C5/C6 alkane isomerization catalyst supported by nickel boride and its preparation and use method

An alkane isomerization and catalyst technology, which is applied in the field of catalysts for catalyzing C5/C6 alkane isomerization, can solve the problem of high use temperature, and achieve the effects of avoiding pollution, good stability and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Preparation method of the active ingredient:

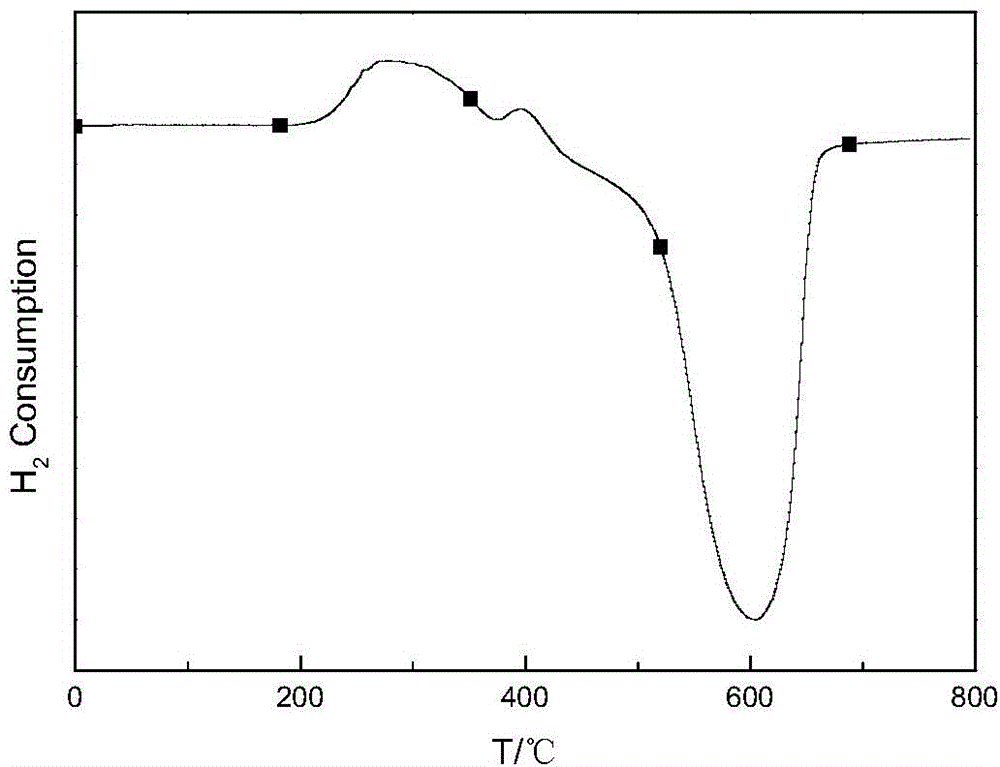

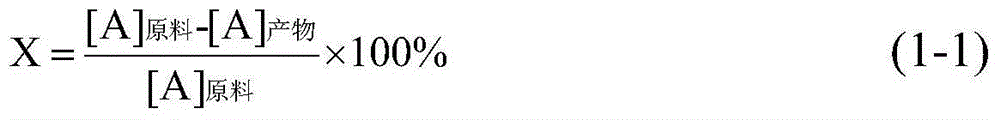

[0041] Dissolve 5g of nickel chloride hexahydrate in 150g of distilled water, add hydrochloric acid dropwise to adjust the pH to 1-2, add 10g of n-hexane to the solution as a dispersion, then slowly add 150g of 3% hydroboration solution dropwise while vigorously stirring Sodium aqueous solution, let stand for 1 hour after the dropwise addition, filter, and dry at 50°C to obtain nickel boride. The TPR spectrogram of described nickel boride is as figure 1 shown in the figure 1 Among them, the negative peak is around 300°C, indicating that hydrogen gas is released in the nickel boride system, which proves that it contains hydrogen.

[0042] As an optional embodiment, when preparing the nickel boride, the molar ratio of the sodium borohydride and nickel chloride can be any value in 8:1-4:1, the quality of the sodium borohydride aqueous solution used The concentration is then preferably 1%-5%. And, also can use potassium boroh...

Embodiment 1

[0044] The catalyst for C5 / C6 alkane isomerization described in this example comprises a carrier and nickel boride accounting for 5wt% of the carrier weight, wherein the carrier is composed of alumina and Hβ molecular sieve, and the alumina The weight ratio to Hβ molecular sieve is 1:3.

[0045] The preparation method of the catalyst for C5 / C6 alkane isomerization described in this example is:

[0046] Calcinate the Hβ molecular sieve at 500°C for 4h, then mix 1 weight part of alumina powder with 3 weight parts of the roasted Hβ molecular sieve, add 0.2 weight part of nickel boride, mix well and extrude into a rod, 50°C After drying, it was ground into particles with a particle size of 0.45 mm, and then the particles were dried at 200° C. under a nitrogen atmosphere for 2 hours to prepare catalyst A1.

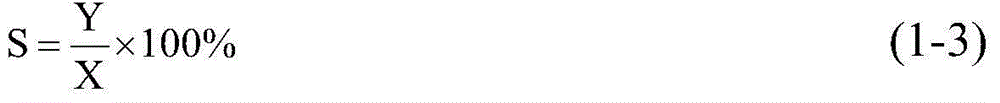

[0047] The catalyst A1 prepared in this example was prepared at a reaction temperature of 230°C; a reaction pressure of 2.0 MPa; a hydrogen-oil molar ratio of 4.0, and a mass ...

Embodiment 2

[0049] The catalyst for C5 / C6 alkane isomerization described in this example comprises a carrier and nickel boride accounting for 1 wt% of the carrier weight, wherein the carrier is composed of alumina and Hβ molecular sieve, and the alumina The weight ratio to Hβ molecular sieve is 1:9.

[0050] The preparation method of the catalyst for C5 / C6 alkane isomerization described in this example is:

[0051] Calcinate the Hβ molecular sieve at 500°C for 4 hours, then mix 1 weight part of alumina powder with 9 weight parts of the roasted Hβ molecular sieve, add 0.1 weight part of nickel boride, mix evenly and extrude into strips, 50°C After drying, it was ground into particles with a particle size of 0.45 mm, and then the particles were dried at 200° C. under a nitrogen atmosphere for 2 hours to prepare catalyst A2.

[0052] The catalyst A2 prepared in this example was prepared at a reaction temperature of 230°C; a reaction pressure of 2.0MPa; a hydrogen-oil molar ratio of 4.0, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com