Powder core wire materials for preparing micro crystal and nanocrystalline coatings containing NiB by arc spraying

A technology of powder core wire material and arc spraying, which is applied in the direction of coating, metal material coating process, fusion spraying, etc., can solve the problems of high temperature oxidation corrosion, erosion wear, etc., and achieve good wear resistance and uniform coating , the effect of high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] All embodiment spraying wires are prepared by powder core wire forming machine:

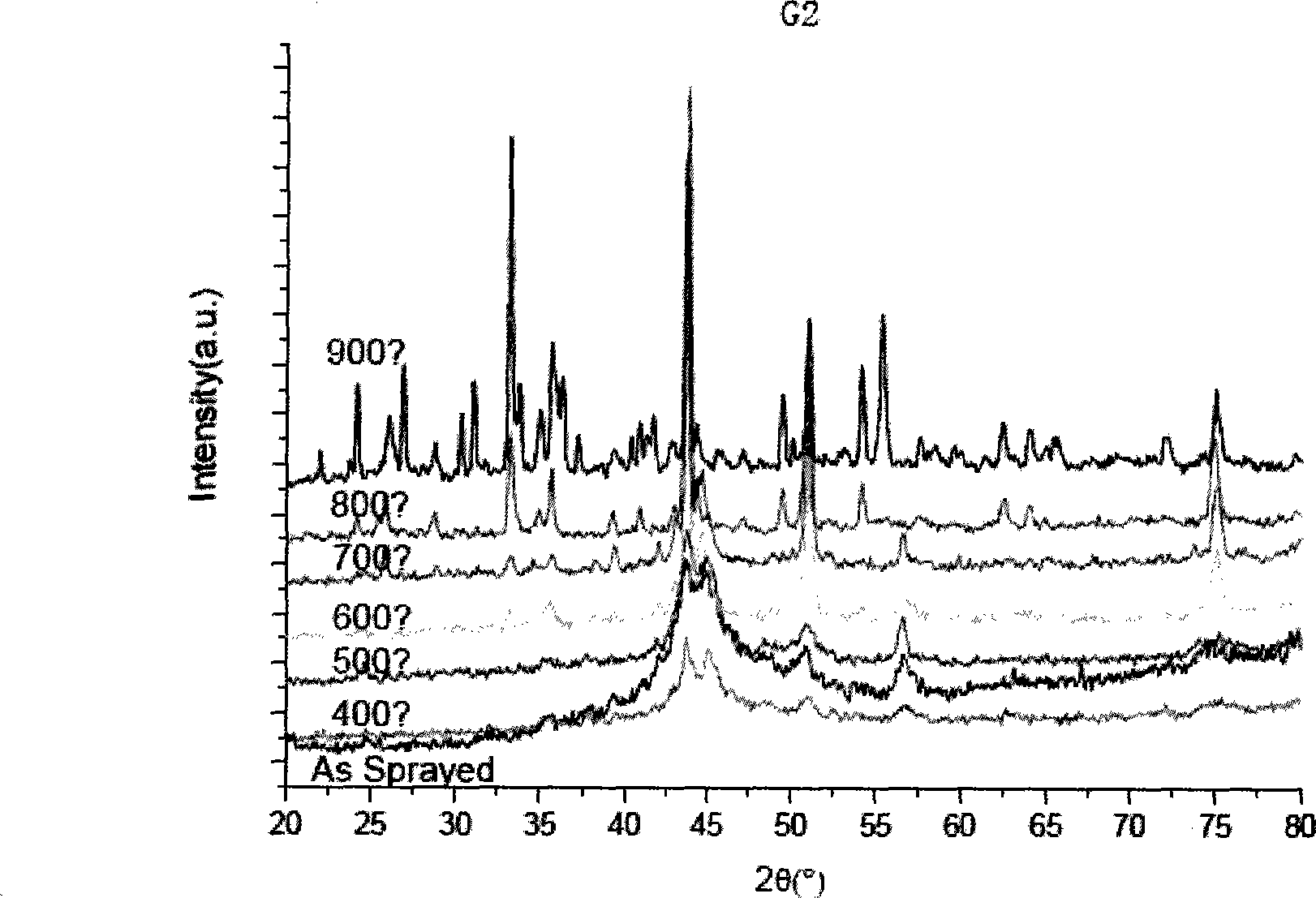

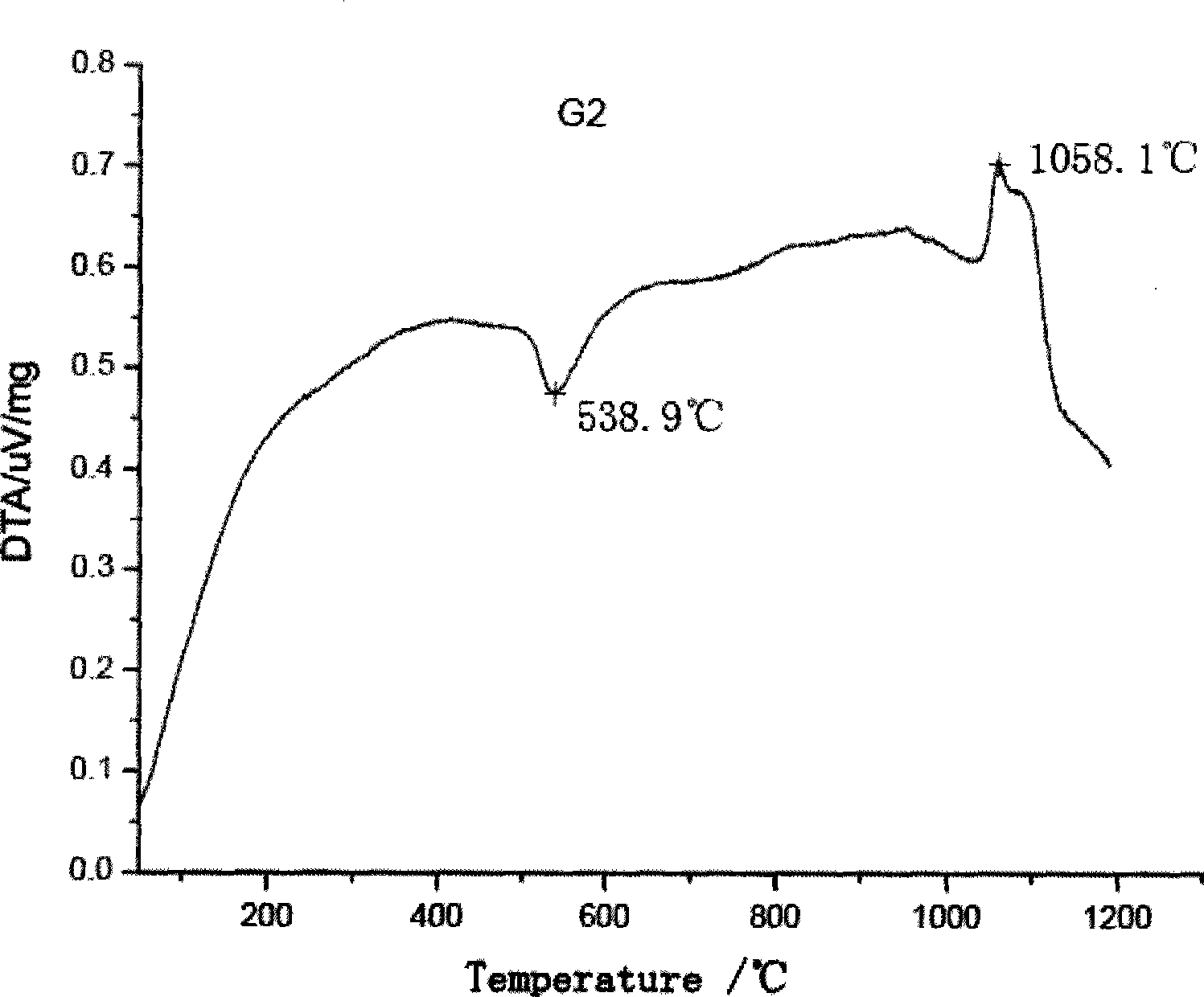

[0019] 1. Use 304L stainless steel strip of 10×0.3mm (10mm in width and 0.3mm in thickness). Roll it into a U shape first. Get 600 grams of nickel-boron powder, 150 grams of Mo powder, 100 grams of WC powder, 50 grams of TiC powder, and 100 grams of nickel powder. The various powders taken were put into a powder mixer and mixed for 10 minutes, and then the mixed powder was added into a U-shaped 304L stainless steel belt groove, and the filling rate was 30%. Close the U-shaped groove so that the medicine powder is wrapped in it, and then gradually reduce the diameter through the wire drawing die to make the diameter reach 2.0mm. The arc spraying coating is prepared on the metal substrate roughened by sand blasting, the spraying current is 150-180A, the spraying voltage is 30-32V, the spraying air pressure is 0.55MP, and the spraying distance is 150mm. The coating hardness and relative we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com