Preparation method of water-retaining and air-permeable dry-mixed mortar

A dry-mixed mortar and air-permeable technology is applied in the field of preparation of water-retaining and air-permeable dry-mixed mortar, which can solve the problems of poor air permeability and water retention performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

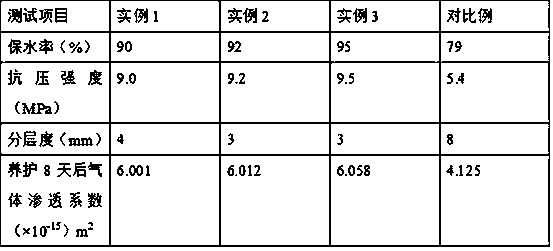

Examples

example 1

[0025] Measure the sodium silicate solution with a mass fraction of 30% and pour it into a beaker, adjust the pH of the sodium silicate solution to 5.5 with a concentration of 1mol / L hydrochloric acid, stir and react for 20 minutes, then move the beaker into an oil bath, and heat up to 110°C , continue to stir and react for 40 minutes to obtain a reaction solution; the above reaction solution is mixed with a mass fraction of 16% sodium hydroxide solution and a mass fraction of 20% lithium metaaluminate solution to obtain a prefabricated solution at a mass ratio of 1:3:12. Put the prefabricated liquid into the high-pressure hydrothermal kettle, and then add nickel boride with 2% of the prefabricated liquid quality and 8% tartaric acid with the prefabricated liquid quality in the high-pressure hydrothermal kettle; Under the conditions of pressure of 1.2MPa and temperature of 200°C, hydrothermal reaction was carried out for 20 hours. After the reaction was completed, the filter re...

example 2

[0027] Measure the sodium silicate solution with a mass fraction of 30% and pour it into a beaker, adjust the pH of the sodium silicate solution to 6.0 with a concentration of 1mol / L hydrochloric acid, stir and react for 25 minutes, then move the beaker into an oil bath, and heat up to 115°C , continue to stir and react for 50 minutes to obtain a reaction solution; the above reaction solution is mixed with a mass fraction of 16% sodium hydroxide solution and a mass fraction of 20% lithium metaaluminate solution to obtain a prefabricated solution at a mass ratio of 1:3:12. Put the prefabricated liquid into the high-pressure hydrothermal kettle, and then add nickel boride with 2% of the prefabricated liquid quality and 8% tartaric acid with the prefabricated liquid quality in the high-pressure hydrothermal kettle; Under the condition of pressure of 1.3MPa and temperature of 210°C, hydrothermal reaction was carried out for 22 hours. After the reaction was completed, the filter res...

example 3

[0029] Measure the sodium silicate solution with a mass fraction of 30% and pour it into a beaker, adjust the pH of the sodium silicate solution to 6.5 with a concentration of 1mol / L hydrochloric acid, stir and react for 30 minutes, then move the beaker into an oil bath, and heat up to 120°C , continue to stir and react for 60 minutes to obtain a reaction solution; the above reaction solution is mixed with a mass fraction of 16% sodium hydroxide solution and a mass fraction of 20% lithium metaaluminate solution to obtain a prefabricated solution at a mass ratio of 1:3:12. Put the prefabricated liquid into the high-pressure hydrothermal kettle, and then add nickel boride with 2% of the prefabricated liquid quality and 8% tartaric acid with the prefabricated liquid quality in the high-pressure hydrothermal kettle; Under the conditions of pressure of 1.4MPa and temperature of 220°C, hydrothermal reaction was carried out for 24 hours. After the reaction was completed, the filter re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com