Preparation method of hollow carbon bowl powder

A hollow bowl, carbon material technology, applied in the preparation/purification of carbon, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of raw materials polluting the environment, destroying materials, and complex preparation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

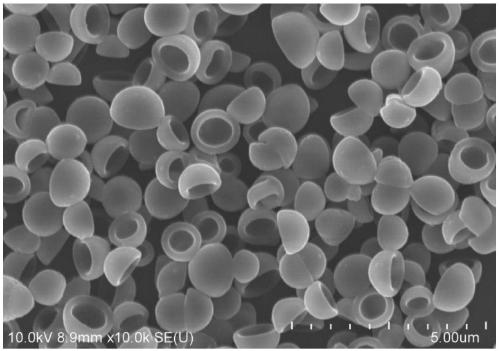

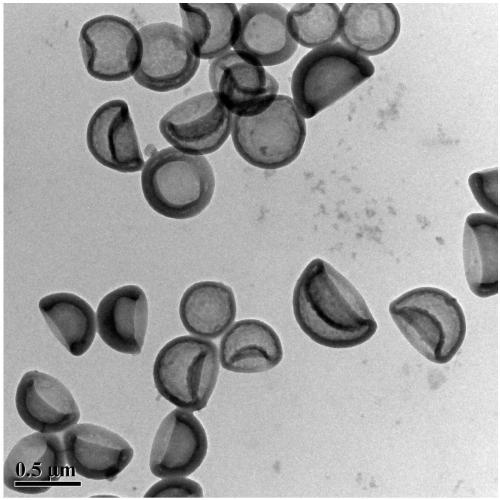

Image

Examples

Embodiment 1

[0017] Mix 20 milliliters of deionized aqueous solution containing 3 grams of rotten apple juice, 5 milliliters of sodium oleate solution (10 mmol / L) and 5 milliliters of P123 solution (1 mmol / L), and stir until uniformly mixed, and the mixed transparent liquid Put it into a 50 ml polytetrafluoroethylene-lined stainless steel water heating tank, tighten the lid, put the water heating tank in an oven at 150°C, keep it warm for 10 hours, take the water heating tank out of the oven, and cool it in the air until room temperature, then open the water-heated jar, pour out the mixture inside, and centrifuge in a centrifuge at 8000 rpm to obtain a precipitate, which is then repeatedly washed with water and ethanol to obtain a hollow carbon bowl.

Embodiment 2

[0019] 20 milliliters of deionized aqueous solution containing 5 grams of grape juice, 10 milliliters of sodium dodecylbenzene sulfonate solution (10mmol / L) and 10 milliliters of F127 solution (1mmol / L) are mixed, and stir until mixing evenly, will Put the mixed transparent liquid into an 80ml polytetrafluoroethylene-lined stainless steel water heating tank. After tightening the lid, put the water heating tank in an oven at 130°C. After 20 hours of heat preservation, take the water heating tank out of the oven and place Cool to room temperature in the air, then open the water heat tank, pour out the mixture inside, and centrifuge in a centrifuge at 8000 rpm to obtain a precipitate, then repeatedly wash with water and ethanol to obtain a hollow carbon bowl.

Embodiment 3

[0021] 20 milliliters of deionized water containing 3 grams of sugarcane juice, 20 milliliters of sodium stearate solution (10mmol / L) and 20 milliliters of Tween 40 solution (1mmol / L) were mixed, and stirred until uniformly mixed, the mixed Put the transparent liquid into an 80ml polytetrafluoroethylene-lined stainless steel water heating tank. After tightening the lid, put the water heating tank in an oven at 120°C. After keeping it warm for 48 hours, take the water heating tank out of the oven and place it in the air Cool to room temperature, then open the hydrothermal jar, pour out the mixture inside, and centrifuge in a centrifuge at 8000 rpm to obtain a precipitate, then repeatedly wash with water and ethanol to obtain a hollow carbon bowl.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com