Method for preparing cyclohexanol and cyclohexanone by virtue of electrochemically catalytic oxidation of cyclohexane

A technology of catalytic oxidation and cyclohexane, which is applied in the direction of electrolysis process, electrolysis components, electrolysis organic production, etc., can solve the problems of separation of reactants and products, high energy consumption, hindering new reactions, etc., to achieve high efficiency and high selectivity, The process is simple and the effect of promoting high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

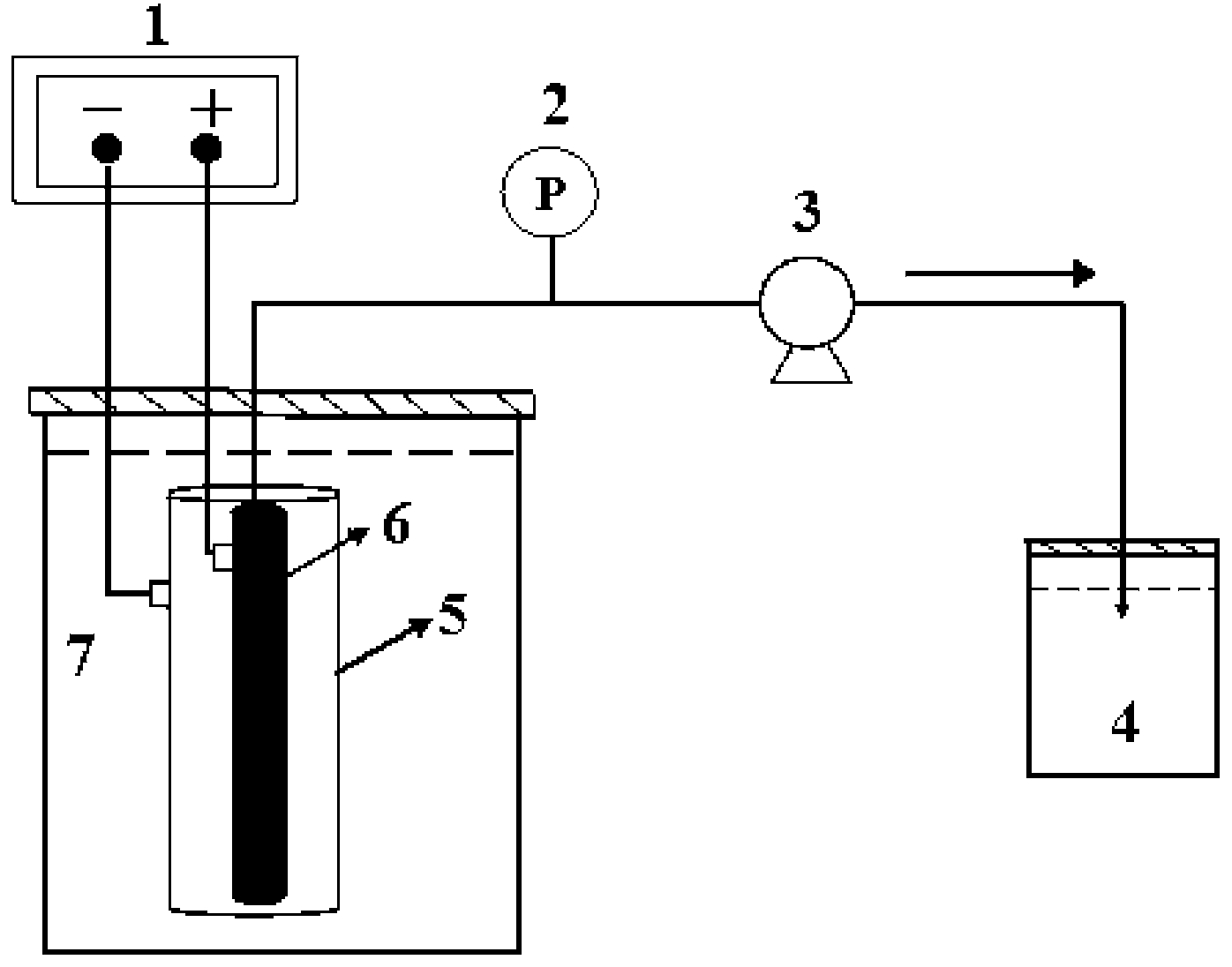

[0055] The porous titanium-based electrocatalytic membrane loaded with titanium dioxide is used as the anode, and the auxiliary electrode is used as the cathode to form an electrocatalytic membrane reactor;

[0056] The reaction raw material solution is prepared by the following method: the acetic acid solution of cyclohexane is placed in a membrane reactor, and an aqueous electrolyte solution (NaCl solution) is added thereto to obtain a completely miscible homogeneous transparent solution, wherein, in the reaction raw material solution, cyclohexane The volume ratio of alkane to acetic acid is 1:0.5, the concentration of electrolyte NaCl is 5.0g / L, and the concentration of cyclohexane is 0.1mol / L;

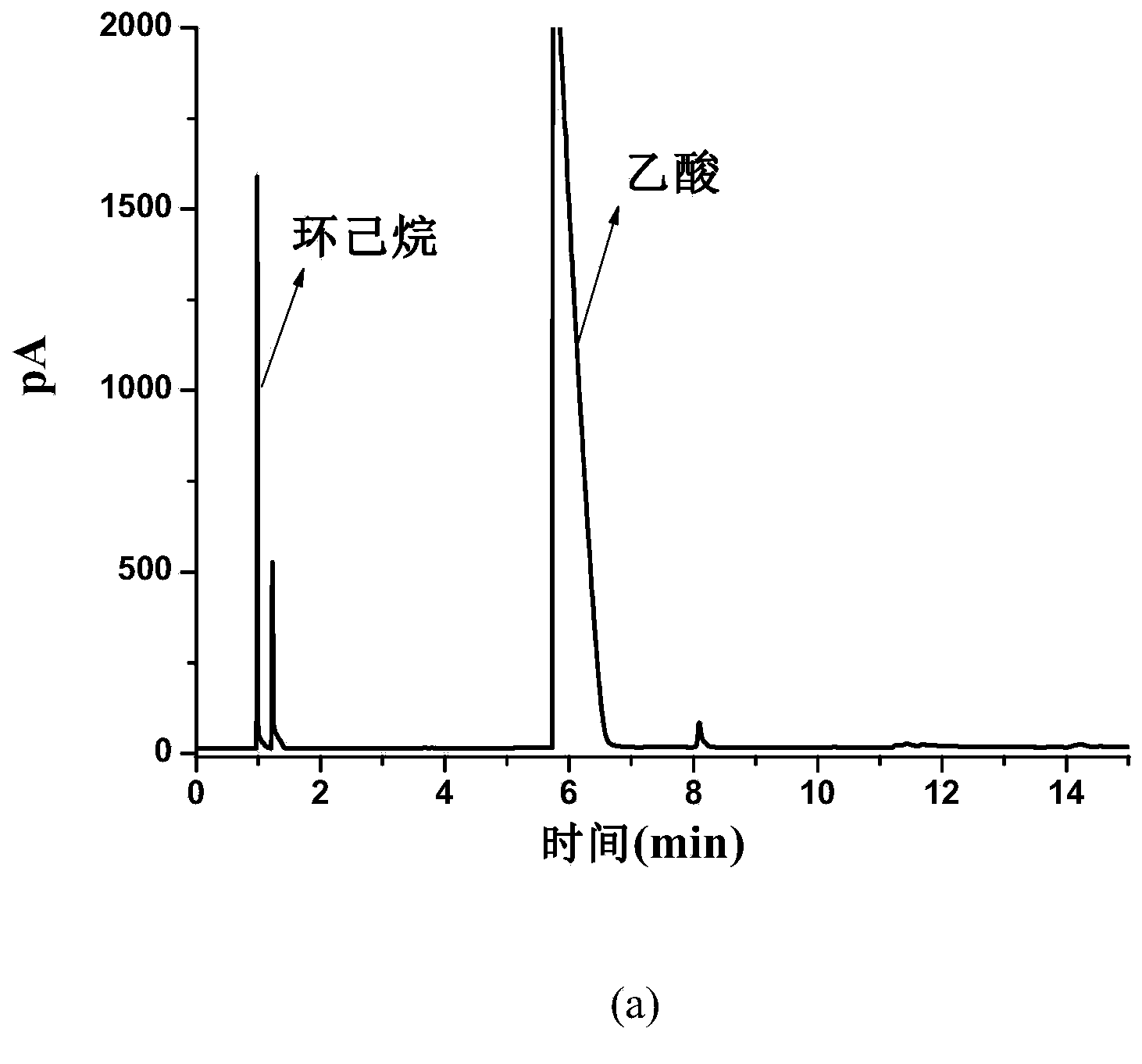

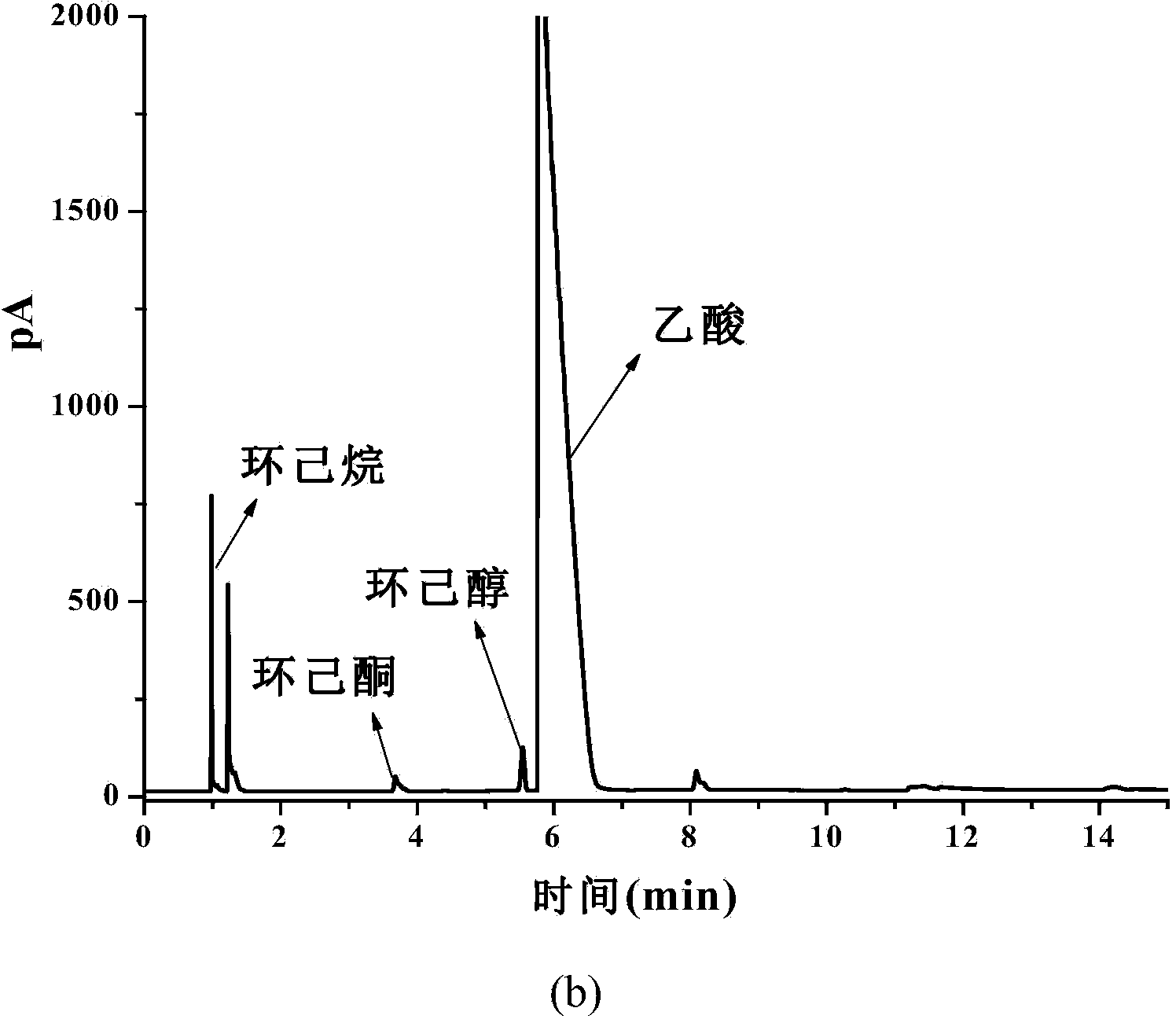

[0057] Under normal temperature and pressure, the working voltage is 3.0V, and the current density is 1.0mA / cm 2 Under certain conditions, the porous titanium-based electrocatalytic membrane loaded with titanium dioxide is used to catalyze the oxidation of cyclohexane to synthesize...

Embodiment 2

[0060] The porous titanium-based electrocatalytic membrane loaded with manganese oxide is used as the anode, and the auxiliary electrode is used as the cathode to form an electrocatalytic membrane reactor;

[0061] The reaction raw material solution is prepared by the following method: the propionic acid solution of cyclohexane is placed in a membrane reactor, and the aqueous solution (NaOH solution) of electrolyte is added thereto to obtain a completely miscible homogeneous transparent solution, wherein, in the reaction raw material solution, cyclohexane The volume ratio of hexane to propionic acid is 1:5, the concentration of electrolyte NaOH is 2.0g / L, and the concentration of cyclohexane is 0.05mol / L;

[0062] Under normal temperature and pressure, the working voltage is 4.0V, and the current density is 2.0mA / cm 2 Under certain conditions, the porous titanium-based electrocatalytic membrane loaded with manganese oxide is used to catalyze the oxidation of cyclohexane to syn...

Embodiment 3

[0065] The porous nickel-based electrocatalytic membrane loaded with vanadium oxide is used as the anode, and the auxiliary electrode is used as the cathode to form an electrocatalytic membrane reactor;

[0066] The reaction raw material solution is prepared by the following method: the acetonitrile solution of cyclohexane is placed in a membrane reactor, and the aqueous solution of the electrolyte (NaNO 3 solution) to obtain a completely miscible homogeneous transparent solution, wherein, in the reaction raw material solution, the volume ratio of cyclohexane to acetonitrile is 1:1, and the electrolyte NaNO 3 The concentration of cyclohexane is 15.0g / L, and the concentration of cyclohexane is 1.0mol / L;

[0067] Under normal pressure, the reaction temperature is 10°C, the working voltage is 4.0V, and the current density is 3.0mA / cm 2 Under the conditions, the porous nickel-based electrocatalytic membrane loaded with vanadium oxide catalyzes the oxidation of cyclohexane to synt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com