Water system asymmetric supercapacitor based on porous carbon nitride/graphene/nickel disulfide and carbon nitride/graphene and preparation method thereof

A supercapacitor and nickel disulfide technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of poor capacitance and cycle stability, high specific capacitance, low electron mobility volume change electrode structure, etc. , to achieve the effect of no capacity attenuation, high energy density, and stable cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0046] Preparation method of aqueous asymmetric supercapacitor based on porous carbon nitride / graphene / nickel disulfide as positive electrode material and carbon nitride / graphene as negative electrode material, using porous layered porous carbon nitride / graphene / disulfide Nickel is the positive electrode material, and the carbon nitride / graphene of the porous structure is the negative electrode material. The specific preparation steps are as follows:

[0047] (1) Preparation of cathode material carbon nitride / graphene / nickel disulfide

[0048] The cellulose powder is dispersed in the N,N-dimethylacetamide solvent, and under the conditions of heating and stirring, it reacts with small organic molecules to obtain a modified cellulose dispersion solution; , N-dimethylformamide dispersion, stir evenly, and then disperse into water through centrifugation, separation, washing, and obtain a modified cellulose-modified graphene aqueous solution. The graphene aqueous solution was adde...

Example Embodiment

[0058] Example 1

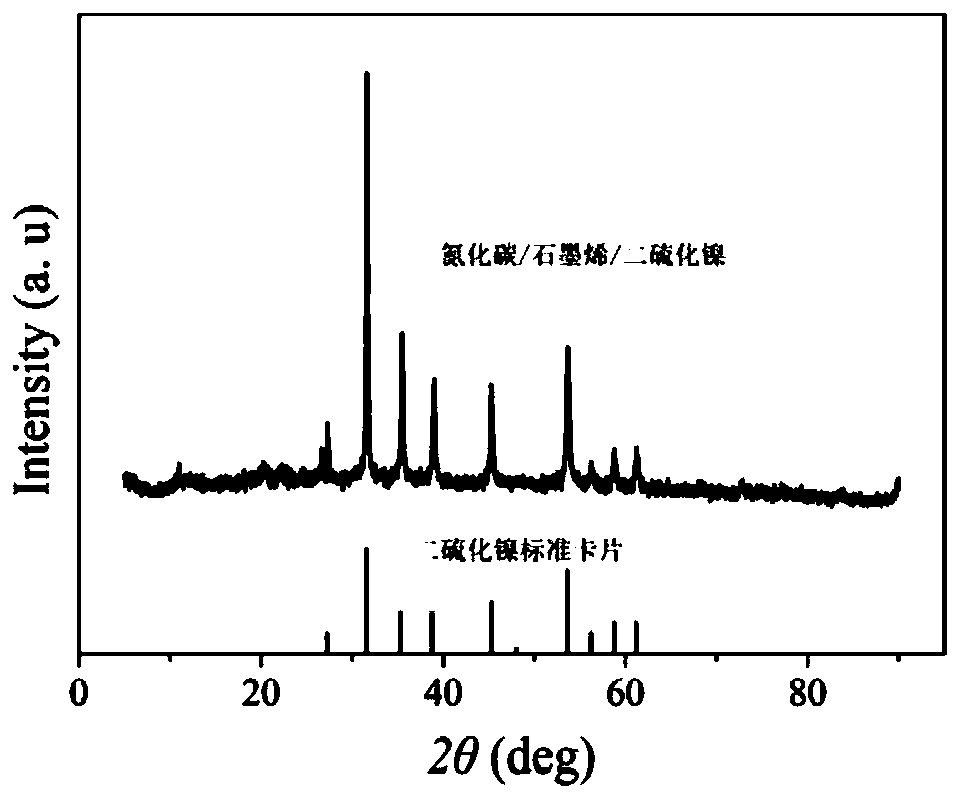

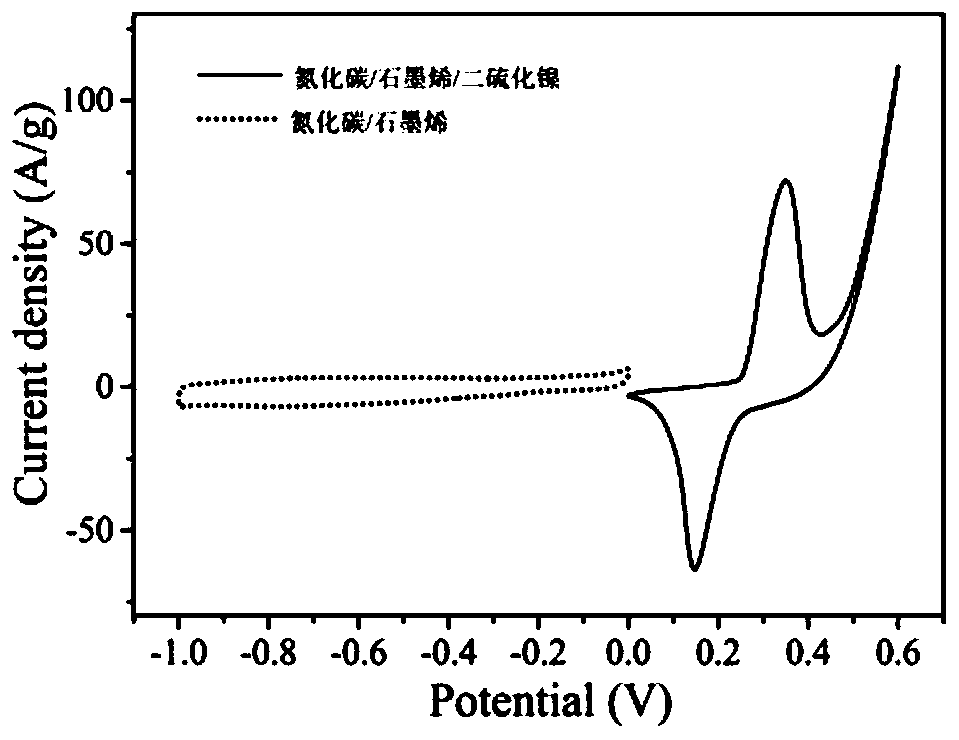

[0059] Preparation and characterization of carbon nitride / graphene / nickel disulfide material: Disperse 0.5 mmol of cellulose powder in N,N-dimethylacetamide solvent, add 5 mmol of succinic anhydride, and stir at 80 °C for a period of time. , and then dropwise added 40 mL of 2 mg / mL graphene N,N-dimethylformamide dispersion, stirred at room temperature for a period of time, filtered, washed, and then dispersed into water to obtain a modified cellulose-modified graphene aqueous solution. Dissolve 1 g of melamine in an acidic aqueous solution of pH 1, stir for 30 minutes, add 20 mg of modified cellulose-modified graphene dispersed in water, stir evenly, dry, and then calcine at 550 °C for 4 h to obtain g-C 3 N 4 / Graphene composites. Take 30mg of g-C 3 N 4 / Graphene was first sonicated for 2h under the power of 250W in N,N-dimethylformamide solution, then filtered, washed, and then dispersed in 15mL of aqueous solution, followed by 15mL of 0.6mmol nickel ni...

Example Embodiment

[0068] Example 2

[0069] Preparation of carbon nitride / graphene / nickel disulfide material: Disperse 0.5mmol of cellulose powder in N,N-dimethylacetamide solvent, add 4mmol of citric acid, stir and react at 80°C for a period of time, then dropwise Add 80 mL of 0.5 mg / mL graphene dispersion in N,N-dimethylformamide, and after stirring at room temperature for a period of time, filter, wash and redisperse in water to obtain an aqueous solution of modified cellulose modified graphene. Dissolve 0.2 g of melamine in an acidic solution with a pH of 2, stir for 30 minutes, add 20 mg of modified cellulose-modified graphene dispersed in water, stir evenly, dry, and then calcine at a high temperature of 500 ° C for 6 hours to obtain g-C 3 N 4 / Graphene composites. 15mg g-C 3 N 4 / Graphene was first sonicated for 4h under the power of 250W in N,N-dimethylformamide solution, then filtered, washed, and then dispersed in 30mL of water, followed by ethylene glycol solution with 0.6mmol n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy density | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com