Patents

Literature

33results about How to "Improve the utilization of specific surface area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene/SiO2 composite material as well as preparation method and application thereof

ActiveCN103524785AAvoid reunionLarge specific surface areaBulk chemical productionDispersityGraphene

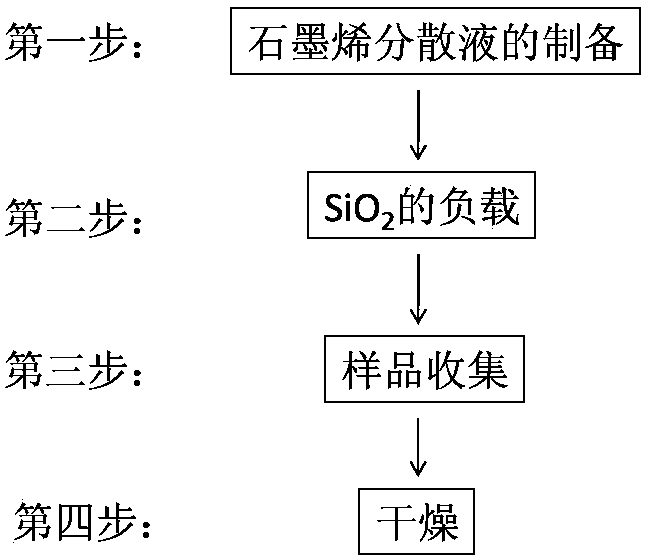

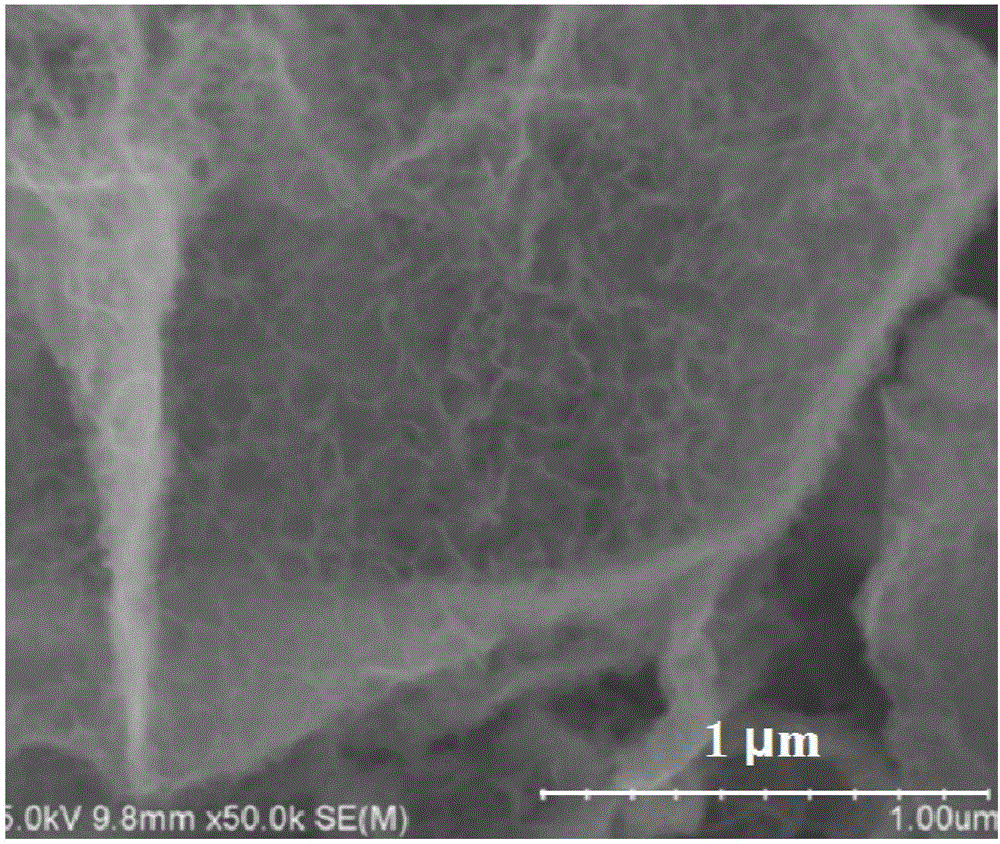

The invention relates to the field of material chemistry and provides a graphene / SiO2 composite material for solving various problems existing in the existing preparation method of a graphene material. The composite material is composed of two components graphene and SiO2. The composite material disclosed by the invention is good in dispersity; and meanwhile, specific surface area utilization rate of the graphene is improved. Meanwhile, the invention further discloses a preparation method and an application of the graphene / SiO2 composite material. A preparation process in the invention is simple and applied to reinforcement filler of organic silicon polymer.

Owner:HANGZHOU NORMAL UNIVERSITY

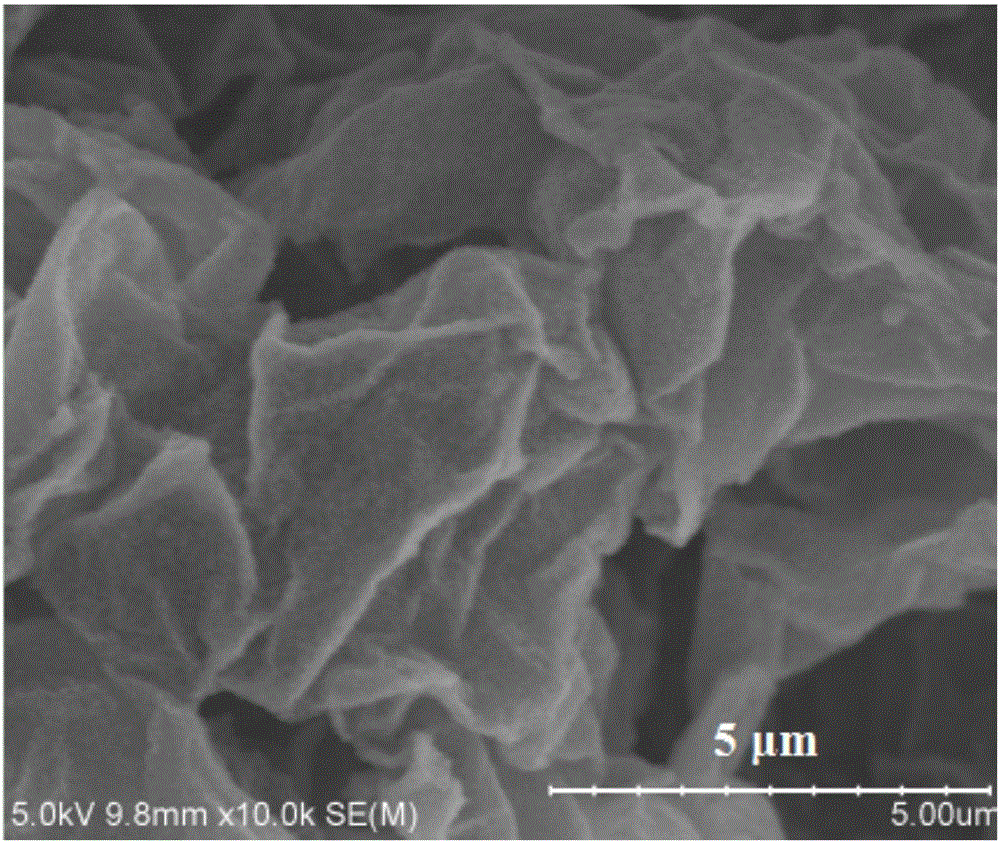

Nickel hydroxide/graphene nano composite, preparation method thereof, supercapacitor electrode and supercapacitor

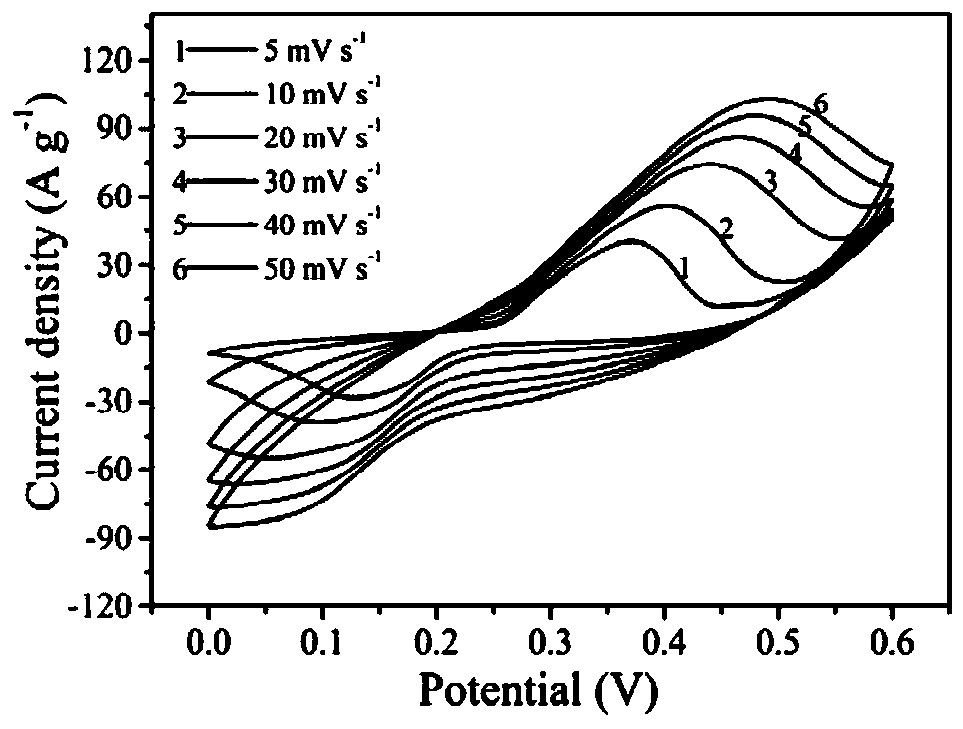

ActiveCN106158405APrevent heavy accumulationImprove the utilization of specific surface areaMaterial nanotechnologyHybrid capacitor electrodesCapacitanceGraphene nanocomposites

The invention discloses a nickel hydroxide / graphene nano composite, a preparation method thereof, a supercapacitor electrode and a supercapacitor. The composite is formed by base material graphene and a nickel hydroxide nanosheet growing on the surface of the graphene in situ, and the composite integrally has a three-dimensional porous structure. A graphene-based composite is prepared by loading a transition metal hydroxide on the surface of the graphene with high specific surface area and excellent conductivity in a composition manner. Due to synergistic effect of all componenta of the composite, all components can mutually enhance advantages and avoid disadvantages; and meanwhile, long circle life, high power density and high stability of an electric double-layer capacitor and high specific capacitance characteristic of a pseudocapacitor are combined, thereby improving the comprehensive performances of the supercapacitor.

Owner:嘉兴企远网信息科技有限公司

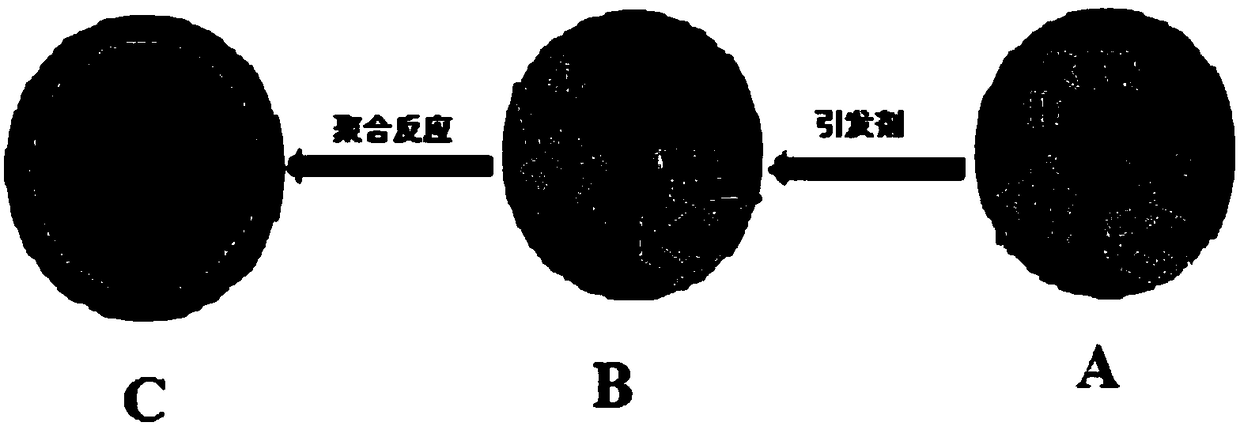

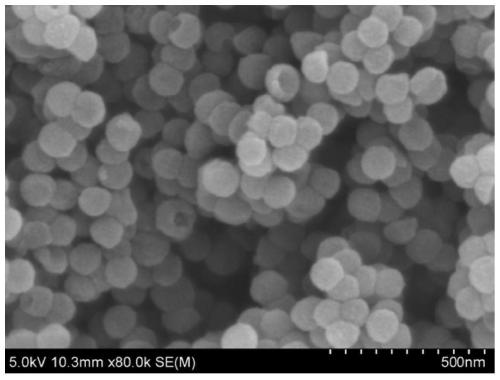

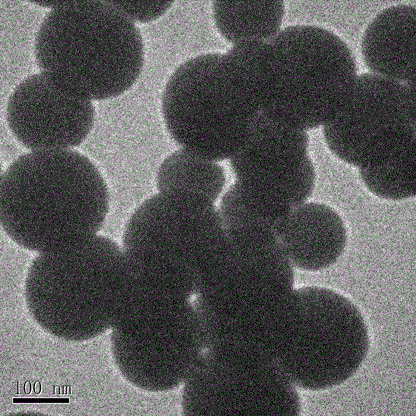

Nitrogen-oxygen co-doped hollow carbon nanospheres as well as preparation method and application thereof

ActiveCN108439369AImprove wettabilityUniform sizeMaterial nanotechnologyHybrid capacitor electrodesMicrosphereCarbonization

The invention discloses nitrogen-oxygen co-doped hollow carbon nanospheres, a preparation method thereof, a supercapacitor electrode and a supercapacitor. The preparation method of the nitrogen-oxygenco-doped hollow carbon nanospheres comprises the steps as follows: pyrrole and aniline are subjected to a polymerization reaction in a water liquor containing a soft template, and a hollow carbon nanosphere precursor is obtained; the hollow carbon nanosphere precursor is washed, pulverization treatment, carbonization treatment and ammonia water activation treatment are performed, and the nitrogen-oxygen co-doped hollow carbon nanospheres are obtained. The nitrogen-oxygen co-doped hollow carbon nanospheres prepared with the preparation method have larger specific surface area, good wettabilityand high specific surface area utilization rate. The supercapacitor electrode and the supercapacitor comprise the nitrogen-oxygen co-doped hollow carbon nanospheres prepared with the method.

Owner:SHENZHEN UNIV

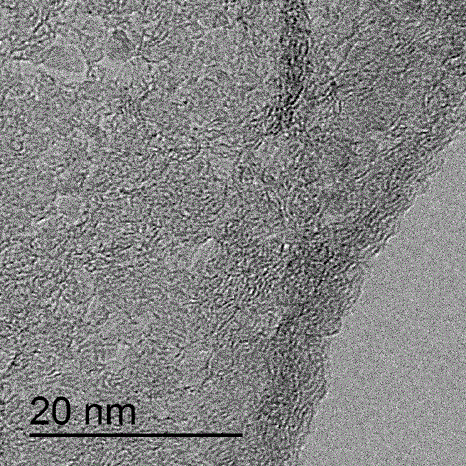

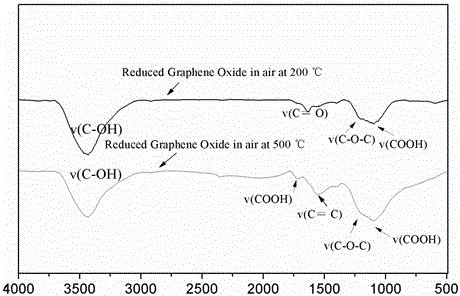

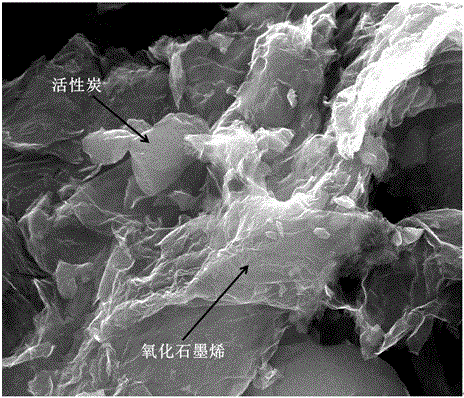

Preparation method for high-specific-capacitance graphene/high-surface-activated carbon composite material

InactiveCN106486295AImprove performanceSimple preparation processCarbon compoundsHybrid capacitor electrodesCapacitanceAir atmosphere

The invention discloses a preparation method for a high-specific-capacitance graphene / high-surface-activated carbon composite material, and aims to provide the preparation method for active carbon composite material with low cost, high specific capacitance and high specific surface area utilization ratio. The preparation method is realized by the technical scheme as follows: taking peeled graphite oxide slurry as a raw material, and drying the graphite oxide slurry at a temperature of minus 40 to minus 20 DEG C; then reducing the graphite oxide into graphene oxide at a temperature of 200-500 DEG C, and adding high-surface-activated carbon in the graphite oxide stage; meanwhile, adding a dispersing agent to be stirred and mixed, and performing ultrasonic dispersion to enable the graphite oxide and the high-surface-activated carbon to be uniformly mixed, coating the surface of the high-surface-activated carbon with the graphite oxide to realize in-situ compositing of the graphite oxide and active carbon; and after performing low-temperature freezing and drying, performing puffing and reducing in the air atmosphere at a lower temperature of lower than 500 DEG C to reduce the graphite oxide into graphene oxide to prepare the in-situ composited graphene oxide / high-surface-activated carbon composite material.

Owner:DAYING JUNENG TECH & DEV

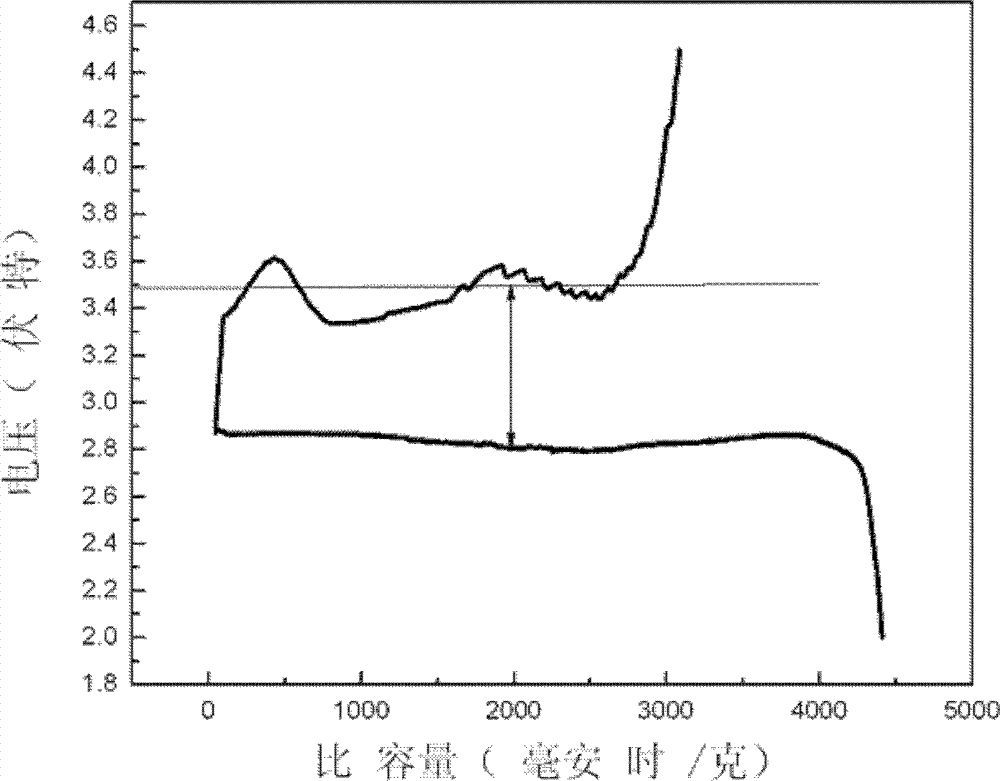

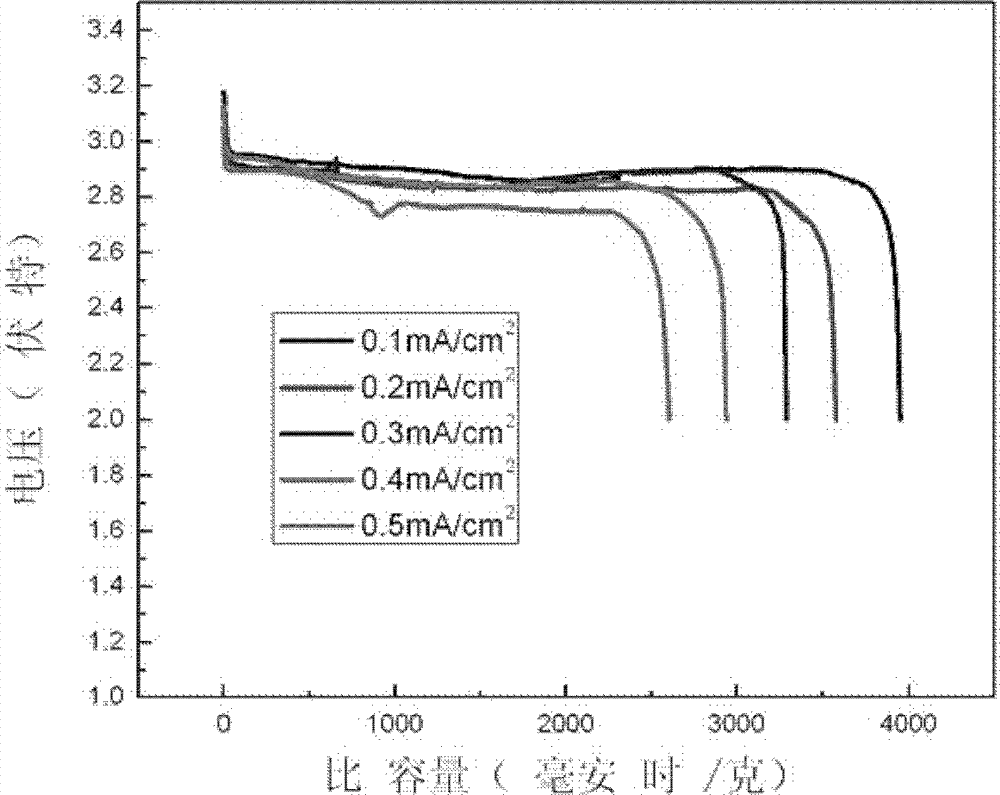

Porous carbon nanobelt positive electrode material for lithium-sulfur battery, preparation method and application thereof

ActiveCN108666570AImprove wettabilityIncrease profitMaterial nanotechnologyCell electrodesNanometreSodium–sulfur battery

The invention discloses a porous carbon nanobelt positive electrode material for lithium-sulfur battery, a preparation method thereof a positive electrode of lithium-sulfur battery, and a lithium-sulfur battery. The method for preparing the porous carbon nanobelt positive electrode material for lithium-sulfur battery comprises the following steps of: preparing a carbon nanobelt precursor; carbonizing and activating the carbon nanobelt precursor; and depositing elemental sulfur in the oxynitride co-doped porous carbon nanobelt. The porous carbon nanobelt positive electrode material for lithium-sulfur battery prepared by the preparation method of the invention has electrochemical properties such as large specific surface area, good wettability and high elemental sulfur content, significantlyimproved sulfur-fixing performance, and effective inhibition of the ''shuttle effect'' of poly sulfides. The positive electrode of lithium-sulfur battery and the lithium-sulfur battery contain the positive electrode material for lithium-sulfur battery prepared by the method of the invention.

Owner:SHENZHEN UNIV

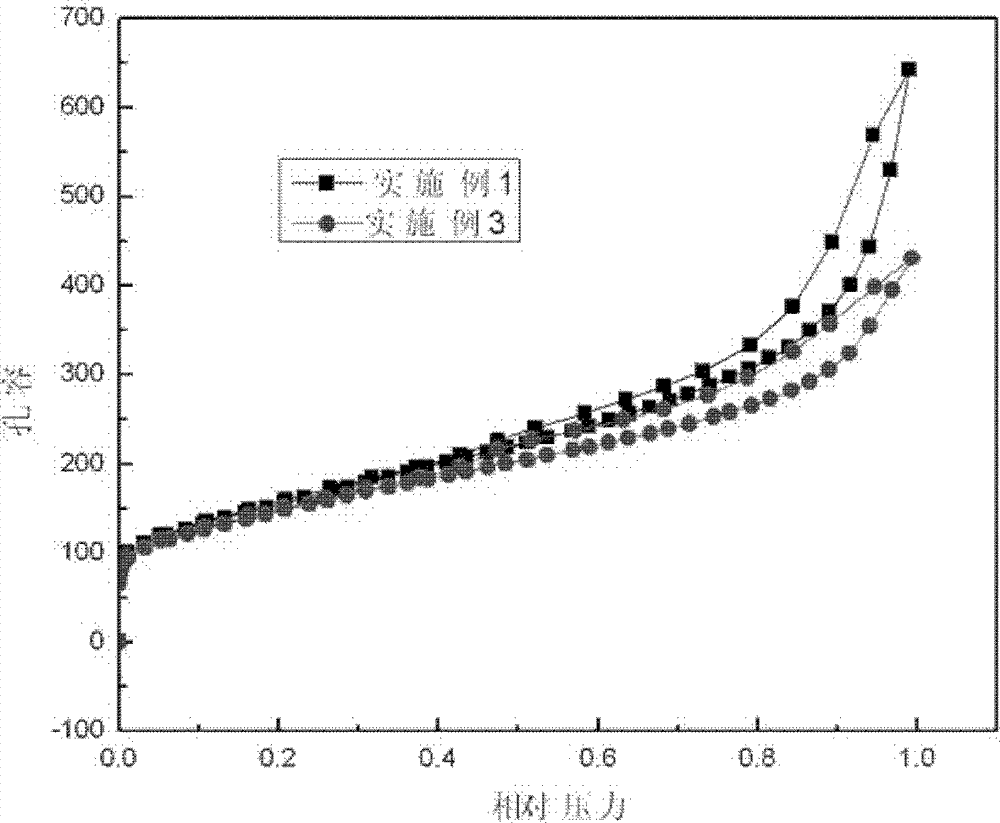

Preparation method of porous carbon material, supercapacitor electrode and supercapacitor

ActiveCN110451507ALarge specific surface areaImprove performanceCarbon compoundsHybrid capacitor electrodesPorous carbonNitrogen

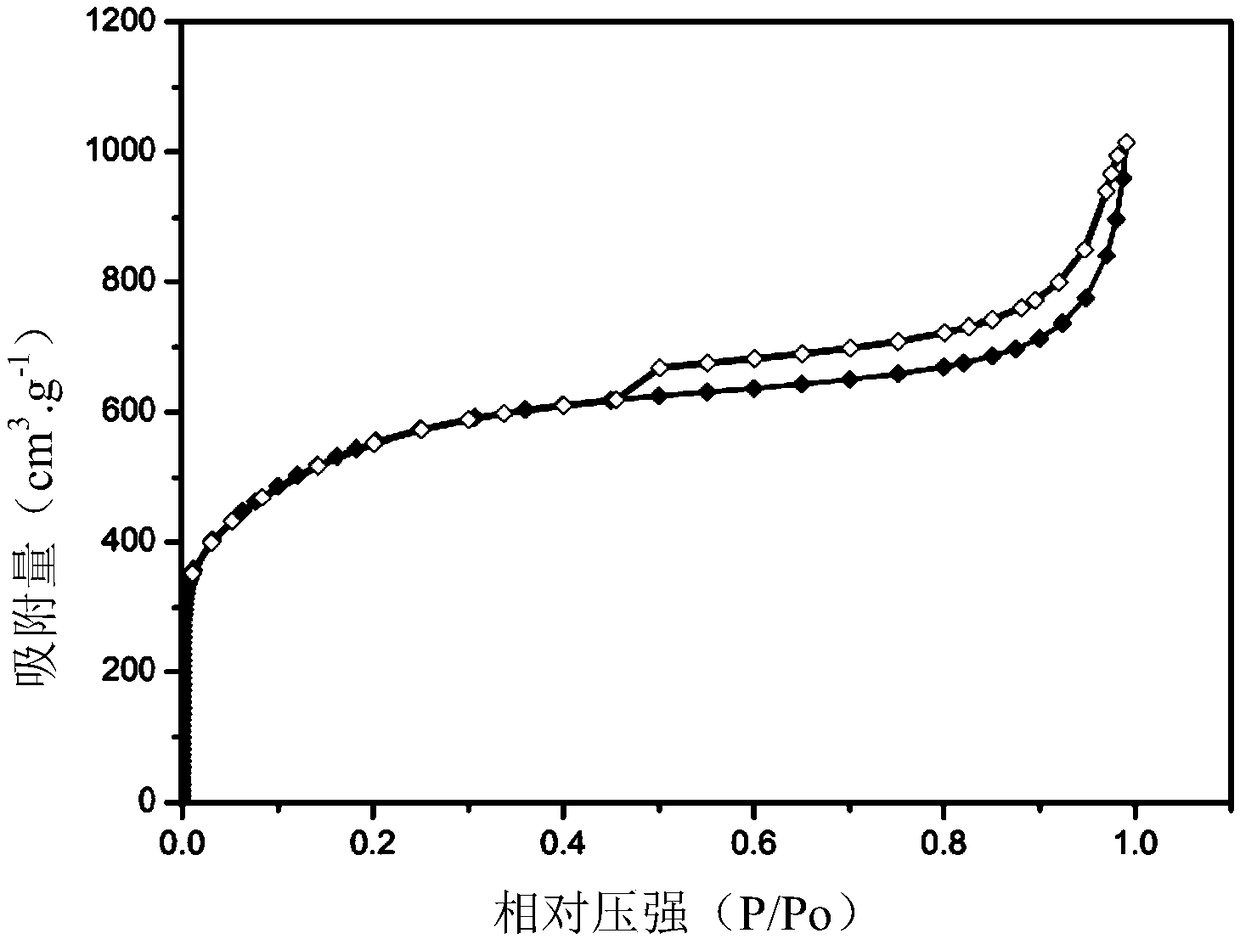

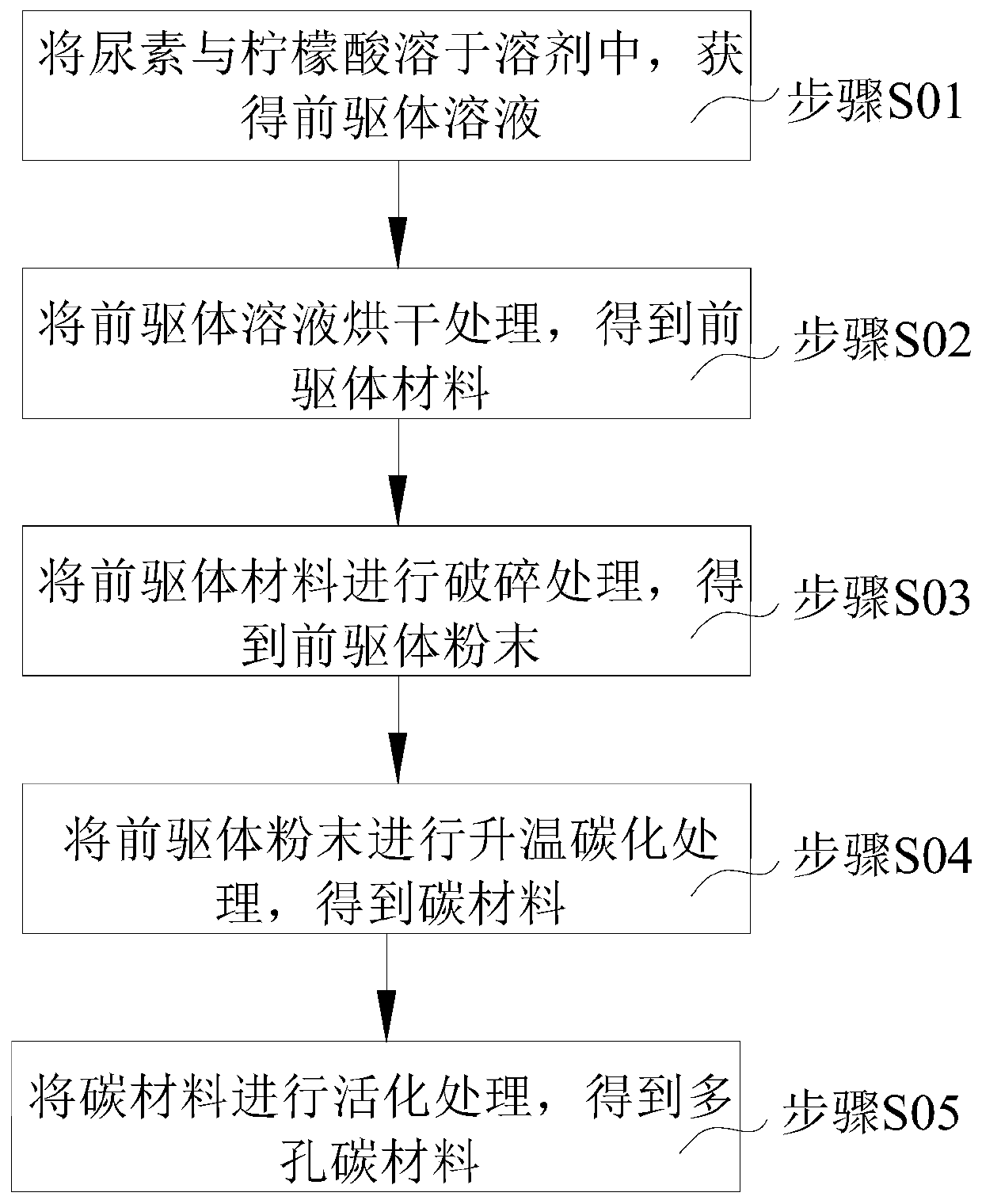

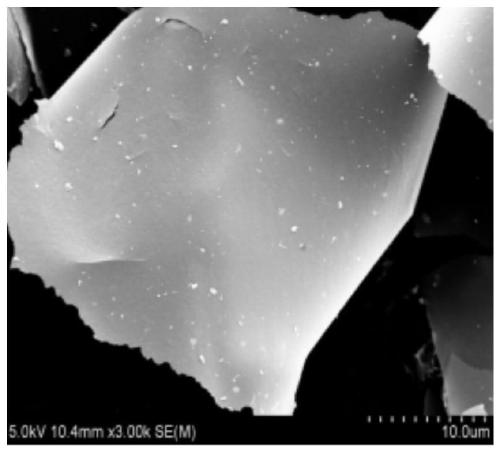

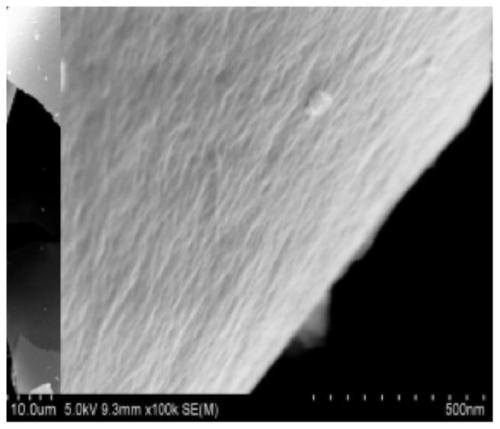

The invention relates to the technical field of supercapacitor electrode materials and in particular discloses a preparation method of a porous carbon material, a supercapacitor electrode and a supercapacitor. The preparation method comprises the following steps: dissolving urea and citric acid into a solvent so as to obtain a precursor solution; performing drying treatment on the precursor solution so as to obtain a precursor material; crushing the precursor material into precursor powder; increasing the temperature of the precursor powder to (700-1000) DEG C at a temperature increase velocity of (2-10) DEG C / minute so as to carbonize the precursor powder to obtain a carbon material with a regular morphology; in the presence of a protection atmosphere, mixing the carbon material with an activator, increasing the temperature to (360-400) DEG C, keeping the temperature for (20-30) minutes, further increasing the temperature to (600-800) DEG C, and keeping the temperature for (60-120) minutes, so as to obtain the porous carbon material. The porous carbon material disclosed by the invention is stable in property and large in specific surface area, has nitrogen functional groups on thesurface, and is applicable to use as a supercapacitor electrode material.

Owner:SHENZHEN UNIV

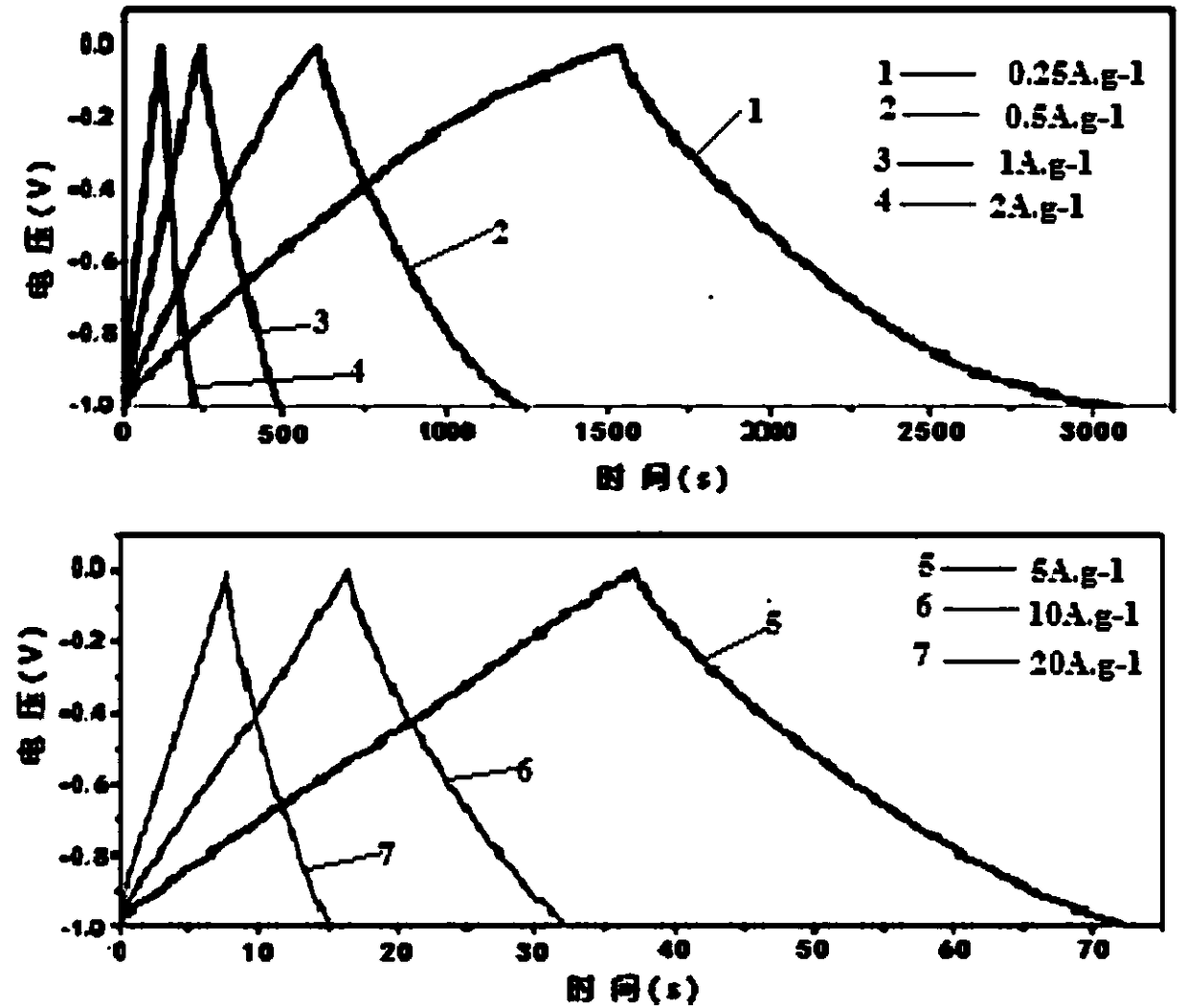

Activated carbon material applied to supercapacitor electrode material

InactiveCN112194133AUniform distribution of poresIncrease the areaCarbon compoundsHybrid capacitor electrodesCapacitancePotassium hydroxide

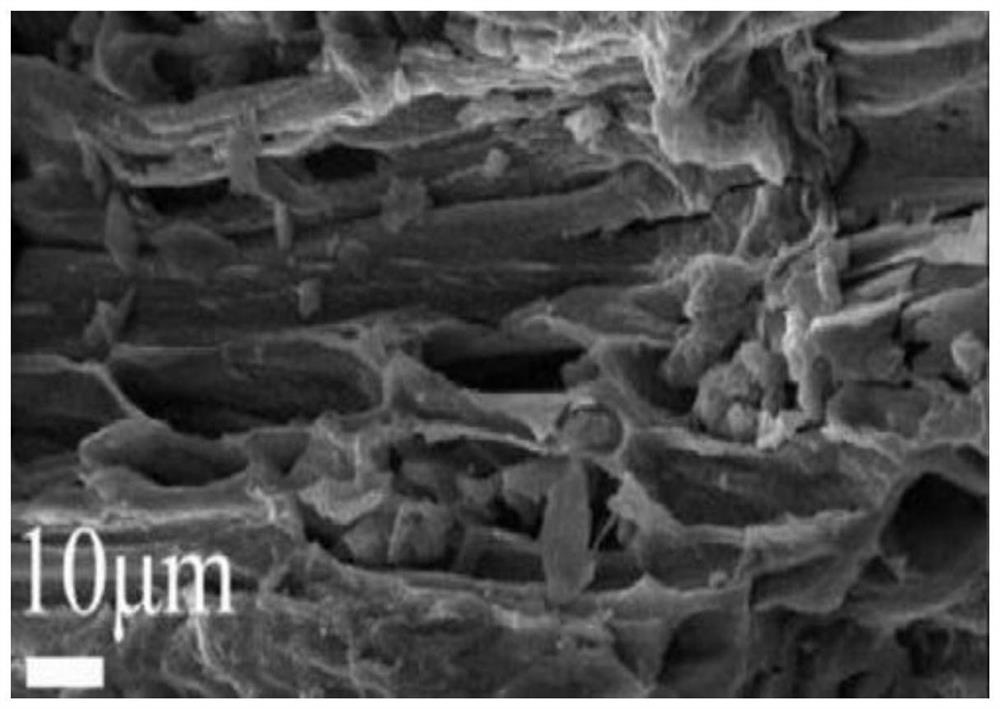

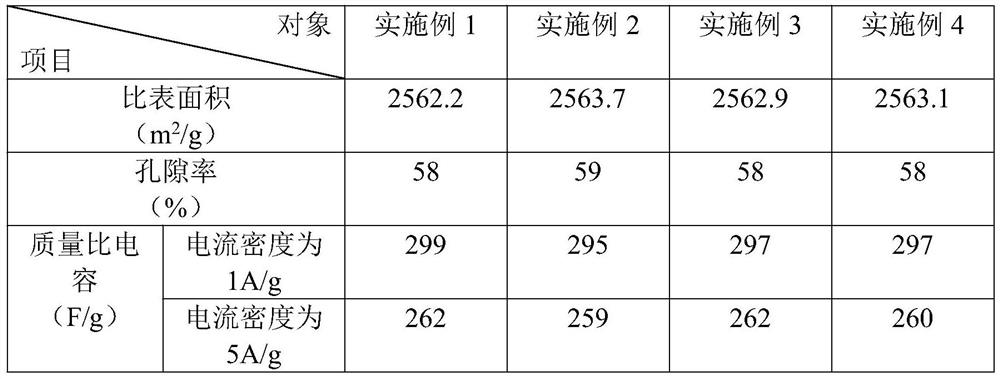

The invention discloses an activated carbon material applied to a supercapacitor electrode material. The activated carbon material is prepared by pretreating a wood raw material, a seaweed raw material and a crop straw raw material, and performing mixing and carbonizing, wherein bamboo sawdust is selected as the wood raw material, sargassum is selected as the seaweed raw material, and cotton strawis selected as the crop straw raw material; and carbonizing the pretreated bamboo sawdust powder, cotton straw powder and sargassum powder in an oxygen atmosphere, performing chemical activation by using a potassium hydroxide solution and citric acid, mixing with ferric trichloride, grinding, and performing high-temperature calcination activation to obtain the activated carbon material. The activated carbon material has very high specific surface area and porosity, the specific surface area reaches 2563.1 m<2> / g, and when the material is applied to a supercapacitor, the mass specific capacitance reaches 299F / g under the current density of 1A / g. The activated carbon material is a low-cost green electrode material with excellent electrochemical performance.

Owner:管小丹

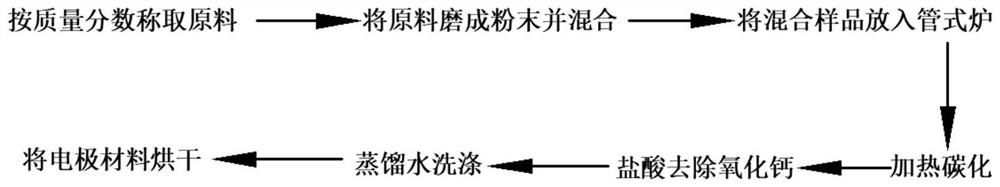

Electrode material, preparation method and application thereof

ActiveCN110459409AHigher than capacitanceImprove electrochemical performanceHybrid capacitor electrodesHybrid/EDL manufactureCapacitancePotassium hydroxide

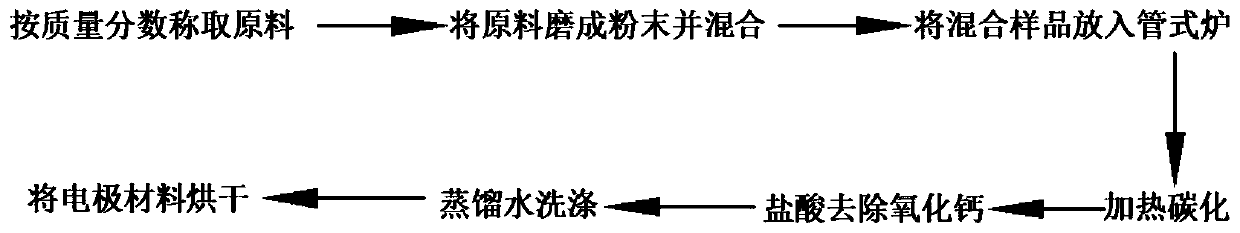

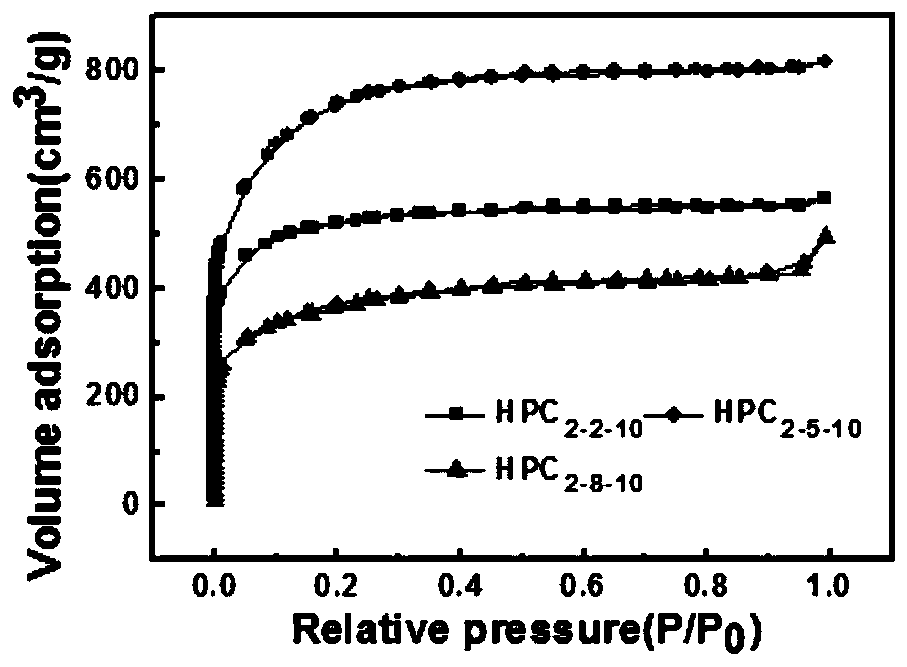

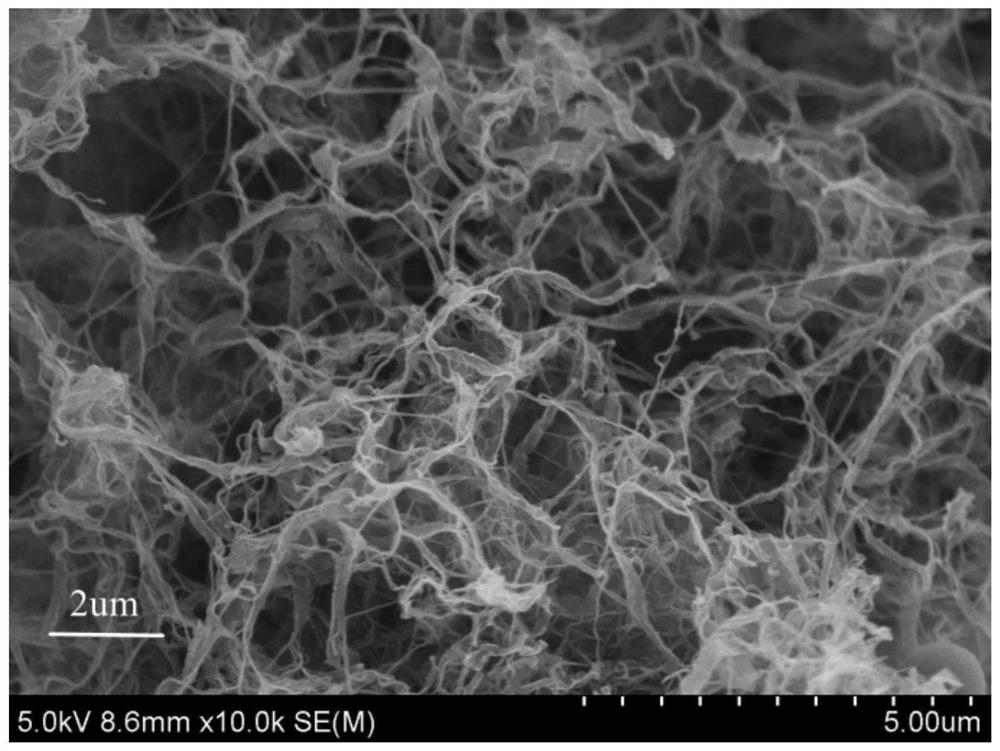

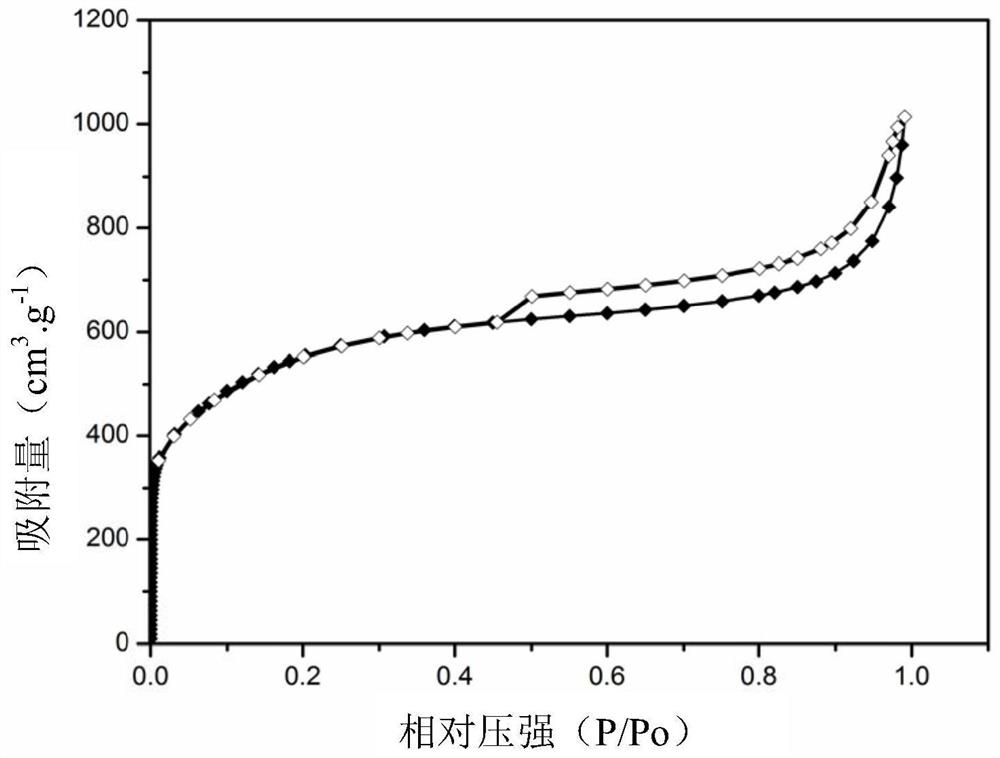

The invention provides an electrode material as well as a preparation method and the application thereof. The electrode material takes coal pitch as a carbon source, takes nano calcium oxide as a template agent and takes potassium hydroxide as an activating agent. The preparation method comprises the following steps: S1, weighing the raw materials in parts by mass; S2, grinding the raw materials into powder and mixing; S3, putting the mixed sample into a tubular furnace, and introducing inert gas; S4, heating and carbonizing; S5, performing acid pickling to remove nano calcium oxide; s6, washing with distilled water; S7, drying the electrode material. The electrode material prepared by the method has the characteristics of large specific surface area, proper pore size distribution range and high oxygen element content, so that the electrode material is high in specific surface area utilization rate, high in specific capacitance, high in energy density and good in cycle performance. Thematerial can be used as an electrode material for a supercapacitor.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

Cap-shaped nanometer graphite as well as preparation method and application thereof

ActiveCN103086365ALow cost of preparationIncrease energy densityMaterial nanotechnologyCarbon compoundsElectrochemical energy storageEnergy density

The invention discloses cap-shaped nanometer graphite as well as a preparation method and an application thereof, and belongs to the technical field of nanometer material preparation and electrochemistry energy storage. The preparation method comprises the following steps of: firstly preparing a template agent capable of generating nonuniform carbon deposition under chemical vapor deposition atmosphere, generating cap-shaped nanometer graphite on the prepared template agent, and finally removing and drying the template agent so as to prepare the cap-shaped nanometer graphite. The prepared cap-shaped nanometer graphite is in a cap-shaped structure, the diameter of the widest part of the cap-shaped nanometer graphite is 6-1000nm, and the height of the cap-shaped nanometer graphite is 1 / 5-1 / 2 of the diameter of the widest part of the cap-shaped nanometer graphite, and the specific surface area of the cap-shaped nanometer graphite is 80-2000m<2> / g. The cap-shaped nanometer graphite served as an electrode material is used for manufacturing a supercapacitor, wherein the mass percent of the cap-shaped nanometer graphite to the supercapacitor is 20-40%; the preparation method disclosed by the invention has the advantages of simple operation, low cost and environment protection; the utilization rate of the specific surface area and the energy density of the prepared cap-shaped nanometer graphite are high; and the effect is good when the prepared cap-shaped nanometer graphite serving as the electrode material is used for manufacturing the supercapacitor.

Owner:TSINGHUA UNIV

Preparation methods of super-capacitor carbons

InactiveCN107879343ALow costImprove the utilization of specific surface areaCarbon compoundsHybrid capacitor electrodesCapacitanceWater vapor

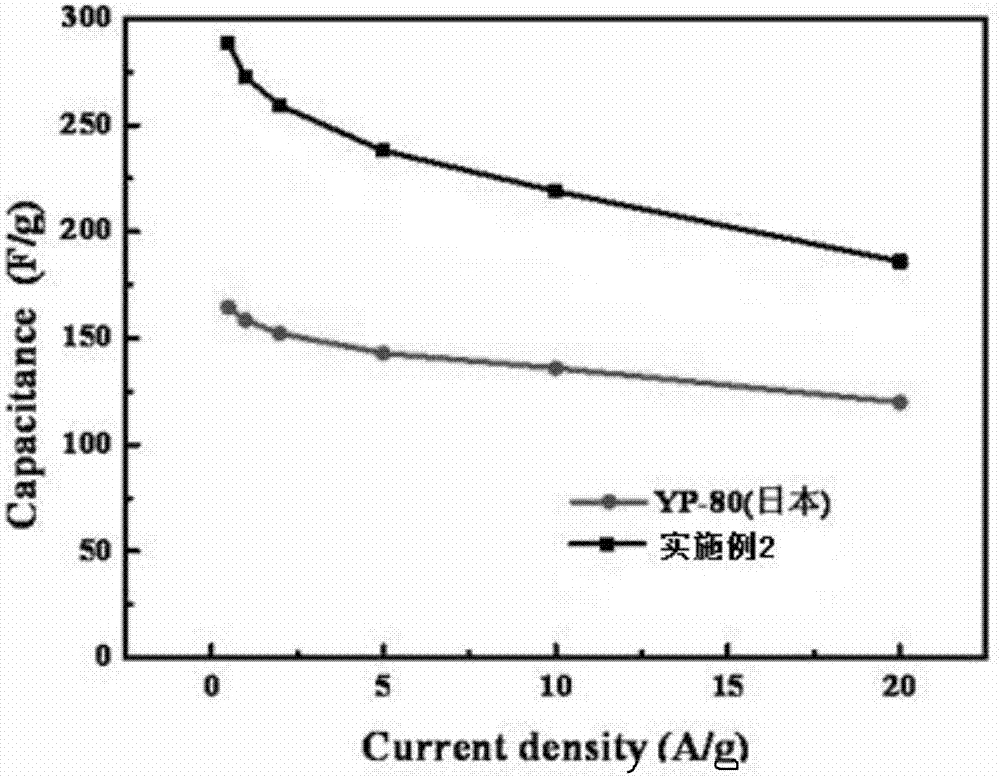

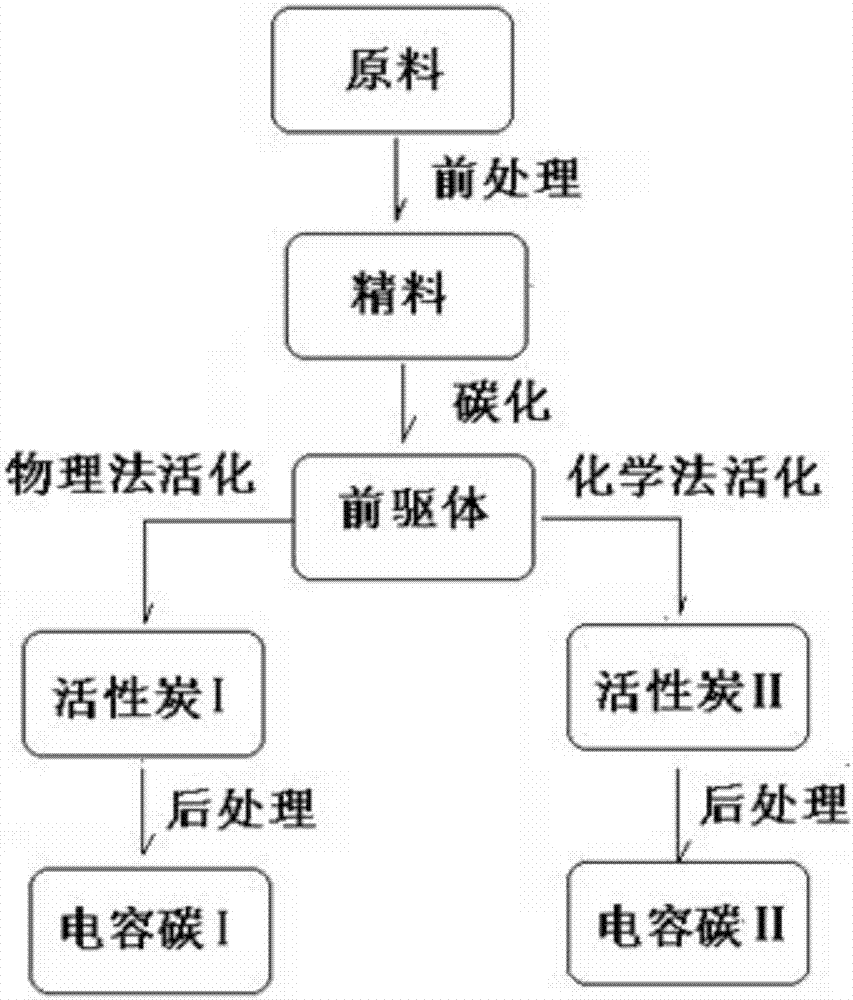

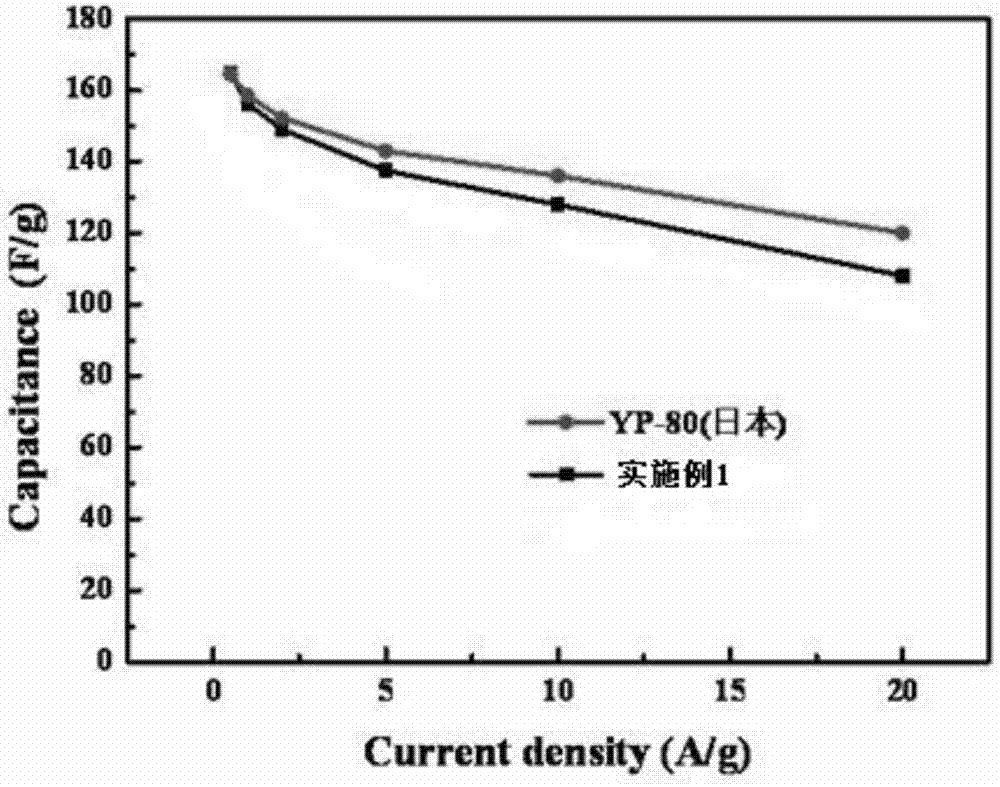

The invention discloses preparation methods of super-capacitor carbons. The preparation methods comprise the following steps: (1) corn is used as a raw material, pretreatment of degreasing and de-ashing is performed on the corn, and then moisture and low-temperature volatile components are removed through stepwise heating, so that a carbonized precursor is prepared; (2) a physical method and a chemical method are respectively used to perform respective activation on the precursor through high-temperature steam and strong alkali, so that porous activated carbons with different performance indicators are obtained; and (3) no impurity oxidation doping and molding are performed on the porous activated carbons, so that super-capacitor carbons with different performance indicators are obtained,wherein the super-capacitor carbon prepared through the physical method has a specific surface area of >=1800m<2> / g, a specific capacity of >=160F / g, a tap density of >=0.30g / cm<3>, an electrical resistivity of <=2.0[omega]m, a particle size distribution of D<50><=17[mu]m, and an ash content of <=0.2%; and the super-capacitor carbon prepared through the chemical method has a specific surface areaof >=1700m2 / g; a specific capacity of >=260F / g, a tap density of >=0.30g / cm<3>, an electrical resistivity of <=2.0[omega]m, a particle size distribution of D<50><=17[mu]m, and an ash content of <=0.2%.

Owner:山西锦筑化工技术有限公司

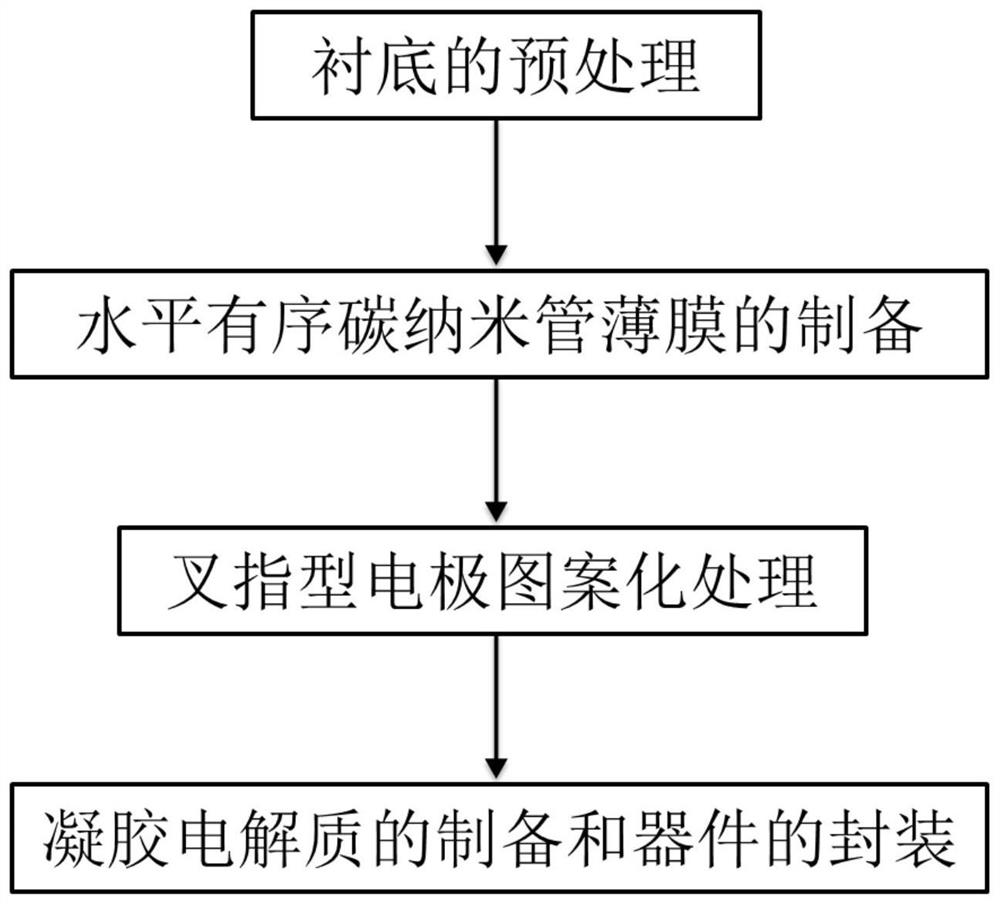

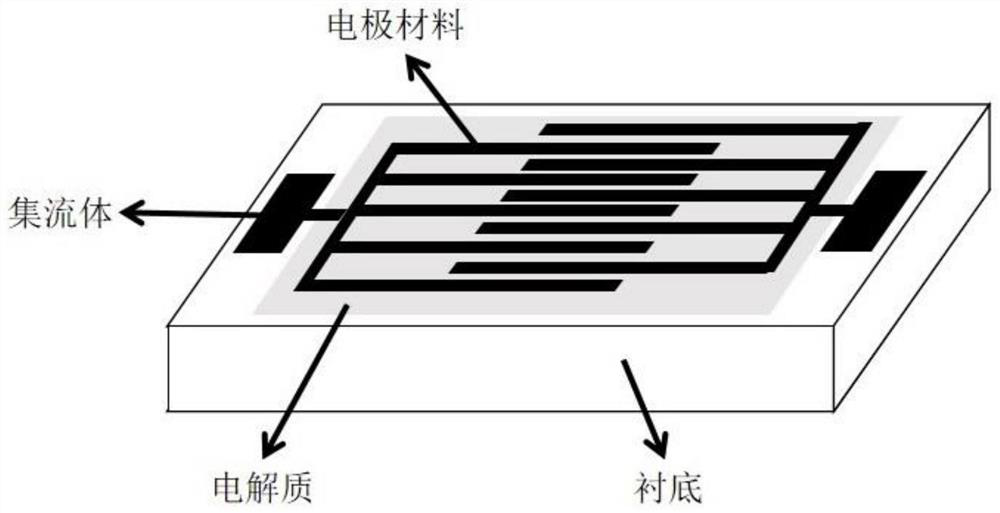

Preparation method of horizontal ordered carbon nanotube array micro supercapacitor

InactiveCN112366095AImprove performanceQuick migrationHybrid/EDL manufactureOxygen plasmaCarbon nanotube

The invention discloses a preparation method of a horizontal ordered carbon nanotube array micro supercapacitor. The device has an interdigital planar configuration. The preparation method comprises the following specific process steps of firstly, carrying out cutting, cleaning and hydrophilic pretreatment on a Si substrate with a SiO2 thin layer, then depositing a horizontally ordered carbon nanotube film on the substrate by using a vacuum evaporation self-assembly method, and then carrying out interdigital electrode patterning treatment, including designing an interdigital electrode mask, photoetching and depositing a current collector, and etching by using oxygen plasma to obtain the horizontal ordered carbon nanotube array film microelectrode, and finally, packaging a gel electrolyte preparation device, including preparing PVA-based gel electrolyte and coating the electrolyte on an electrode for packaging, so as to prepare the on-chip integrated horizontal ordered carbon nanotube array micro supercapacitor. The preparation of the on-chip integrated micro super capacitor with a controllable device structure can be realized.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

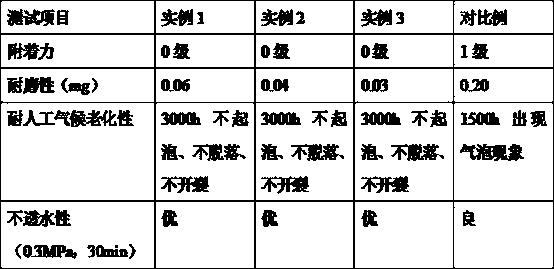

Preparation method of high-adhesion fluorocarbon coating

InactiveCN108034312AHigh adsorption activityImprove the utilization of specific surface areaCoatingsKetoneOxidation resistant

The invention relates to the technical field of preparation of coatings, in particular to a preparation method of high-adhesion fluorocarbon coating. A base and the aluminum source lithium metaaluminate are added to a self-made silicon source; nickel boride and lemon juice are added during hydrothermal reaction; nickel boride is used as a catalyst, the catalyst and cheating property of organic acids in the lemon juice enable metal ions in aluminum silicon molecular sieve to leave original lattice and enter the organic acids; tea polyphenols and microbes are then used to perform further modification on the molecular sieve and nano silica, so that adhesion of the coating is improved; the nano silica can improve wear resistance of the fluorocarbon coating. Grape wine contains rich organic carboxylic acid and other active ingredients; by adding the grape wine to the fluorocarbon coating, adhesion of the fluorocarbon coating is further improved; phenols and ketones having natural antioxidant action can be added such that the final fluorocarbon coating has significantly improved aging resistance and has a promising application prospect.

Owner:谢新昇

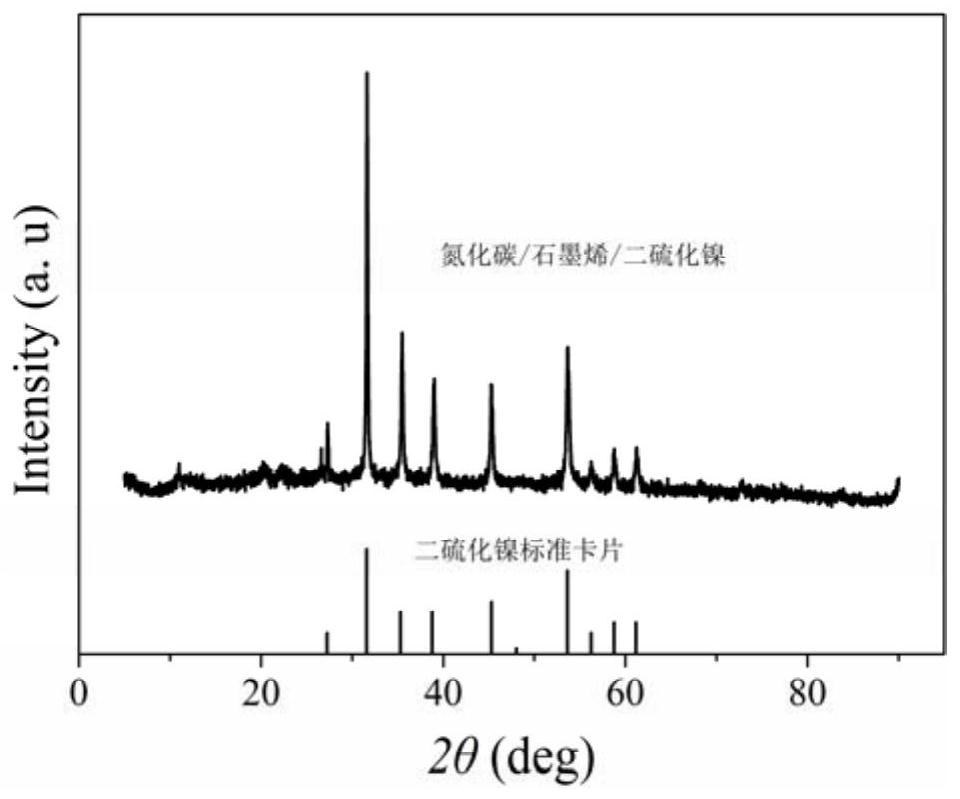

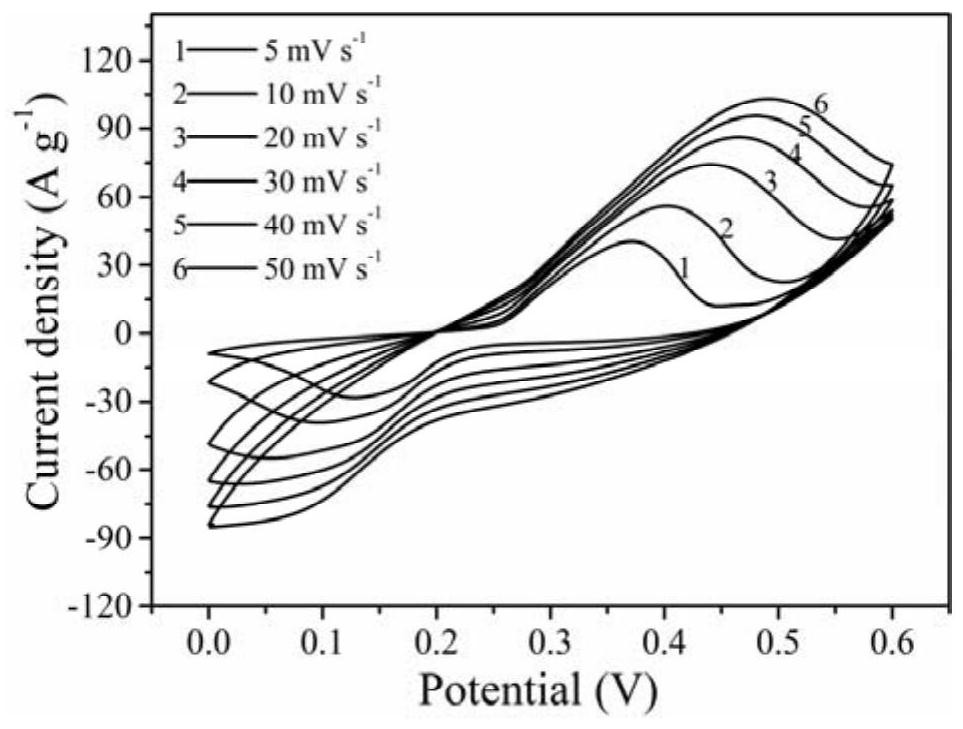

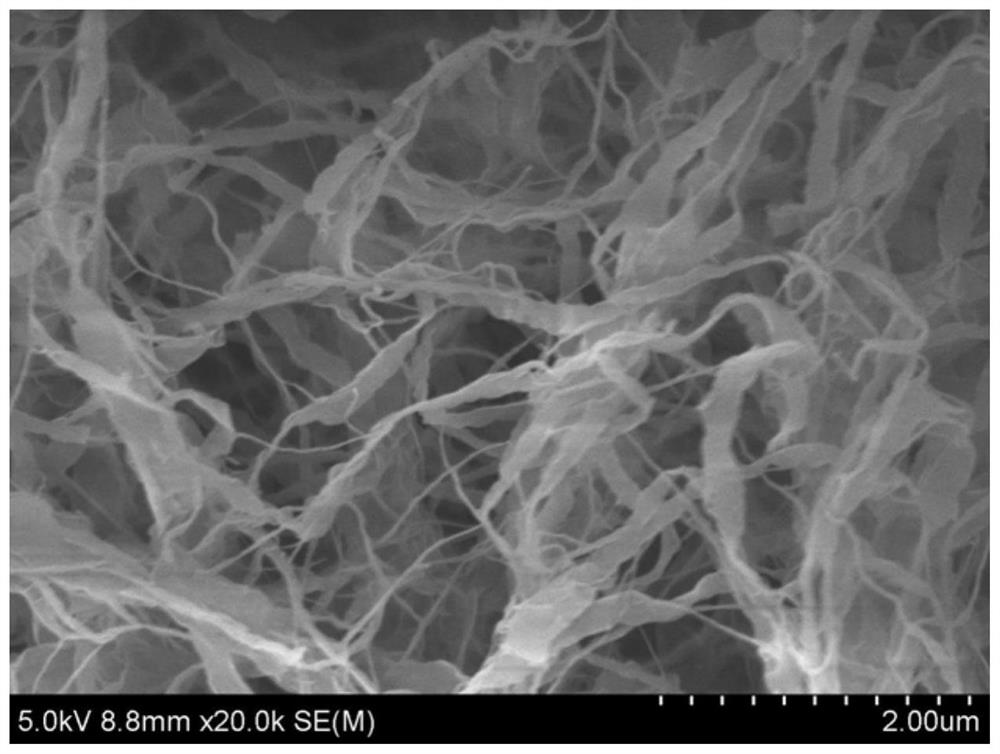

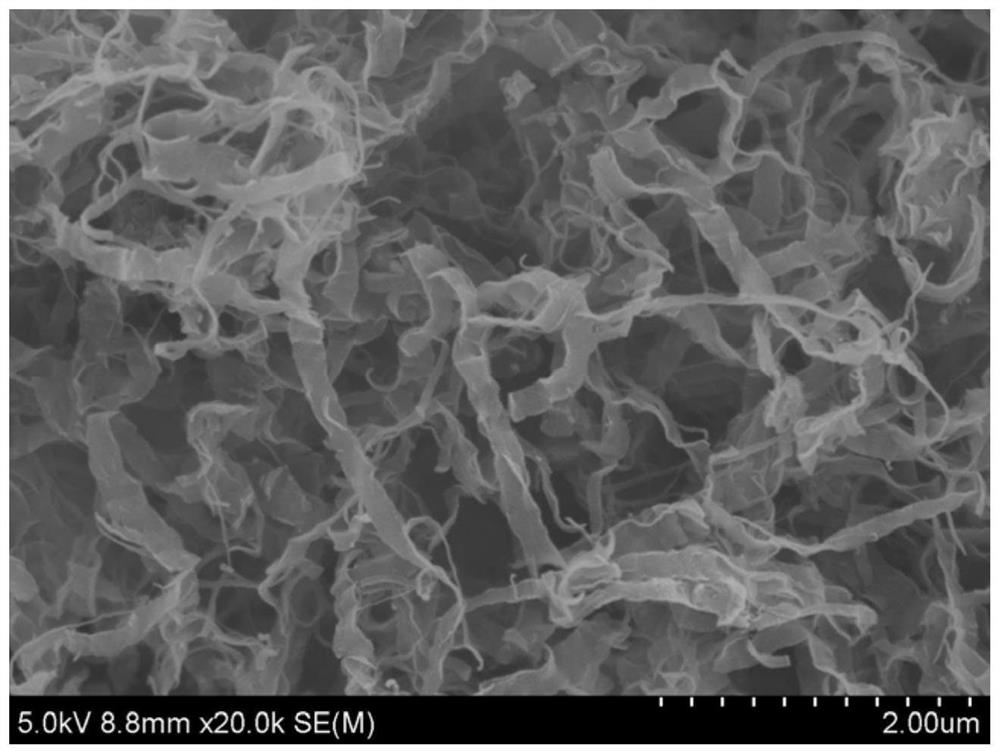

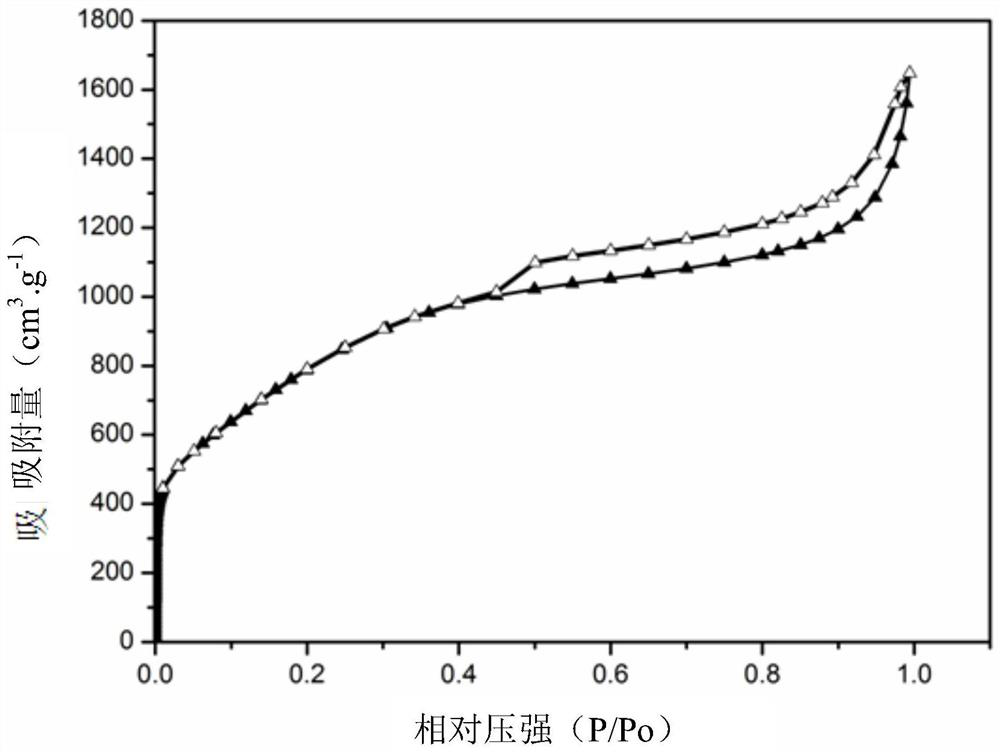

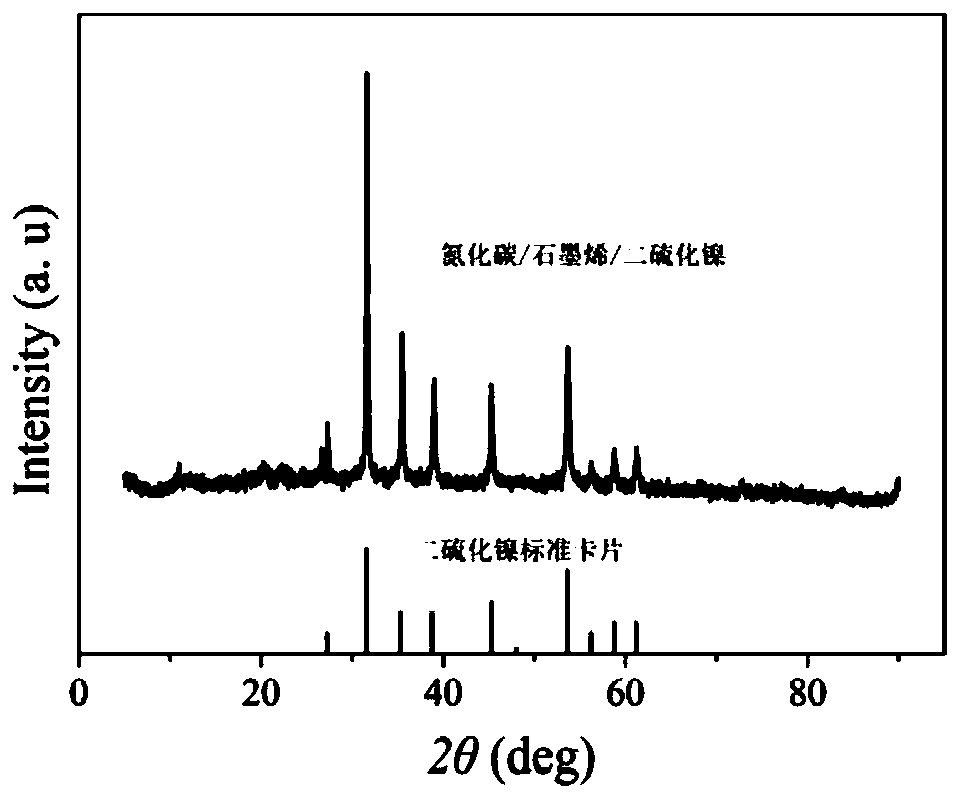

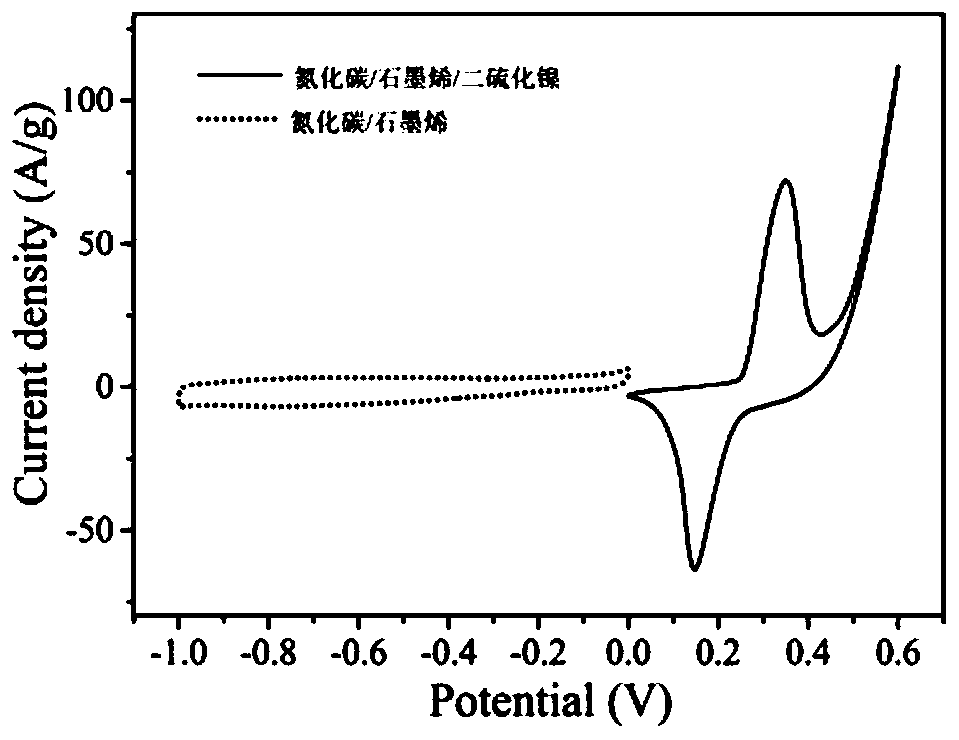

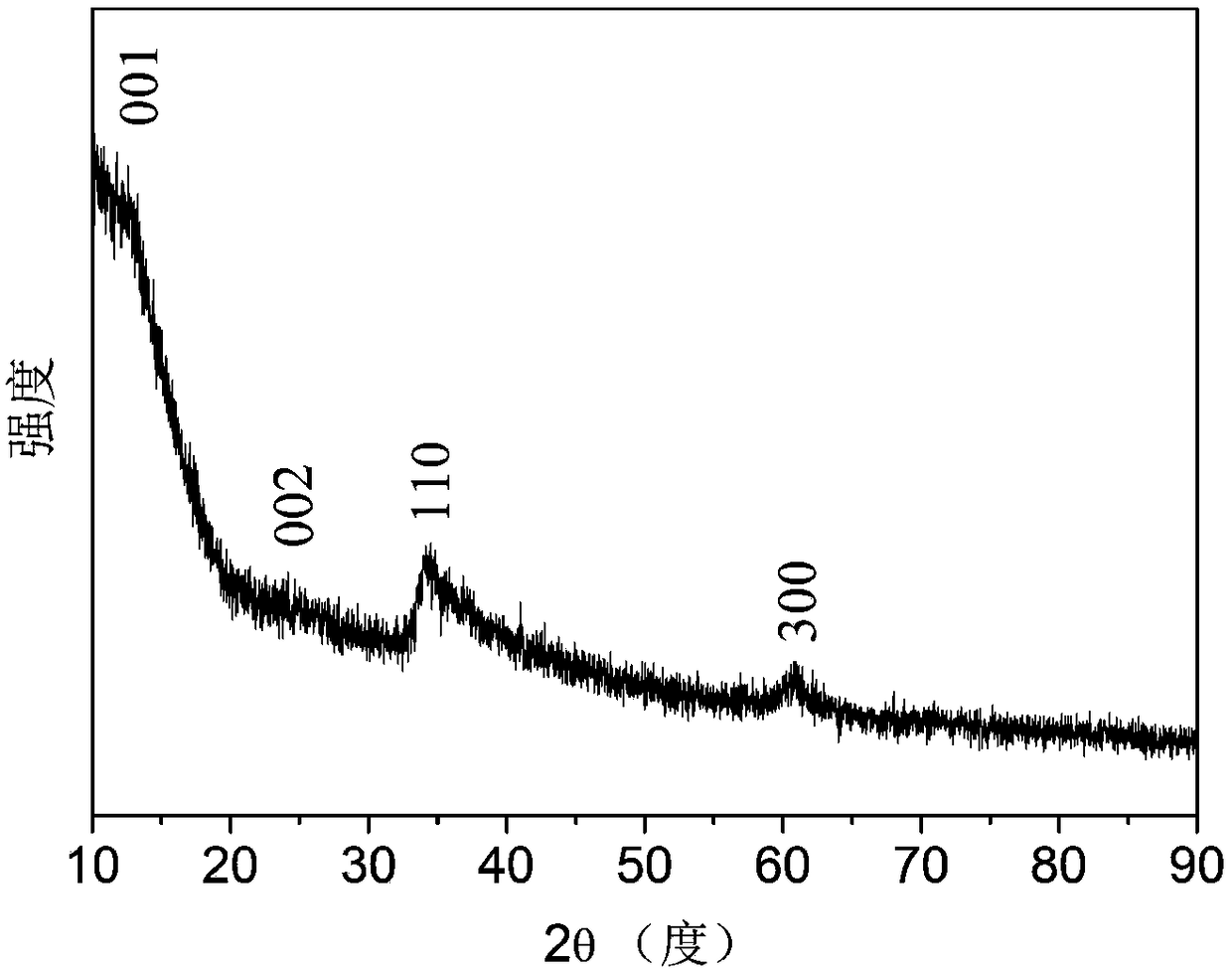

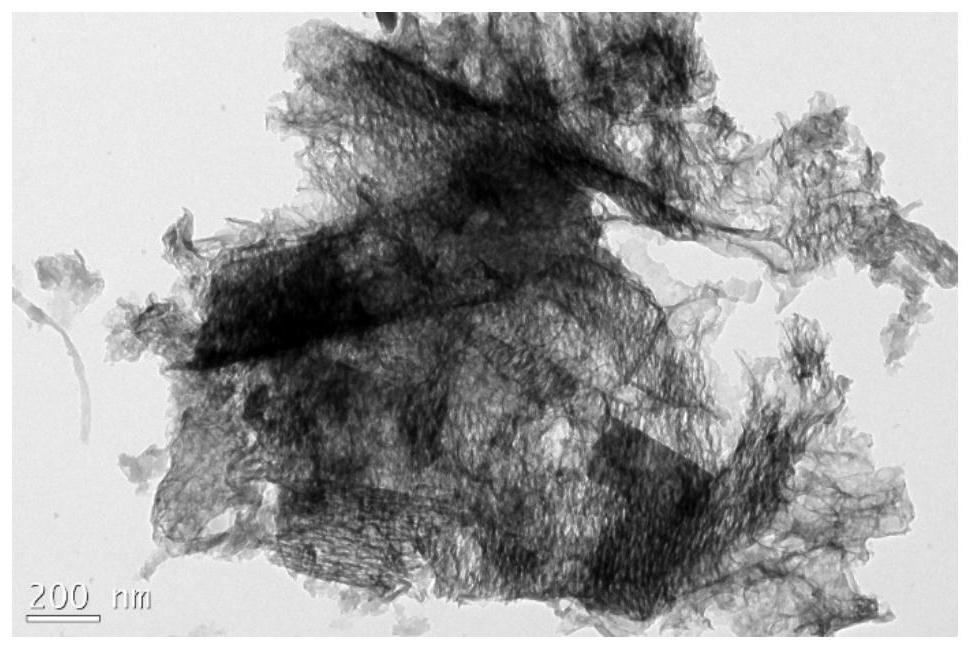

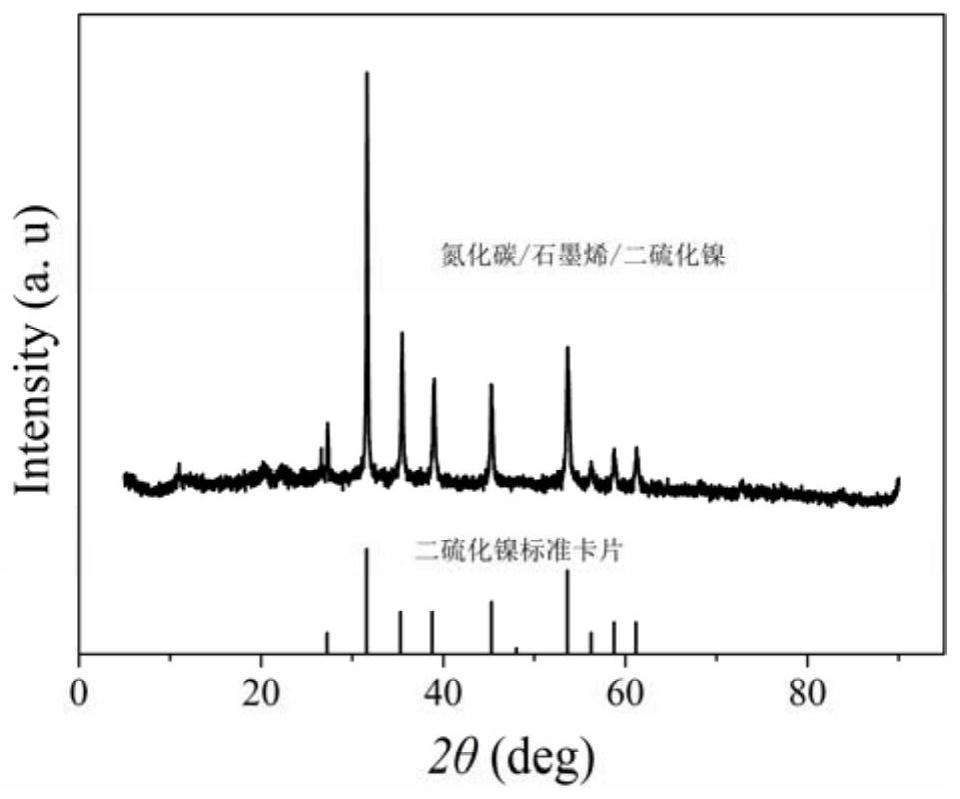

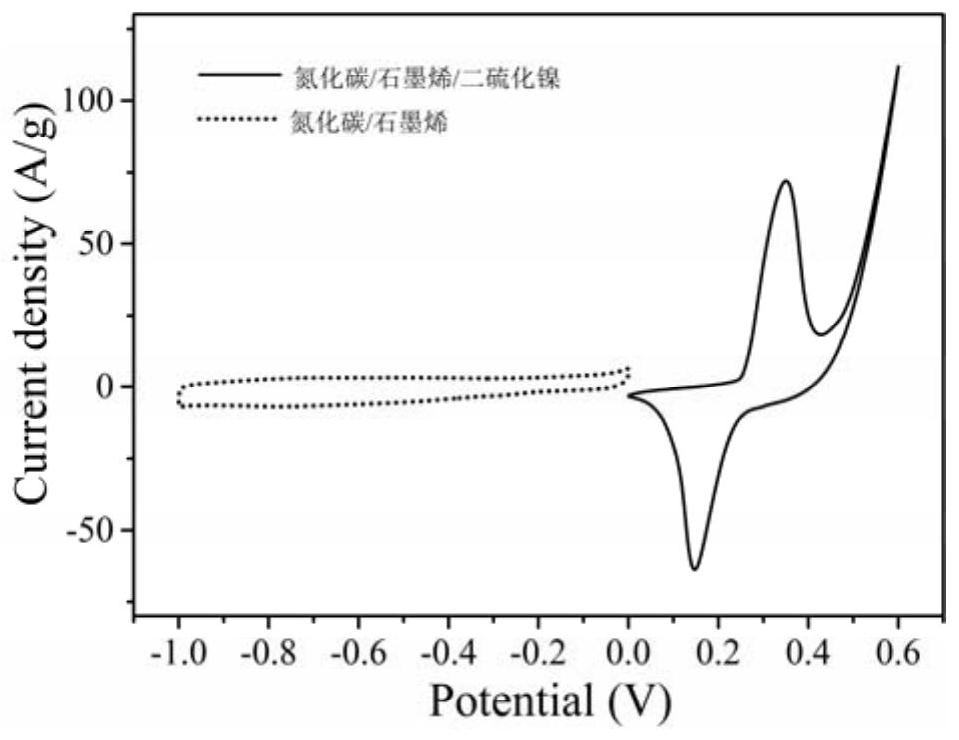

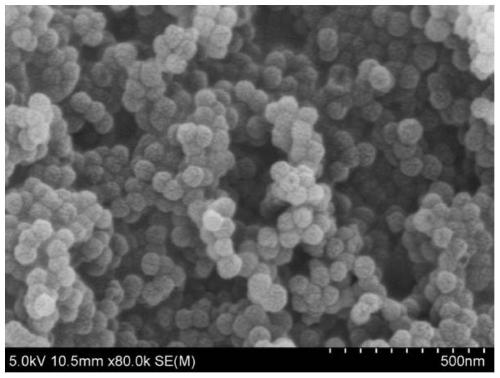

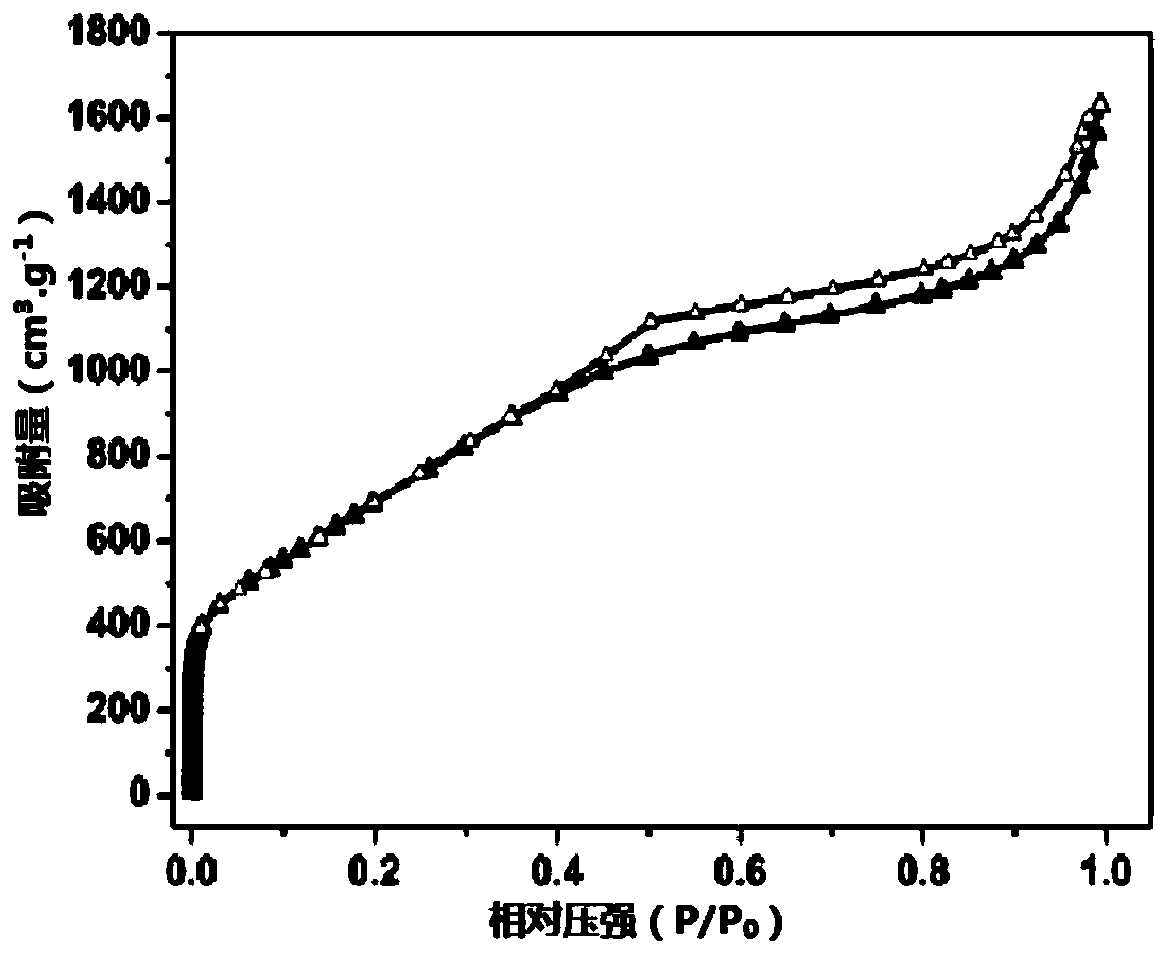

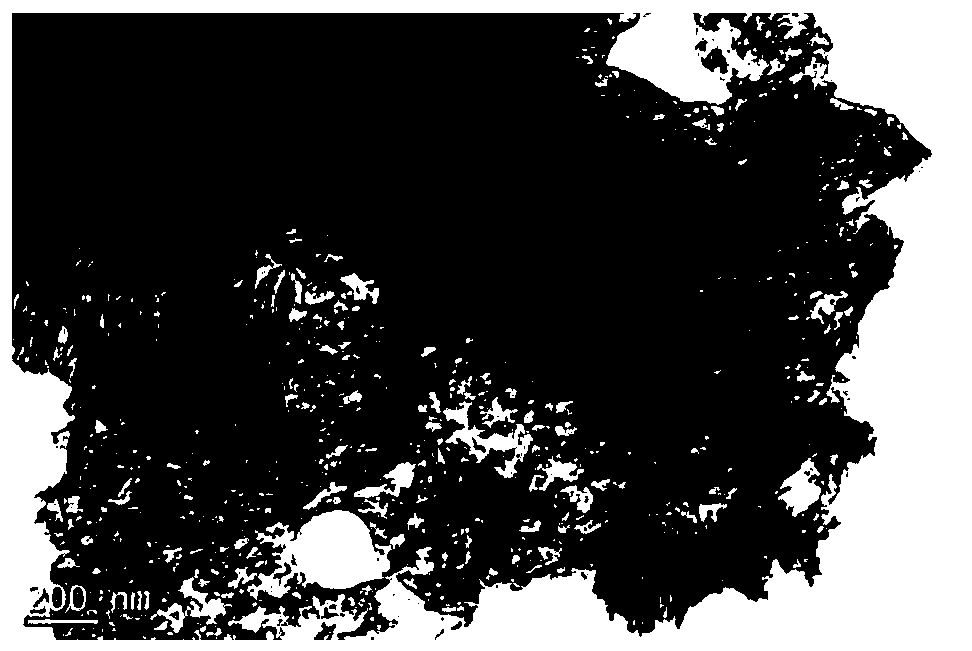

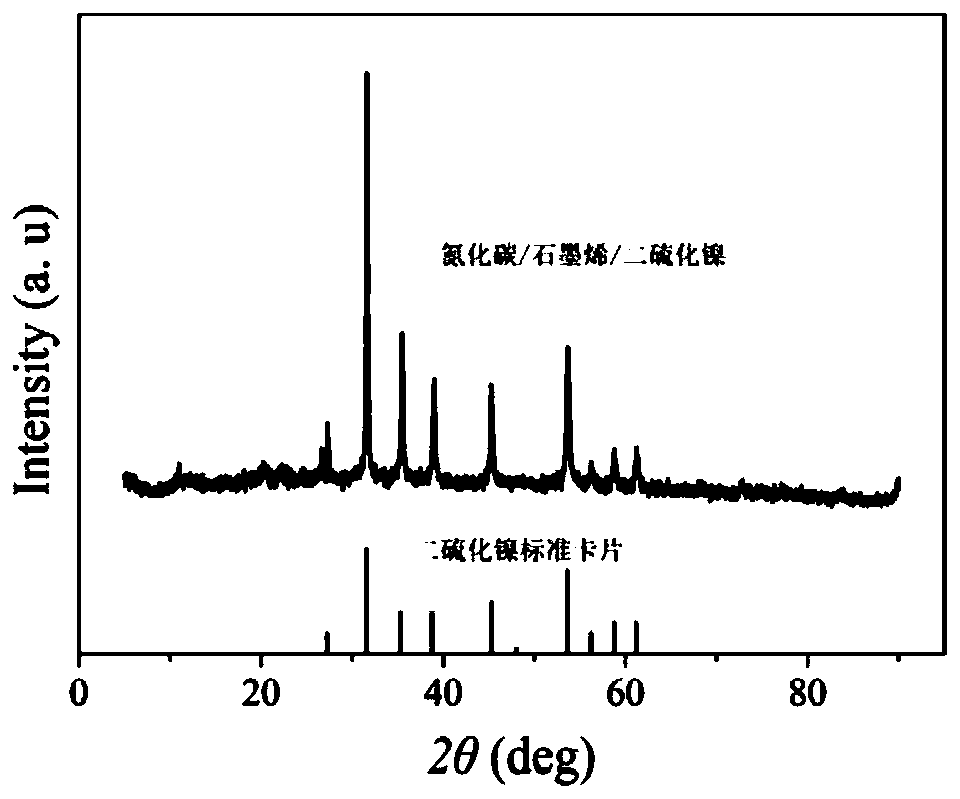

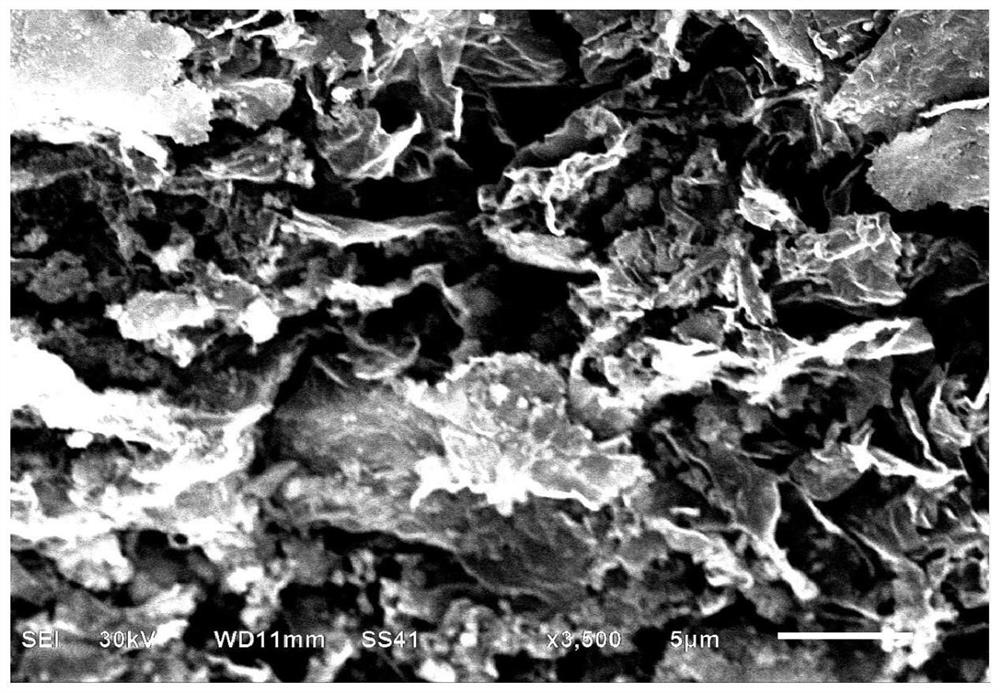

A kind of porous layer structure carbon nitride/graphene/nickel disulfide supercapacitor material and preparation method thereof

ActiveCN110828191BImprove the utilization of specific surface areaQuick migrationHybrid capacitor electrodesCapacitanceHeterojunction

The invention discloses a porous layered carbon nitride / graphene / nickel disulfide super capacitor material and a preparation method thereof. Porous layered g-C3N4 / graphene is compounded with a NiS2 pseudo-capacitive material to form the carbon nitride / graphene / nickel disulfide material with a heterostructure. The electrode material has the characteristics of high specific capacity and good stability.

Owner:XI AN JIAOTONG UNIV

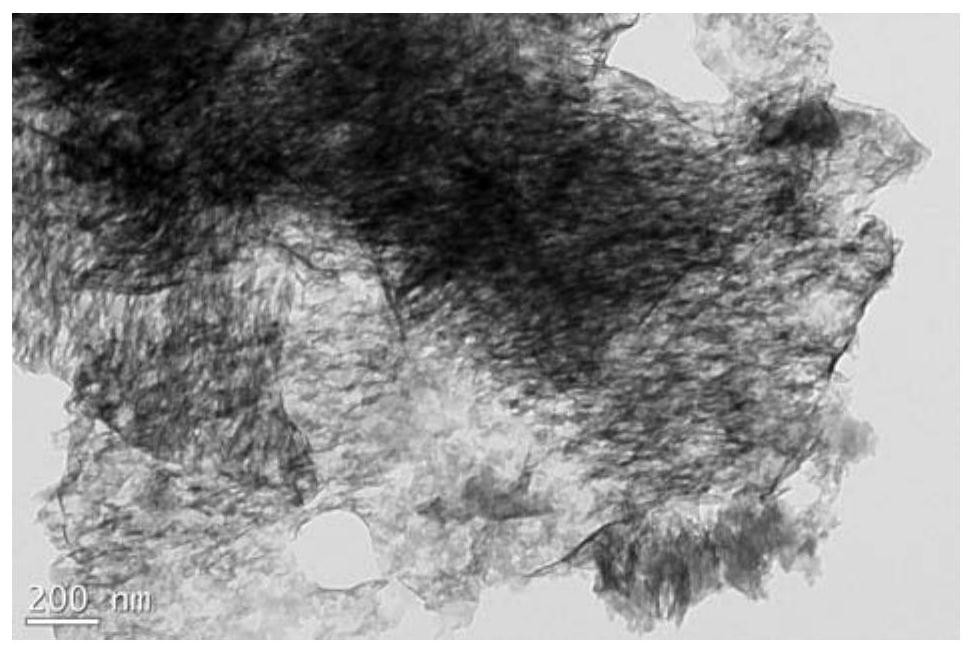

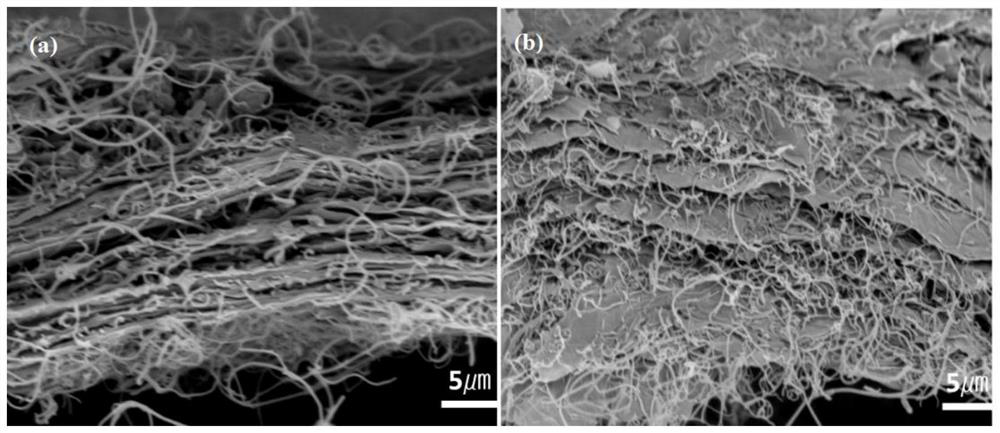

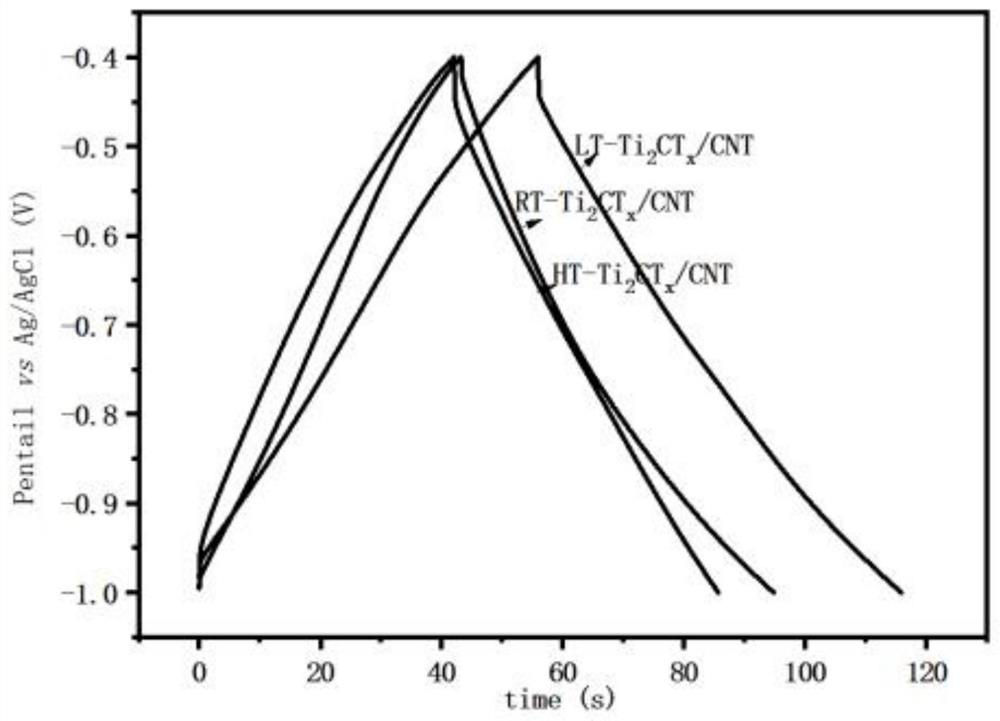

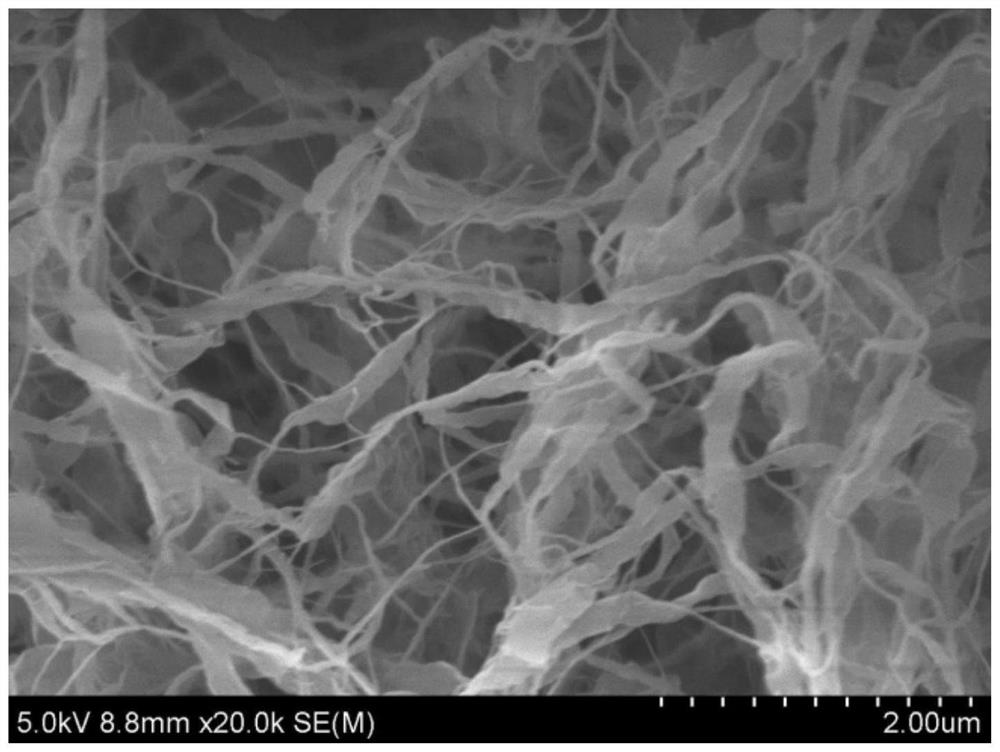

Self-supporting MXene/MWCNT flexible composite film, and preparation method and application thereof

ActiveCN113223776AImprove flexibilityFast transferMaterial nanotechnologyConductive layers on insulating-supportsFiberComposite film

The invention provides a self-supporting MXene / MWCNT flexible composite film, and a preparation method and application thereof, and belongs to the field of composite materials. The preparation method comprises the following steps: carrying out first filtration on a Ti2CTx MXene colloidal solution on a composite fiber filter membrane, carrying out second filtration on an MWCNT dispersion liquid on an obtained first thin film layer, sequentially and circularly repeating the first filtration and the second filtration on the obtained first MWCNT layer, finally filtering the Ti2CTx MXene colloidal solution, carrying out vacuum freeze drying, and removing the composite fiber filter membrane to obtain the self-supporting MXene / MWCNT flexible composite film. The interlayer structure of the MXene / MWCNT composite film electrode prepared by adopting the vacuum freeze drying technology is looser, the interlayer spacing is larger, the storage and transmission performance of ions between the layers is remarkably improved, more electrode / electrolyte interfaces are exposed, an open and firm structure is established, and the structural stability is improved.

Owner:北京理工大学前沿技术研究院

Nitrogen-oxygen co-doped porous carbon nanobelt and its preparation method and application

ActiveCN108711518BSimple processProcess conditions are easy to controlMaterial nanotechnologyCarbon compoundsPorous carbonSupercapacitor

The invention discloses a nitrogen oxygen co-doped porous carbon nano belt, a preparation method, a super capacitor electrode and a super capacitor. The preparation method comprises steps of carryingout a hydrothermal reaction on formaldehyde and hydroquinone in the acid solution so as to obtain a carbon nano belt precursor; and carrying out carbonizing treatment and ammonium hydroxide activatingtreatment on the carbon nano belt precursor so as to obtain a nitrogen oxygen co-doped porous carbon belt. According to the invention, the nano belt has quite big specific area, good wettability, andhigh specific area utilization rate. The super capacitor electrode and the super capacitor have the prepared nitrogen oxygen co-doped porous carbon nano belt.

Owner:SHENZHEN UNIV

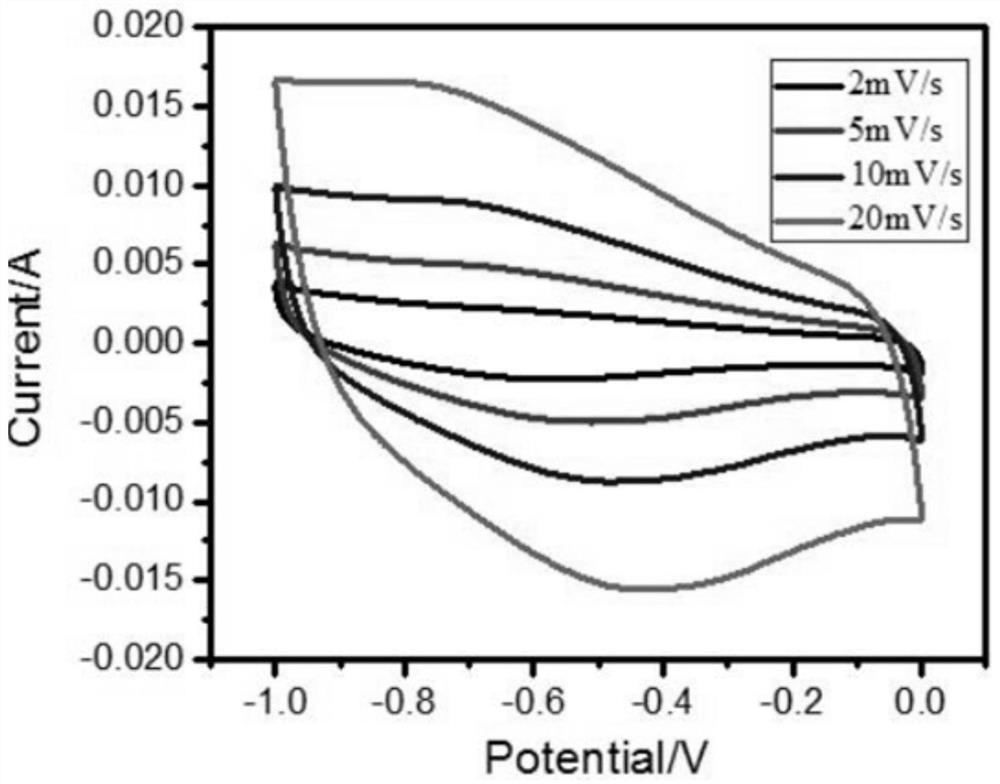

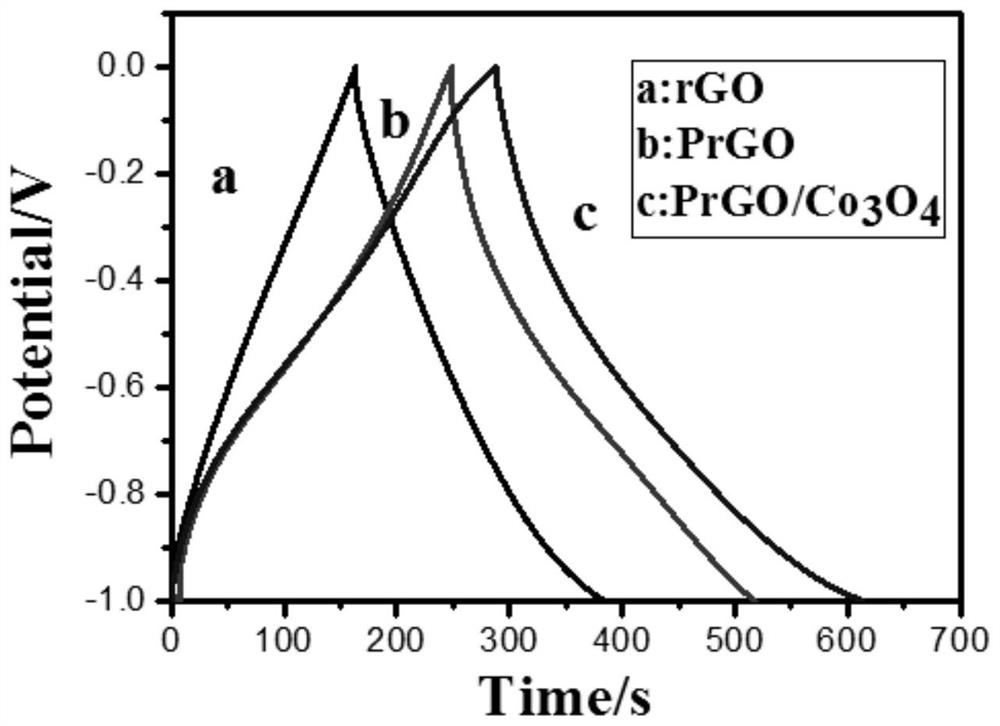

Water system asymmetric supercapacitor based on porous carbon nitride/graphene/nickel disulfide and carbon nitride/graphene and preparation method thereof

ActiveCN110808170AQuick migrationHigh specific powerHybrid capacitor electrodesHybrid/EDL manufactureGrapheneGraphite

Owner:XI AN JIAOTONG UNIV

A kind of nickel hydroxide/graphene nanocomposite material and preparation method thereof, supercapacitor electrode and supercapacitor

ActiveCN106158405BPrevent heavy accumulationImprove the utilization of specific surface areaMaterial nanotechnologyHybrid capacitor electrodesCapacitanceGraphene nanocomposites

The invention discloses a nickel hydroxide / graphene nano composite, a preparation method thereof, a supercapacitor electrode and a supercapacitor. The composite is formed by base material graphene and a nickel hydroxide nanosheet growing on the surface of the graphene in situ, and the composite integrally has a three-dimensional porous structure. A graphene-based composite is prepared by loading a transition metal hydroxide on the surface of the graphene with high specific surface area and excellent conductivity in a composition manner. Due to synergistic effect of all componenta of the composite, all components can mutually enhance advantages and avoid disadvantages; and meanwhile, long circle life, high power density and high stability of an electric double-layer capacitor and high specific capacitance characteristic of a pseudocapacitor are combined, thereby improving the comprehensive performances of the supercapacitor.

Owner:嘉兴企远网信息科技有限公司

Cap-shaped nanometer graphite as well as preparation method and application thereof

ActiveCN103086365BNot easy to overlapImprove the utilization of specific surface areaMaterial nanotechnologyCarbon compoundsMaterials preparationGas phase

Owner:TSINGHUA UNIV

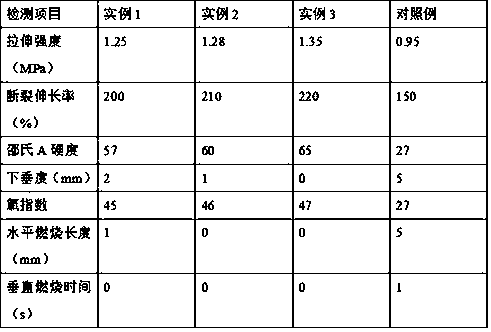

Preparation method for flame-retardant high-strength building seal gum

InactiveCN108192560AHigh adsorption activityImprove the utilization of specific surface areaNon-macromolecular adhesive additivesMacromolecular adhesive additivesPotassium thiocyanatePolymer chemistry

The invention relates to the technical field of preparation of seal gums, and in particular relates to a preparation method for a flame-retardant high-strength building seal gum. Nano-scale hydrotalcite is firstly prepared by a hydrothermal method, potassium thiocyanate and tartaric acid are added while the hydrothermal reaction is performed, under the action of the potassium thiocyanate and the tartaric acid, metal ions in the hydrotalcite leave an original crystal lattice position to enter an organic phase of the tartaric acid, so that holes are generated in the crystal lattice, and the adsorption activity of the hydrotalcite is improved; and hydroxylation modification is performed on the hydrotalcite by using anhydrous ethanol to obtain a self-prepared reinforcing filler, then further modification is performed on the self-prepared reinforcing filler by utilizing organosiloxane and an organic acid, and finally mixing is performed with silicone rubber and other auxiliary materials toprepare the building seal gum. According to the method provided by the invention, smooth immersion of a gum material into abundant pores of the nano-scale hydrotalcite is facilitated, the silicone rubber is easily penetrated and anchored in the pores of the highly-active nano-scale hydrotalcite, the bonding compactness of the silicone rubber and the nano-scale hydrotalcite is improved, and the cohesive energy and mechanical strength of the seal gum are improved.

Owner:常州市绿意管道有限公司

Micro/nano structured cathode material for lithium air batteries

InactiveCN102856611BImprove electrochemical activityRealize NanoizationHybrid cell detailsNano catalystFiber

The invention discloses a micro / nano structured cathode material for lithium air batteries. The cathode material comprises hollow porous composite fibers, is obtained by compounding catalyst nano particles used for lithium air battery positive electrode reaction with a hollow micron-sized carbon fiber carrier, the carbon fiber tube wall comprises a plurality of nano pores which are interconnected, and the catalyst nano particles are dispersedly loaded on the carbon fiber tube wall and in the pores. The prepared cathode material can provide sufficient active substance reaction zones, simultaneously the porous structure of the tube wall increases the reaction activity of the active substance, and the hollow structure in the tube guarantees the unblocked delivery channel of oxygen. According to the invention, the cathode material disclosed herein has a structure of hollow in the tube and porous on the tube wall; the micro / nano structured cathode material formed by compounding the nano catalyst, thus the material has excellent electrical conductivity, can effectively raise the charge and discharge capacity of the lithium air batteries, reduce the polarization of charge and discharge, raise the high rate discharge capability and power density of the lithium air batteries are raised, the battery inner resistance is reduced, thus the material disclosed herein is an ideal cathode material.

Owner:CENT SOUTH UNIV

High-energy supercapacitor with porous carbon nitride interlayer material configuration and preparation method

ActiveCN110808170BQuick migrationHigh specific powerHybrid capacitor electrodesHybrid/EDL manufacturePorous carbonSupercapacitor

The invention discloses a water system asymmetric supercapacitor based on porous carbon nitride / graphene / nickel disulfide and carbon nitride / graphene and a preparation method thereof. The positive electrode material is obtained in a way that a one-step calcination method is utilized to obtain a g-C3N4 / graphene as the substrate and NiS2 is further loaded to obtain porous layered structure carbon nitride / graphene / nickel disulfide, and the negative electrode material is three-dimensional porous structure carbon nitride / graphene prepared by a solvothermal method. The working voltage of the assembled water system asymmetric supercapacitor is 1.6 V. When the energy density is 56Wh kg-1, the power density reaches 800W kg-1, and there is almost no attenuation of the capacity after 10000 cycles. The high specific energy is realized and the supercapacitor has the characteristics of high specific power, low preparation cost, environmental protection and high practical application value.

Owner:XI AN JIAOTONG UNIV

Nitrogen-oxygen co-doped hollow carbon nanospheres, preparation method and application thereof

ActiveCN108439369BImprove wettabilityUniform sizeMaterial nanotechnologyHybrid capacitor electrodesMicrosphereSupercapacitor

The invention discloses nitrogen-oxygen co-doped hollow carbon nanospheres, a preparation method thereof, a supercapacitor electrode and a supercapacitor. The preparation method of the nitrogen-oxygenco-doped hollow carbon nanospheres comprises the steps as follows: pyrrole and aniline are subjected to a polymerization reaction in a water liquor containing a soft template, and a hollow carbon nanosphere precursor is obtained; the hollow carbon nanosphere precursor is washed, pulverization treatment, carbonization treatment and ammonia water activation treatment are performed, and the nitrogen-oxygen co-doped hollow carbon nanospheres are obtained. The nitrogen-oxygen co-doped hollow carbon nanospheres prepared with the preparation method have larger specific surface area, good wettabilityand high specific surface area utilization rate. The supercapacitor electrode and the supercapacitor comprise the nitrogen-oxygen co-doped hollow carbon nanospheres prepared with the method.

Owner:SHENZHEN UNIV

Porous layered carbon nitride/graphene/nickel disulfide super capacitor material and preparation method thereof

ActiveCN110828191AImprove the utilization of specific surface areaQuick migrationHybrid capacitor electrodesCapacitanceHeterojunction

The invention discloses a porous layered carbon nitride / graphene / nickel disulfide super capacitor material and a preparation method thereof. Porous layered g-C3N4 / graphene is compounded with a NiS2 pseudo-capacitive material to form the carbon nitride / graphene / nickel disulfide material with a heterostructure. The electrode material has the characteristics of high specific capacity and good stability.

Owner:XI AN JIAOTONG UNIV

A kind of 3D porous graphene/transition metal oxide composite material and its preparation method and application

ActiveCN108231427BLarge specific surface areaPrevent heavy accumulationHybrid capacitor electrodesCell electrodesPorous grapheneSodium bicarbonate

The invention discloses a 3D porous graphene / transition metal oxide composite material and its preparation method and application. The preparation method of the composite material: after ultrasonically dispersing graphite oxide into water, then adding transition metal salt and sodium bicarbonate and stirring dissolved to obtain a mixed solution; the mixed solution is transferred into a hydrothermal reaction kettle for hydrothermal reaction, and the hydrothermal reaction product is dried and calcined under a protective atmosphere to obtain a 3D porous structure, and the original transition metal oxide 3D porous graphene / transition metal oxide composite material grown on the surface of graphene, the composite material has good electrochemical properties, can be applied to supercapacitor electrode materials or lithium ion negative electrode materials, and its preparation method is simple and cheap , Environmentally friendly and meet industrial production standards.

Owner:XIANGTAN UNIV

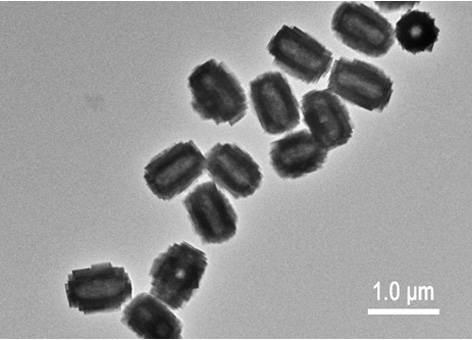

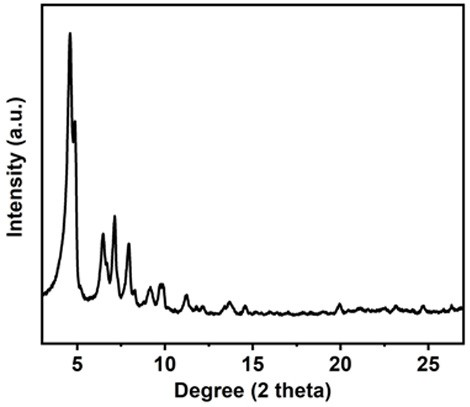

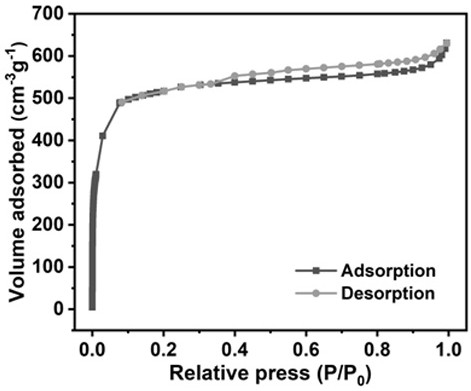

Preparation and application of hollow zirconium-based porphyrin type metal organic framework solid-phase microextraction fiber

ActiveCN113893835ASpecial hollow structureImprove the utilization of specific surface areaGas treatmentOther chemical processesAlpha-naphtholCarboxylic group

The invention discloses a method for preparing a solid-phase microextraction fiber with a hollow zirconium-based porphyrin type metal organic framework material as a coating based on an in-situ growth method, and belongs to the field of solid-phase microextraction fiber preparation. The solid-phase microextraction fiber is prepared by taking a stainless steel fiber modified by polydopamine as a matrix and taking zircon salt, benzoic acid, meso-tetra(4-carboxyphenyl)porphin and water as raw materials, and can be used for detecting 1-naphthol and 2-naphthol. The prepared hollow zirconium-based porphyrin type metal organic framework material is good in thermal stability, rich in adsorption active sites and large in specific surface area, solid-phase microextraction fibers prepared from the hollow zirconium-based porphyrin type metal organic framework material are good in reproducibility and long in service life, and 1-naphthol and 2-naphthol in a complex matrix can be measured at the same time through the established method.

Owner:FUZHOU UNIV

A kind of electrochemical capacitor and electroadsorption desalination electrode material

InactiveCN104916457BStrong ion adsorptionStrong cycle lifeHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceNickel salt

The invention discloses an electrochemical capacitor and electro-adsorption desalination electrode material, which is formed by the combination of nano nickel oxide and nano carbon materials. The preparation method of the electrochemical capacitor and electro-adsorption desalination electrode material comprises the steps of: 1, preparing a nickel salt aqueous solution; 2, mixing the nickel salt aqueous solution with the nano carbon materials; 3, preparing nanocarbon / nickel oxide composite powder; 4, and preparing an electrode. The electrochemical capacitor and electro-adsorption desalination electrode material obtains large capacitance by utilizing oxidation-reduction property of the nano nickel oxide, is high in conductivity, high in specific surface area and high in utilization rate of specific surface area, endows the electrode with high capacitance of capacitor and energy density, has good charging-discharging repeatability, is easy to implement technological parameter control, is even to coat the nano carbon with the nano nickel oxide, and is suitable for industrialized mass production; and the prepared nickel oxide electrode is small in expansion and high in specific capacity, and has good charging-discharging performance, excellent inorganic ion electro-adsorption performance, long service life, and very high practical value.

Owner:HUAIBEI NORMAL UNIVERSITY

Porous carbon nanobelt lithium-sulfur battery positive electrode material and its preparation method and application

ActiveCN108666570BImprove sulfur fixation effectImprove performanceMaterial nanotechnologyCell electrodesLithium–sulfur batteryElectrical battery

The invention discloses a porous carbon nanobelt positive electrode material for lithium-sulfur battery, a preparation method thereof a positive electrode of lithium-sulfur battery, and a lithium-sulfur battery. The method for preparing the porous carbon nanobelt positive electrode material for lithium-sulfur battery comprises the following steps of: preparing a carbon nanobelt precursor; carbonizing and activating the carbon nanobelt precursor; and depositing elemental sulfur in the oxynitride co-doped porous carbon nanobelt. The porous carbon nanobelt positive electrode material for lithium-sulfur battery prepared by the preparation method of the invention has electrochemical properties such as large specific surface area, good wettability and high elemental sulfur content, significantlyimproved sulfur-fixing performance, and effective inhibition of the ''shuttle effect'' of poly sulfides. The positive electrode of lithium-sulfur battery and the lithium-sulfur battery contain the positive electrode material for lithium-sulfur battery prepared by the method of the invention.

Owner:SHENZHEN UNIV

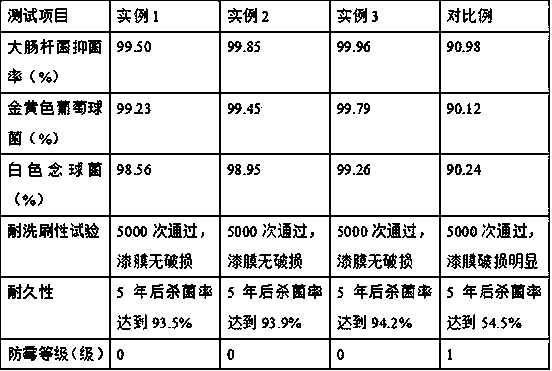

A kind of preparation method of mildew-proof and antibacterial latex paint

ActiveCN107868553BHigh adsorption activityImprove the utilization of specific surface areaAntifouling/underwater paintsPaints with biocidesCell membraneIon exchange

The invention relates to the technical field of coating preparation, in particular to a preparation method of an anti-mold and anti-bacterial latex paint. The preparation method comprises the following steps: firstly, taking polyhydroxy konjac starch as a structure-oriented template, mixing the polyhydroxy konjac starch with sodium silicate, and finally, blending a mixture with a latex paint basematerial to obtain the anti-mold and anti-bacterial latex paint. By use of the anti-mold and anti-bacterial latex paint, the adsorption activity of a molecular sieve is improved, and a binding force between an inorganic antibacterial agent and the latex paint base material is favorably enhanced; the molecular sieve is further modified by using organosiloxane and organic acid, so that active hydroxyls on the surface of the molecular sieve and small organic molecules undergo condensation reaction, a binding force between the inorganic antibacterial agent and the latex paint base material is enhanced and the compatibility between the inorganic antibacterial agent and the latex paint base material is improved. The molecular sieve disclosed by the invention has unique properties of adsorption and selective ion exchange; silver has a sterilizing effect, and the latex paint can slowly release silver ions; when trace silver ions are in contact with a microbial cell membrane, bacterial cells die due to loss of division and proliferation capabilities, and a persistent sterilizing effect is realized; the anti-mold and anti-bacterial latex paint has a broad application prospect.

Owner:广州市奥捷体育设施工程有限公司

Electrode material, preparation method and application thereof

ActiveCN110459409BHigher than capacitanceImprove electrochemical performanceHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceHigh energy

The invention provides an electrode material, a preparation method and its application. The electrode material uses coal tar pitch as a carbon source, uses nano-calcium oxide as a template, and uses potassium hydroxide as an activator; it is prepared through the following steps: S1, Weigh the raw materials according to the number of parts by mass; S2, grind the raw materials into powder and mix them; S3, put the mixed sample into the tube furnace and feed inert gas; S4, heat carbonization; S5, pickling to remove nano-calcium oxide; S6: Washing with distilled water; S7, drying the electrode material; the electrode material prepared by the method of the present invention has the characteristics of large specific surface area, appropriate pore size distribution range and high oxygen element content, these characteristics make the specific surface area utilization rate of the electrode material high, and the ratio is high. High capacitance, high energy density, and good cycle performance can be used as electrode materials for supercapacitors.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

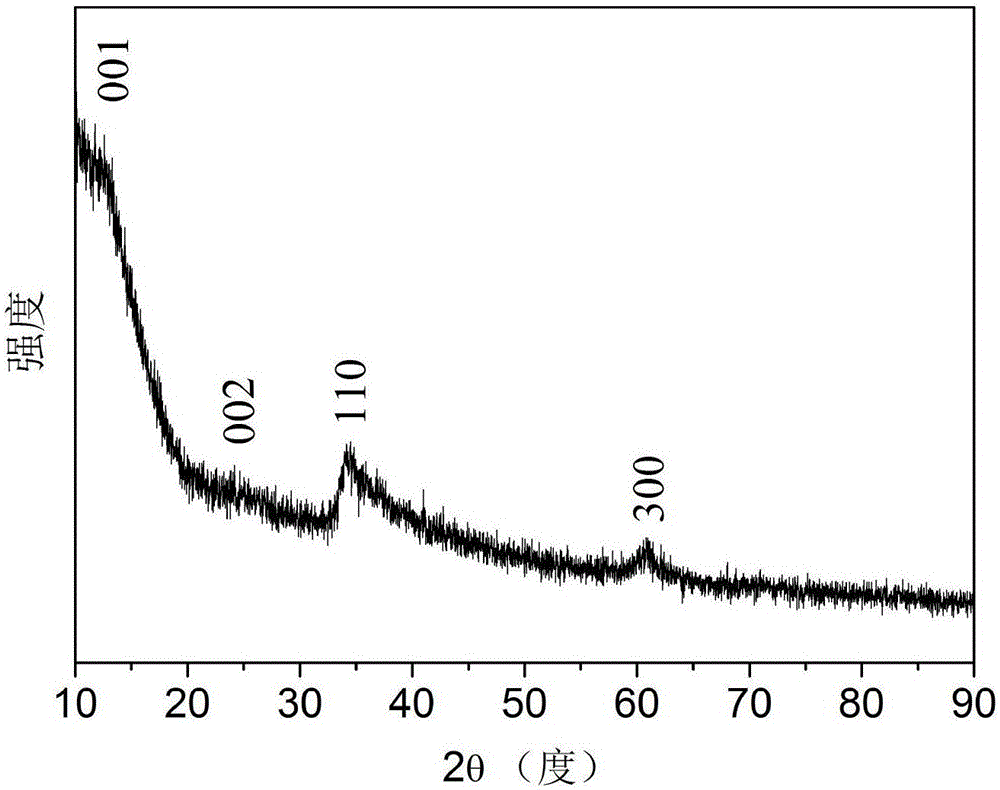

A graphene oxide/sio 2 Application of Composite Materials

ActiveCN104124068BLarge specific surface areaImprove the utilization of specific surface areaHybrid capacitor electrodesNew energyAdhesive

The invention relates to the crossing field of inorganic composite materials and new energy technology, and discloses an application for a graphene oxide / SiO2 composite material, aiming at solving the problems that a single graphene oxide material is easy to stack, low in electrochemical stability, poor in electricity storage performance, and the like at present. The application comprises the step of preparing a graphene oxide dispersion liquid at first, and then preparing graphene oxide / SiO2, and then treating the product to obtain the graphene oxide / SiO2 composite material, and finally mixing the graphene oxide / SiO2 composite material with a conductive agent, and pressing on a current collector by an adhesive to prepare an electrode material or further assembling to form an electricity storage component. The raw materials used in the application disclosed by the invention are common and easy to get, and low in cost; the preparation process is simple, safe, low in energy consumption, and high in operability; the composite material is good in electricity storage performance.

Owner:HANGZHOU NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com