Preparation method of gold nanoparticles

A gold nanoparticle, chloroauric acid technology, applied in the preparation of organic compounds, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of environmental pollution, non-degradation, and high cost, and achieve uniform particle size and low cost. , The effect of taking materials is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing gold nanoparticles, comprising the following steps:

[0031] The ginkgo biloba polysaccharide solution and the chloroauric acid solution are mixed, the reduction reaction of the chloroauric acid is carried out, and the obtained reduction product system is dialyzed to obtain gold nanoparticles.

[0032] In the present invention, the mass concentration of the ginkgo leaf polysaccharide solution is preferably 0.1-30 mg / mL, more preferably 1-25 mg / mL, most preferably 5-20 mg / mL. In the present invention, the ginkgo leaf polysaccharide is preferably dissolved in deionized water to obtain a ginkgo leaf polysaccharide solution.

[0033] The present invention has no special limitation on the source of the ginkgo leaf polysaccharide, and the ginkgo leaf polysaccharide product prepared by a method well known to those skilled in the art can be used. In the present invention, the preparation method of the ginkgo leaf polysaccharide pre...

Embodiment 1

[0045] Ginkgo leaf polysaccharide was dissolved in deionized water to prepare 0.1mg / mL ginkgo leaf polysaccharide solution, and 0.1mg / mL ginkgo leaf polysaccharide solution and 0.1mmol / mL chloroauric acid solution The molar ratio of 1:10 is mixed in the centrifuge tube, and then the centrifuge tube is put into the constant temperature metal mixer, the speed of the constant temperature metal mixer is controlled to 400rpm, and the temperature of the constant temperature metal mixer is 20°C. After the reduction reaction for 4 hours, the mixed solution turned purple, and the mixed solution was dialyzed with a dialysis bag with a molecular weight cut-off of 8000-14000 to obtain a solution of ginkgo biloba polysaccharide-gold 10 nanoparticles.

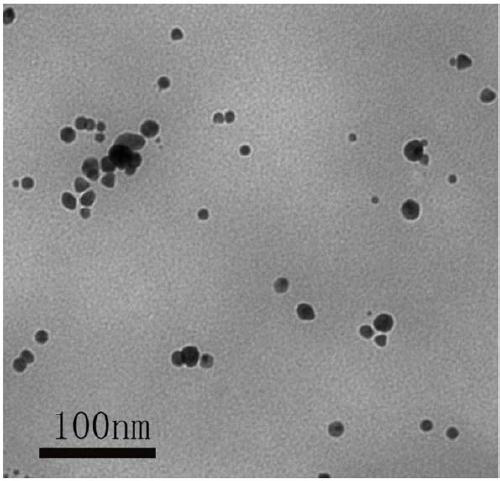

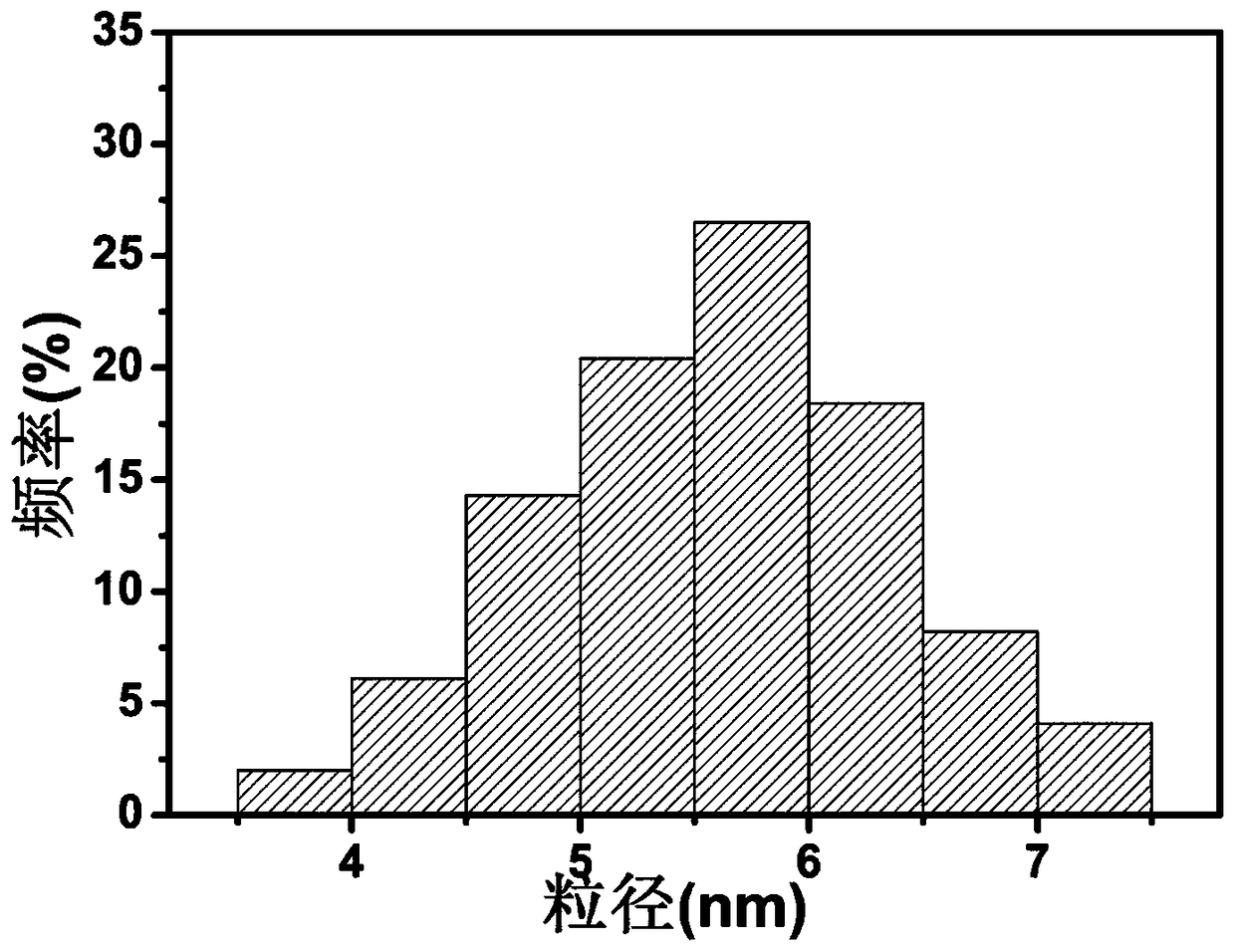

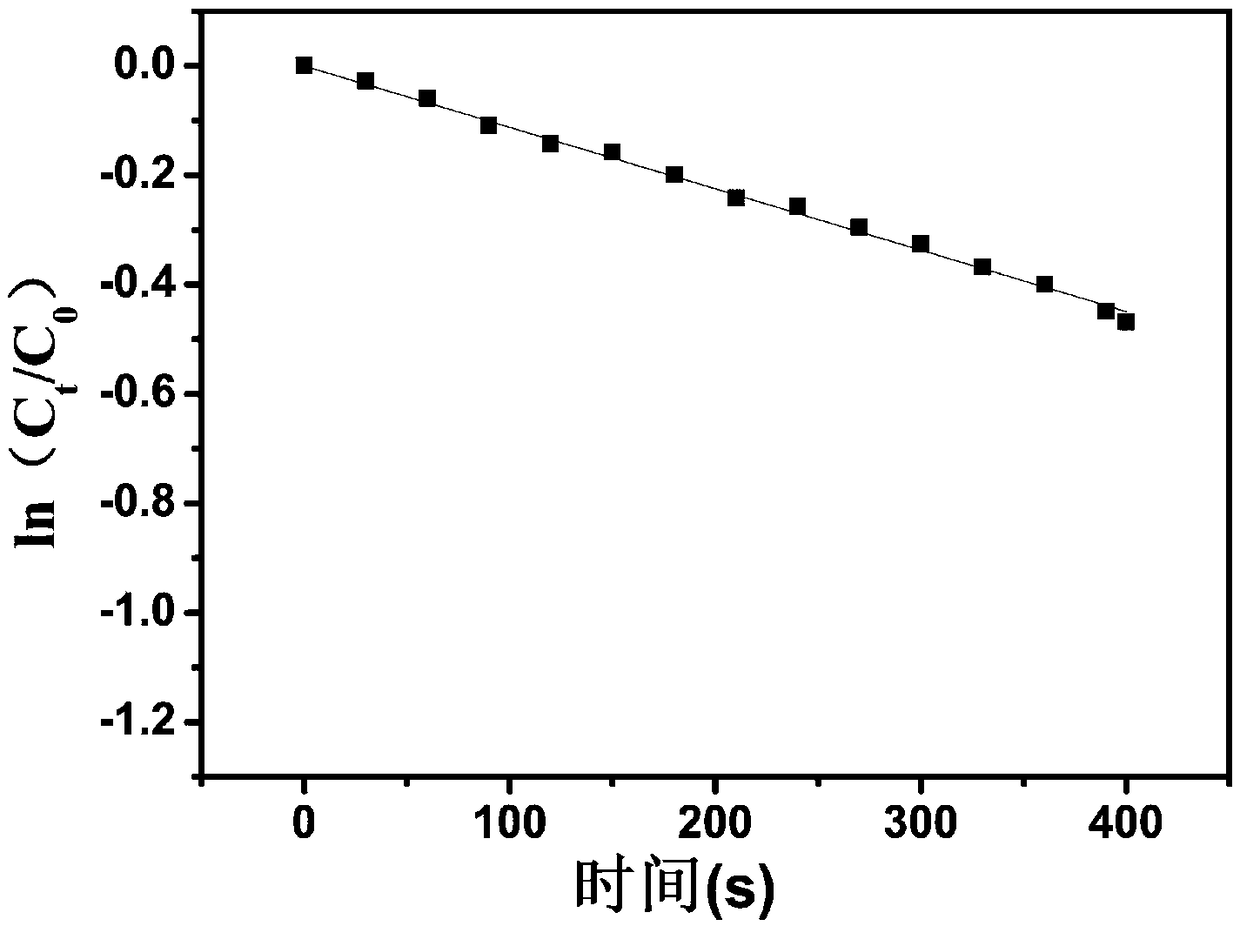

[0046] figure 1 It is a transmission electron microscope picture of Ginkgo biloba polysaccharide-gold 10 nanoparticles, showing that its shape is spherical. figure 2 for figure 1 The particle size distribution histogram of the Ginkgo bilo...

Embodiment 2

[0049] Ginkgo leaf polysaccharide was dissolved in deionized water to prepare 1mg / mL ginkgo leaf polysaccharide solution, and 1mg / mL ginkgo leaf polysaccharide solution and 1mmol / mL chloroauric acid solution were prepared according to the molar ratio of ginkgo leaf polysaccharide and chloroauric acid Mix it in a centrifuge tube at a ratio of 1:70, then put the centrifuge tube into a constant temperature metal mixer, control the speed of the constant temperature metal mixer to 500rpm, and the temperature of the constant temperature metal mixer to 40°C, and carry out the reduction reaction for 5h , when the mixed solution turns purple, dialyze the mixed solution with a dialysis bag with a molecular weight cut-off of 8000-14000 to obtain a solution of ginkgo biloba polysaccharide-gold 70 nanoparticles.

[0050] Figure 4 It is a transmission electron microscope picture of Ginkgo biloba polysaccharide-gold 70 nanoparticles, showing that its shape is spherical. Figure 5 for Fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com