Graphene/SiO2 composite material as well as preparation method and application thereof

A composite material and graphene technology, applied in the field of material chemistry, can solve the problems that graphene oxide is difficult to effectively peel off and disperse, the particle size and uniformity dimension are not easy to control, the reduction conditions and reduction degree are not easy to control, etc., to achieve a higher ratio Surface area utilization, low cost, effect of preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

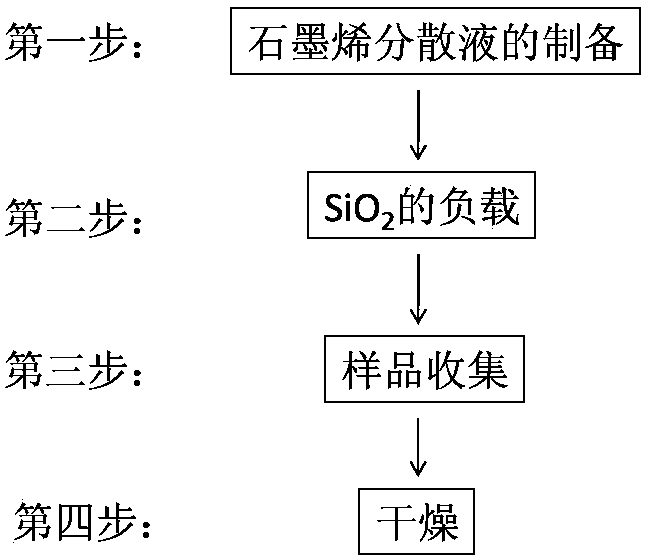

[0034] (1) Preparation of graphene dispersion: 5000 mL of graphene suspension of 0.01 mg / mL was prepared with polyethylene glycol, and subjected to ultrasonic oscillation (50 W) for 2 h to form a graphene dispersion.

[0035] (2) Add 180 g (0.86 mol) tetraethyl orthosilicate and 100 mL of water to the graphene dispersion obtained in step (1) to make a reaction mixture. The water in the reaction mixture is 5.56 mol, and diethylamine or Triethylamine adjusted the pH of the reaction mixture to 7.1-8.5 to make the mixture weakly alkaline, and then reacted with magnetic stirring at 10°C for 12 h.

[0036] (3) Sediment the product of step (2) with a centrifuge at a speed of 10,000 rpm, collect the solid product after standing, and repeat the operation 3 to 5 times. The collected product is then filtered and washed repeatedly with water or an organic solvent to remove various unreacted raw materials, impurities and by-products.

[0037] (4) Put the product in step (3) into an ordina...

Embodiment 2

[0040] (1) Preparation of graphene dispersion: 1000 mL of a 0.1 mg / mL suspension of graphene was prepared with water, and subjected to ultrasonic oscillation (100 W) for 2 h to form a graphene dispersion.

[0041] (2) Add 28.16 g (0.14 mol) tetraethyl orthosilicate to the graphene dispersion obtained in step (1) to make a reaction mixture, the water in the reaction mixture is 55.56 mol, adjust the pH value of the reaction mixture with ammonia water 8-10 to make the reaction mixture moderately alkaline, and then react with magnetic stirring at 10°C for 10 min.

[0042] (3) Sediment the product of step (2) with a centrifuge at a speed of 10,000 rpm, collect the solid product after standing, and repeat the operation 3 to 5 times. The collected product is then filtered and washed repeatedly with water or an organic solvent to remove various unreacted raw materials, impurities and by-products.

[0043] (4) Put the product in step (3) into an ordinary oven at 60°C for 3 h°C to remo...

Embodiment 3

[0046] (1) Preparation of graphene dispersion: Graphene was made into 1000 mL of 1 mg / mL suspension with ethanol / water mixed solvent, the volume ratio of ethanol / water was 1:8, and ultrasonically oscillated (300 W) for 1 h , forming a graphene dispersion.

[0047] (2) Add 14.3 g (0.13 mol) tetramethyl orthosilicate to the graphene ethanol / water dispersion obtained in step (1) to make a reaction mixture, the water in the reaction mixture is 49.38 mol, adjust the pH with sodium hydroxide The value is 10~12, making the mixture medium-strongly alkaline, and then reacting with magnetic stirring at 20°C for 2 h.

[0048] (3) Collect the product by vacuum distillation at a pressure of -0.1MPa and a temperature of 50~60°C.

[0049] (4) Put the product of step (3) in an ordinary oven at 80°C for 3 h to remove residual solvent and moisture, then place it in a vacuum drying oven, heat it up to 100°C under reduced pressure, and obtain graphene / SiO after further processing for 5 h 2 Comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com