Method for extracting, reducing and desulfurizing fuel oil in deep eutectic solvent

A deep eutectic solvent and fuel oil technology, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrogenation process, etc., to achieve the effect of improving efficiency, small particle size and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

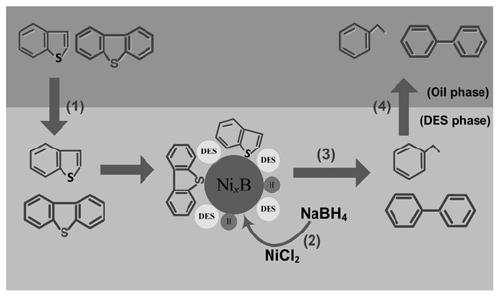

Problems solved by technology

Method used

Image

Examples

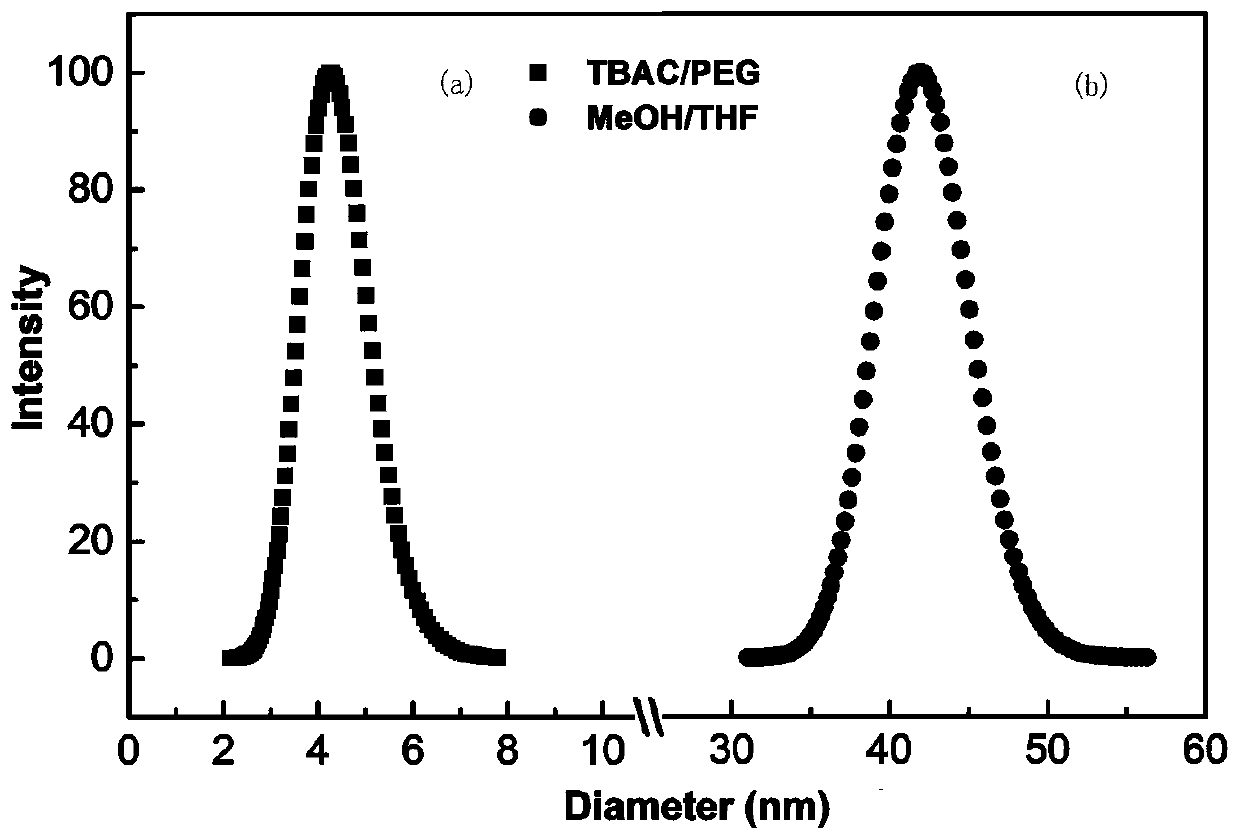

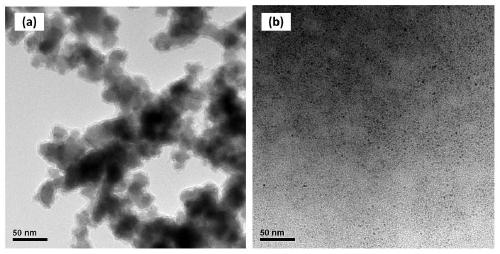

Embodiment 1

[0029] The deep eutectic solvent was synthesized with tetrabutylammonium chloride as the hydrogen bond acceptor and polyethylene glycol as the hydrogen bond donor in a molar ratio of 1:2. Fuel oil, deep eutectic solvent, NaBH 4 After mixing in proportion, add it to the reactor, wherein the volume ratio of deep eutectic solvent to fuel oil is 1.5:1, NaBH 4 The molar ratio of the fuel to the sulfur in the fuel is 12:1; then, slowly mix the NiCl 2 ·6H 2 O is added to the reactor for desulfurization reaction, the added NiCl 2 ·6H 2 The molar ratio of O to sulfur in the fuel oil was 3:1; after reacting for 60 minutes, the mixture in the reactor was separated, and the upper oil phase was taken to measure the sulfur content, and the desulfurization rate of the fuel oil was calculated to be 97.3%.

Embodiment 2

[0031] A deep eutectic solvent was synthesized with tetrabutylammonium chloride as the hydrogen bond acceptor and ethylene glycol as the hydrogen bond donor at a molar ratio of 1:2. Fuel oil, deep eutectic solvent, NaBH 4 After mixing in proportion, add it to the reactor, wherein the volume ratio of deep eutectic solvent to fuel oil is 1.5:1, NaBH 4 The molar ratio of the fuel to the sulfur in the fuel is 12:1; then, slowly mix the NiCl 2 ·6H 2 O is added to the reactor for desulfurization reaction, the added NiCl 2 ·6H 2 The molar ratio of O to sulfur in the fuel oil was 3:1; after reacting for 60 minutes, the mixture in the reactor was separated, and the upper oil phase was taken to measure the sulfur content, and the desulfurization rate of the fuel oil was calculated to be 95.2%.

Embodiment 3

[0033] A deep eutectic solvent was synthesized with tetrabutylammonium chloride as the hydrogen bond acceptor and glycerol as the hydrogen bond donor at a molar ratio of 1:2. Fuel oil, deep eutectic solvent, NaBH 4 After mixing in proportion, add it to the reactor, wherein the volume ratio of deep eutectic solvent to fuel oil is 1.5:1, NaBH 4 The molar ratio of the fuel to the sulfur in the fuel is 12:1; then, slowly mix the NiCl 2 ·6H 2 O is added to the reactor for desulfurization reaction, the added NiCl 2 ·6H 2 The molar ratio of O to sulfur in the fuel oil was 3:1; after reacting for 60 minutes, the mixture in the reactor was separated, and the upper oil phase was taken to measure the sulfur content, and the desulfurization rate of the fuel oil was calculated to be 90.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com