Preparation methods of super-capacitor carbons

A technology of supercapacitor carbon and activation method, which is applied in the direction of chemical instruments and methods, hybrid capacitor electrodes, carbon compounds, etc., which can solve the problems of low conductivity, fast capacitance decay, and difficulty in meeting the needs of supercapacitors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

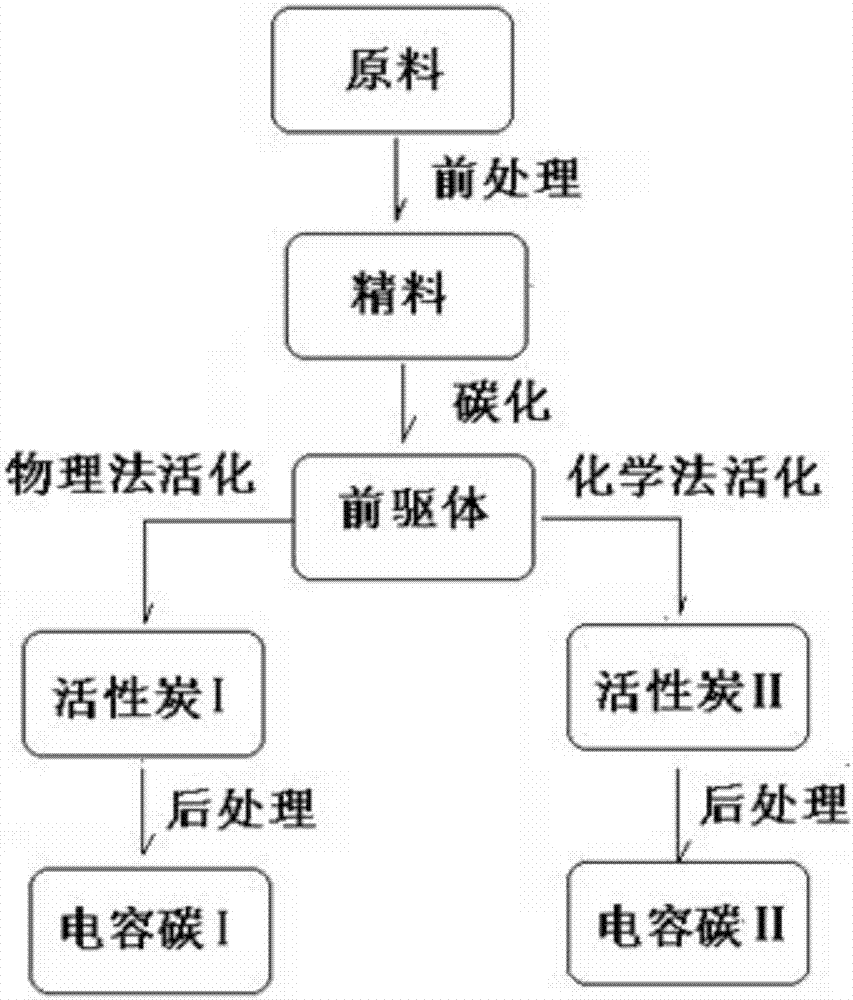

Method used

Image

Examples

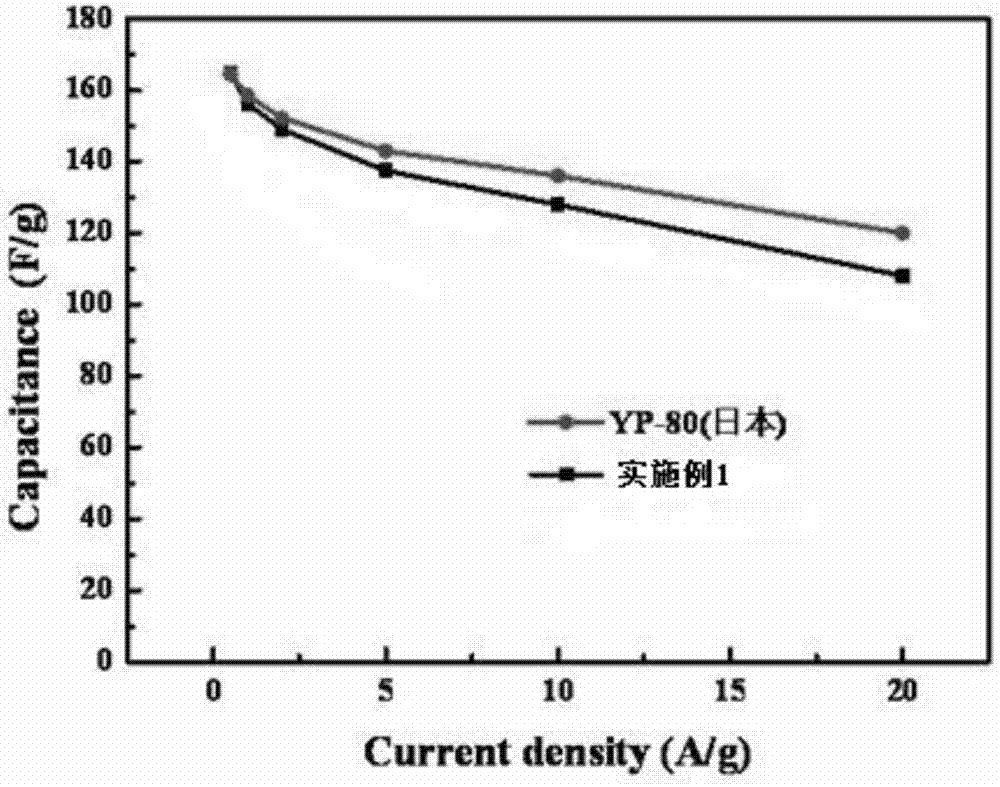

Embodiment 1

[0042] S1. Soak the dry corn in an aqueous surfactant solution for 10 minutes at a room temperature of 25° C., take it out and cool it for 30 minutes until it is semi-dry, and obtain corn that is easy to remove the germ husk;

[0043] S2. At a room temperature of 25°C, use a peeling processing machine to peel the corn in step S1 to remove the inorganic salt contained in the corn to achieve the purpose of deliming;

[0044] S3. At a room temperature of 25° C., use a mill to crush the peeled corn in step S2 to remove the germ, remove the organic matter contained in the corn, and obtain corn pellets to achieve the purpose of degreasing;

[0045] S4. At a temperature of 60° C., dry the corn pellets in step S3 with a drying oven for 2 hours to obtain refined corn pellets;

[0046] S5. Put the corn pellets into the rotary tube furnace, under the protection of 1 atmospheric pressure of nitrogen, increase the temperature by 3 degrees per minute, after rising from room temperature to 1...

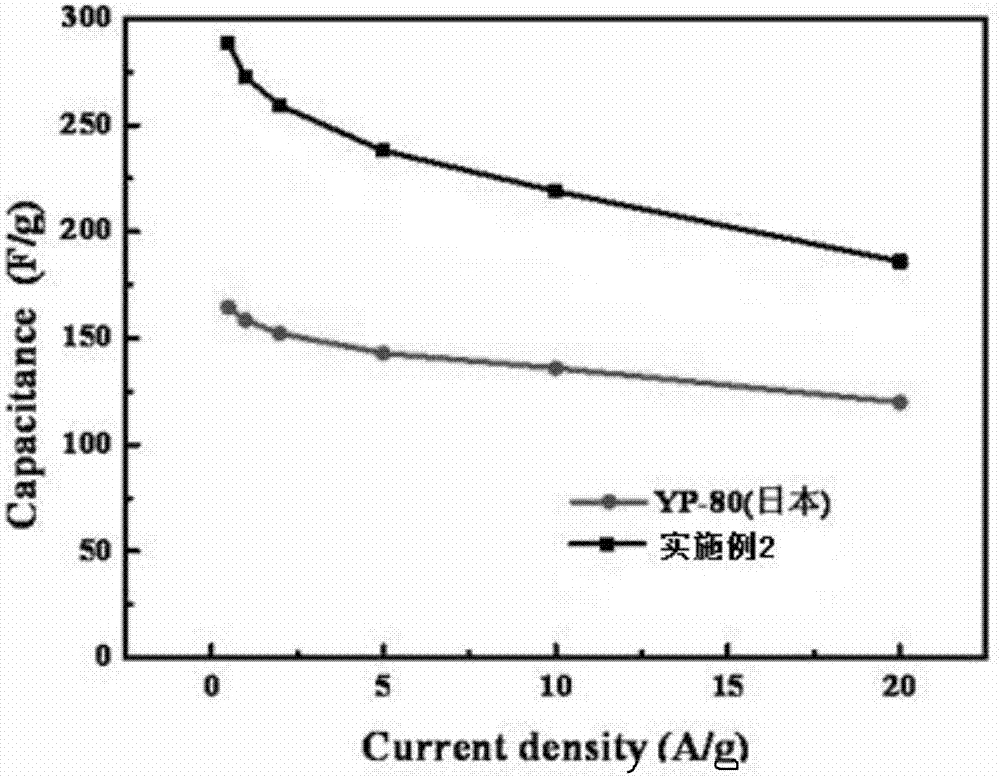

Embodiment 2

[0056] S1. Soak the dry corn in an aqueous surfactant solution for 10 minutes at a room temperature of 25° C., take it out and cool it for 30 minutes until it is semi-dry, and obtain corn that is easy to remove the germ husk;

[0057] S2. At a room temperature of 25°C, use a peeling processing machine to peel the corn in step S1 to remove the inorganic salt contained in the corn to achieve the purpose of deliming;

[0058] S3. At a room temperature of 25° C., use a mill to crush the peeled corn in step S2 to remove the germ, remove the organic matter contained in the corn, and obtain corn pellets to achieve the purpose of degreasing;

[0059] S4. At a temperature of 60° C., dry the corn pellets in step S3 with a drying oven for 2 hours to obtain refined corn pellets;

[0060] S5. Put the corn pellets into the rotary tube furnace, under the protection of 1 atmospheric pressure of nitrogen, increase the temperature by 3 degrees per minute, after rising from room temperature to 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com