Nitrogen-oxygen co-doped hollow carbon nanospheres, preparation method and application thereof

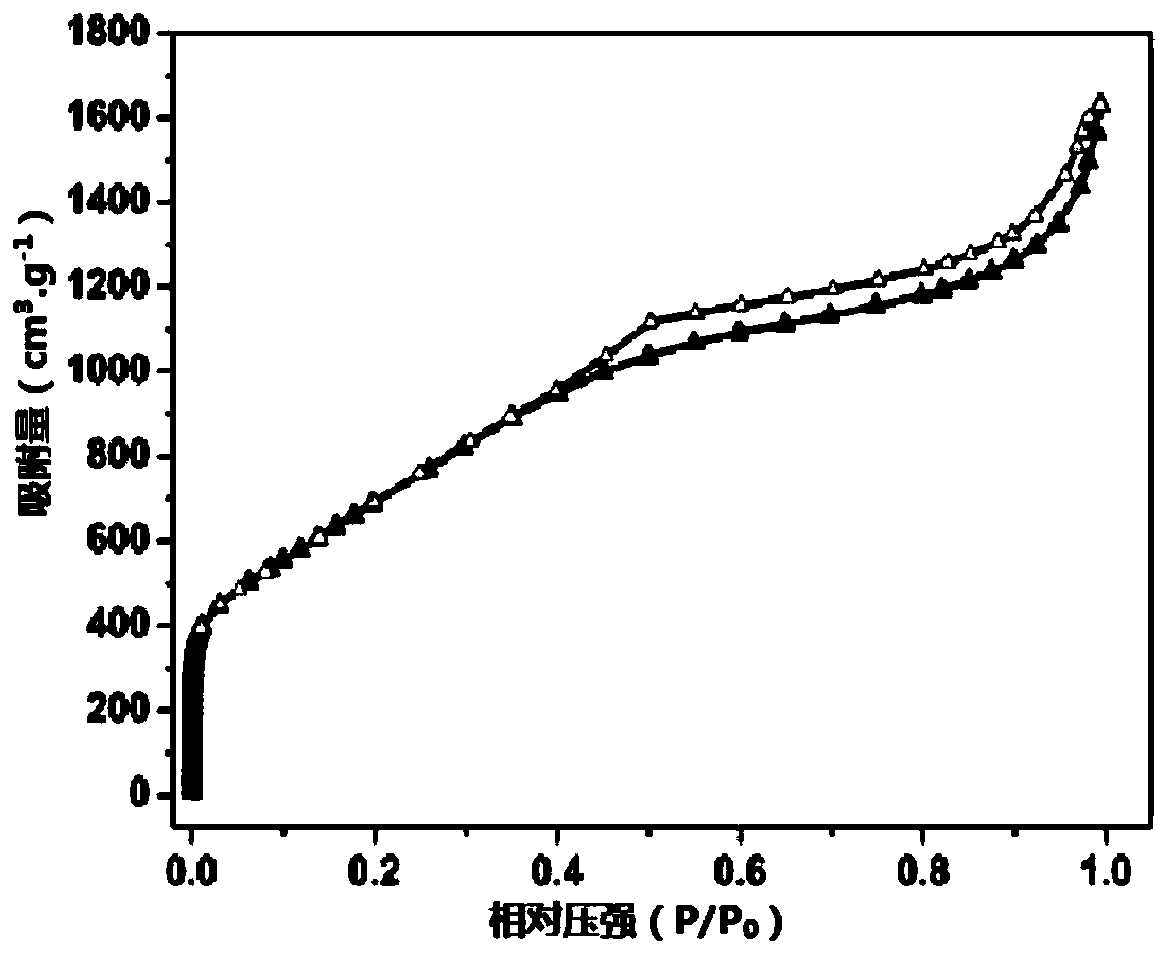

A carbon nano-microsphere, co-doping technology, applied in nano-carbon, nano-technology, nano-technology and other directions, can solve the problem of unsatisfactory surface area utilization rate and electrochemical performance, poor wettability of hollow carbon nano-microsphere, and cycle stability. Unsatisfactory and other problems, to achieve good rate performance and cycle stability, improve the utilization rate of specific surface area, and control the thickness of the spherical shell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] On the one hand, an embodiment of the present invention provides a method for preparing nitrogen and oxygen co-doped hollow carbon nanospheres. The preparation method of the nitrogen-oxygen co-doped hollow carbon nanospheres comprises the following steps:

[0026] Step S01. Prepare hollow carbon nanosphere precursor:

[0027] Polymerize pyrrole and aniline in an aqueous solution containing a soft template to obtain a hollow carbon nanosphere precursor;

[0028] Step S02. Carbonizing and activating the hollow carbon nanosphere precursor:

[0029] The hollow carbon nanometer microsphere precursor is washed, pulverized, and then subjected to carbonization treatment and ammonia water activation treatment to obtain nitrogen and oxygen co-doped hollow carbon nanometer microspheres.

[0030] Wherein, the method for polymerizing the pyrrole and aniline in the aqueous solution containing the soft template in step S01 can be carried out according to the following steps:

[003...

Embodiment 1

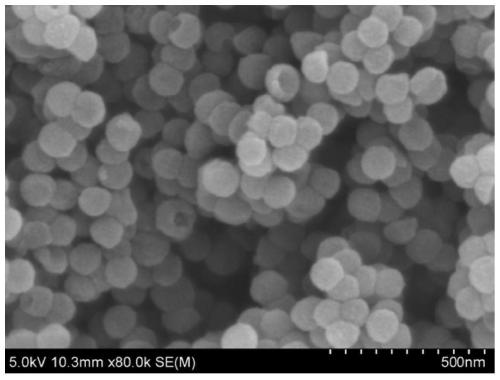

[0053] This embodiment provides a nitrogen-oxygen co-doped hollow carbon nanosphere and a preparation method thereof. The preparation method of the nitrogen-oxygen co-doped hollow carbon nanospheres comprises the following steps:

[0054] S11: Add 0.45 g of Triton X-100 solution at 2°C to 450 g of deionized water at 2°C, stir with a magnetic stirrer for 60 minutes and mix evenly to form a diluted Triton X-100 solution;

[0055] S12: Add 2.2 g of pyrrole at 2°C and 2.8 g of aniline at 2°C to the diluted Triton X-100 solution prepared in the above steps, and continue stirring for 30 minutes to make pyrrole and aniline dissolve in Triton X-100. 100 evenly distributed in the solution;

[0056] S13: Add 60 mL of newly prepared 1M ammonium persulfate solution to the solution in step S12, stir gently for 30 s, and then stand for reaction at an ambient temperature of 0°C for 12 h;

[0057] S14: Wash the product obtained in step S13 with water several times, and filter it with suctio...

Embodiment 2

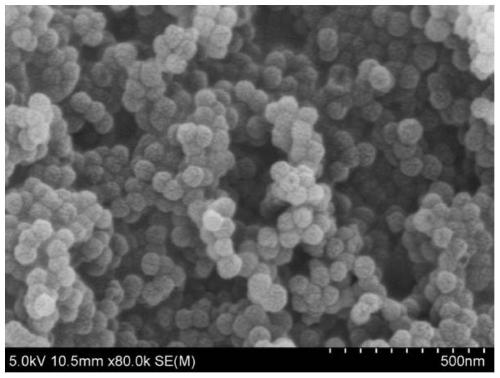

[0061] This embodiment provides a nitrogen-oxygen co-doped hollow carbon nanosphere and a preparation method thereof. The preparation method of the nitrogen-oxygen co-doped hollow carbon nanospheres comprises the following steps:

[0062] S11: add 0.6 g of Triton X-100 solution at 2°C to 500 g of deionized water at 2°C, stir with a magnetic stirrer for 60 minutes and mix evenly to form a diluted Triton X-100 solution;

[0063] S12: Add 2.0 g of pyrrole at 2°C and 2.4 g of aniline at 2°C to the diluted Triton X-100 solution prepared in the above steps, and continue stirring for 30 minutes to make pyrrole and aniline dissolve in Triton X-100. 100 evenly distributed in the solution;

[0064] S13: Add 50 mL of newly prepared 1M ammonium persulfate solution to the solution in step S12, stir gently for 50 s, and then stand for reaction at an ambient temperature of 3° C. for 8 h;

[0065] S14: The product obtained in step S13 is washed with water several times, and suction filtered...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com