Preparation method of carbon dot hybridization mesoporous nickel boride photocatalyst

A catalyst and hybrid technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the carbon dot hybrid mesoporous nickel boride photocatalyst adopts the following steps:

[0026] (1) prepare the citric acid solution of a mol / L, wherein, a is 0.5-1;

[0027] (2) Take b mL of the citric acid solution prepared in (1), add c mmol of nickel powder or nickel foam, and then heat to 60-80°C to completely dissolve the nickel powder or nickel foam, wherein, b is 20-25, c is 4.5-10, and (a * b): c=1-5.5;

[0028] (3) Put the solution obtained in step (2) into a hydrothermal reaction kettle, keep it warm at 175-225° C. for 5-12 hours, and then cool to room temperature;

[0029] (4) Add sodium hydroxide to the solution in step (3) to make the pH of the solution 7-9, then add dmmol of sodium borohydride to it, and stir vigorously for 2-3 hours, wherein d is 4.5-11 , and d:c=1-1.1;

[0030] (5) Collect the black precipitate from the solution obtained in step (4) by centrifugation, and wash it with deionized water for 3-5 times, and fin...

Embodiment 1

[0033] The preparation method of the carbon dot hybrid mesoporous nickel boride photocatalyst adopts the following steps:

[0034] (1) prepare the citric acid solution of 0.5mol / L;

[0035] (2) Take 20mL of the citric acid solution prepared in (1), add 10mmol nickel powder or nickel foam, and then heat to 60-80°C to completely dissolve the nickel powder or nickel foam;

[0036] (3) Put the solution obtained in step (2) into a hydrothermal reaction kettle, keep it warm at 175° C. for 5 hours, and then cool to room temperature;

[0037] (4) Add sodium hydroxide to the solution in step (3) to make the pH of the solution 7, then add 11 mmol of sodium borohydride therein, and stir vigorously for 2 hours;

[0038] (5) Collect the black precipitate from the solution obtained in step (4) by centrifugation, and wash it with deionized water for 4 times, and finally obtain the carbon dot hybrid mesoporous nickel boride photocatalyst.

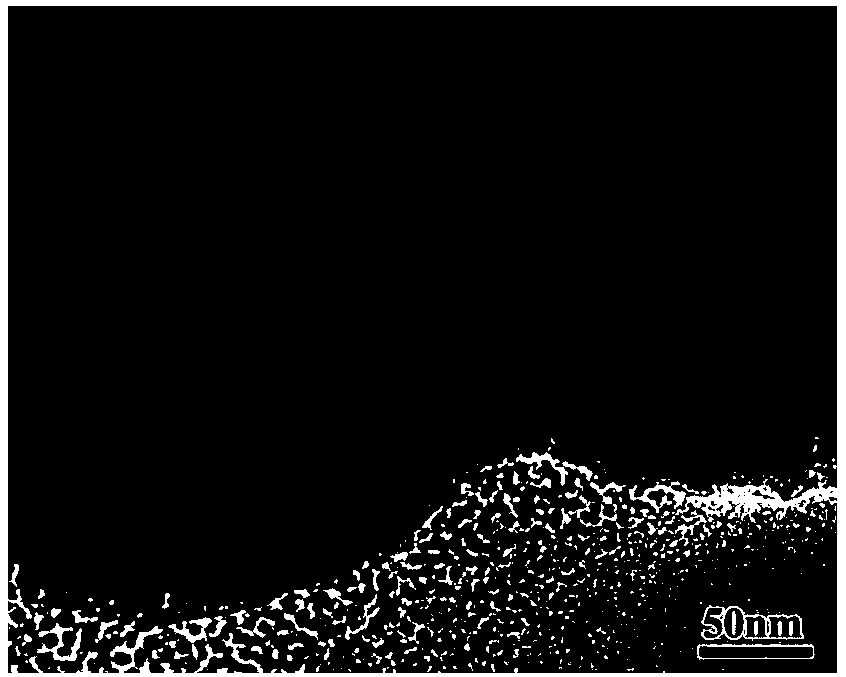

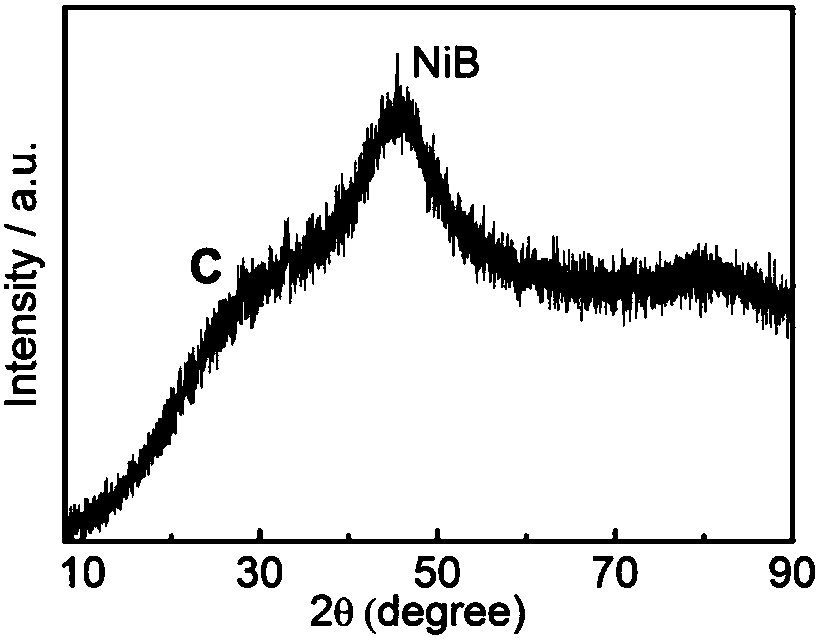

[0039] Characterization and performance testing of...

Embodiment 2

[0041] The preparation method of the carbon dot hybrid mesoporous nickel boride photocatalyst adopts the following steps:

[0042] (1) prepare the citric acid solution of 1mol / L;

[0043] (2) Take 25mL of the citric acid solution prepared in (1), add 4.5mmol nickel powder or nickel foam, and then heat to 80°C to completely dissolve the nickel powder or nickel foam;

[0044] (3) Put the solution obtained in step (2) into a hydrothermal reaction kettle, keep it warm at 200°C for 8 hours, and then cool to room temperature;

[0045] (4) Add sodium hydroxide to the solution in step (3) to make the pH of the solution 8, then add 4.5 mmol of sodium borohydride therein, and stir vigorously for 3 hours;

[0046] (5) Collect the black precipitate from the solution obtained in step (4) by centrifugation, and wash it with deionized water for 4 times, and finally obtain the carbon dot hybrid mesoporous nickel boride photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com