Preparation method of high-strength bamboo shoot shell packing materials

A packaging material, bamboo shoot shell technology, applied in packaging, wrapping paper, biological packaging, etc., can solve the problems of low surface wettability, low internal bonding strength, poor mechanical strength, etc., to achieve high porosity and improve bonding strength. , the effect of widening the aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

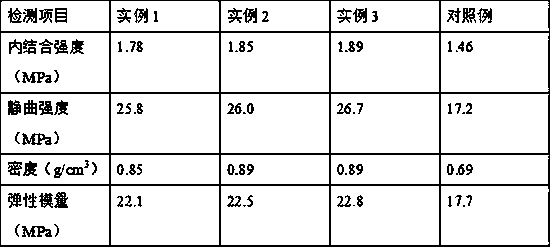

Examples

example 1

[0027] Weigh the bamboo shoot shells and wash them with water for 3 times, and place them flat on the packing plate in the adsorption tower, then cover the surface of the bamboo shoot shells with a layer of zeolite powder with a thickness of 3 mm, and pass into the adsorption tower with a temperature of 200 ° C from the bottom of the adsorption tower. Superheated steam, control the feeding rate of 1L / min, continue feeding and adsorption treatment for 30min; after the adsorption treatment is completed, take out the dewaxed bamboo shoot shells and zeolite powder in the adsorption tower, dewaxed bamboo shoot shells for later use, and put the zeolite powder and lemon juice and a strength of 10 7The cfu / mL Pseudomonas aeruginosa suspension is mixed according to the mass ratio of 1:1:5, then put into the fermenter, seal the mouth of the tank, and ferment for 7 days at a temperature of 30°C; after the fermentation is completed, take out the fermentation product Put it into a high-pre...

example 2

[0029] Weigh the bamboo shoot shells and rinse them with water for 4 times, and place them flat on the packing plate in the adsorption tower, then cover the surface of the bamboo shoot shells with a layer of zeolite powder with a thickness of 4 mm, and pass into the adsorption tower from the bottom of the adsorption tower with a temperature of 220 ° C. Superheated steam, control the feeding rate of 1L / min, continue to feed and adsorb for 35min; after the adsorption treatment is completed, take out the dewaxed bamboo shoot shells and zeolite powder in the adsorption tower, and the dewaxed bamboo shoot shells are used for later use, and the zeolite powder and lemon juice and a strength of 10 7 The cfu / mL Pseudomonas aeruginosa suspension is mixed according to the mass ratio of 1:1:5, put into the fermenter, seal the mouth of the tank, and ferment for 8 days at a temperature of 35°C; after the fermentation is completed, take out the fermentation product Put it into a high-pressur...

example 3

[0031] Weigh the bamboo shoot shells and wash them with water for 5 times and place them flat on the packing plate in the adsorption tower, then cover the surface of the bamboo shoot shells with a layer of zeolite powder with a thickness of 5 mm, and pass into the adsorption tower from the bottom of the adsorption tower with a temperature of 240 ° C. Superheated steam, control the feeding rate of 1L / min, continue feeding and adsorption treatment for 40min; after the adsorption treatment is completed, take out the dewaxed bamboo shoot shells and zeolite powder in the adsorption tower, dewaxed bamboo shoot shells for later use, and put the zeolite powder and lemon juice and a strength of 10 7 The cfu / mL Pseudomonas aeruginosa suspension is mixed according to the mass ratio of 1:1:5, put into the fermenter, seal the mouth of the tank, and ferment for 9 days at a temperature of 40°C; after the fermentation is completed, take out the fermentation product Put it into a high-pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com