Micro/nano structured cathode material for lithium air batteries

A lithium-air battery and positive electrode material technology, applied in the direction of hybrid battery components, etc., can solve the problems of product blockage of oxygen diffusion channels, large catalyst particle size, hindering promotion and application, etc., to enhance the ability of electrochemical conversion, improve the ratio The effect of surface area utilization and simple and feasible preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Weigh 1.8g polyacrylonitrile (PAN), add 15mL N,N-dimethylformamide (DMF), stir in a 60°C water bath for 3h, then add 1.2g cobalt acetate, stir for 1h, control voltage 11kV, indirect The collection distance is 15cm, the liquid flow rate is 30μl / min, and the PAN / cobalt acetate hollow nanofibers are obtained through the electrospinning process. The obtained nanocomposite fibers were put into a tube furnace, pre-oxidized in air at 250 °C for 1 h, and then carbonized at 900 °C for 2 h under the protection of argon to obtain hollow C / Co 3 o 4 fiber, the heating rate is 5°C / min. The obtained material was mixed with KOH in a ratio of 1:4, and chemically activated at 800 ° C for 2 h under the protection of argon, and then changed to CO 2 Gas physical activation, heat preservation 1h, get porous hollow C / Co 3 o 4 fiber.

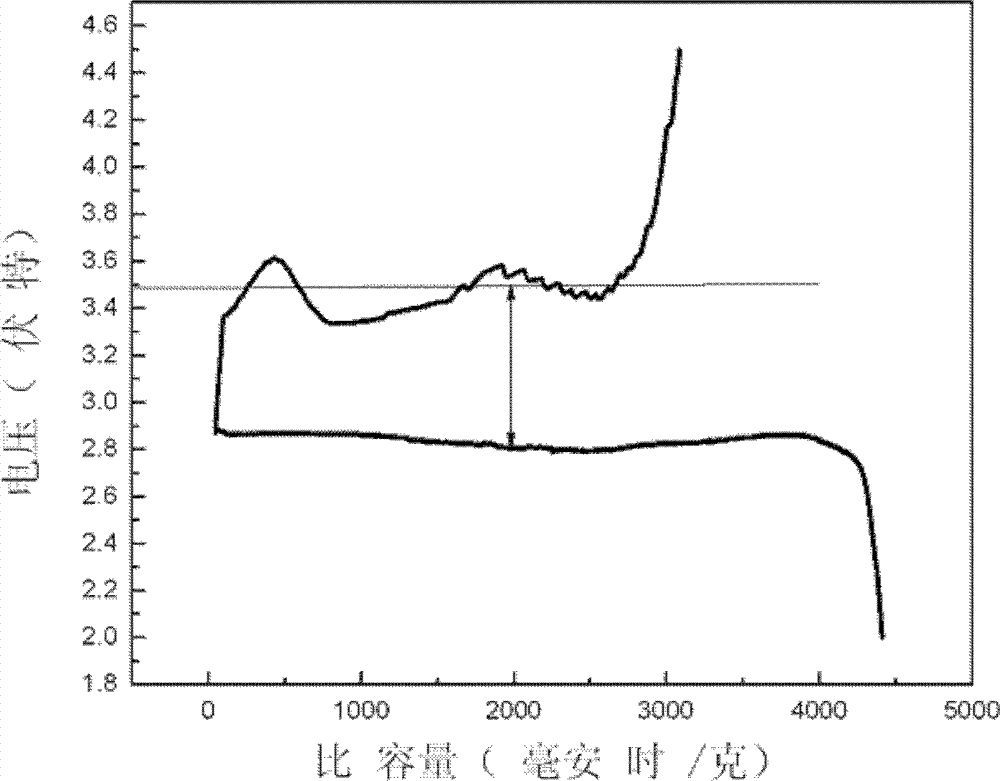

[0049] Electrode preparation, battery assembly and testing are as follows: layered porous hollow carbon fiber, conductive carbon and binder are mixed at a ...

Embodiment 2

[0051] Weigh 1.8g of polyacrylonitrile (PAN), add 15mL of N,N-dimethylformamide (DMF), stir in a 60°C water bath for 3h, then add 0.3g of cobalt acetate, stir for 1h, control voltage 11kV, indirect The collection distance is 15cm, the liquid flow rate is 30μl / min, and the PAN / cobalt acetate hollow nanofibers are obtained through the electrospinning process. The obtained nanocomposite fibers were put into a tube furnace, pre-oxidized in air at 250 °C for 1 h, and then carbonized at 900 °C for 2 h under the protection of argon to obtain hollow C / Co 3 o 4 fiber, the heating rate is 5°C / min. The obtained material was mixed with KOH in a ratio of 1:4, and chemically activated at 800 ° C for 2 h under the protection of argon, and then changed to CO 2 Gas physical activation, heat preservation 1h, get porous hollow C / Co 3 o 4 fiber.

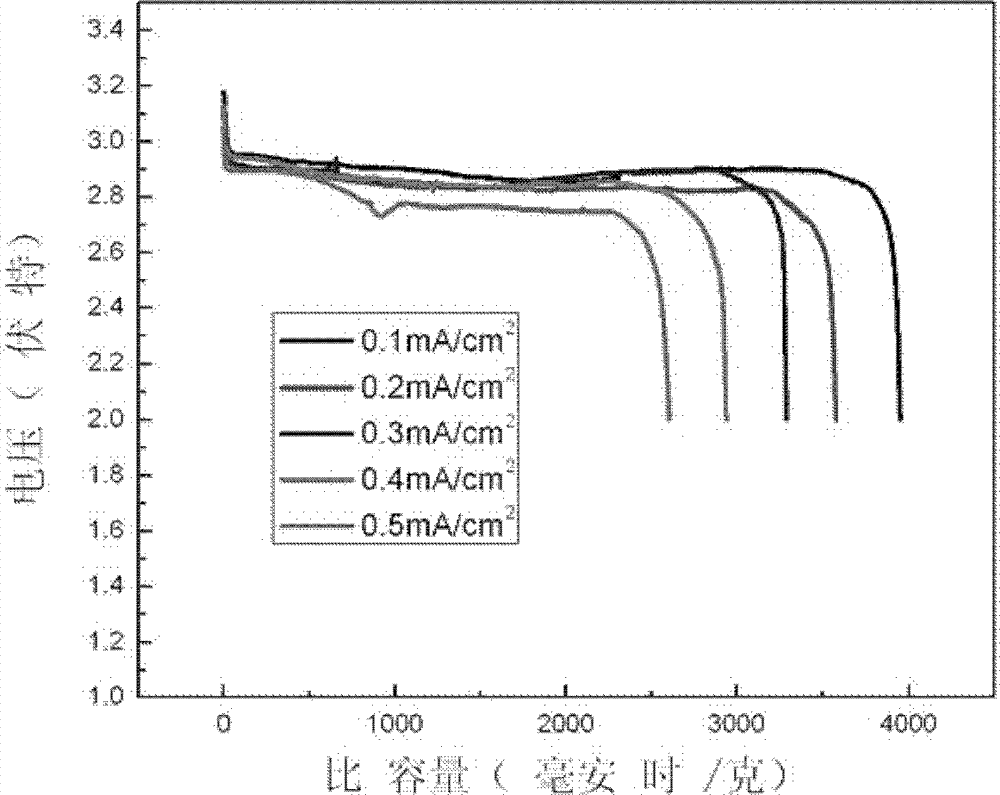

[0052] Pole sheet preparation and battery assembly are the same as the test and Example 1. With the decrease of the catalyst load, the discharge ...

Embodiment 3

[0054] Weigh 2g polyaniline (PANI), add 30mL DMF, stir in 50°C water bath for 3h, then add 0.6g cobalt acetate, stir for 1h, control voltage 11kV, receiving distance between two electrodes 15cm, liquid flow rate 30μl / min, through electrospinning The PAN / cobalt acetate hollow nanofibers were obtained through the silk process. The obtained nanocomposite fibers were placed in a tube furnace, pre-oxidized in air at 300 °C for 1 h, and then carbonized at 900 °C for 2 h under the protection of argon to obtain hollow C / Co 3 o 4 fiber, the heating rate is 5°C / min. The obtained material was mixed with KOH in a ratio of 1:4, and chemically activated at 800 °C for 2 h under the protection of argon to obtain a porous hollow C / Co 3 o 4 fiber.

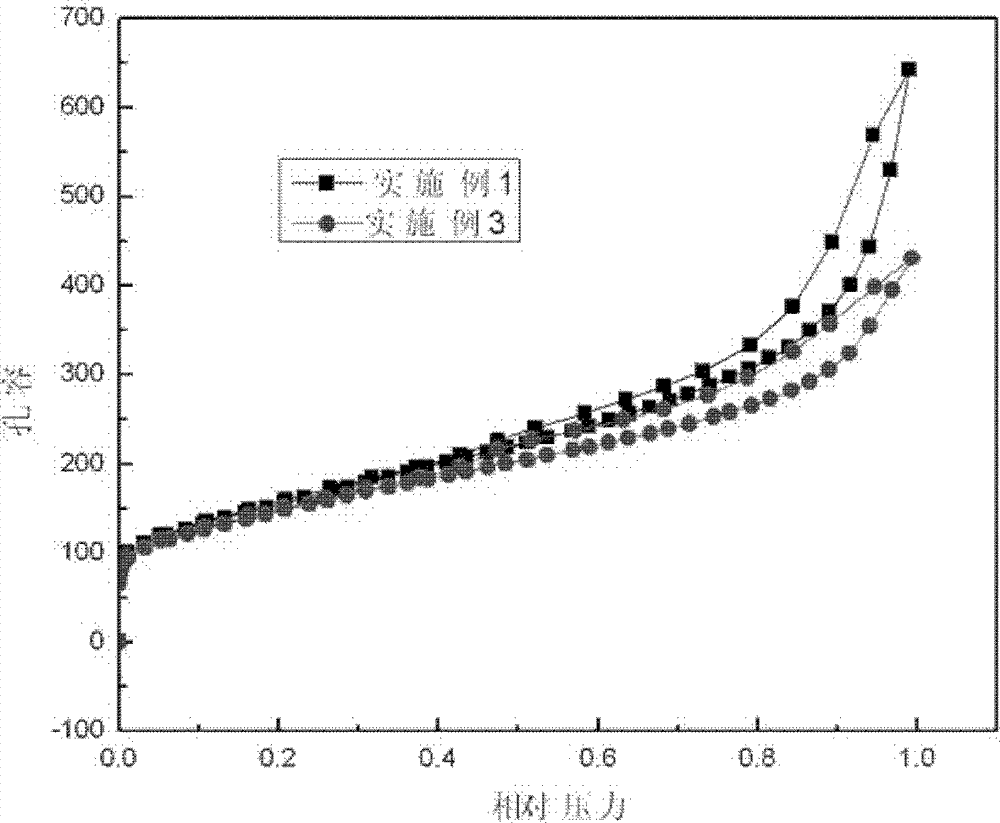

[0055] Pole sheet preparation and battery assembly are the same as the test and Example 1. The specific surface area of the composite fiber material obtained is smaller than that of the material in Example 1, which is 450m 2 / g, such as fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com