A fluorine-modified boron-carbon-nitrogen photocatalytic material and its application in efficient reduction of carbon dioxide

A photocatalytic material, carbon dioxide technology, applied in the field of photocatalytic materials, can solve the problems of high cost, inefficiency, environmental pollution, etc., and achieve the effects of mechanical wear resistance, low cost, and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

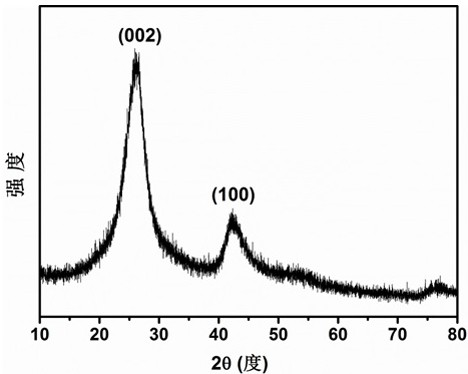

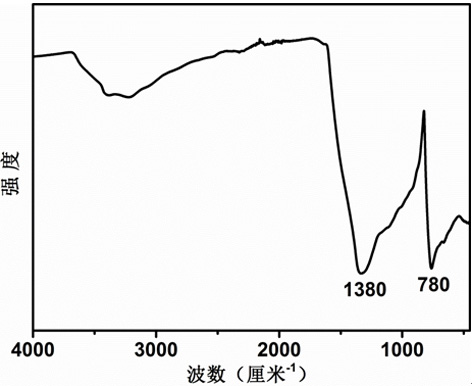

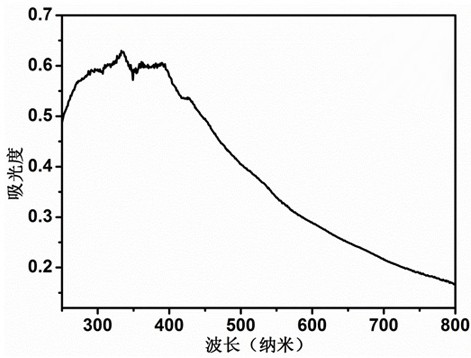

[0025] Completely dissolve 2g of boron oxide, 4g of urea, and 0.6g of glucose in 40-50ml of deionized water. After evaporating all the water at 75°C under normal pressure, place the resulting mixture in a corundum porcelain boat, and then place it in In a horizontal high-temperature tube furnace, the temperature was raised to 1250 °C at a rate of 5 °C / min in an ammonia atmosphere, and then kept for 5 h. After the sample was taken out, it was washed with 0.1 mol / L dilute hydrochloric acid, centrifuged, and dried to obtain Graphite phase boron carbon nitrogen powder; mix potassium fluoride with the obtained boron carbon nitrogen powder at a mass ratio of 0.4:1, grind them evenly, place them in a muffle furnace, and heat up to 400°C at a rate of 5°C / min in an air atmosphere , and then keep warm for 3 hours; after cooling to room temperature, take out the sample, fully wash with deionized water, suction filter, and dry to obtain the fluorine-modified boron carbon nitrogen photocata...

Embodiment 2

[0034] Completely dissolve 2g of boron oxide, 4g of urea, and 0.6g of glucose in 40-50ml of deionized water. After evaporating all the water at 75°C under normal pressure, place the resulting mixture in a corundum porcelain boat, and then place it in In a horizontal high-temperature tube furnace, the temperature was raised to 1250 °C at a rate of 5 °C / min in an ammonia atmosphere, and then kept for 5 h. After the sample was taken out, it was washed with 0.1 mol / L dilute hydrochloric acid, centrifuged, and dried to obtain Graphite phase boron carbon nitrogen powder; mix potassium fluoride with the obtained boron carbon nitrogen powder at a mass ratio of 0.2:1, grind them evenly, place them in a muffle furnace, and heat up to 400°C at a rate of 5°C / min in an air atmosphere , and then keep warm for 3 hours; after cooling to room temperature, take out the sample, fully wash with deionized water, suction filter, and dry to obtain the fluorine-modified boron carbon nitrogen photocata...

Embodiment 3

[0036] Completely dissolve 2g of boron oxide, 4g of urea, and 0.6g of glucose in 40-50ml of deionized water. After evaporating all the water at 75°C under normal pressure, place the resulting mixture in a corundum porcelain boat, and then place it in In a horizontal high-temperature tube furnace, the temperature was raised to 1250 °C at a rate of 5 °C / min in an ammonia atmosphere, and then kept for 5 h. After the sample was taken out, it was washed with 0.1 mol / L dilute hydrochloric acid, centrifuged, and dried to obtain Graphite phase boron carbon nitrogen powder; mix potassium fluoride with the obtained boron carbon nitrogen powder at a mass ratio of 0.3:1, grind them evenly, place them in a muffle furnace, and heat up to 400°C at a rate of 5°C / min in an air atmosphere , and then keep warm for 3 hours; after cooling to room temperature, take out the sample, fully wash with deionized water, suction filter, and dry to obtain the fluorine-modified boron carbon nitrogen photocata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com