Preparation method of efficient fruit and vegetable pesticide cleaning agent

A cleaning agent and pesticide technology, which is applied in the field of preparation of high-efficiency vegetable and pesticide cleaning agents, can solve the problems of pesticide removal rate affecting the nutritional components of vegetables and fruits, cleaning agents being difficult to degrade, and secondary pollution of fruits and vegetables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

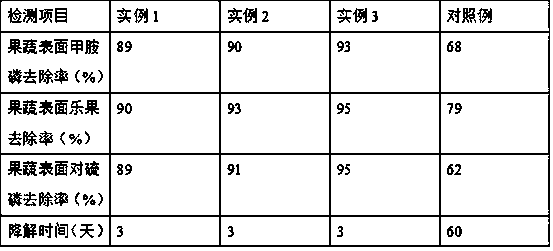

Examples

example 1

[0023] Measure the orthosilicic acid solution with a mass fraction of 60%, heat the orthosilicic acid solution to 100°C, continue to stir and react for 1 hour to obtain a suspension, and mix the suspension, mass fraction 10% sodium hydroxide solution and potassium metaaluminate solution with a mass fraction of 25% were mixed to obtain a precursor solution; The concentration of nickel and 5% of the precursor solution is 0.5mol / L tartaric acid solution, and the high-pressure hydrothermal kettle is closed, heated to 200°C under 1.6MPa, and the hydrothermal reaction is carried out for 28 hours. After the hydrothermal reaction is completed, filter and separate to obtain the filter residue, namely It is a functional adsorption material, and it is ready for use; mix the tea seed and spirulina according to an equal mass ratio, grind and pulverize it with a tissue grinder to obtain a pulverized product, mix the pulverized product and water at a mass ratio of 1:5, and put it into a beake...

example 2

[0025]Measure the orthosilicic acid solution with a mass fraction of 60%, heat the orthosilicic acid solution to 103°C, continue to stir and react for 1 hour to obtain a suspension, and mix the suspension, mass fraction 10% sodium hydroxide solution and potassium metaaluminate solution with a mass fraction of 25% were mixed to obtain a precursor solution; The concentration of nickel and 5% of the precursor solution is 0.5mol / L tartaric acid solution, and the high-pressure hydrothermal kettle is closed, heated to 205°C under 1.6MPa, and the hydrothermal reaction is carried out for 29 hours. After the hydrothermal reaction is completed, filter and separate to obtain the filter residue, namely It is a functional adsorption material, and it is ready for use; mix the tea seed and spirulina according to an equal mass ratio, grind and pulverize it with a tissue grinder to obtain a pulverized product, mix the pulverized product and water at a mass ratio of 1:5, and put it into a beaker...

example 3

[0027] Measure the orthosilicic acid solution with a mass fraction of 60%, heat the orthosilicic acid solution to 105°C, continue to stir and react for 2 hours to obtain a suspension, and mix the suspension, mass fraction 10% sodium hydroxide solution and potassium metaaluminate solution with a mass fraction of 25% were mixed to obtain a precursor solution; The concentration of nickel and 5% of the mass of the precursor solution is 0.5mol / L tartaric acid solution, and the high-pressure hydrothermal kettle is closed, heated to 210°C under 1.7MPa, and the hydrothermal reaction is carried out for 30 hours. After the hydrothermal reaction is completed, the filter residue is obtained by filtration, that is It is a functional adsorption material, and it is ready for use; mix the tea seed and spirulina according to an equal mass ratio, grind and pulverize it with a tissue grinder to obtain a pulverized product, mix the pulverized product and water at a mass ratio of 1:5, and put it in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com