Mixed ether ester type clean diesel oil based on non-national standard diesel oil component

A mixed ether, non-national standard technology, used in the petroleum industry, liquid carbon-containing fuels, fuel additives, etc., can solve the problems of difficult transportation, storage and use, high emissions of harmful gases, and difficult to control oil quality. The effect of stable and normal conditions, reducing emissions and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

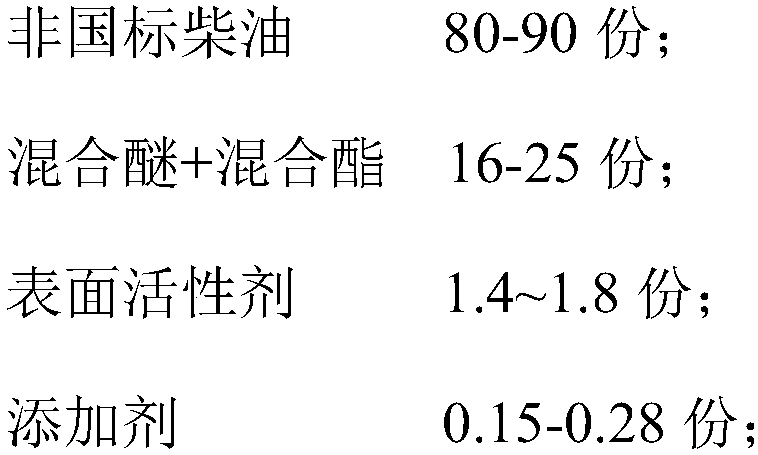

[0034] A clean diesel component formulation comprises the following raw materials by weight: 0.8 parts of urea; 80 parts of non-national standard diesel oil; 9 parts of mixed ethers; 7 parts of mixed esters; 1.4 parts of surfactants; and 0.15 parts of additives. Among them, the mixed ether is DMM 3 with DMM 4The mixture in a weight ratio of 4:3, the mixed ester is composed of isomerized bio-oil (sourced from kitchen waste oil), the surfactant is polyoxyethylene sorbitan ester, and the additive is alkylamine retarder Solvent and polyethylene glycol affinity agent (weight ratio of 1:1), non-national standard diesel oil (close to 0 # The octane number of the national standard diesel oil is 35, and the sulfur content is 70 ppm. After stirring and mixing the above components, clean diesel oil is obtained.

Embodiment 2

[0036] A clean diesel component formula includes the following raw materials by weight: 1.8 parts of urea; 90 parts of non-national standard diesel oil; 14 parts of mixed ethers; 11 parts of mixed esters; 1.8 parts of surfactants; and 0.28 parts of additives. Among them, the mixed ether is DMM 3 with DMM 4 The mixture in a weight ratio of 5:2, the mixed ester is composed of isomerized bio-oil (source is vegetable oil), the surfactant is polyoxyethylene sorbitan ester, and the additive is alkylamine slow solvent and Polyethylene glycol affinity agent (weight ratio of 2:1), non-national standard diesel (close to -10 # The octane number of the national standard diesel oil is 37, and the sulfur content is 68 ppm. The clean diesel oil is obtained by stirring and mixing the above components.

Embodiment 3

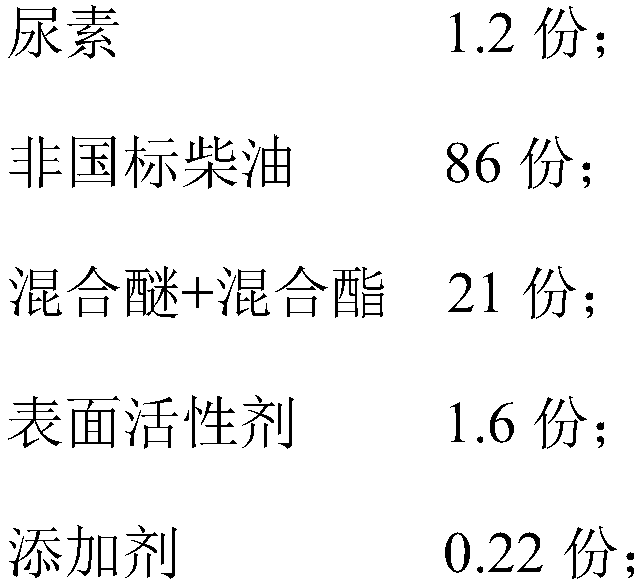

[0038] A clean diesel component formula comprises the following raw materials by weight: 1.2 parts of urea; 86 parts of non-national standard diesel oil; 12 parts of mixed ethers; 9 parts of mixed esters; 1.6 parts of surfactants; and 0.22 parts of additives. Among them, the mixed ether is DMM 3 with DMM 4 The mixture is 3:2 by weight, the mixed ester is composed of isomerized bio-oil (source is kitchen waste oil), the surfactant is polyoxyethylene sorbitan ester, and the additive is alkylamine retarder Solvent and polyethylene glycol affinity agent (weight ratio of 3:2), non-national standard diesel oil (close to 10 # The octane number of the national standard diesel oil is 37, and the sulfur content is 70 ppm. After stirring and mixing the above components, clean diesel oil is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com