Nickel-encapsulated boron and nitrogen co-doped carbon nanotube wave-absorbing material and preparation method thereof

A technology of carbon nanotubes and wave absorbing materials, applied in the field of wave absorbing materials, can solve the problems such as the inability to realize large-scale mass production of carbon nanotubes, which is unfavorable for industrial production, and achieve the realization of large-scale large-scale production and equal distribution of pipe diameters. , the effect of simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of the nickel-encapsulated boron and nitrogen co-doped carbon nanotube wave-absorbing material of the present invention comprises the following steps:

[0033] Step 1: Dissolve 2.38g nickel chloride hexahydrate in 20ml water and stir well.

[0034] Step 2: Dissolve 0.76g sodium borohydride and 0.08g sodium hydroxide in 20ml water and mix well. Slowly and uniformly drop the prepared solution into the prepared solution in step 1 to obtain a black nickel boride precipitate.

[0035] Step 3: wash the nickel boride precipitate obtained in step 2 with ethanol and water, filter, and dry in an oven at 80°C.

[0036] Step 4: Mix 0.3846g of the clean nickel boride obtained in step 3 with 5.045g of dicyandiamide and grind them evenly.

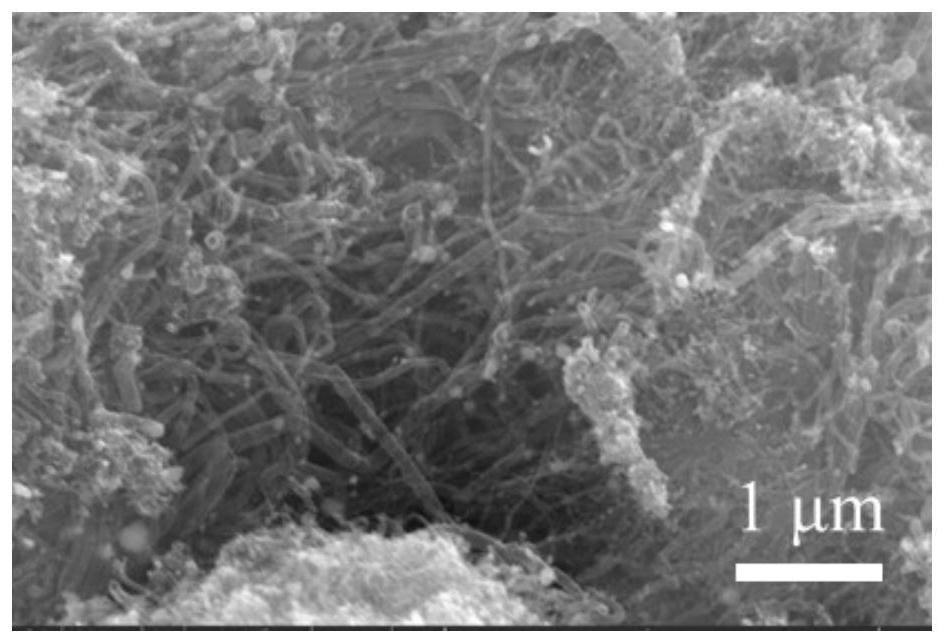

[0037] Step 5: Transfer the mixture obtained in step 4 into a porcelain boat, and heat-treat it under inert gas. Min rise 700 ℃ heat preservation 2h, natural cooling, you can get a black powder material, that is, carbon na...

Embodiment 2

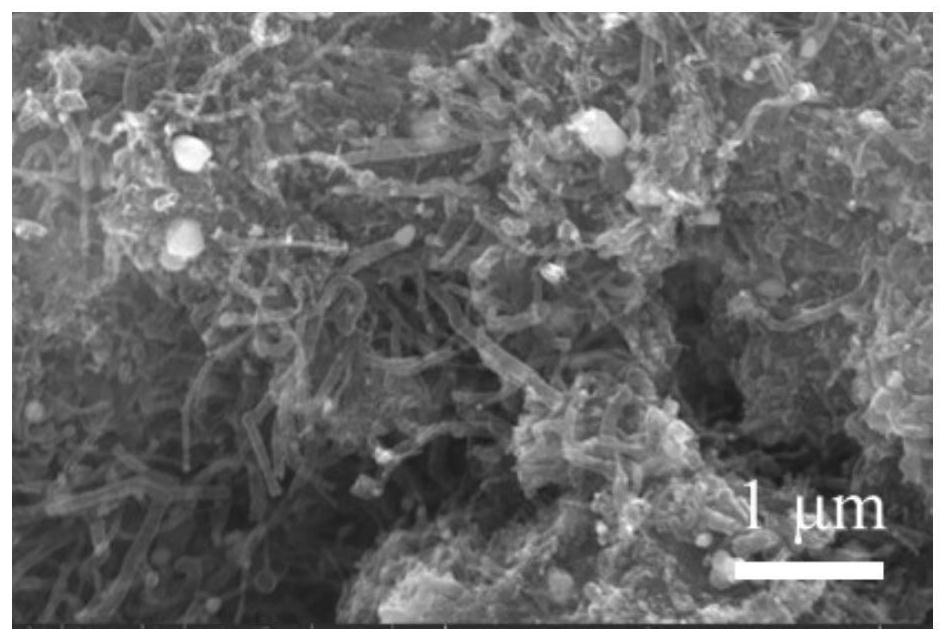

[0040] The preparation method of the nickel-encapsulated boron and nitrogen co-doped carbon nanotube wave-absorbing material of the present invention comprises the following steps:

[0041] Step 1: Dissolve 2.38g nickel chloride hexahydrate in 20ml water and stir well.

[0042] Step 2: Dissolve 0.76g sodium borohydride and 0.08g sodium hydroxide in 20ml water and mix well. Slowly and uniformly drop the prepared solution into the prepared solution in step 1 to obtain nickel boride precipitation.

[0043] Step 3: wash the nickel boride precipitate obtained in step 2 with ethanol and water, filter, and dry in an oven at 80°C.

[0044] Step 4: Mix 0.3846g of the clean nickel boride obtained in step 3 with 5.045g of dicyandiamide and grind them evenly.

[0045] Step 5: Transfer the mixture obtained in step 4 into a porcelain boat, and heat-treat it under inert gas. Min liter 800 ℃ heat preservation 2h, natural cooling, you can get the black powder material.

[0046] The carbon ...

Embodiment 3

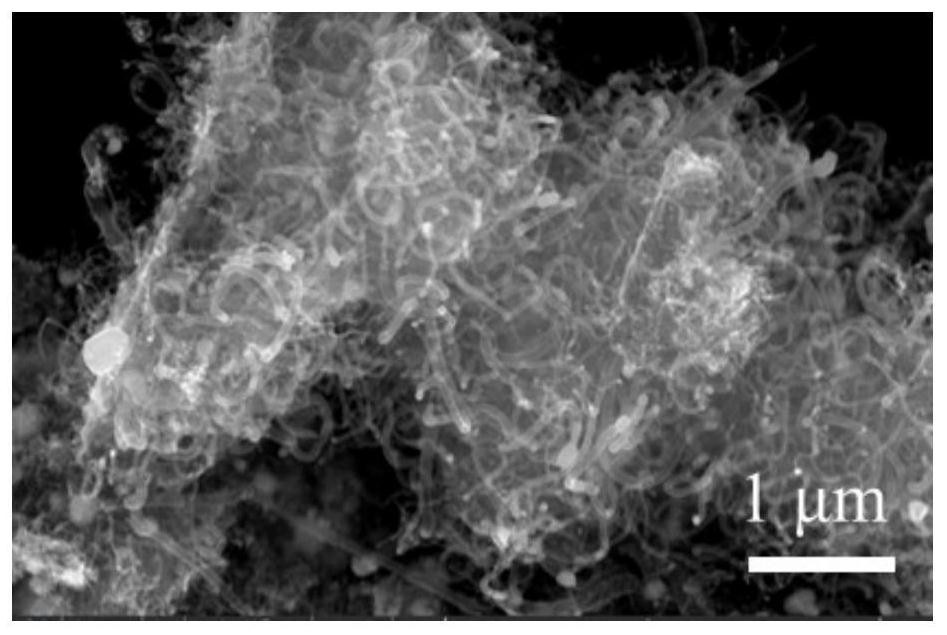

[0048] The preparation method of the nickel-encapsulated boron and nitrogen co-doped carbon nanotube wave-absorbing material of the present invention comprises the following steps:

[0049] Step 1: Dissolve 2.38g nickel chloride hexahydrate in 20ml water and stir well.

[0050] Step 2: Dissolve 0.76g sodium borohydride and 0.08g sodium hydroxide in 20ml water and mix well. Slowly and uniformly drop the prepared solution into the prepared solution in step 1 to obtain nickel boride precipitation.

[0051] Step 3: wash the nickel boride precipitate obtained in step 2 with ethanol and water, filter, and dry in an oven at 80°C.

[0052] Step 4: Mix 0.3846g of the clean nickel boride obtained in step 3 with 5.045g of dicyandiamide and grind them evenly.

[0053] Step 5: Transfer the mixture obtained in step 4 into a porcelain boat, and heat-treat it under inert gas. Incubate at 900°C for 2 hours, cool naturally to obtain black powdery material.

[0054] The diameter of the carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com