Novel electro-catalytic composite membrane material and preparation method thereof

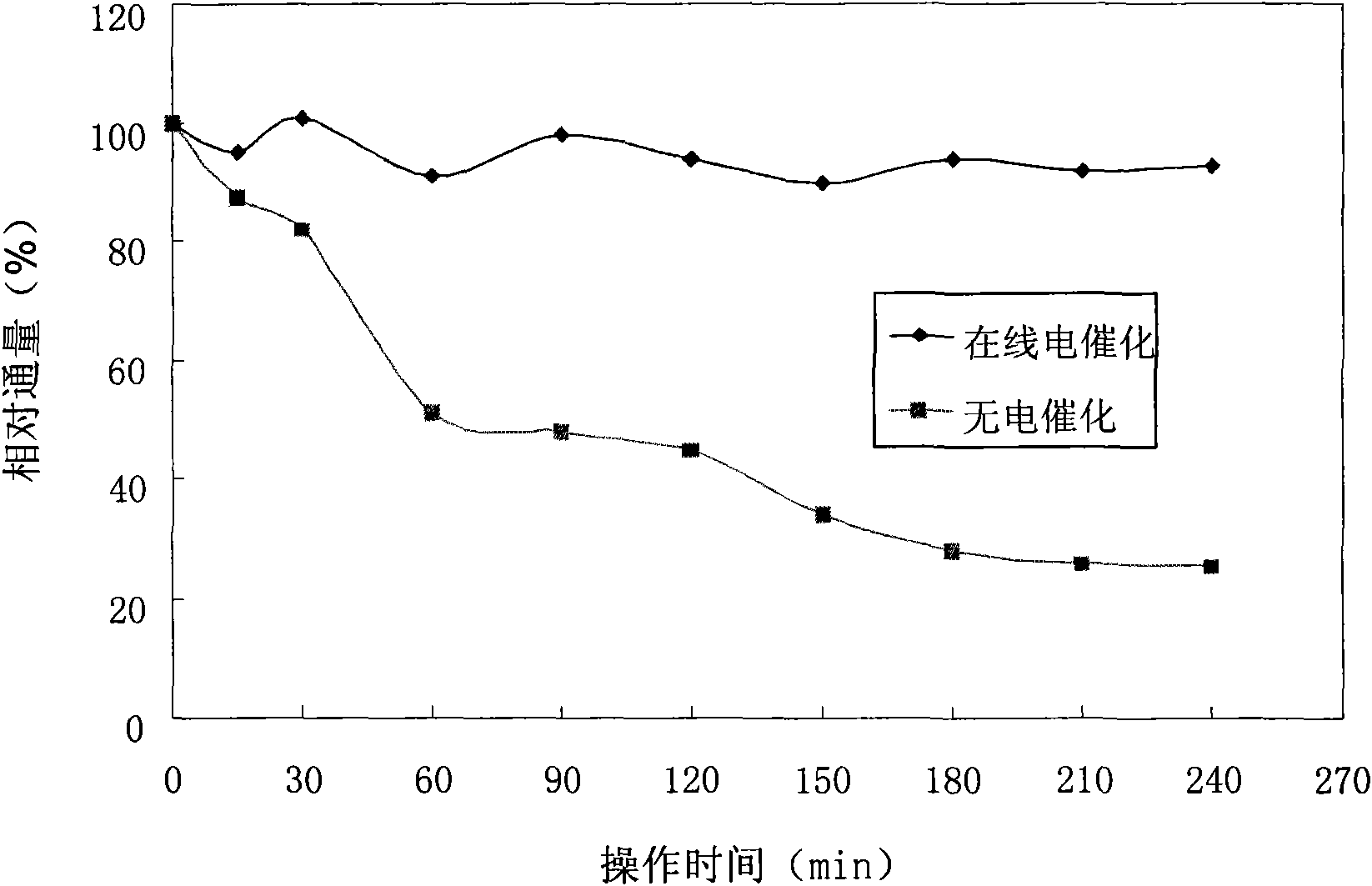

An electrocatalysis and composite membrane technology, applied in chemical instruments and methods, electrochemical water/sewage treatment, membrane technology, etc., can solve the problems of high energy consumption, limit the application of electrochemical technology, and high processing costs, and achieve low energy consumption. , strong anti-pollution, high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, a carbon film with an average pore diameter of 0.4 microns is used as the substrate, and Pt / SiO 2 For the catalyst coating, the electrocatalytic composite carbon membrane was prepared by the sol-gel method.

[0028] (1) Pretreatment of the carbon membrane: place the carbon membrane in an ethanol solution and ultrasonically clean it for 30 minutes, and then wash it with 65% HNO 3 Pretreatment for 10 hours, washed with water, and dried in an oven at 120°C;

[0029] (2)Pt / SiO 2 Preparation of the sol: Mix ethyl orthosilicate, absolute ethanol, distilled water and acetylacetone uniformly according to a certain molar ratio, then add hydrochloric acid to adjust the pH to about 2, and then vigorously stir in a water bath at 40°C for 2 hours. Use a pipette to measure a certain concentration of water, catalyst, hydrolysis inhibitor, and then add H 2 PtCl 6 , Stir until completely dissolved, and slowly drop this solution into the above-mentioned Si-contain...

Embodiment 2

[0033] The original film material and pretreatment process used in this embodiment are the same as in Embodiment 1.

[0034] TiO 2 Preparation of sol: Prepare sol with butyl titanate, absolute ethanol, distilled water, nitric acid, and acetylacetone according to a certain molar ratio, stir vigorously for 2 hours, age at room temperature for 24 hours, and set aside.

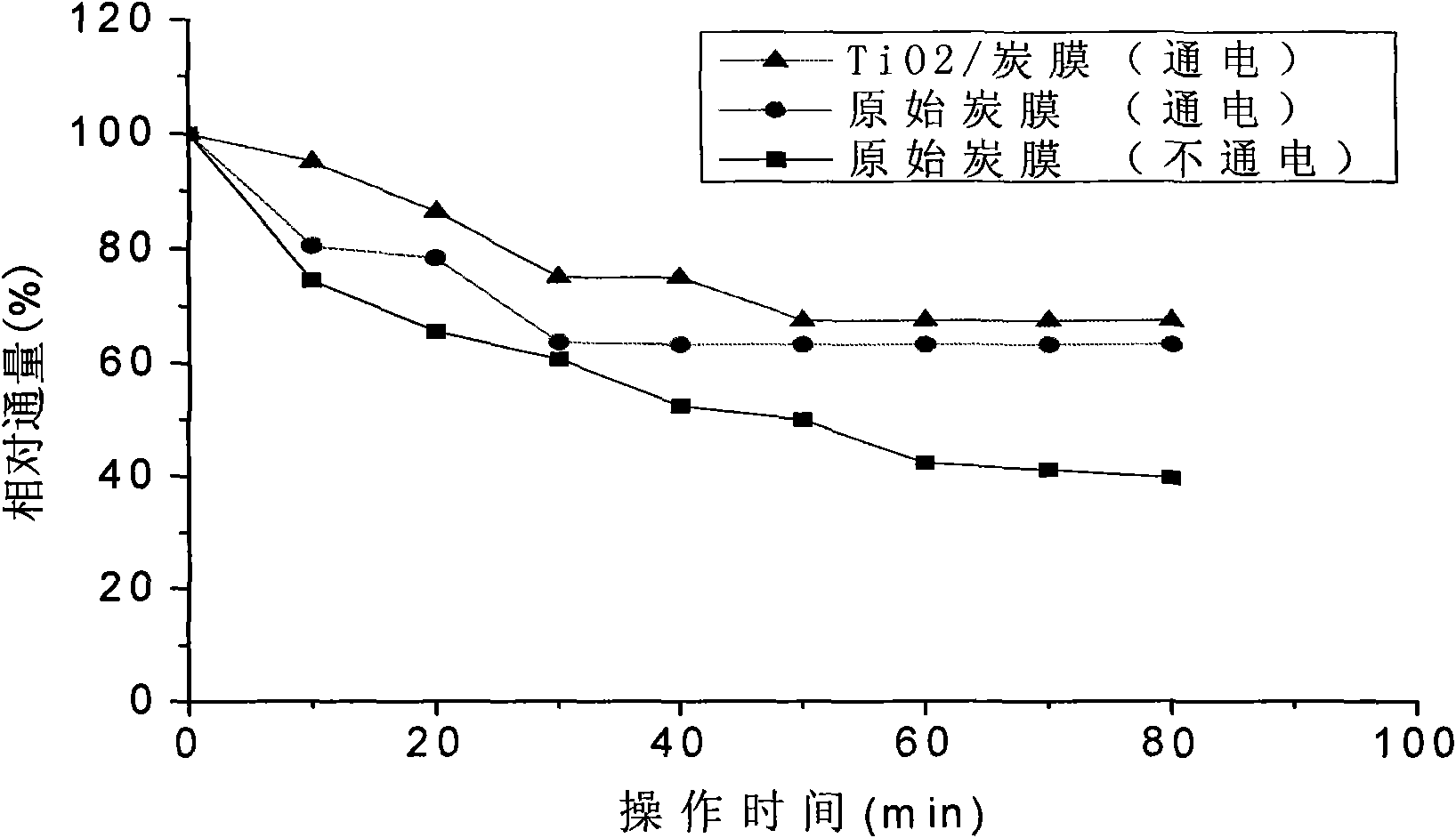

[0035] Preparation of composite carbon membrane: Soak the carbon membrane substrate in TiO 2 In the sol, after standing for 30s, the substrate was pulled out of the sol at a pulling speed of 3mm / s, and dried at room temperature; then the carbon film was subjected to post-heat treatment: in the muffle furnace, 1 The heating rate of ℃ / min is raised to 100 ℃, and the temperature is kept for 0.5h, and then the temperature is raised to the predetermined heat treatment temperature of 400 ℃ at a heating rate of 5 ℃ / min. 2 Coated electrocatalytic composite carbon membrane.

[0036] Take the original carbon membrane of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com