A kind of 3D porous graphene/transition metal oxide composite material and its preparation method and application

A technology of porous graphene and transition metals, which is applied in the manufacture of hybrid/electric double layer capacitors, electrochemical generators, hybrid capacitor electrodes, etc., can solve the problems of increasing costs and increasing the experimental process, so as to improve electrolysis and reduce agglomeration , the effect of rich pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Preparation of graphite oxide: Mix 180mL of concentrated sulfuric acid and 20mL of phosphoric acid in a beaker, then pour 1.5g of graphite powder into the beaker, stir magnetically for 1 hour, then weigh 9gKMnO 4 , slowly poured into a beaker, and continued magnetic stirring for 24 hours to obtain a purple-red liquid. Prepare 300mL of frozen deionized water, pour the obtained purple-red liquid into the frozen deionized water, add 15mL of H after a while 2 o 2 , the solution turns into a brighter yellow color at this time, after being fully reacted, it is centrifuged and washed to obtain graphite oxide.

[0044] Take 0.2g of graphite oxide, disperse it in 50mL of deionized water, and ultrasonicate for 2 hours to obtain solution A, during which the water temperature is controlled at 15°C. Weigh 0.04g of cobalt chloride and add to solution A and stir for 30 minutes to obtain solution B, then weigh 0.6g of sodium bicarbonate and add to solution B to obtain solution C. Po...

Embodiment 2

[0052] The preparation method of graphite oxide is with example 1. Take 0.2g of graphite oxide, disperse it in 50mL of deionized water, and ultrasonicate for 2 hours to obtain solution A, during which the water temperature is controlled at 20°C. Weigh 0.6g of sodium bicarbonate and dissolve it in solution A and stir to obtain solution B. Pour solution B into a 100mL polytetrafluoroethylene reactor and react at 110°C for 10 hours.

[0053] The product was first washed with deionized water and ethanol by centrifugation, and then dried to obtain 3D porous graphene.

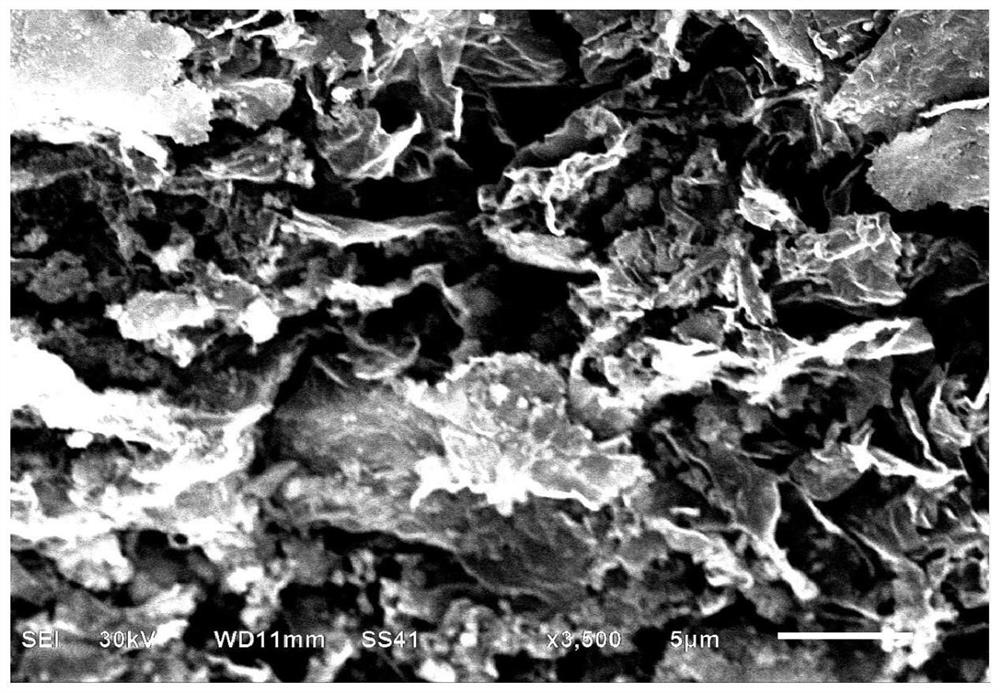

[0054] SEM image of the prepared 3D porous graphene Figure 5 shown by Figure 5 A porous structure can be observed. It shows that it is feasible to use sodium bicarbonate as a pore-forming agent for the preparation of porous graphene by hydrothermal method.

Embodiment 3

[0056] The preparation method of graphite oxide is with example 1. Take 0.2g of graphite oxide, disperse it in 50mL of deionized water, and ultrasonicate for 2 hours to obtain solution A, during which the water temperature is controlled at 15°C. Weigh 0.04g of cobalt chloride and dissolve in solution A and stir to obtain solution B, then weigh 0.16g of urea and add to solution B to obtain solution C. Pour solution C into a 100mL polytetrafluoroethylene reactor, and react at 110°C for 10 hours.

[0057] The product was first washed with deionized water and ethanol by centrifugation, and then dried to obtain a 3D graphene / cobalt hydroxide composite material. The 3D graphene / cobalt hydroxide composite material was calcined at a constant temperature of 350°C for 4 hours in a tube furnace to obtain a 3D graphene / cobalt trioxide composite material.

[0058] The SEM image of the prepared graphene / cobalt tetroxide composite Figure 6 shown by Figure 6 It was found that when urea ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com