Plug of wiring terminal

A terminal and hosel technology, which is applied in the field of wire terminal hosels, can solve the problems of low raw material utilization, low production efficiency, and many processing procedures, and achieve high raw material utilization, high production efficiency, and simple processing procedures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

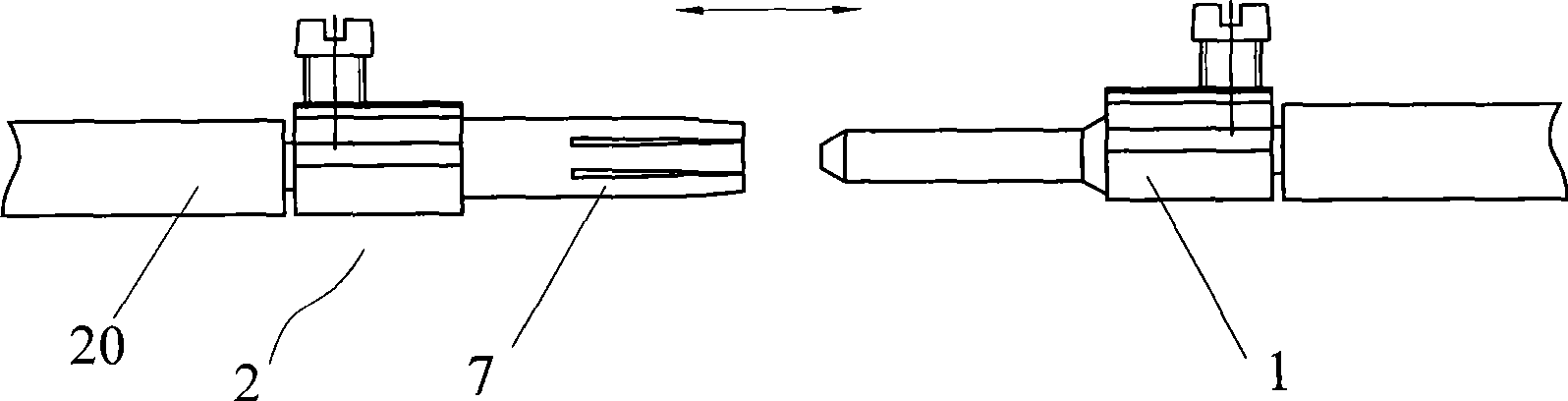

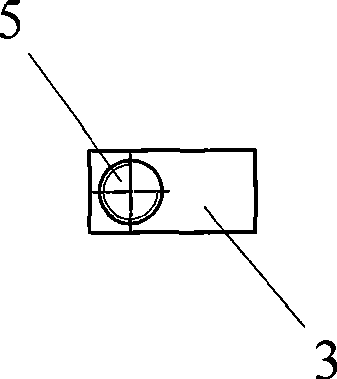

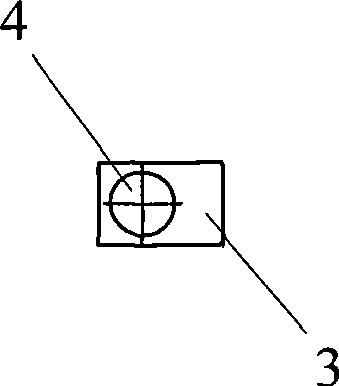

[0018] refer to figure 2 , image 3 , Figure 4 , a hosel for wire terminals. The hosel is fixed by a sheath block 3 and a sheath body 6. For example, the fixed connection method of the sheath block 3 and the sheath clip 8 is spot welding, which is convenient for the sheath block 3 and the sheath The body 6 is processed separately; the sheath block 3 is a one-piece body with an electric wire installation hole 4 and a screw hole 5 for fixing the electric wire on it, for installing and fixing the electric wire 20; the sheath body 6 includes a sheath clip 8 and a sheath tube 7, The sheath tube 7 is used to cooperate with the plug 1 of the terminal; the sheath body 6 is fixedly connected with the sheath block 3 through the sheath clip 8 to form a hosel.

[0019] refer to Figure 4 , Figure 5 , the sheath body 6 is stamped from a metal sheet; refer to Figure 6 , Figure 7 , can also be obtained by cutting one end of the pipe and flattening it into a sheath clamp 8; refer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com