Preparation method of modified polyacrylonitrile film

A polyacrylonitrile membrane and polyacrylonitrile technology, applied in the field of membrane materials, can solve problems such as difficult degradation, less obvious hydrophilic effect, environmental hazards, etc., and achieve low processing cost, good hydrophilic effect improvement, and environmental friendliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] The preparation method (abbreviation preparation method) of the modified polyacrylonitrile film (abbreviation modified film) of the present invention's design, comprises following processing steps:

[0013] 1. Prepare the hydrophilic material solution: first cut the hydrophilic material or fiber into a length of 2-10mm, preferably 3-8mm, then add it to the co-solvent and stir to dissolve it. After the dissolution is complete, you can get Hydrophilic material solution; the hydrophilic material refers to a polymer with carboxyl, amino or hydroxyl groups in the main chain or side chain, including at least one of mulberry silk fibroin, tussah silk fibroin or spider silk fibroin The silk fibroin is a long-bond macromolecule composed of a variety of α-amino acid residues linked by amide bonds, also known as a peptide chain, and its hydrolyzed products mainly include glycine, alanine, phenylalanine and glutamine Acid; said co-solvent refers to the common solvent of film-formin...

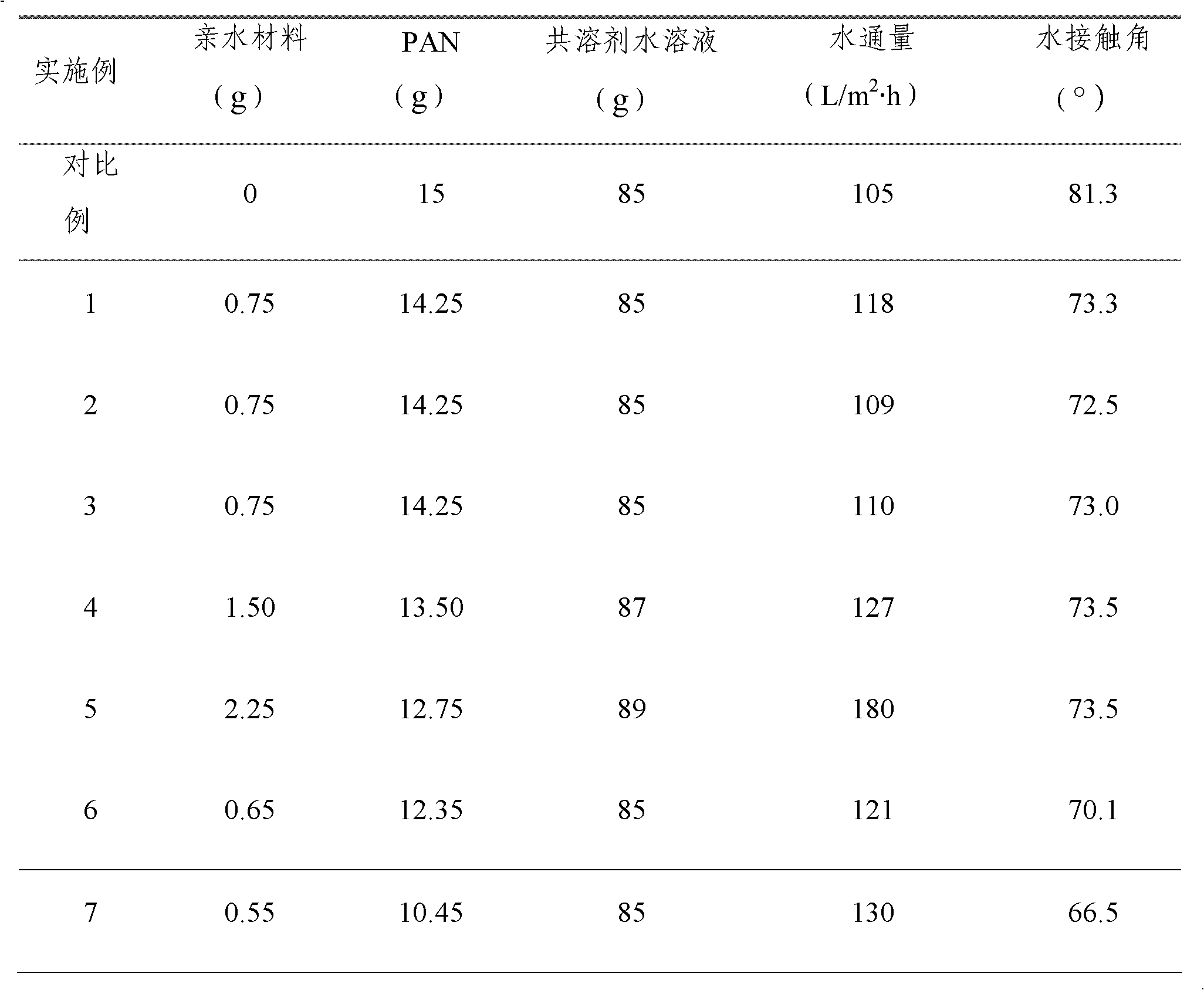

Embodiment 1

[0024] (1) Preparation of hydrophilic material solution (the same below): Add 0.75 g of silk fibroin short fibers, a hydrophilic material with a length of 3-8 mm, to 85.00 g of a NaSCN aqueous solution with a concentration of 55% by mass, and heat at 80° C. Dissolve for 0.5 h to obtain a hydrophilic material solution with a mass concentration of 0.9%.

[0025] (2) Preparation of the blend solution (the same below): add 14.25g of PAN powder to the hydrophilic material solution, stir at 70°C for 2.5h, vacuum insulate at -0.08MPa, 70°C, and statically defoam for 20h to obtain hydrophilic A blend solution in which the material accounts for the total mass percentage of the blend with a concentration of 5%.

[0026] (3) Scraping film and post-treatment (the same below): Under the conditions of 25±2°C and 70% humidity, use the L-S phase inversion method to scrape the film on the glass plate, and then immerse the glass plate and the film on it into the distilled water coagulation bath...

Embodiment 2

[0028] (1) Add 0.75 g of mulberry silk fibroin short fibers with a length of 3-8 mm to 85.00 g of NaSCN aqueous solution with a mass percentage concentration of 50%, and dissolve it for 1.0 h at 70°C to obtain a hydrophilic material with a mass concentration of 0.9% solution.

[0029] (2) Add 14.25g of PAN powder to the hydrophilic material solution, stir at 60°C for 3.0h, vacuum insulate at -0.05MPa, 60°C, and stand for 25h of defoaming to obtain the concentration of the hydrophilic material in the total mass percentage of the blend 5% blend.

[0030] (3) Under the conditions of 25±2°C and 70% humidity, use the L-S phase inversion method to scrape the film on the glass plate, then immerse the glass plate and the film on the glass plate and the film on the glass plate with a mass concentration of 50% in ethanol aqueous solution, and wait for it to naturally Take it out after peeling off, and soak it in 50% ethanol aqueous solution for 24 hours to obtain the modified membrane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com