Method for preparing rare-earth transition metal composite oxide porous hollow spheres

A composite oxide, transition metal technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, cobalt oxide/cobalt hydroxide, etc., can solve the problem of limited types of MOF materials, high price, synthesis The problems of complex and limited process, to achieve the effect of low cost of raw materials, low cost of raw materials, and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

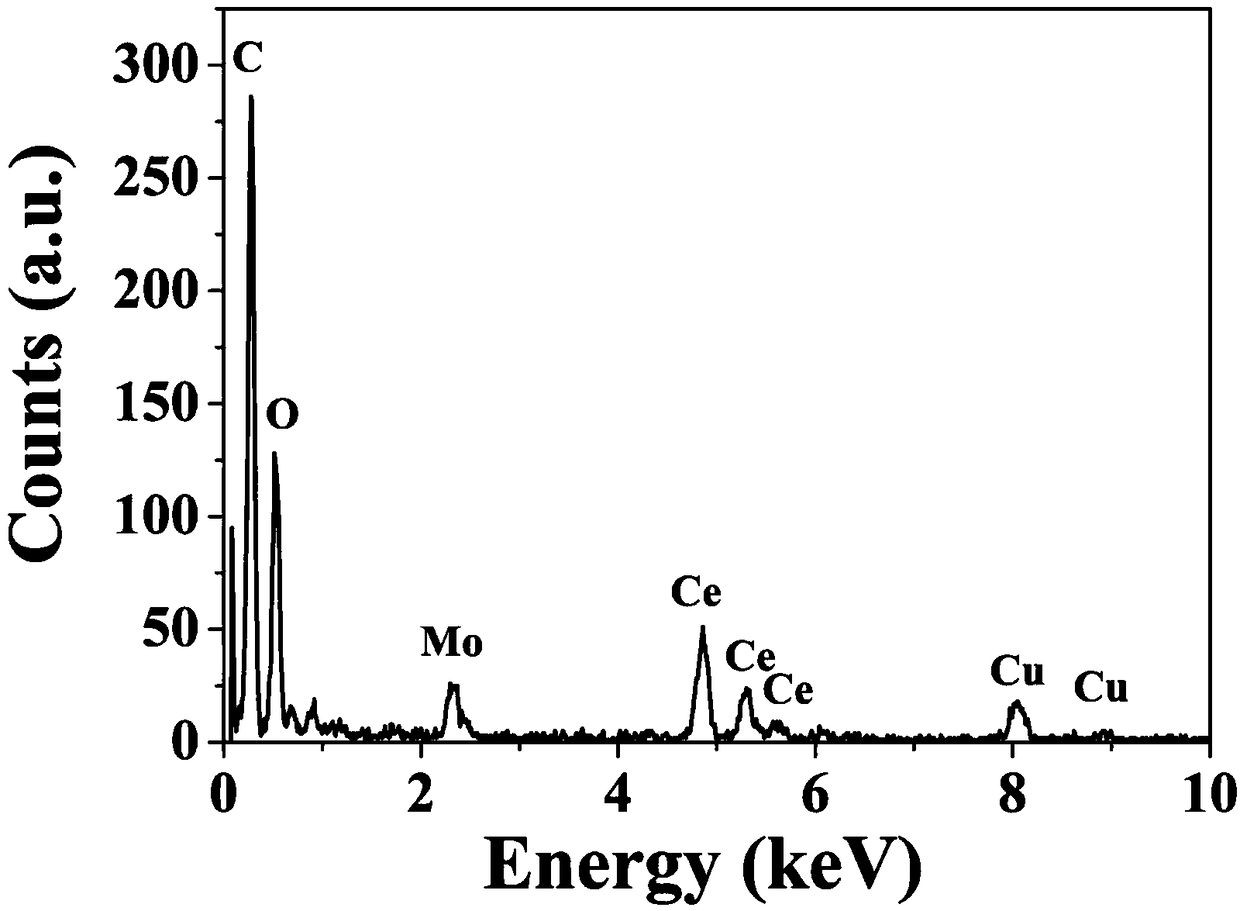

[0039](1) According to the molar concentration of total metal ions of 12mmol / L, wherein the molar ratio of Cu:Ce is 3:17, respectively weigh 0.157g of copper nitrate trihydrate and 1.594g of cerium nitrate hexahydrate, fully dissolve in 360mL of isopropanol and Mixed solution of glycerol (glycerol: isopropanol volume ratio 1:3), transferred to a reaction kettle, reacted at 180°C for 16h, cooled naturally to room temperature, centrifuged, washed with ethanol, and dried in vacuum to obtain Copper cerium metal alkoxide solid pellets;

[0040] (2) Put the porcelain boat with the above-mentioned alkoxide precursor in a muffle furnace, heat treatment in the air atmosphere, set the heating rate to 3°C / min, program the temperature to 450°C, and keep it for 2h to synthesize copper-cerium composite metal oxide Hollow ball;

[0041] The transmission electron microscope TEM picture ( figure 1 ) shows that the composite oxide is a hollow spherical structure with a diameter of about 600nm...

Embodiment 2

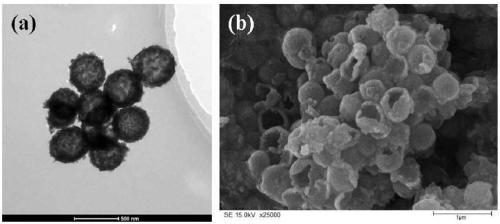

[0045] (1) According to the molar concentration of total metal ions of 10mmol / L, wherein the molar ratio of Mn:Co:Ce is 1:1:4, respectively weigh 0.151g of manganese nitrate tetrahydrate, 0.175g of cobalt nitrate hexahydrate and cerium nitrate hexahydrate 1.042g, fully dissolved in 360mL of a mixed solution of isopropanol and glycerol (glycerol: isopropanol volume ratio 1:5), transferred to a reaction kettle, reacted at 180°C for 10h, cooled naturally to room temperature , centrifuged, washed with acetone, and vacuum-dried to obtain solid pellets of cerium cobalt manganese alkoxide.

[0046] (2) Put the porcelain boat with the above-mentioned alkoxide precursor in a muffle furnace, heat treatment in an air atmosphere, set the heating rate at 5°C / min, program the temperature to 300°C, and keep it for 4h to synthesize cerium-cobalt-manganese composite metal oxide hollow spheres.

[0047] The transmission electron microscope TEM picture ( image 3 a) shows that the composite ox...

Embodiment 3

[0050] (1) According to the molar concentration of total metal ions of 8mmol / L, wherein the molar ratio of Zn:Co:Ce is 2:2:3, weigh 0.244g of zinc nitrate hexahydrate, 0.239g of cobalt nitrate hexahydrate and 0.536g of cerium nitrate hexahydrate g, fully dissolved in 360 mL of a mixed solution of isopropanol and glycerol (glycerol: isopropanol volume ratio 1:7), transferred to a reaction kettle, reacted at 190°C for 6 hours, cooled naturally to room temperature, Centrifuge, wash with ethanol, and vacuum dry to obtain solid pellets of cerium-cobalt-zinc metal alkoxide.

[0051] (2) Put the porcelain boat with the above-mentioned alkoxide precursor in a muffle furnace, heat-treat in an air atmosphere, set the heating rate at 10°C / min, program the temperature to 500°C, and keep it for 1h to synthesize cerium-cobalt-zinc composite metal oxide hollow spheres.

[0052] The transmission electron microscope TEM picture ( Figure 5 ) shows that the composite oxide is a hollow spheric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com