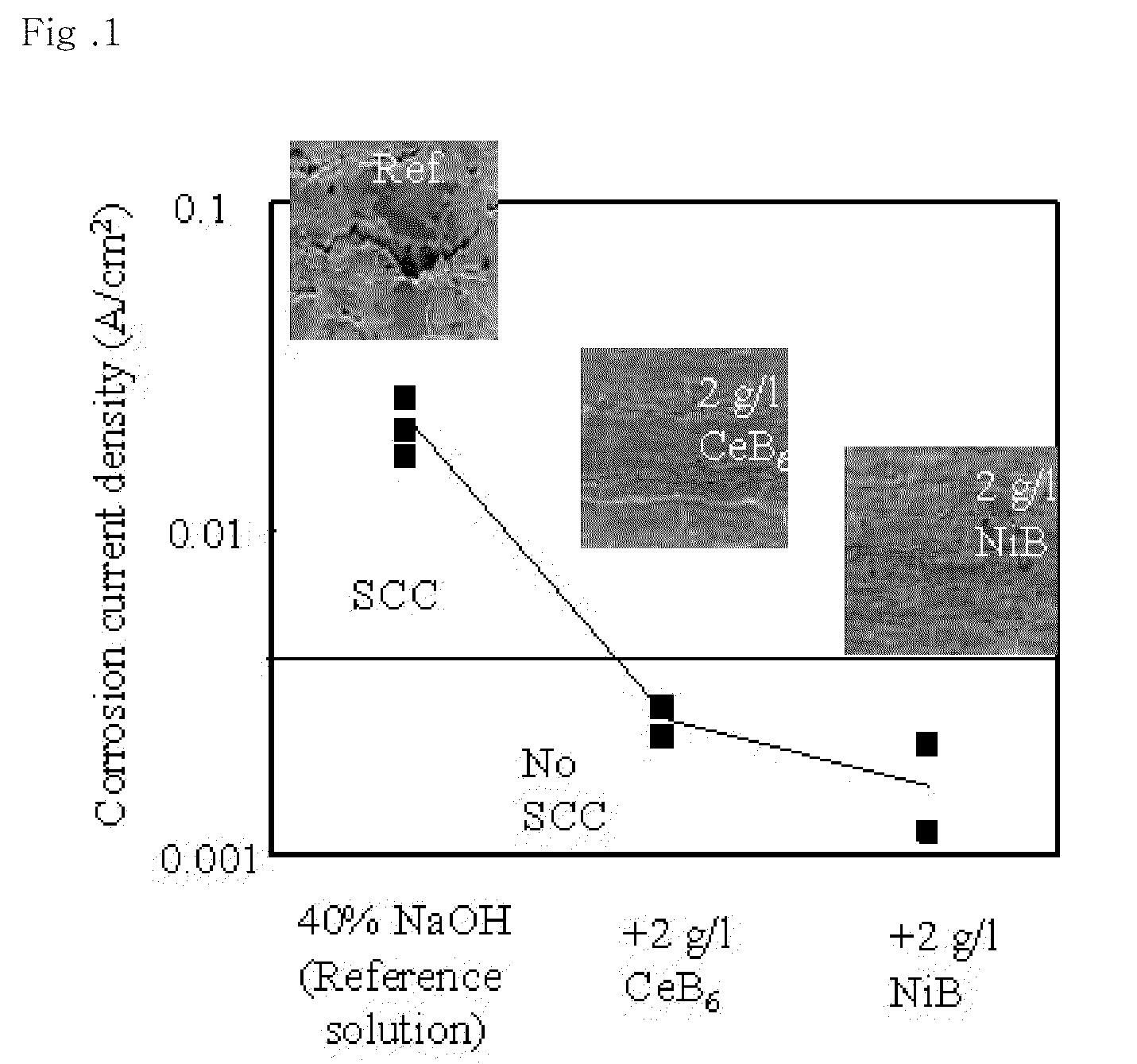

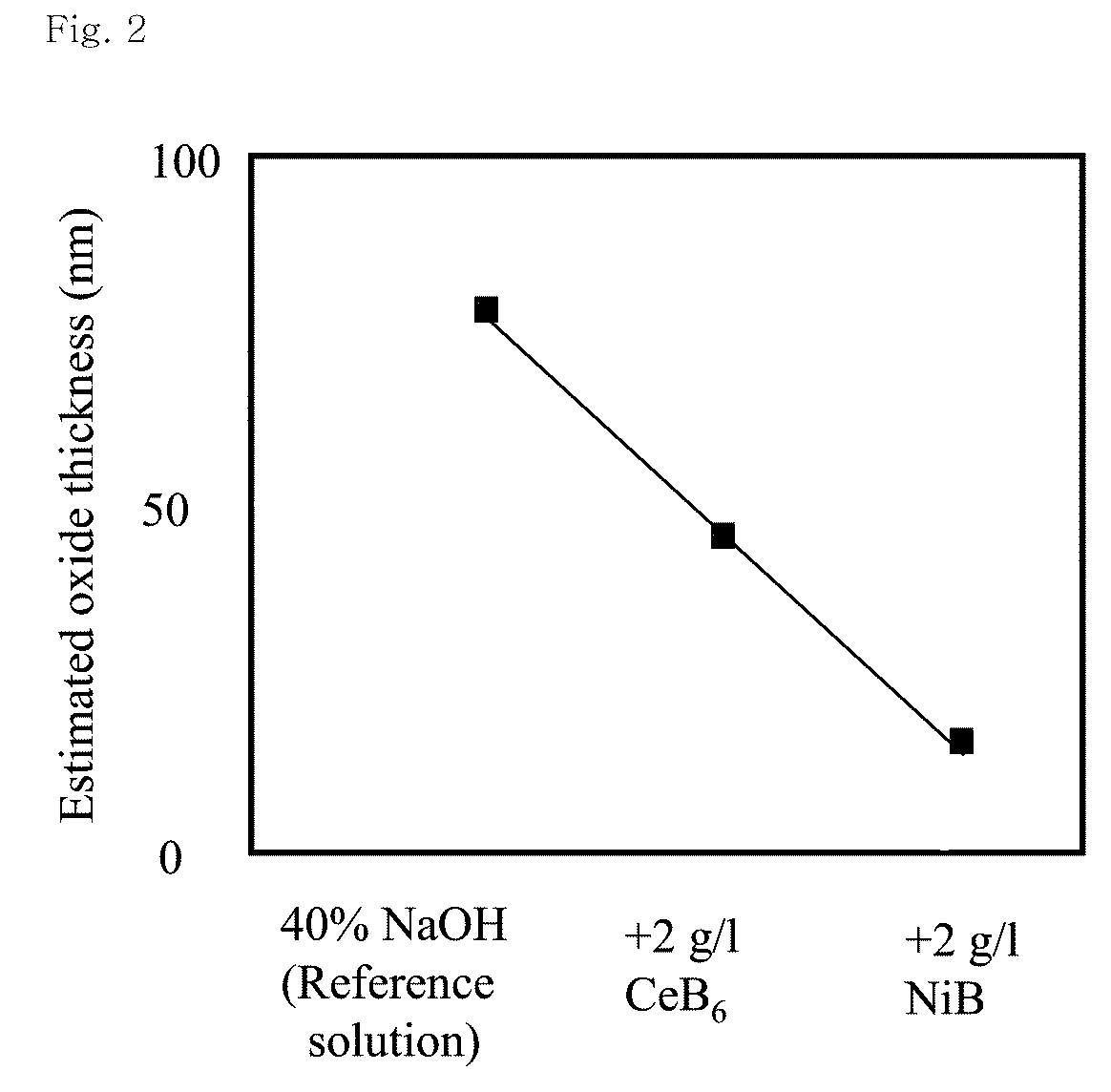

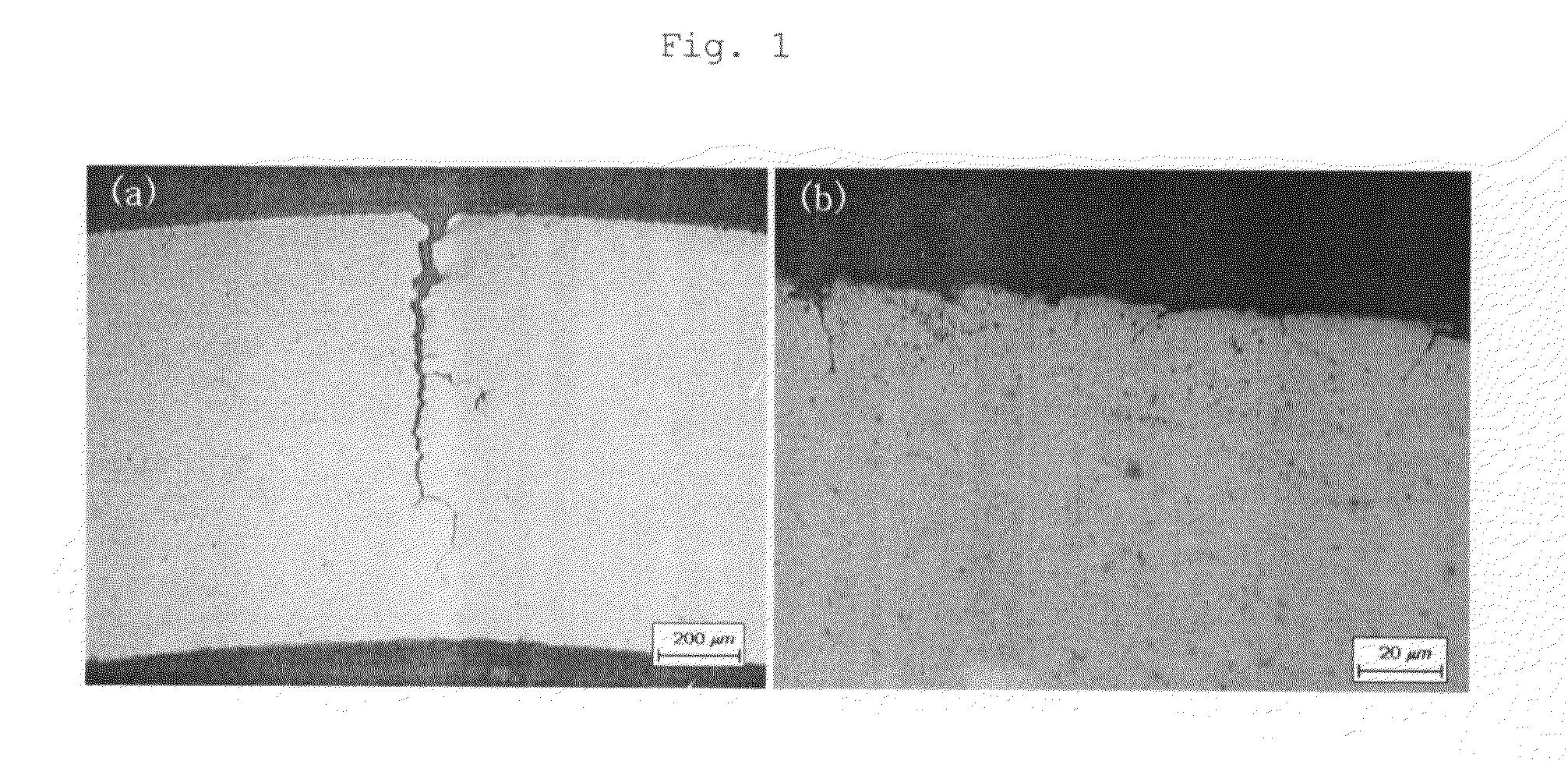

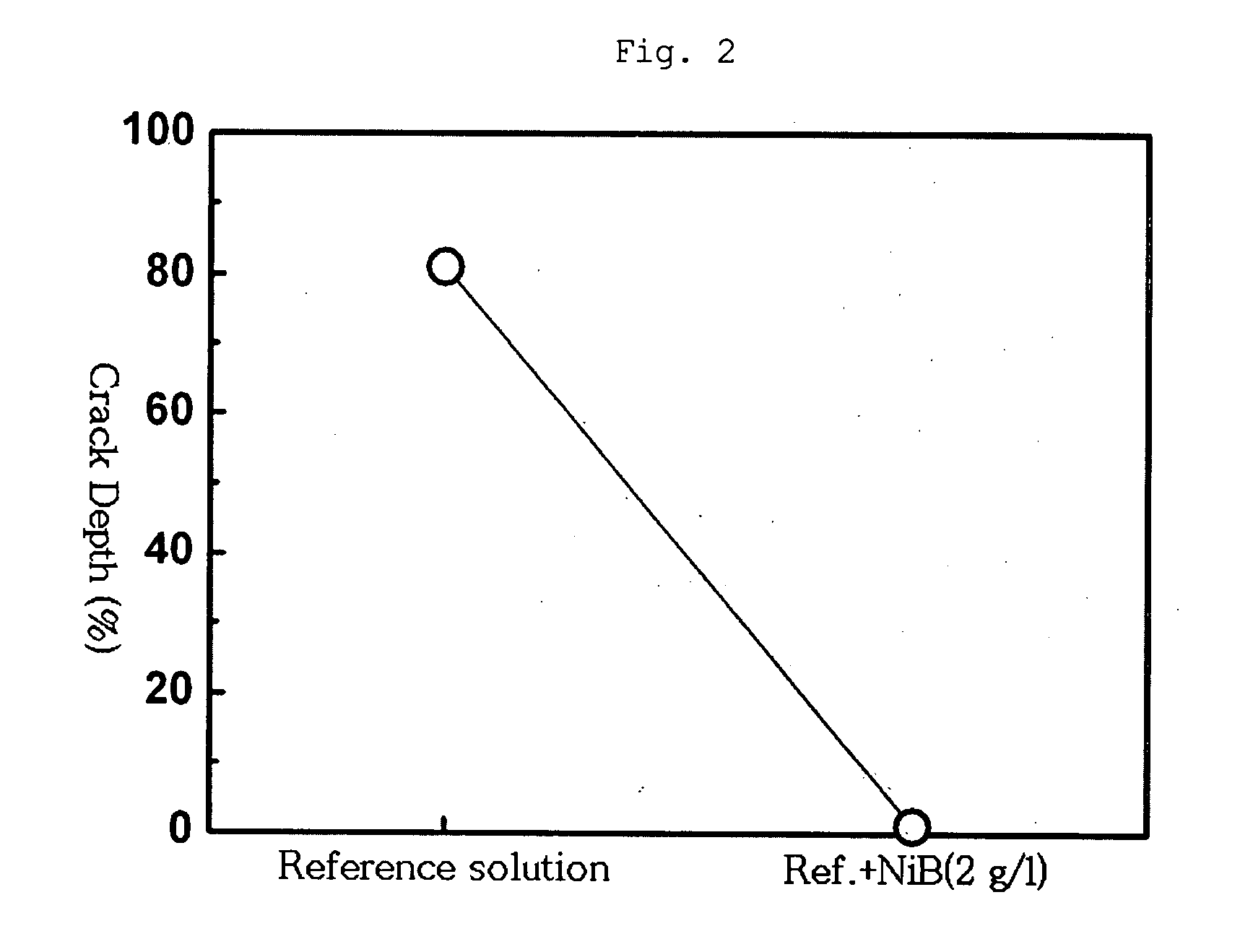

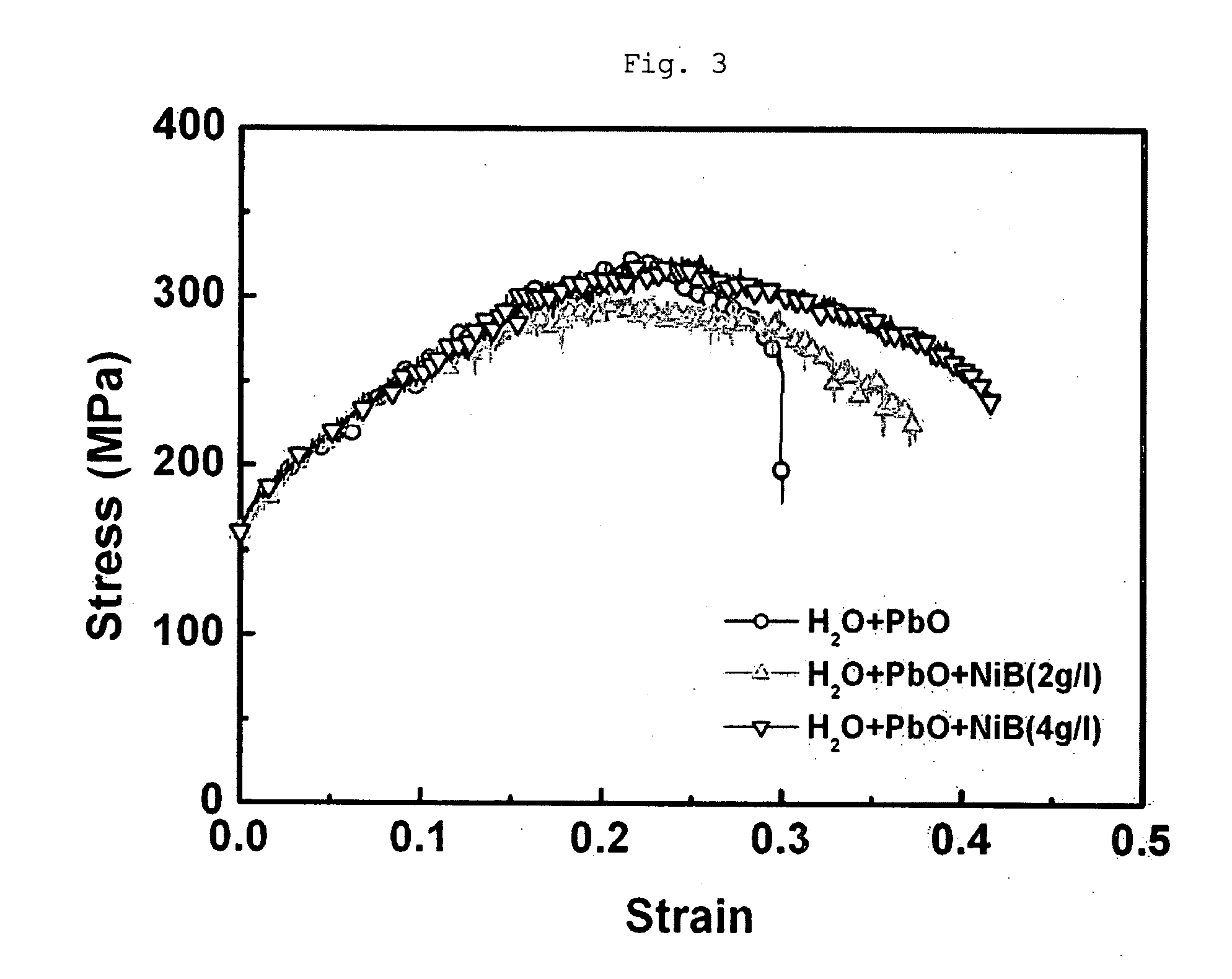

INHIBITOR OF CORROSION AND STRESS CORROSION CRACKING CONTAINING NICKEL BORIDE (NiB) IN THE SECONDARY SIDE OF STEAM GENERATOR TUBES IN A NUCLEAR POWER PLANT AND INHIBITING METHOD USING THE SAME

InactiveUS20090010377A1Avoid corrosionRelieve stressCasings with connectors and PCBSteam generation heating methodsNuclear plantNuclear power

Owner:KOREA ATOMIC ENERGY RES INST +1

Preparation method of carbon dot hybridization mesoporous nickel boride photocatalyst

ActiveCN107715881AEfficient Catalytic ReductionMetal/metal-oxides/metal-hydroxide catalystsHydrogenCentrifugation

The invention discloses a preparation method of a carbon dot hybridization mesoporous nickel boride photocatalyst. According to the method, the carbon dot hybridization mesoporous nickel boride photocatalyst is prepared by the steps of citric acid solution preparation, nickel addition, hydrothermal reaction, pH (potential of hydrogen) value adjustment, sodium borohydride addition reaction and centrifugation. The preparation method of the carbon dot hybridization mesoporous nickel boride photocatalyst has the advantages of simple process, easiness in control, high yield and the like.

Owner:ZHONGBEI UNIV

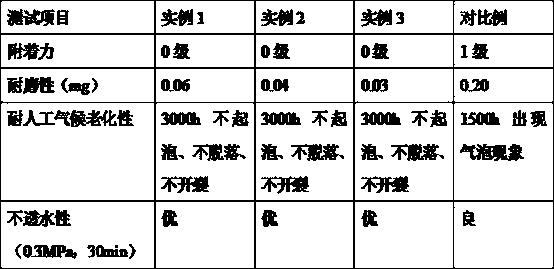

Preparation method of high-adhesion fluorocarbon coating

InactiveCN108034312AHigh adsorption activityImprove the utilization of specific surface areaCoatingsKetoneOxidation resistant

The invention relates to the technical field of preparation of coatings, in particular to a preparation method of high-adhesion fluorocarbon coating. A base and the aluminum source lithium metaaluminate are added to a self-made silicon source; nickel boride and lemon juice are added during hydrothermal reaction; nickel boride is used as a catalyst, the catalyst and cheating property of organic acids in the lemon juice enable metal ions in aluminum silicon molecular sieve to leave original lattice and enter the organic acids; tea polyphenols and microbes are then used to perform further modification on the molecular sieve and nano silica, so that adhesion of the coating is improved; the nano silica can improve wear resistance of the fluorocarbon coating. Grape wine contains rich organic carboxylic acid and other active ingredients; by adding the grape wine to the fluorocarbon coating, adhesion of the fluorocarbon coating is further improved; phenols and ketones having natural antioxidant action can be added such that the final fluorocarbon coating has significantly improved aging resistance and has a promising application prospect.

Owner:谢新昇

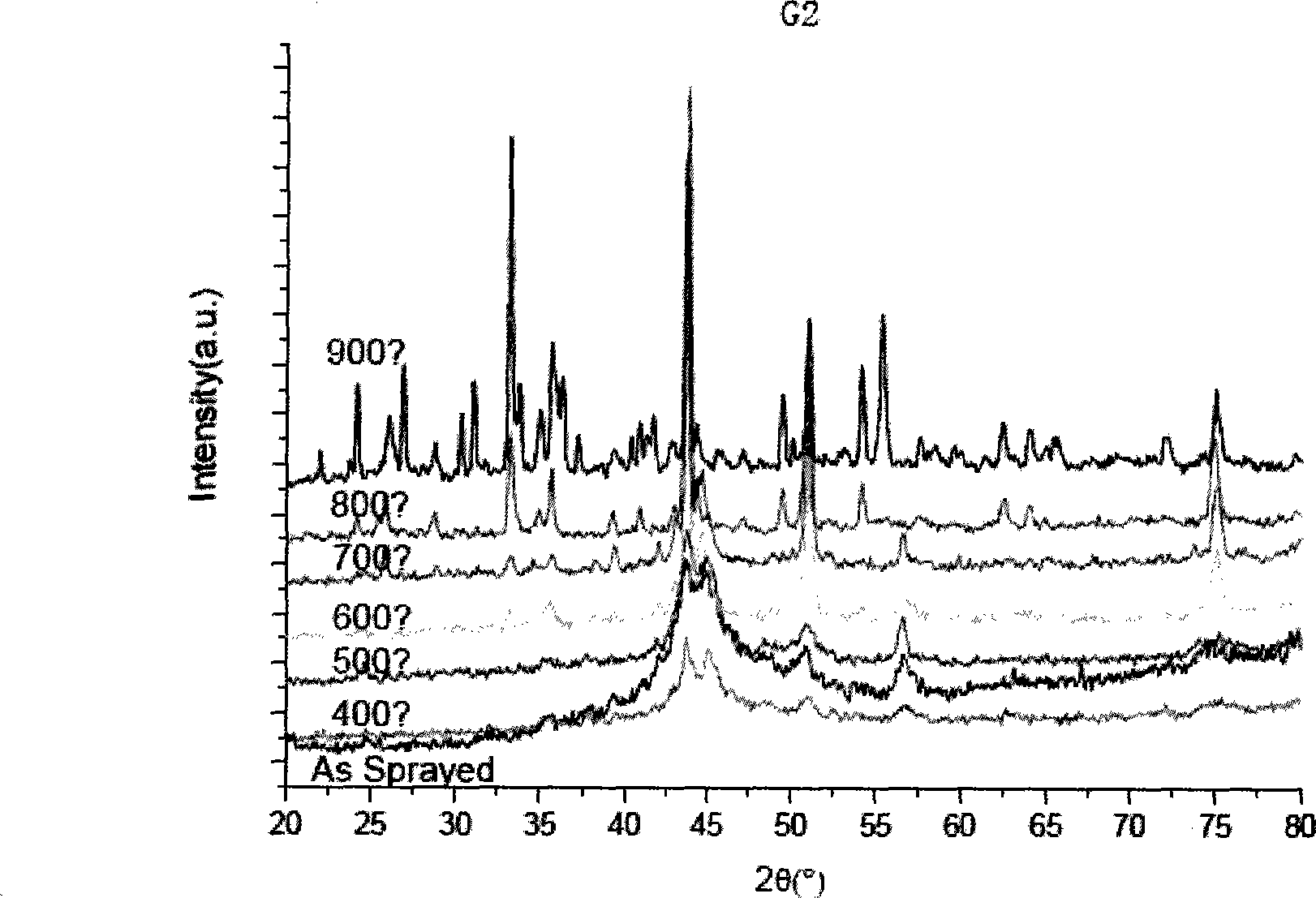

Powder core wire materials for preparing micro crystal and nanocrystalline coatings containing NiB by arc spraying

The invention provides a NiB-containing microcrystal and nanocrystalline powder core wire for arc spraying. The powder core wire belongs to the field of hot spraying in material processing engineering, and is mainly used for anticorrosion and wearing resistance of 'four tubes' of a power plant boiler and so on. The microcrystal and the nanocrystalline crystalline state alloy is a crystalline state material with small grains formed by restructuring the internal structure of an amorphous state material at a high temperature, and is integration of high strength, hardness, toughness, wear resistance and corrosion resistance, but no patent report on microcrystal and nanocrystalline powder core wire is seen at home and abroad. The invention is a NiB-containing microcrystal and nanocrystalline powder core wire and is characterized by comprising the following powder core components in percentage by mass: 60 to 80 percent of nickel boride, 2 to 5 percent of Mo, 5 to 15 percent of WC, 2 to 5 percent of TiC and the balance being nickel powder. The coating prepared by the powder core wire can be decomposed to generate microcrystal and nanocrystalline during high-temperature spraying, and the coating is uniform in structure, high in hardness with HV0.1more than1000, and good in wear resistance, and the relative wear resistance can reach 14 times of that of Q235 steel.

Owner:北京赛亿表面工程技术有限公司

Method for producing nickel boride with high purity

The invention provides a method for producing high-purity nickel boride, and relates to a method for producing nickel boride, in particular to a method for producing the high-purity nickel boride. The method is to mix 25 to 35 weight portions of simple substance boride, 45 to 55 weight portions of metallic nickel and 5 to 60 weight portions of carbon-containing additive, and carry out electrofusion and smelting on the mixture for 4 to 5 hours at a temperature of between 2,000 and 2,400 DEG C through a vacuum electrical resistance furnace to obtain the high-purity nickel boride. The method has the advantages of low cost and environmental protection. The high-purity nickel boride prepared by the method is stable in quality and not easy to volatilize and oxidize.

Owner:鲍迎全

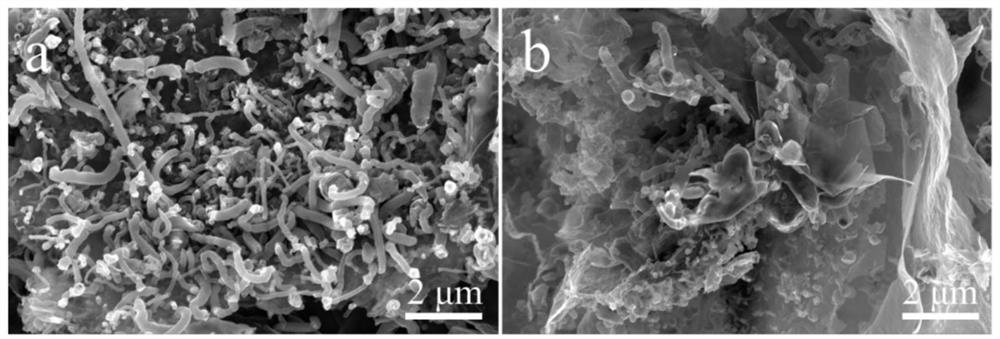

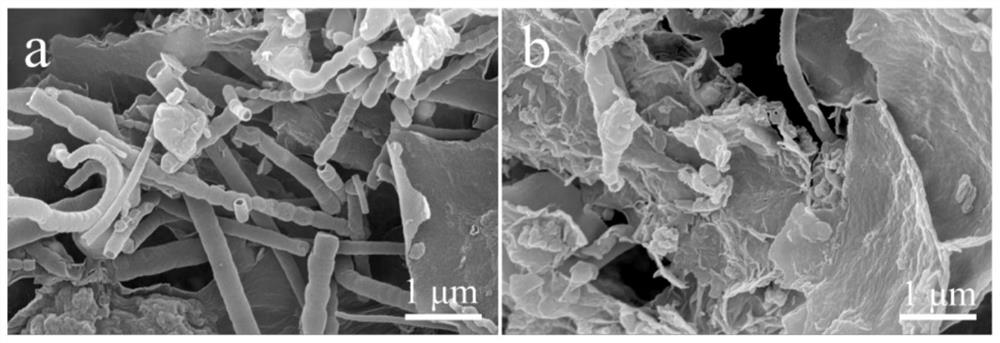

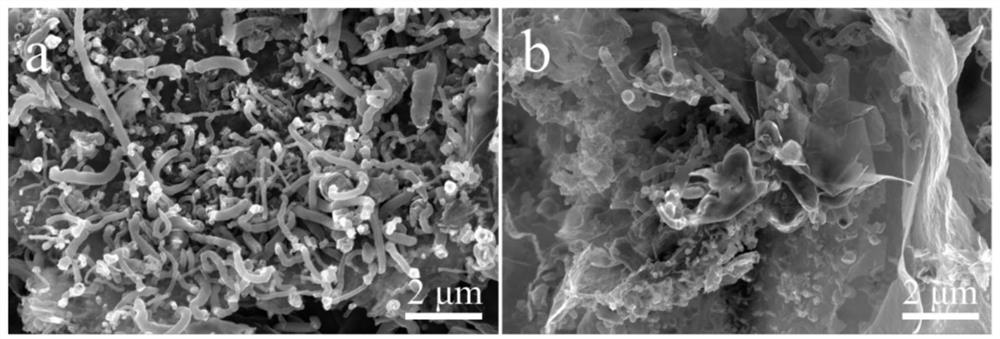

Nickel-encapsulated boron and nitrogen co-doped carbon nanotube wave-absorbing material and preparation method thereof

InactiveCN113336219ADivided evenlyPipe diameter can be adjustedMaterial nanotechnologyOther chemical processesNanotubeCalcination

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

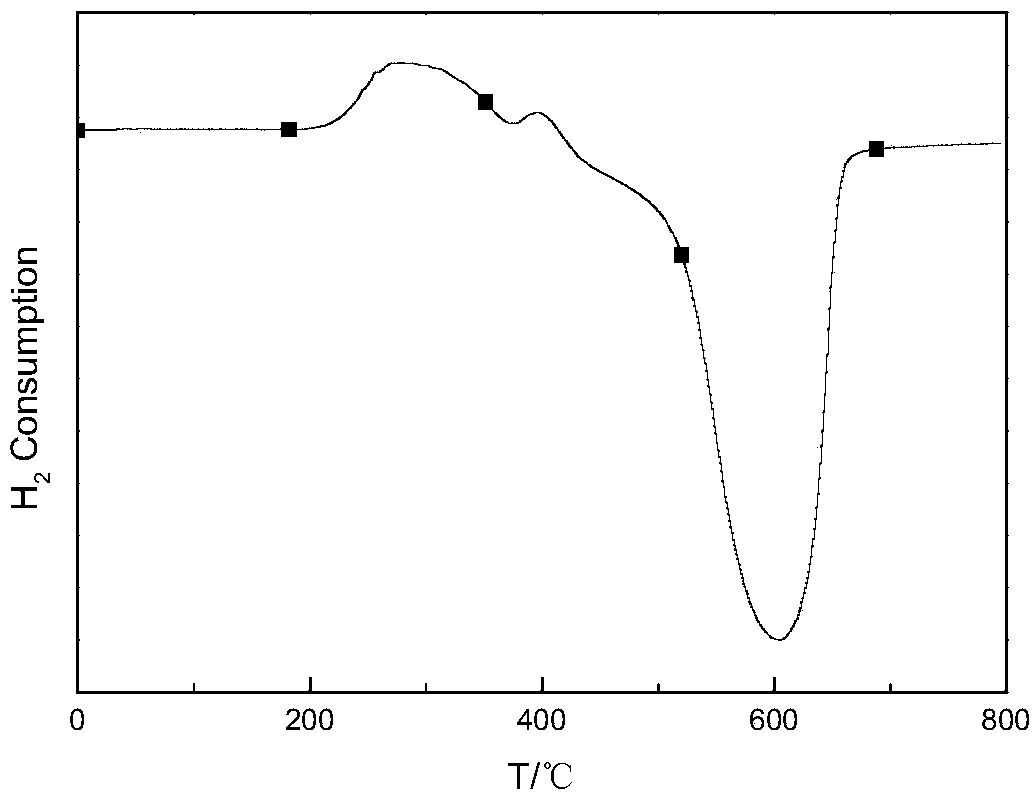

Nickel-based catalyst of special hydrogen used for preparing fuel cell and preparation method

InactiveCN108588753AAvoid pollutionHigh oxygen evolution activityElectrodesMetallic materialsVacuum evaporation

The invention relates to a nickel-based catalyst of special hydrogen used for preparing a fuel cell and a preparation method. The nickel-based catalyst is composed of a core layer and a shell layer. The core layer is integrally formed through a base metal material and a nickel boride nanometer wire, and an amorphous phase nickel borate nanometer array is adopted as the shell layer. The preparationmethod comprises the following steps that 1, the nickel boride nanometer wire is prepared; the surface of the base metal material is covered with an aluminum oxide mask plate, the nickel nanometer array is deposited on the nickel piece base in advance through a vacuum evaporation coating method, after depositing is carried out for 25-35 minutes, boron hydride gas is introduced to grow the nickelboride nanometer wire in an epitaxial manner, after boron hydride gas is introduced, depositing is carried out, the base metal material is taken out, and the mask plate is stripped off to obtain the core layer for standby; and 2, the nickel borate-nickel boride hydrogen manufacturing catalyst for the core and shell structure is prepared, protective gas is used for loading boric acid steam to carryout annealing on the core layer to generate the amorphous phase nickel borate nanometer array, and the nickel borate-nickel boride catalyst of the core and shell structure is prepared and obtained.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Inhibitor of lead-induced stress corrosion cracking comprising nickel boride in secondary side of steam generator tubes in nuclear power plants and inhibition method using the same

InactiveUS20080093584A1Reduce morbidityAvoid attackLiquid surface applicatorsOther chemical processesCrack resistanceNuclear power

This invention relates to an inhibitor of lead-induced stress corrosion cracking including nickel boride in the secondary side of steam generator tubes in nuclear power plants and an inhibition method using the same, and more particularly, to an inhibitor of lead-induced stress corrosion cracking, in which nickel boride is added to secondary side cooling water of the steam generator in an amount of 0.2˜6 g / l, and to an inhibition method using the same. According to this invention, when the inhibitor of lead-induced stress corrosion cracking is added to the secondary side of the steam generator tube in nuclear power plants, stress corrosion cracking of the tubes, which occurs in the lead-containing neutral or caustic solution, and a crack growth rate are decreased, thus increasing elongation. Further, a stress corrosion cracking ratio is decreased, and therefore the stress corrosion cracking resistance of metal or alloy can be improved. Therefore, nickel boride can be usefully used as an inhibitor of lead-induced stress corrosion cracking of the steam generator tubes in nuclear power plants.

Owner:KOREA ATOMIC ENERGY RES INST +1

C5/C6 alkane isomerization catalyst supported by nickel boride and its preparation and use method

The invention relates to a C5 / C6 alkane isomerization catalyst loaded with nickel boride as well as a preparation method and an application method thereof. The catalyst comprises a carrier and the nickel boride the weight of which is 1-5% of that of the carrier, wherein the carrier is formed by aluminium oxide and an H beta molecular sieve; the weight ratio of the aluminium oxide to the H beta molecular sieve is (1:9)-(9:1). According to the catalyst provided by the invention, halogen components are not needed to be added, and noble metals are not used, so that the environmental pollution is avoided and the catalyst cost is reduced; besides, the catalyst can be directly used for isomerization process without requiring pre-hydrogenation for reduction. Tests prove that when the catalyst is used for isomerization reaction for catalyzing n-hexane and n-pentane, the activity of the catalyst is higher, and the isoalkane selectivity and the catalyst stability are better.

Owner:BC P INC CHINA NAT PETROLEUM CORP

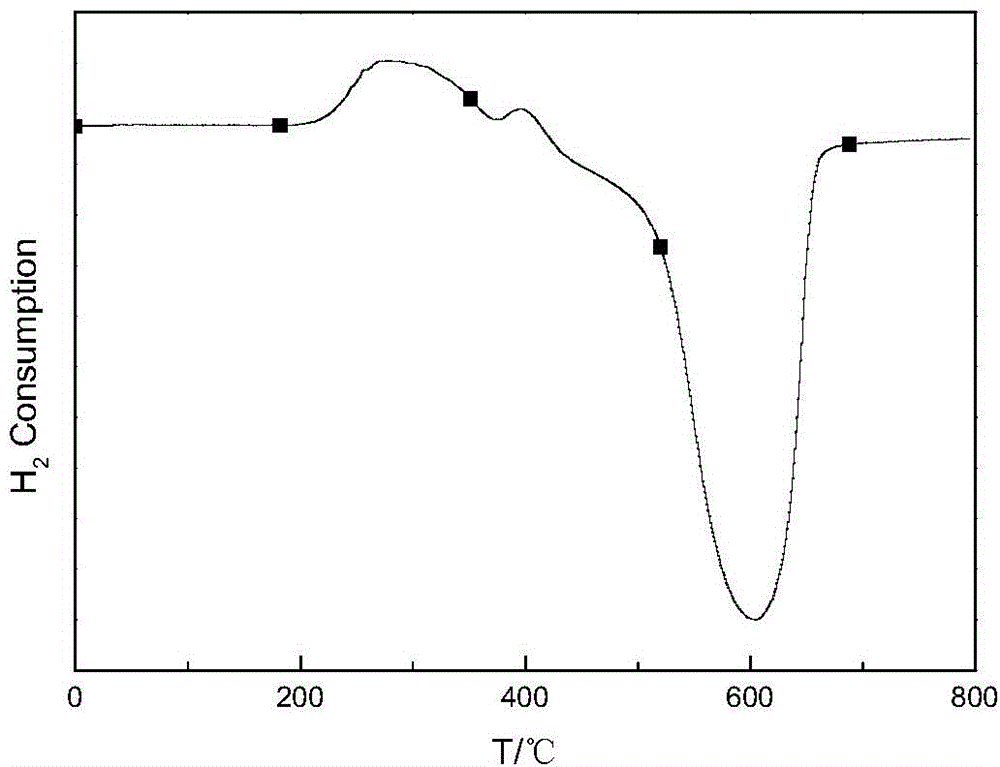

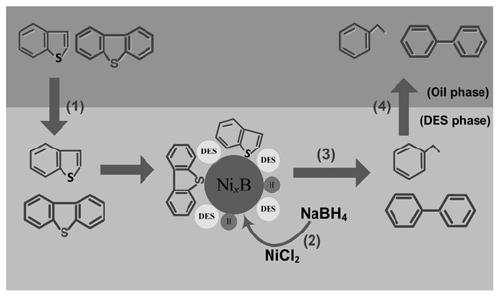

Method for extracting, reducing and desulfurizing fuel oil in deep eutectic solvent

InactiveCN111484874AImprove the efficiency of reduction desulfurizationAvoid problemsTreatment with hydrotreatment processesNickel saltOrganosolv

The invention provides a method for extracting, reducing and desulfurizing fuel oil in a deep eutectic solvent. The method comprises the steps: proportionally mixing the fuel oil, the deep eutectic solvent and sodium borohydride, and adding the mixture into a reactor; then, slowly adding nickel salt into the reactor while stirring, and carrying out desulfurization reaction; and after the reactionis finished, separating the mixture in the reactor to obtain an upper oil phase, namely low-sulfur fuel oil. According to the method, the deep eutectic solvent is used as a reaction medium in the NaBH4 reduction desulfurization process, the problems existing in an organic solvent can be avoided, nickel boride particles generated through the reaction of sodium borohydride and nickel salt are smallin particle size and large in specific surface area, and the NaBH4 reduction desulfurization efficiency is greatly improved.

Owner:SHANGRAO NORMAL UNIV

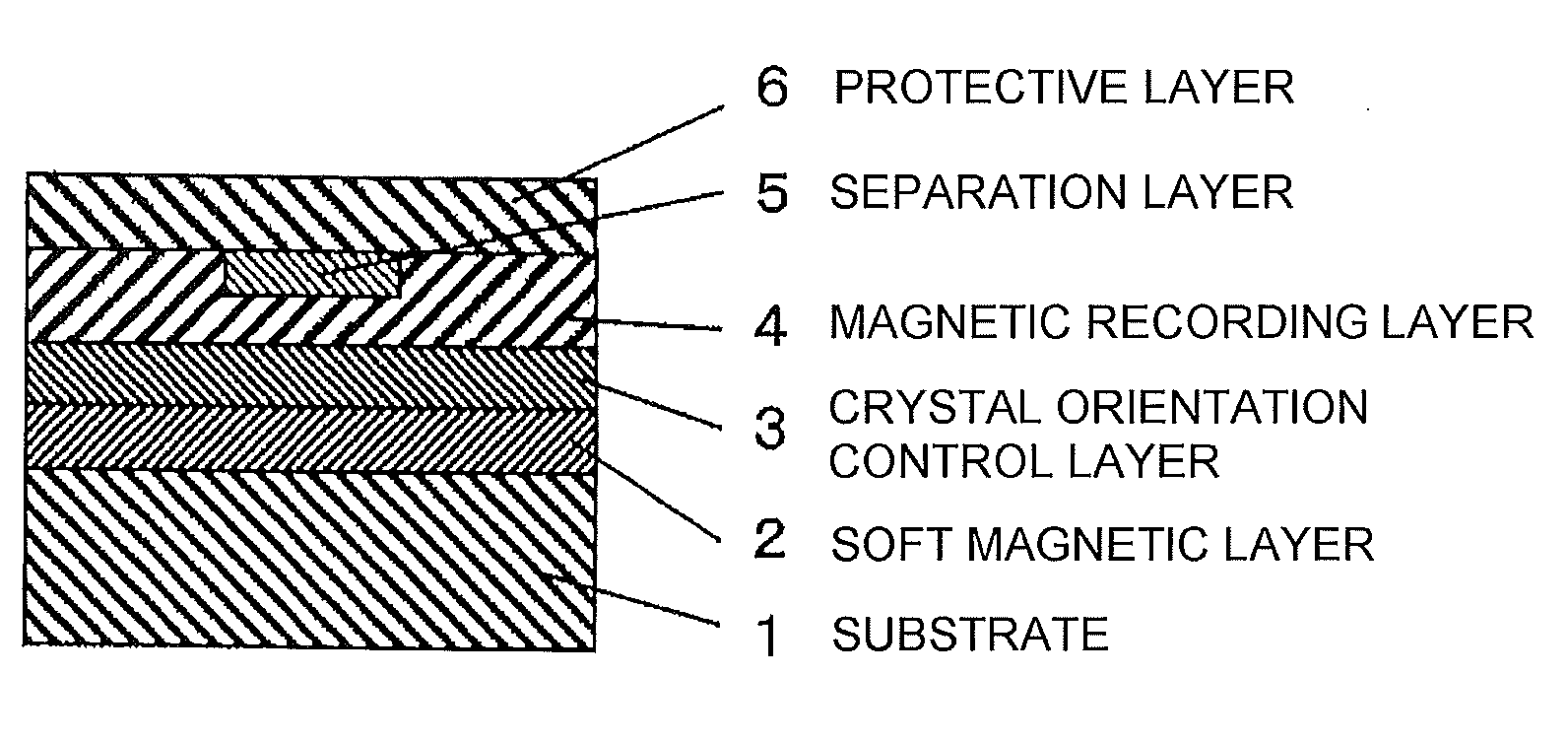

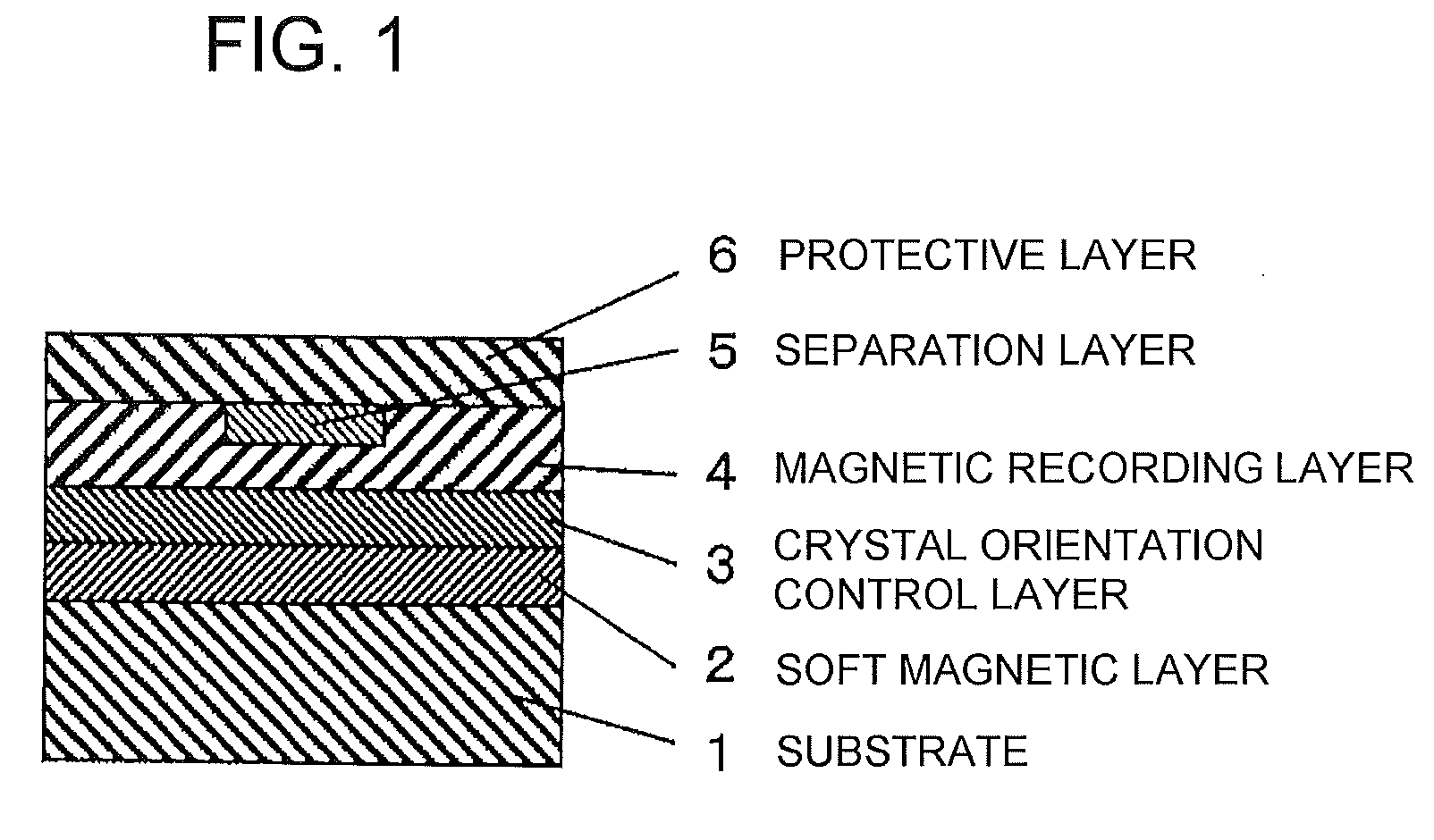

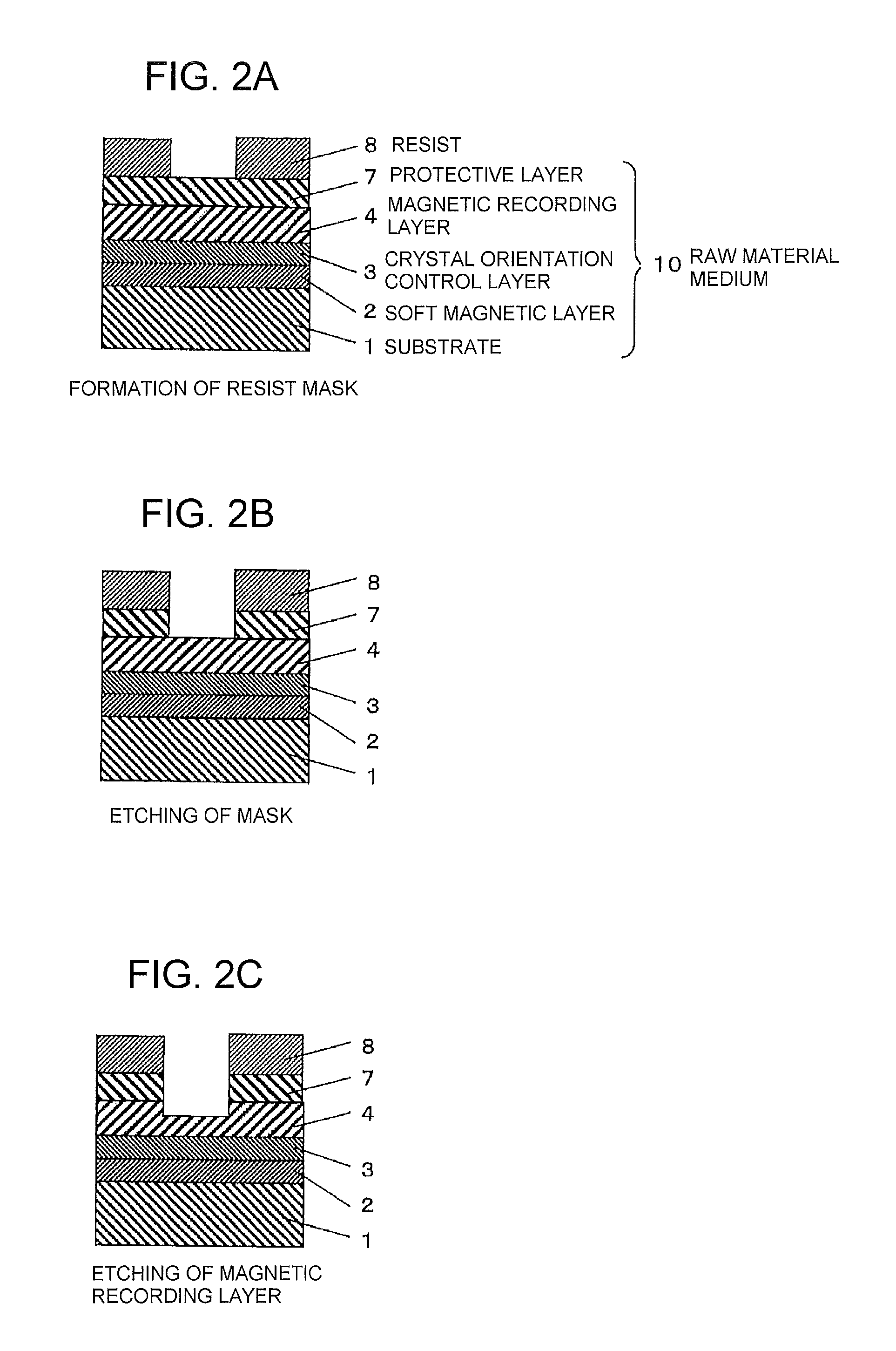

Magnetic recording medium

InactiveUS20110076514A1Improve corrosion resistanceWithout spoiling reliabilityNanoinformaticsPatterned record carriersBorideFilling materials

A magnetic recording medium includes a substrate; a magnetic recording layer that is provided on the substrate and that has a plurality of tracks; and a separation layer that magnetically separates respective tracks of the plurality of tracks of the magnetic recording layer from one another and that is composed of a material including a nonmagnetic amorphous alloy selected from the group consisting of chromium boride (CrB), nickel boride (NiB), chromium phosphide (CrP), and nickel phosphide (NiP). The nonmagnetic amorphous alloy is used as a filler material for the separation layer and has a smooth surface after filling and an excellent corrosion resistance. This enables production of the magnetic recording medium by a simple method so that producibility is excellent and without spoiling reliability.

Owner:FUJI ELECTRIC CO LTD

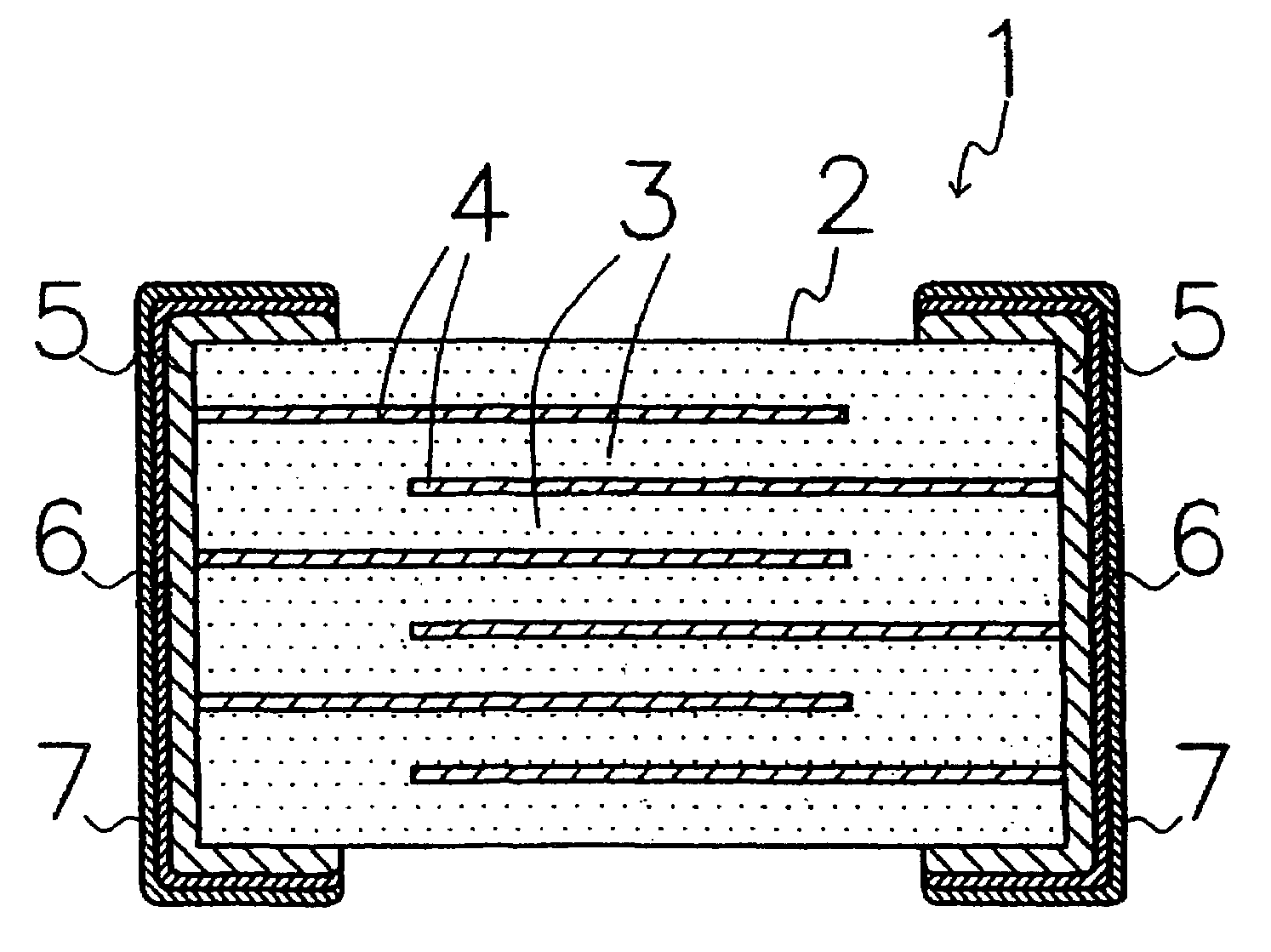

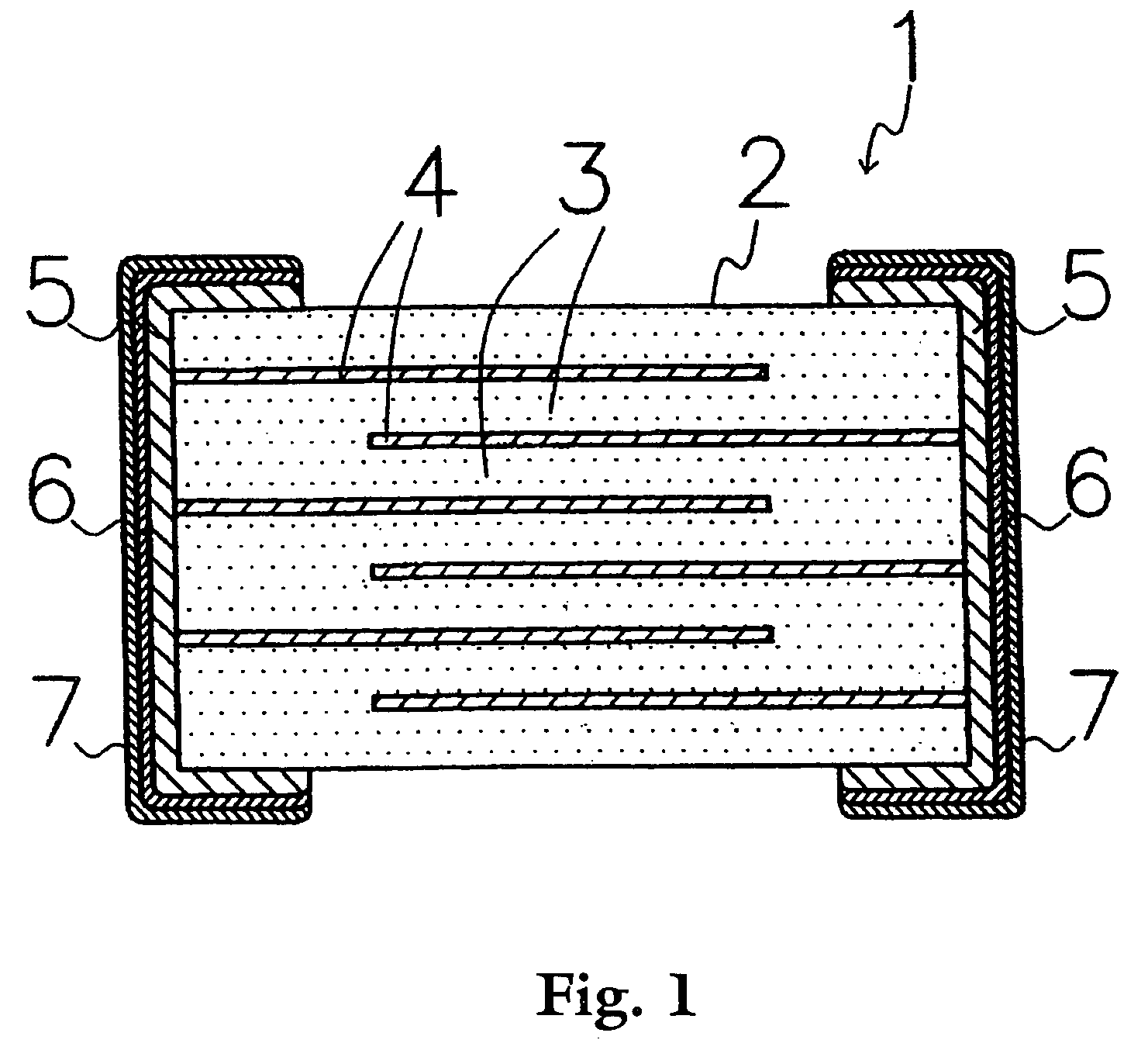

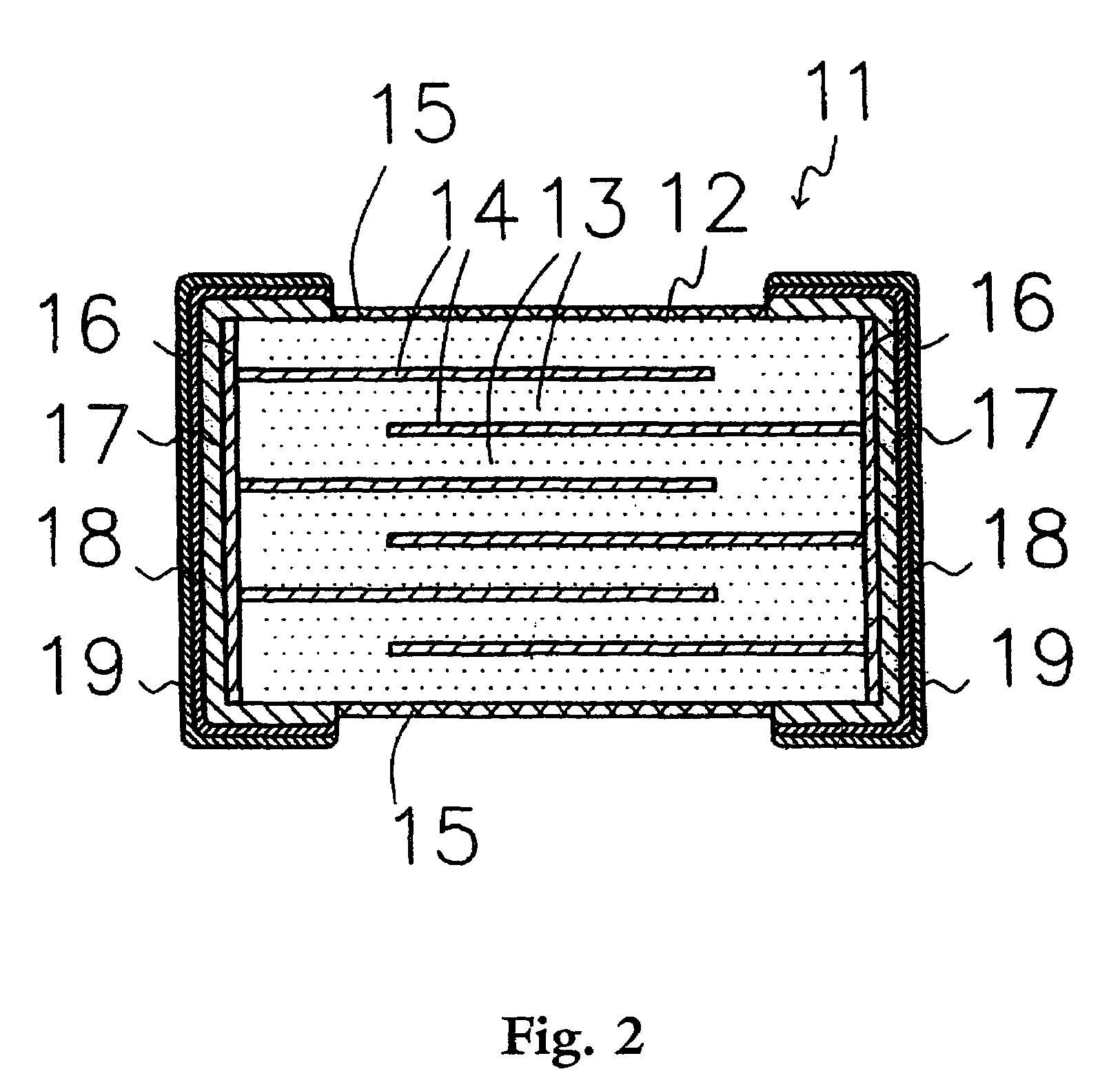

Method for manufacturing laminated electronic component

InactiveUS7067173B2Prevent oxidationFavorable joiningFixed capacitor dielectricStacked capacitorsCooking & bakingConductive paste

Provided is a Ag-based conductive paste for a terminal electrode which suppresses oxidation of the Ni surface of an internal conductor and therefore brings about excellent joining with Ni even when baking is performed in the atmosphere in the case where Ni is used as the internal conductor of a laminated ceramic electronic component. The conductive paste includes at least one of an Ag powder and an Ag alloy powder, a nickel boride powder, an inorganic binder and an organic vehicle, wherein the quantity of the nickel boride powder is within the range of about 5% by weight or more, but less than about 60% by weight of the total paste.

Owner:MURATA MFG CO LTD

Oxidation-resistant conductive paste composition, conductive coating and preparation method thereof

ActiveCN110246605AImprove antioxidant capacitySimple application processNon-conductive material with dispersed conductive materialElectrically-conductive paintsAir atmosphereConductive paste

The invention belongs to the technical field of material preparation and in particular relates to an oxidation-resistant conductive paste composition, a conductive coating and a preparation method thereof. The conductive paste composition comprises, in parts by weight, 75 to 95 parts of boron nickel powder, 5 to 15 parts of boron-containing inorganic binder, 1 to 5 parts of organic vehicle, and 10 to 30 parts of solvent, wherein the boron nickel powder is a conductive metal powder having a surface coated with nickel boride; the boron content in the boron nickel powder is 2 to 8%; the boron content in the boron-containing inorganic binder is 2 to 20%. The conductive paste composition can be sintered under an air atmosphere, has excellent oxidation resistance, can be sintered at about 600 degrees, and has a simple application process and a low energy consumption process. The conductive coating prepared from the conductive paste composition has the characteristics of low cost, good electrical conductivity and good adhesion, and can be widely used in RFID antenna production.

Owner:SHENZHEN ACAD OF AEROSPACE TECH

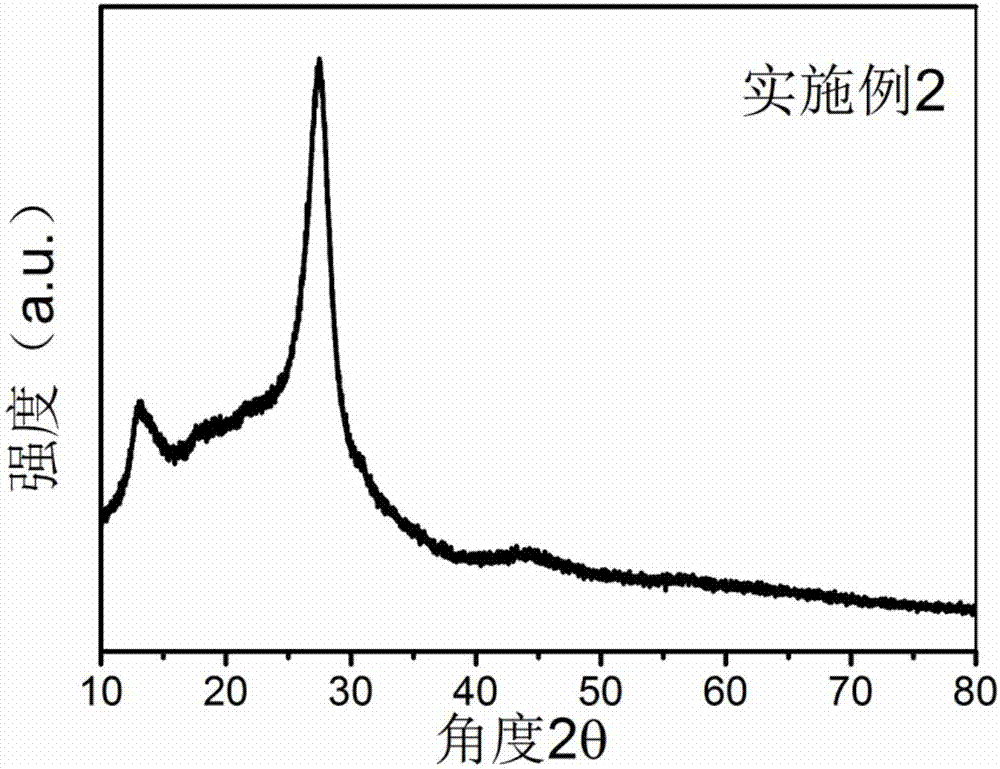

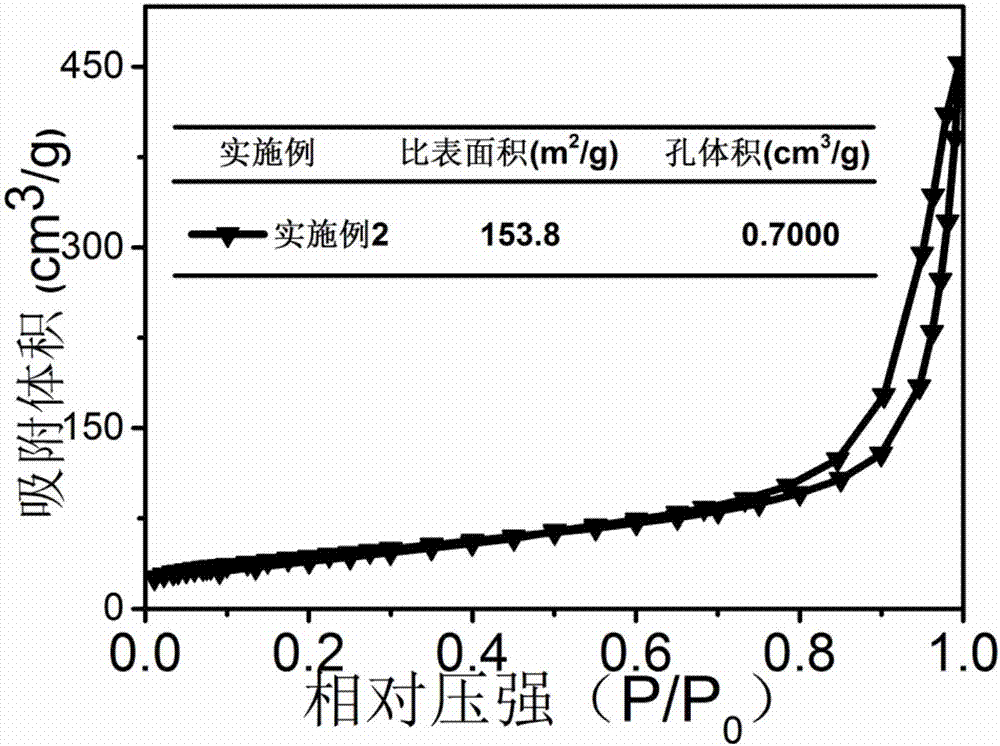

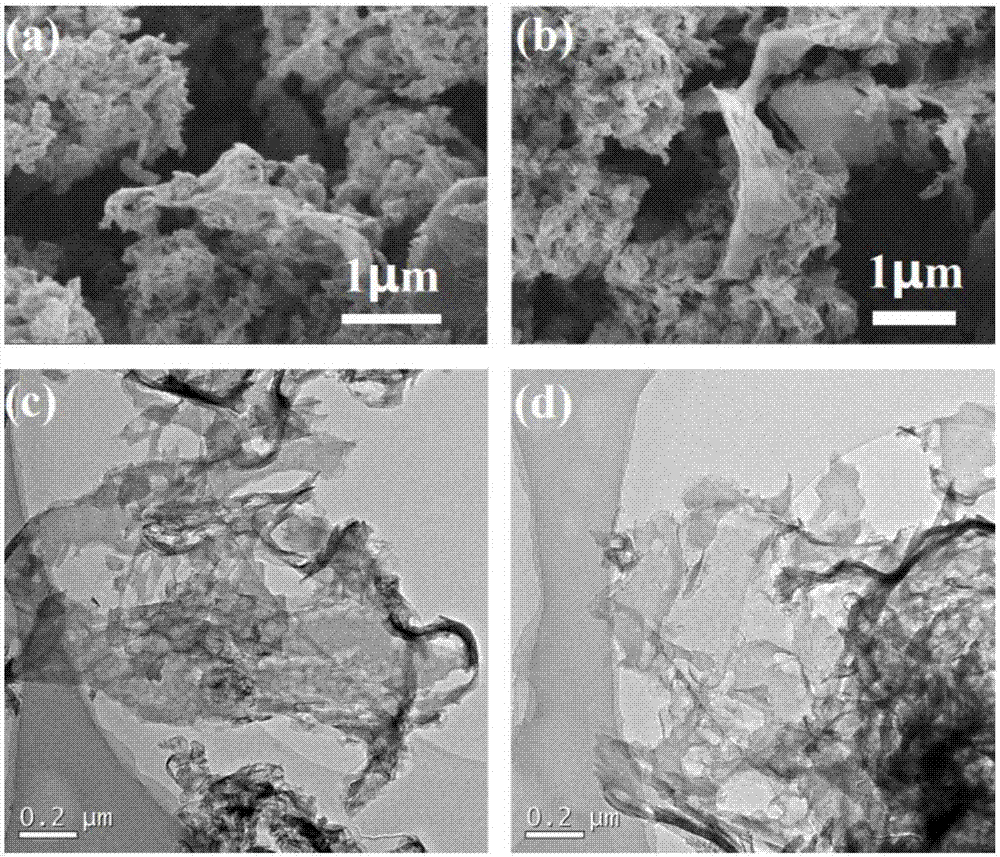

Nickel boride-modified graphite-phase carbon nitride catalyst and preparation method thereof

ActiveCN107321374ASave raw materialsEasy to makePhysical/chemical process catalystsChemical compositionCarbon nitride

The invention discloses a nickel boride-modified graphite-phase carbon nitride catalyst, of which the specific surface area is 50-160m<2> / g, the pore volume is 0.2-0.7cm<3> / g and the thickness is 1-5nm. The nickel boride-modified graphite-phase carbon nitride catalyst comprises the following chemical components in percentage by weight: 99.9-99.99% of graphite-phase carbon nitride and 0.1-0.01% of nickel boride. A preparation method of the catalyst mainly comprises the steps of with nickel boride synthesized by an oxidation-reduction method and graphite-phase carbon nitride burnt and synthesized by urea as precursors, mixing the nickel boride and the graphite-phase carbon nitride, sintering in a muffle furnace to a certain temperature, cooling to room temperature and carrying out washing and drying to obtain the final catalyst. The raw materials are cheap and environmentally friendly, the preparation process is simple, the specific surface area of the catalyst is increased, the pore volume of the catalyst is increased, the thickness of the catalyst is reduced, the catalytic performance is improved, the lowest initial overpotential reaches 100mV, the overpotential is 707mV under the current density of 10mA / cm<2> and the lowest Tafel slope is 221mV / dec.

Owner:YANSHAN UNIV

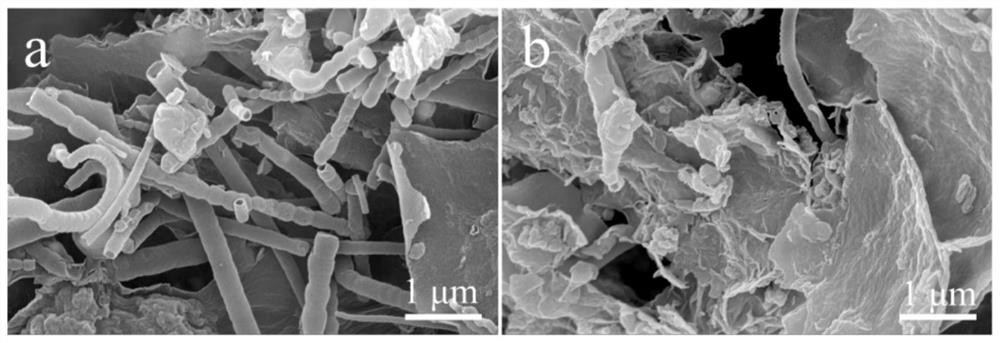

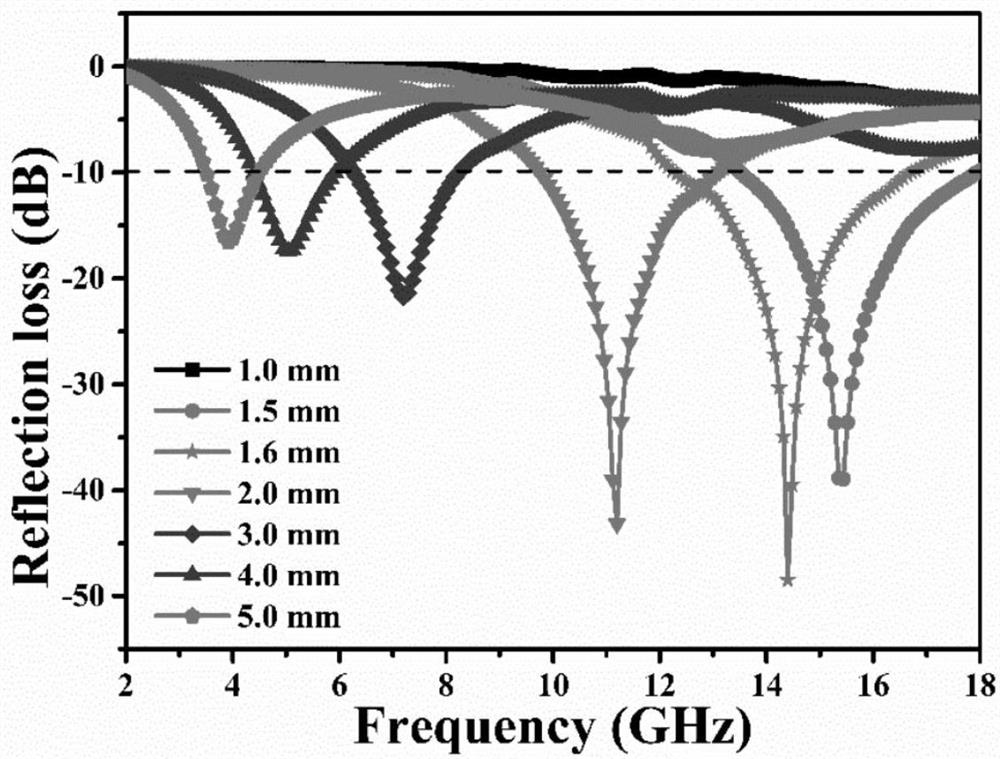

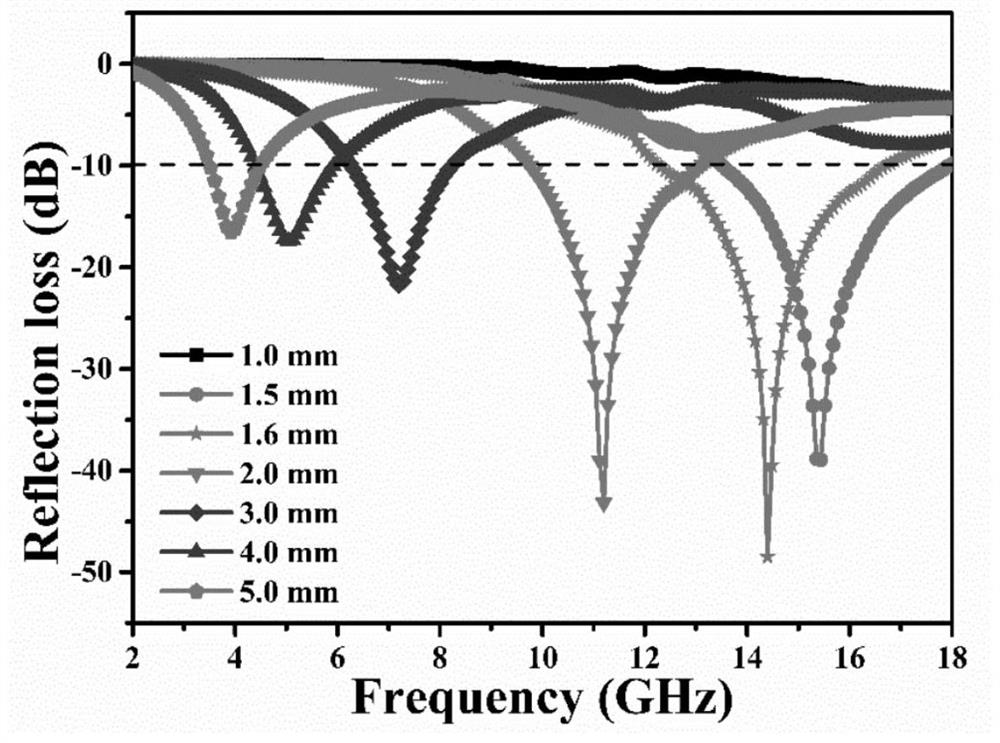

Boron/nitrogen double-doped carbon nanotube-carbon nanosheet composite material and preparation method thereof

ActiveCN113480973AEasy to adjustStrong absorptionOther chemical processesMagnetic/electric field screeningBoridingNanotube

The invention discloses a boron / nitrogen double-doped carbon nano tube-carbon nanosheet composite material and a preparation method, the composite material is composed of an ultrathin carbon nano sheet and a bamboo-like carbon nano tube, and metal nickel nano particles are wrapped in the carbon nano tube. The method comprises the step of preparing nickel boride through a mild chemical reduction method; mixing nickel boride, dicyandiamide and sodium chloride in proportion and ground evenly; and carrying out high-temperature calcination treatment on the mixture in an inert atmosphere to obtain the black powdery material. The method disclosed by the invention is simple in process and high in repeatability, and the boron / nitrogen double-doped carbon nanotube-carbon nanosheet composite material prepared by one-step cracking has the characteristics of light weight, small density, excellent electromagnetic wave-absorbing performance and the like, and has excellent absorption strength and absorption bandwidth under different thicknesses.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Aluminum alloy glue injection profile material and preparation process thereof

The invention discloses an aluminum alloy glue injection profile material and a preparation process thereof, and relates to the technical field of profiles. The material is prepared by the following components in parts by weight: 100-120 kg of aluminum, 0.2-0.8 kg of tephroite, 1 kg of modified kaolin, 5 kg of nanoceramic powder, 0.6 kg of innelite, 3 kg of silicon carbide, 0.4 kg of tungstate, 0.6 kg of zirconium oxide, 3 kg of magnesium oxide, 0.4 kg of calcined uvarovite, 0.2 kg of carbon monofluoride, 0.3 kg of nickel boride, and 0.5 kg of lanthanum pentanickel. The preparation method is performed according to the following steps: firstly, lead is smelted at 500-700 DEG C for slagging and stirring, and then, is continuously insulated by 30 minutes at 500-700 DEG C; remained materials are added to heat up to reach 1000-1200 DEG C until all the materials are molten; the materials are continuously stirred by 20 minutes; molten liquid is fed in a mold for direct extrusion to prepare an alloy aluminum rod; and then, the alloy aluminum rod is molten to prepare the profile. The aluminum alloy glue injection profile material has such physical properties as high mechanical strength, high stability, corrosion resistance and low heat conductivity, and can achieve the purposes of energy conservation and consumption reduction.

Owner:ANHUI JINGCHANG ALUMINUM

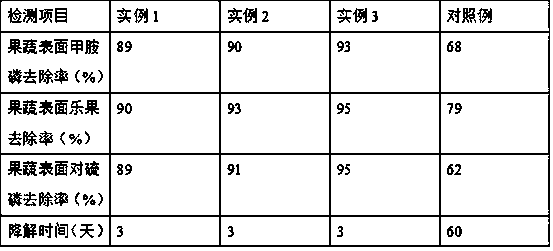

Preparation method of efficient fruit and vegetable pesticide cleaning agent

InactiveCN108219986AHigh adsorption activityHigh removal rateInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsCerium nitrateAtherion elymus

The invention relates to a preparation method of an efficient fruit and vegetable pesticide cleaning agent and belongs to the technical field of preparation of cleaning agents. The preparation methodcomprises the following steps: firstly taking orthosilicic acid as a silicon source, and then, adding alkali and lithium metaaluminate as an aluminum source; synthesizing a silicon-aluminum molecularsieve carrier by utilizing a hydrothermal method, taking nickel boride as a catalyst, and enabling metal ions in the silicon-aluminum molecular sieve to leave original crystal lattices through the chelating property of tartaric acid and then enter an organic phase of the tartaric acid so as to generate holes in the original crystal lattices of the silicon-aluminum molecular sieve to improve the adsorption activity of the molecular sieve; taking tea seeds rich in tea saponins and spirulina rich in polysaccharides as raw materials, performing water extraction and alcohol precipitation to enablethe tea saponins and the spirulina polysaccharides to be separated out and adsorbed and fixed by a high-adsorbability molecular sieve, and then, performing reaction with a cerium nitrate solution to obtain reaction filter residue; then, pulverizing oyster shells, performing calcination, performing reaction with water, and performing filtration to obtain an alkaline calcium ion solution; and finally, blending and concentrating a calcium ion solution and the reaction filter residue to obtain the fruit and vegetable pesticide cleaning agent.

Owner:董晓

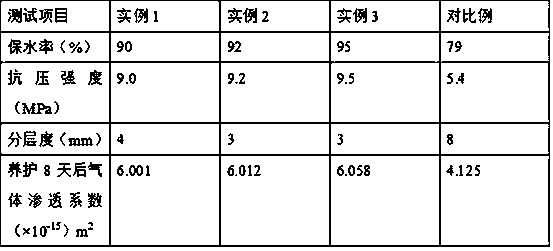

Method for preparing high-bonding-strength inorganic adhesive for concrete interface

The invention relates to the technical field of building material preparation, in particular to a method for preparing high-bonding-strength inorganic adhesive for an concrete interface. The method comprises the steps of: adopting bauxite and montmorillonite as raw materials, and performing a reaction on the raw materials, organic acids and nickel boride under the conditions of a high temperatureand high pressure, wherein nickel boride is adopted as a catalyst, and metal ions in the bauxite and montmorillonitethe are made to leave original crystal lattices and enter the organic acids throughthe chelating property of the organic acids, so that cavities are formed in the original lattices of the bauxite and montmorillonite; and performing high-temperature dehydration in a resistance furnace so as to remove oxygen atoms at vertexes of tetrahedral and octahedral structures of the bauxite is removed and form six-coordinate structures, wherein oxygen cavities are formed in the original positions of the oxygen atoms, and the adsorption activity of the bauxite and montmorillonite can be increased through the generation of the cavities. The adsorption cohesion inside the inorganic adhesive prepared from the materials can be improved, and the adsorption strength of the adhesive and the concrete surface can be improved, so that the bonding strength of the inorganic adhesive for the concrete interface is improved.

Owner:张家界万众新型建筑材料有限公司

Preparation method of water-retaining and air-permeable dry-mixed mortar

InactiveCN108178569AHigh adsorption activityImprove adsorption capacityCeramicwareSilicic acidLithium aluminate

The invention discloses a preparation method of water-retaining and air-permeable dry-mixed mortar, and belongs to the technical field of mortar preparation. The method comprises the following steps:firstly, hydrochloric acid and sodium silicate are subjected to reaction, and orthosilicic acid is generated and taken as a silicon source; then, alkali and aluminum source lithium metaaluminate are added, organic acid and nickel boride are added, swim bladder is boiled with water, a boiled solution rich in swim bladder collagen protein is obtained, the boiled solution and glucose are blended, concentrated and fermented with grape skin, glucose is decomposed, and hydrophilic hydroxy and formyl are generated; finally, a functionalized molecular sieve, a fermentation filtrate rich in hydrophilicgroups, spider webs, silk and cement are blended, and the dry-mixed mortar is obtained. By means of high adsorption and high air permeability of the functionalized molecular sieve, air permeability of the dry-mixed mortar prepared with the method is remarkably improved, pores of the physical network structure can be left in the mortar after spider silks and silkworm silks which exist in the mortar in a physical network structure are microbiologically degraded, and the pores just constitute air permeable channels of the mortar. Therefore, broad application prospect is achieved.

Owner:陈合华

Boron/nitrogen double-doped carbon nanotube-carbon nanosheet composite material and preparation method

ActiveCN113480973BEasy to adjustStrong absorptionOther chemical processesMagnetic/electric field screeningNanoparticleBoriding

The invention discloses a boron / nitrogen double-doped carbon nanotube-carbon nanosheet composite material and a preparation method thereof. The composite material is composed of ultra-thin carbon nanosheets and bamboo-shaped carbon nanotubes. The carbon nanotubes The interior is wrapped with metallic nickel nanoparticles. The method includes: preparing nickel boride through a mild chemical reduction method. Mix nickel boride, dicyandiamide and sodium chloride in proportion and grind them evenly. The mixture is calcined at a high temperature under an inert atmosphere to obtain a black powder material. The method of the invention has simple process and strong repeatability, and the boron / nitrogen double-doped carbon nanotube-carbon nanosheet composite material obtained by one-step cracking has the characteristics of light weight, low density, excellent electromagnetic wave absorption performance, etc. Both have excellent absorption strength and absorption bandwidth.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com