Preparation method for flame-retardant high-strength building seal gum

A sealant, high-strength technology, used in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem of poor flame retardant performance, low mechanical strength, and difficulty in meeting building quality requirements, etc. problems, to achieve the effect of improving the utilization rate of specific surface area, mechanical strength, and bonding tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

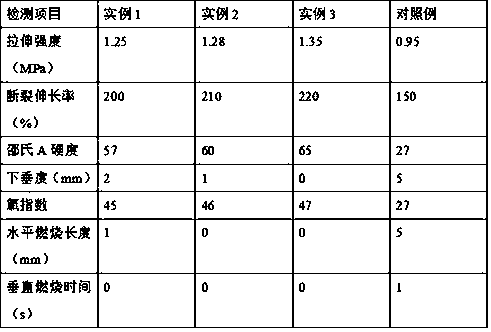

example 1

[0024] In parts by weight, take 20 parts of magnesium nitrate, 25 parts of aluminum nitrate, 15 parts of nickel nitrate and 250 parts of deionized water and mix them for 10 minutes to obtain a mixed solution. The ratio is 15:2:1 to obtain the reaction precursor solution after mixing; the reaction precursor solution is packed in the high-pressure hydrothermal kettle, and then in the high-pressure hydrothermal kettle, the potassium thiocyanate and the reaction precursor solution quality 1% of the reaction precursor solution are added 10% tartaric acid solution with a concentration of 0.5mol / L, in a closed high-pressure hydrothermal kettle, heated to 200°C at 0.8MPa, and hydrothermally reacted for 20 hours; after the hydrothermal reaction was completed, filter and separate to obtain the filter residue, and the filter residue and absolute ethanol After mixing according to the mass ratio of 1:20, put it into an ultrasonic oscillator, treat it with 30kHz ultrasonic oscillation for 2 ...

example 2

[0026]In parts by weight, take by weighing 25 parts of magnesium nitrate, 30 parts of aluminum nitrate, 18 parts of nickel nitrate and 280 parts of deionized water and mix them for 13 minutes to obtain a mixed solution. The ratio is 15:2:1 to obtain the reaction precursor solution after mixing; the reaction precursor solution is packed in the high-pressure hydrothermal kettle, and then in the high-pressure hydrothermal kettle, the potassium thiocyanate and the reaction precursor solution quality 1% of the reaction precursor solution are added 10% tartaric acid solution with a concentration of 0.5mol / L, in a closed high-pressure hydrothermal kettle, heated to 210°C at 0.9MPa, and hydrothermally reacted for 22 hours; after the hydrothermal reaction was completed, filter and separate to obtain the filter residue, and the filter residue and absolute ethanol After mixing according to the mass ratio of 1:20, put it into an ultrasonic oscillator, treat it with ultrasonic oscillation a...

example 3

[0028] In parts by weight, take 30 parts of magnesium nitrate, 35 parts of aluminum nitrate, 20 parts of nickel nitrate and 300 parts of deionized water and mix them for 15 minutes to obtain a mixed solution. The ratio is 15:2:1 to obtain the reaction precursor solution after mixing; the reaction precursor solution is packed in the high-pressure hydrothermal kettle, and then in the high-pressure hydrothermal kettle, the potassium thiocyanate and the reaction precursor solution quality 1% of the reaction precursor solution are added 10% tartaric acid solution with a concentration of 0.5mol / L, in a closed high-pressure hydrothermal kettle, heated to 220°C at 1.0MPa, and hydrothermally reacted for 24 hours; after the hydrothermal reaction was completed, filter and separate to obtain the filter residue, and the filter residue and absolute ethanol After mixing according to the mass ratio of 1:20, put it into an ultrasonic oscillator, treat it with 40kHz ultrasonic vibration for 3 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com