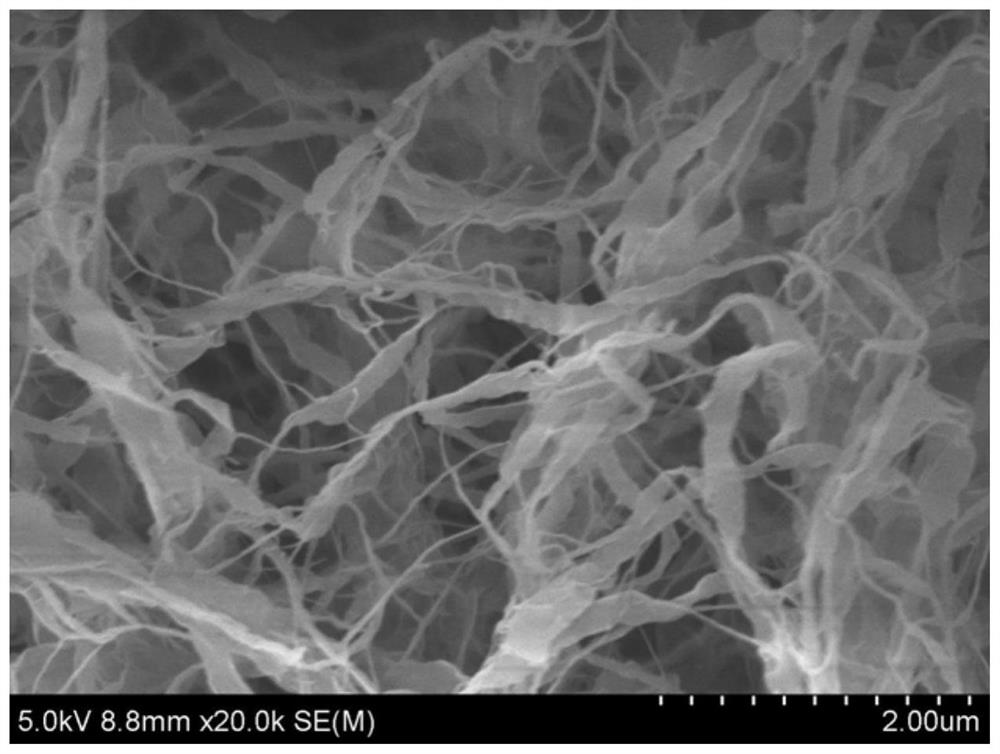

Nitrogen-oxygen co-doped porous carbon nanobelt and its preparation method and application

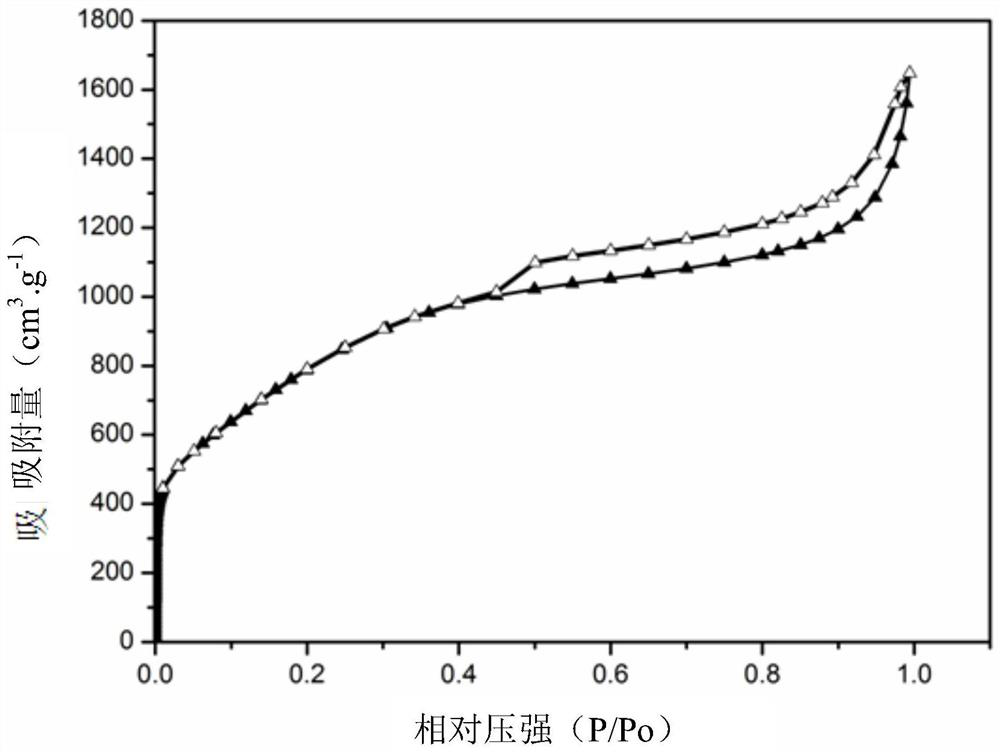

A carbon nanobelt and co-doping technology, applied in the field of electrode materials, can solve the problems of unsatisfactory electrochemical performance, unsatisfactory rate performance, low capacity, etc., achieve good rate performance and cycle stability, improve electrochemical performance, The effect of high specific surface area utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] On the one hand, the embodiment of the present invention provides a preparation method of nitrogen and oxygen co-doped porous carbon nanobelts. The preparation method of the nitrogen-oxygen co-doped porous carbon nanobelt comprises the following steps:

[0026] Step S01. Prepare carbon nanobelt precursor:

[0027] Formaldehyde and hydroquinone are hydrothermally reacted in an acidic solution to obtain a carbon nanobelt precursor;

[0028] Step S02. Carbonizing and activating the carbon nanobelt precursor:

[0029] The carbon nanobelt precursor is subjected to carbonization treatment and ammonia water activation treatment to obtain nitrogen and oxygen co-doped porous carbon nanobelts.

[0030] Wherein, in step S01, the polymerization reaction of formaldehyde and hydroquinone in an acidic solution is carried out to generate a ladder-shaped polymer. The hydrothermal reaction chemical formula between described formaldehyde and hydroquinone is as follows:

[0031]

[...

Embodiment 1

[0052] This embodiment provides a nitrogen-oxygen co-doped porous carbon nanobelt and a preparation method thereof. The preparation method of the nitrogen-oxygen co-doped porous carbon nanobelt comprises the following steps:

[0053] S11: Weigh 120g of 10% dilute hydrochloric acid, 2.5g of 37% formaldehyde solution, and 1.65g of hydroquinone, and stir the three for 30 minutes until a uniform and transparent solution is formed;

[0054] S12: Pour the solution prepared in the above steps into a polytetrafluoroethylene-lined hydrothermal reaction kettle, seal the hydrothermal kettle and put it in an oven at 180°C, react for 12 hours, and cool it down to room temperature naturally;

[0055] S13: Filter the product obtained in the above steps, wash it with deionized water for 5 times, then place it in a vacuum drying oven, and dry it at 60°C for 24 hours;

[0056] S14: Grinding the dried product (carbon nanobelt precursor) into powder, sealed and stored for later use;

[0057] S1...

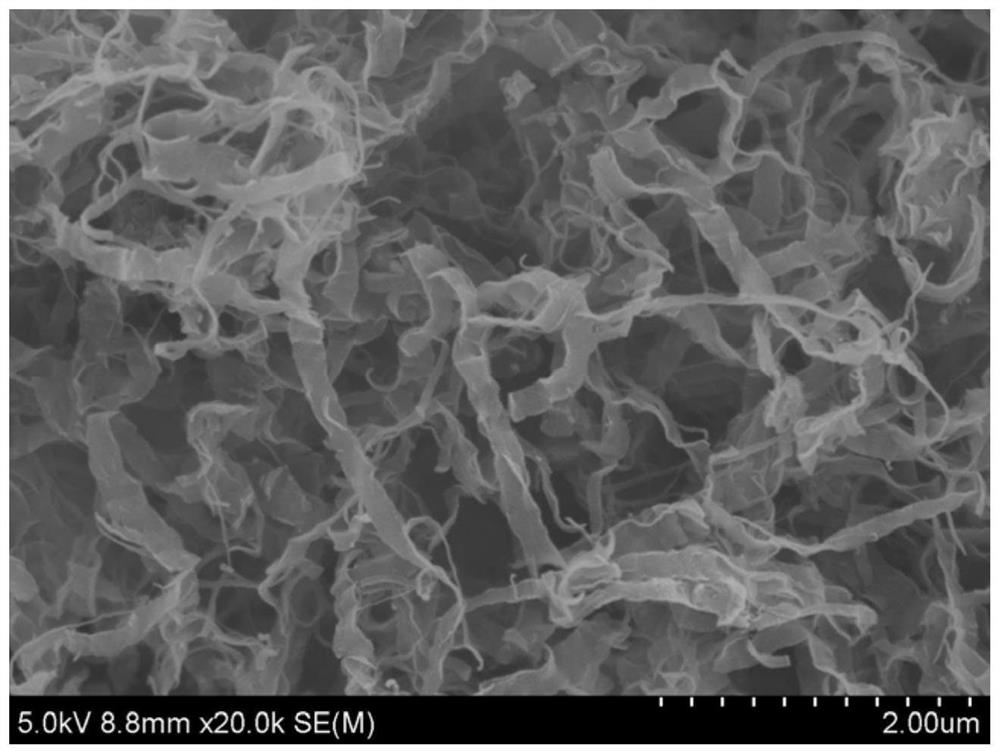

Embodiment 2

[0060] This embodiment provides a nitrogen-oxygen co-doped porous carbon nanobelt and a preparation method thereof. The preparation method of the nitrogen-oxygen co-doped porous carbon nanobelt comprises the following steps:

[0061] S11: Weigh 125g of 10% dilute hydrochloric acid, 2.8g of 37% formaldehyde solution, and 1.5g of hydroquinone, and stir the three for 20 minutes;

[0062] S12: Pour the solution prepared in the above steps into a polytetrafluoroethylene-lined hydrothermal reaction kettle, seal the hydrothermal kettle and place it in an oven at 150°C, react for 15 hours, and naturally cool to room temperature;

[0063] S13: Filter the product obtained in the above steps, wash it with deionized water for 6 times, and then place it in a common drying oven and dry it at 80°C for 15 hours;

[0064] S14: Grinding the dried product (carbon nanobelt precursor) into powder, sealed and stored for later use;

[0065] S15: Take 1.0 g of carbon nanobelts and put them in a cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com