Preparation method for biomass adhesive-free plate

A biomass and rubber sheet technology, applied in flat products, household components, applications, etc., can solve the problems of poor fire resistance, poor mechanical properties, and low internal bonding strength of non-plastic sheets, so as to improve mechanical properties and adsorption activity. , the effect of the best flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

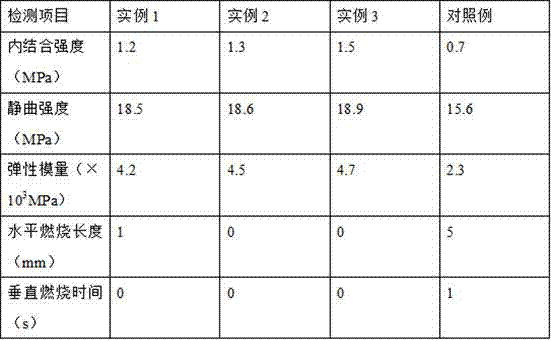

Examples

example 1

[0024] In parts by weight, weigh 20 parts of magnesium nitrate, 25 parts of aluminum nitrate, 15 parts of ferric nitrate and 250 parts of deionized water and mix them for 10 minutes to obtain a mixed solution. The reaction liquid is obtained after mixing at a ratio of 15:2:1; the reaction liquid is mixed with a concentration of 0.5mol / L citric acid solution and nickel boride at a mass ratio of 10:60:1 to obtain a mixture, and the high-pressure hydrothermal In the kettle, close the high-pressure hydrothermal kettle, heat it up to 190°C under 1.2MPa, and conduct a hydrothermal reaction for 25 hours. After the hydrothermal reaction is completed, filter and separate to obtain the filter residue, which is a self-made reinforced flame retardant; the mass ratio is 1:10 Mix bagasse and sodium hydroxide solution with a mass fraction of 20% and put it into a pressure cooker, heat up to 180°C at 150kPa, heat-preserve and cook for 1 hour, filter and separate the filter residue after heat-p...

example 2

[0026]In parts by weight, take 25 parts of magnesium nitrate, 30 parts of aluminum nitrate, 18 parts of ferric nitrate and 280 parts of deionized water and mix for 13 minutes to obtain a mixed solution. The mixed solution and the mass fraction are 30% ammonia and potassium carbonate The reaction liquid is obtained after mixing at a ratio of 15:2:1; the reaction liquid is mixed with a concentration of 0.5mol / L citric acid solution and nickel boride at a mass ratio of 10:60:1 to obtain a mixture, and the high-pressure hydrothermal In the kettle, close the high-pressure hydrothermal kettle, heat it up to 200°C under 1.3MPa, and conduct the hydrothermal reaction for 28 hours. After the hydrothermal reaction is completed, filter and separate to obtain the filter residue, which is the self-made reinforced flame retardant; the mass ratio is 1:10 Mix bagasse and sodium hydroxide solution with a mass fraction of 20% and put it into a pressure cooker, heat up to 190°C at 180kPa, heat-pre...

example 3

[0028] In parts by weight, 30 parts of magnesium nitrate, 35 parts of aluminum nitrate, 20 parts of iron nitrate and 300 parts of deionized water were weighed and mixed for 15 minutes to obtain a mixed solution, and the mixed solution and mass fraction were 30% ammonia and potassium carbonate by mass The reaction liquid is obtained after mixing at a ratio of 15:2:1; the reaction liquid is mixed with a concentration of 0.5mol / L citric acid solution and nickel boride at a mass ratio of 10:60:1 to obtain a mixture, and the high-pressure hydrothermal In the kettle, close the high-pressure hydrothermal kettle, heat it up to 210°C under 1.4MPa, and conduct a hydrothermal reaction for 30 hours. After the hydrothermal reaction is completed, filter and separate to obtain the filter residue, which is a self-made reinforced flame retardant; the mass ratio is 1:10 Mix bagasse and sodium hydroxide solution with a mass fraction of 20% and put it into a pressure cooker, heat up to 200°C at 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com