Low-temperature denitration catalyst and preparation method and application thereof

A low-temperature denitrification and catalyst technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, heterogeneous catalyst chemical elements, etc., can solve the problems of poor low-temperature removal performance and achieve low cost, simple preparation process, excellent resistance Effects of High Mercury Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

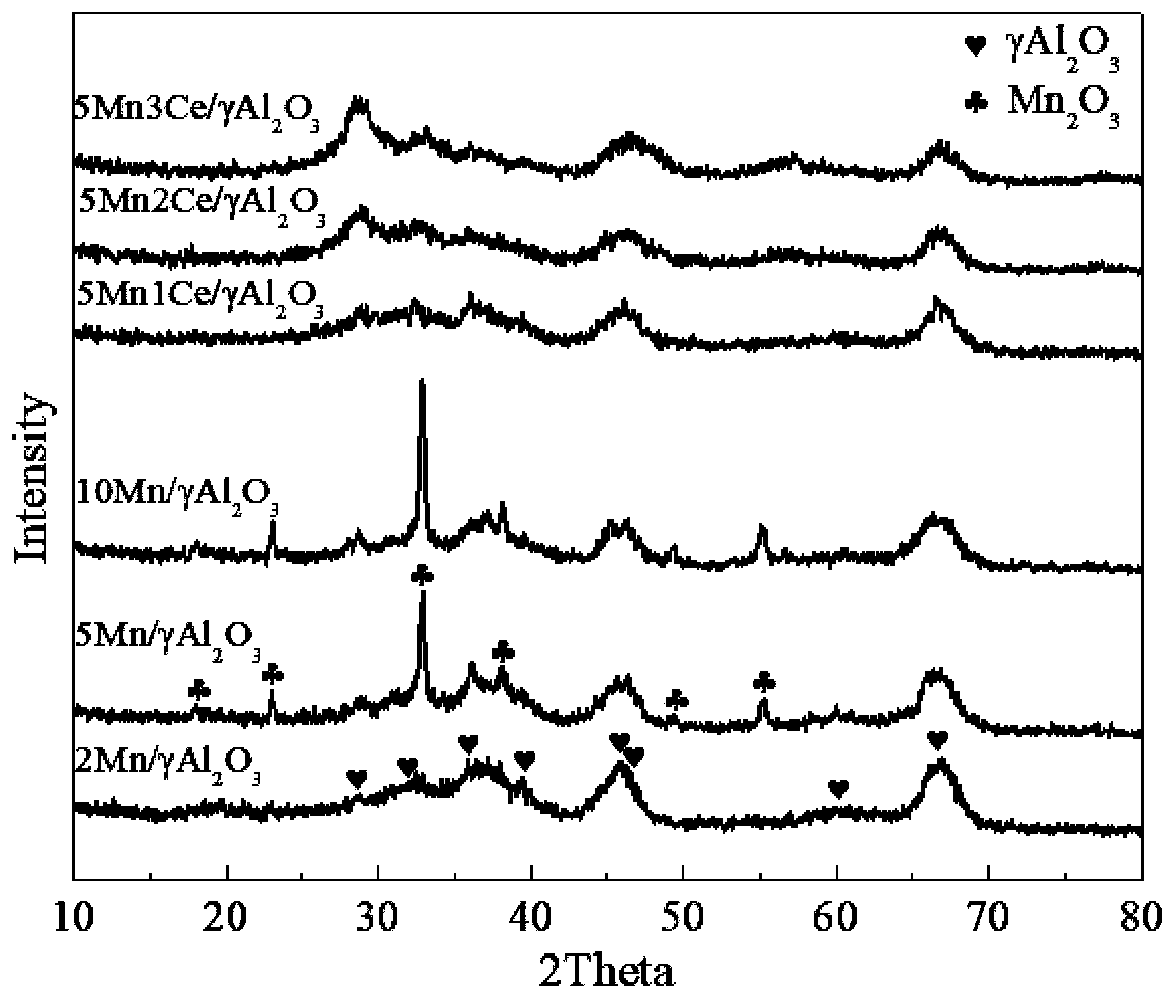

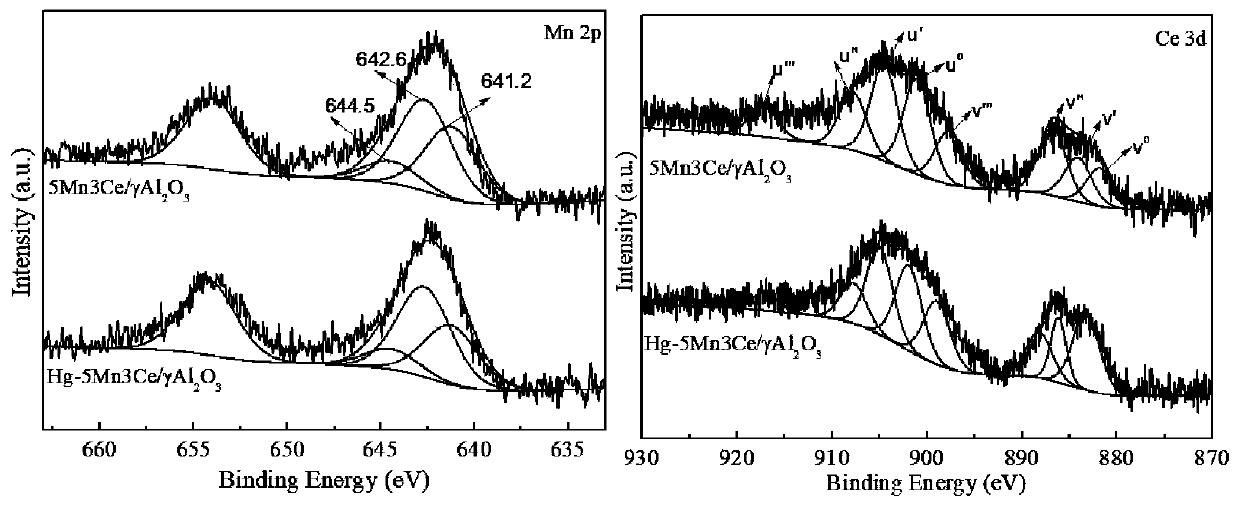

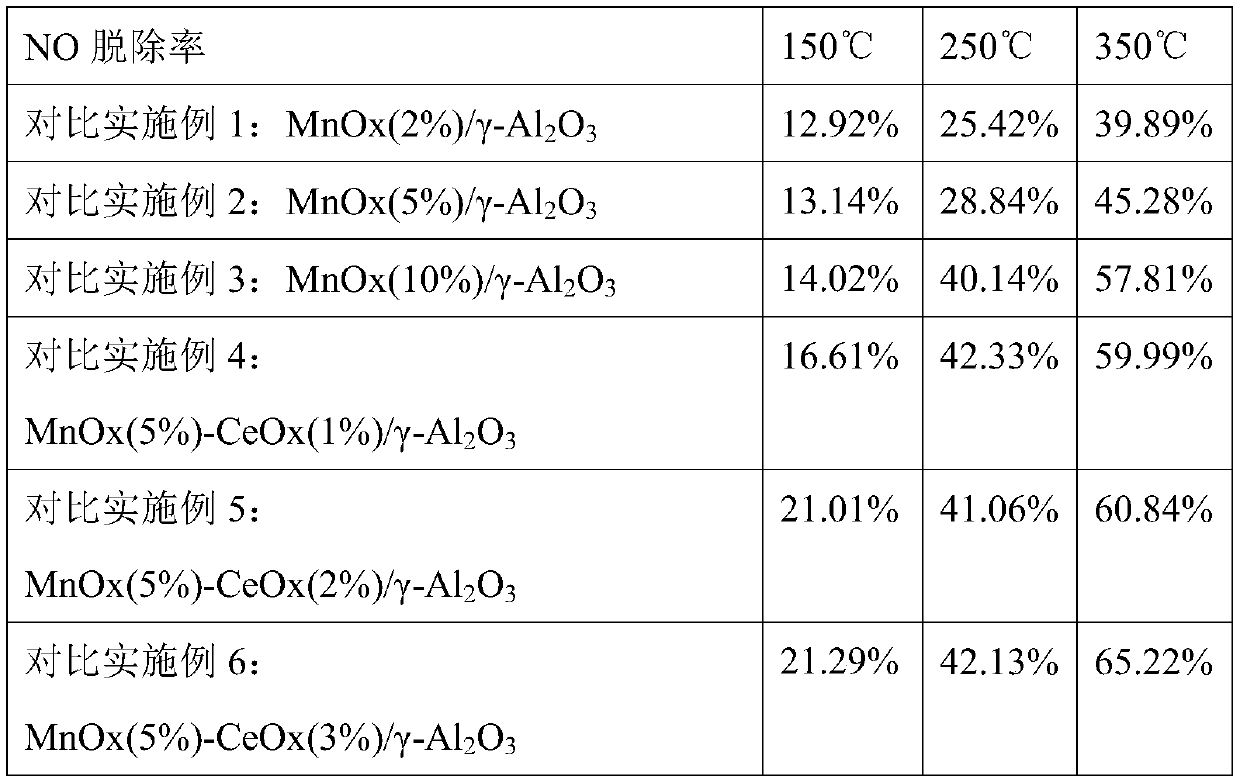

[0055] Take 0.753g manganese nitrate Mn(NO 3 ) 2 4H 2 O and 0.27g cerium nitrate Ce(NO 3 ) 2 ·6H 2 O, dissolve it in 30mL of deionized water to make an impregnation solution; use γ-Al with a diameter of 1.5-2mm 2 o 3 As a catalyst carrier, wet impregnation method was used to weigh 3g γ-Al 2 o 3 Immerse in the solution; immerse in ultrasonic for 4 hours, vacuum distill to remove excess deionized water, and then dry the obtained catalyst for 12 hours at 105°C for 2 hours, then the catalyst is placed in N 2 Under the atmosphere, the temperature was raised to 600°C at a rate of 5°C / min, and fired at this temperature for 3h. N 2 Blow and cool, obtain catalyst MnOx (5%)-CeOx (3%) / γ-Al 2 o 3 . The resulting catalyst was placed under Hg 0 The concentration is 230~260mg / m 3 Adsorbed in the flue gas for 5h to get Hg-MnOx(5%)-CeOx(3%) / γ-Al 2 o 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com