Preparation method of high-adhesion fluorocarbon coating

A fluorocarbon coating and adhesion technology, which is applied in the field of preparation of high adhesion fluorocarbon coatings, can solve the problems of poor wear resistance, poor film adhesion and weather resistance, etc., to improve the utilization rate of specific surface area, improve adhesion, The effect of enhancing binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

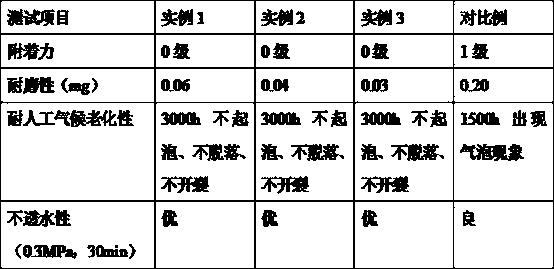

Examples

example 1

[0025]Use hydrochloric acid with a concentration of 1mol / L to adjust the pH of the sodium silicate solution with a mass fraction of 20% to 5.5, stir and react for 20 minutes to obtain a mixed solution, heat the mixed solution to 100°C, and continue to stir and react for 1 hour to obtain a reaction solution. Mix the mass fraction of 10% sodium hydroxide solution with the mass fraction of 20% potassium metaaluminate solution to obtain a precursor solution at a ratio of 1:3:12; Add nickel boride with 2% mass of precursor liquid and lemon juice with 5% mass of precursor liquid, seal the high-pressure hydrothermal kettle, heat up to 180°C under 1.3MPa, conduct hydrothermal reaction for 30h, filter and separate after the hydrothermal reaction is completed The obtained filter residue is a self-made functional filler; the above-mentioned self-made functional filler and nano silicon dioxide are mixed in a mass ratio of 2:1 to obtain a mixed filler, and then the mixed filler, tea polyphe...

example 2

[0027] Use hydrochloric acid with a concentration of 1mol / L to adjust the pH of the sodium silicate solution with a mass fraction of 20% to 6.0, stir and react for 25 minutes to obtain a mixed solution, heat the mixed solution to 103°C, and continue to stir and react for 1.5 hours to obtain a reaction solution. The ratio is 1:3:12, the mass fraction is 10% sodium hydroxide solution and the mass fraction is 20% potassium metaaluminate solution is mixed to obtain the precursor liquid; Add nickel boride with 2% mass of precursor solution and lemon juice with 5% mass of precursor solution to the kettle, seal the high-pressure hydrothermal kettle, heat up to 190°C under 1.4MPa, perform hydrothermal reaction for 33 hours, and filter after the hydrothermal reaction is completed The filter residue obtained by separation is the self-made functional filler; the above-mentioned self-made functional filler and nano-silica are mixed in a mass ratio of 2:1 to obtain a mixed filler, and then ...

example 3

[0029] Use hydrochloric acid with a concentration of 1mol / L to adjust the pH of the sodium silicate solution with a mass fraction of 20% to 6.5, stir and react for 30 minutes to obtain a mixed solution, heat the mixed solution to 105°C, and continue to stir and react for 2 hours to obtain a reaction solution. Mix the mass fraction of 10% sodium hydroxide solution with the mass fraction of 20% potassium metaaluminate solution to obtain a precursor solution at a ratio of 1:3:12; Add 2% nickel boride and 5% lemon juice in the precursor solution, seal the high-pressure hydrothermal kettle, heat it up to 200°C at 1.5MPa, and conduct the hydrothermal reaction for 36 hours. After the hydrothermal reaction is completed, filter and separate The obtained filter residue is a self-made functional filler; the above-mentioned self-made functional filler and nano silicon dioxide are mixed in a mass ratio of 2:1 to obtain a mixed filler, and then the mixed filler, tea polyphenols and water are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com