Submicron narrow particle size distribution type tungsten powder and tungsten carbide powder and preparation method thereof

A narrow particle size distribution, tungsten carbide powder technology, applied in the direction of tungsten/molybdenum carbide, carbide, etc., can solve the practical application of hard alloy preparation, difficult to measure and control and stable safe production, tungsten carbide powder production process Many problems, to achieve the effect of high production efficiency, low carbon residual content and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

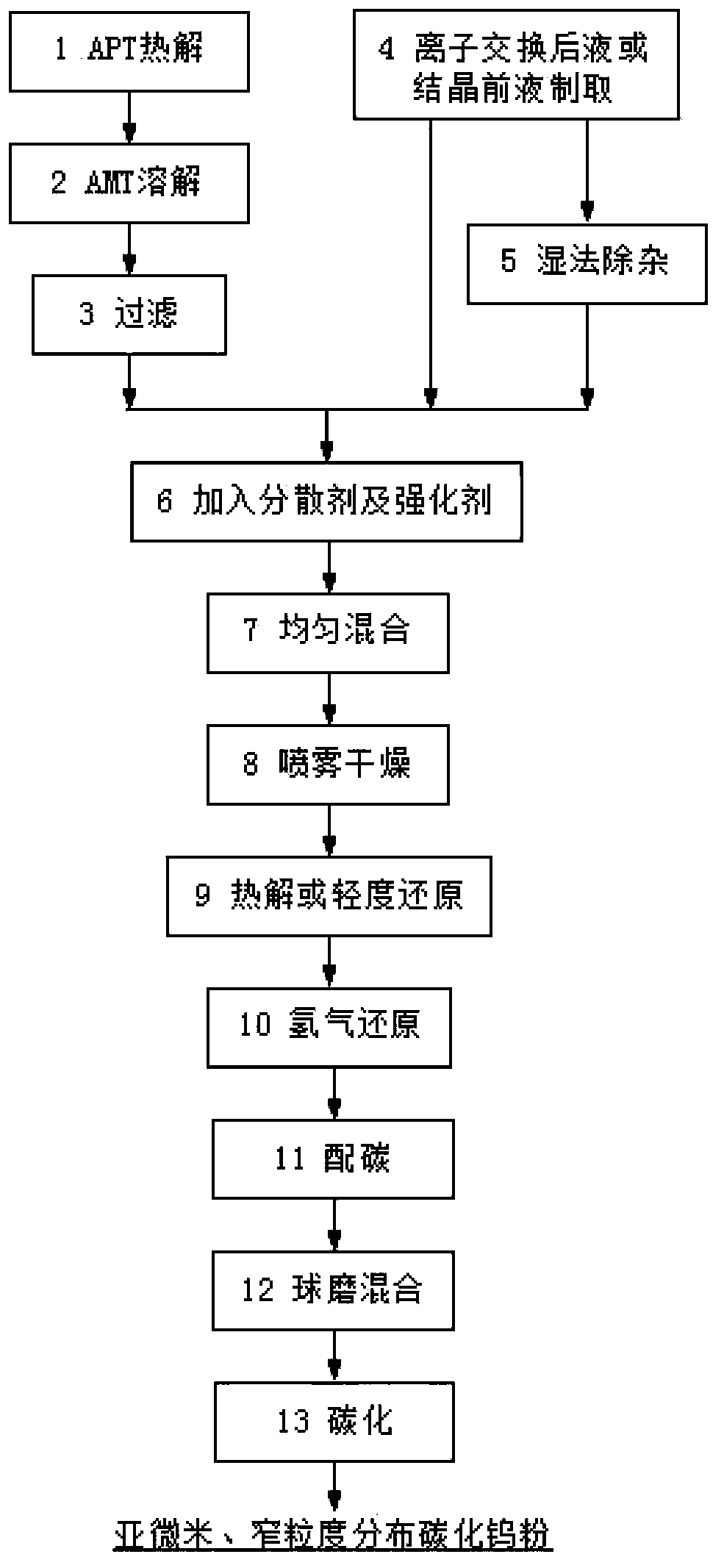

[0037] The technical process of the submicron narrow particle size distribution tungsten powder and tungsten carbide powder preparation method of the present invention is as follows figure 1 As shown, it includes the following steps: 1APT pyrolysis; 2AMT dissolution; 3 filtration; 4 preparation of liquid after ion exchange or liquid before crystallization; Drying; 9 pyrolysis or mild reduction; 10 hydrogen reduction; 11 carbon matching; 12 ball milling;

[0038] The specific steps of the preparation method of submicron narrow particle size distribution tungsten powder and tungsten carbide powder of the present invention include:

[0039] (1) Solution preparation: Use commercially available ammonium paratungstate (APT) as raw material, and conduct static pyrolysis in a muffle furnace or dynamic pyrolysis in a rotary furnace at 270-350°C for 1-3 hours to obtain amorphous ammonium metatungstate (AMT) ) as the main dissociated material, the weight loss rate is controlled at 7~8%;...

Embodiment 1

[0046] Accurately weigh 5,000 grams of ammonium paratungstate (APT-0), and pyrolyze it in a muffle furnace at 310°C for 1.5 hours to obtain 4,625 grams of dissociated material of amorphous ammonium metatungstate (AMT), with a weight loss rate of 7.5%; L of ammonia solution was stirred and dissolved for 2 hours, filtered after standing for 30 minutes, and diluted with deionized water to obtain a specific gravity of 1.20g / cm 3 12.5L of ammonium tungstate solution; at the same time, 625ml of ammonium polyacrylate aqueous solution and 62.5ml of acetone with a concentration of 10% by weight were added, and stirred for 10min to mix evenly; the GZ-5 high-speed centrifugal spray drying equipment with titanium lining on the inner wall of the tower was used for the above dispersion The treated ammonium tungstate solution is subjected to rapid crystallization and drying, the inlet air temperature is 350°C, the outlet air temperature is 150°C, the feed rate is 2.5L / h, and the rotational sp...

Embodiment 2

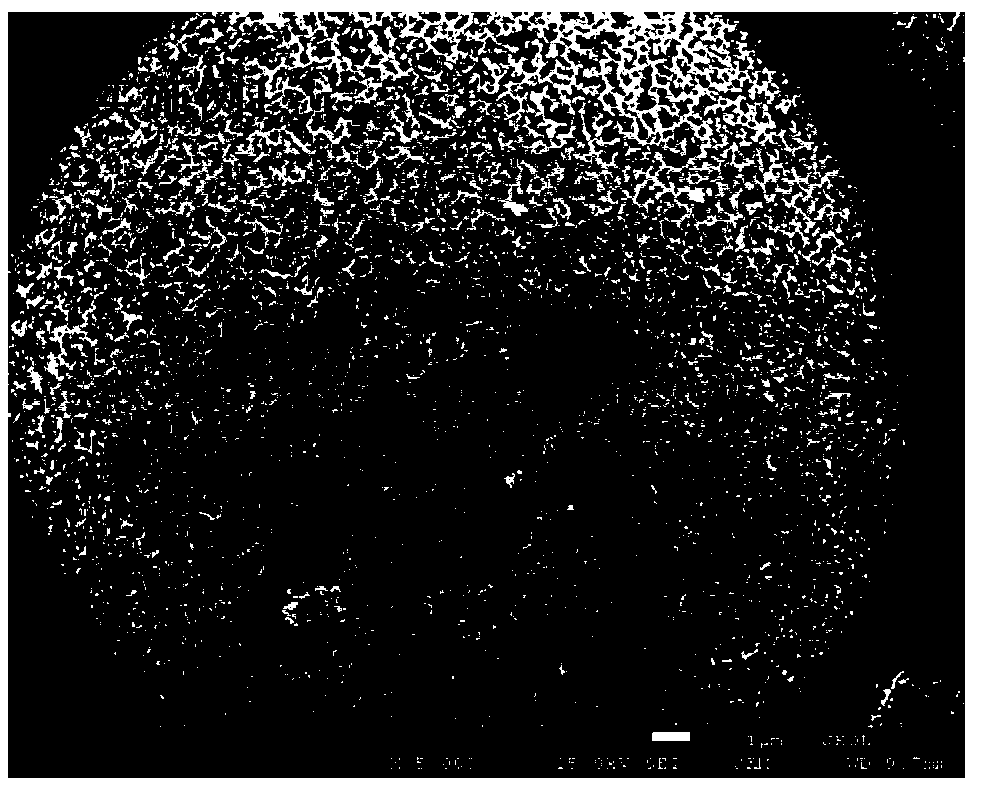

[0048] Perform secondary ion exchange and wet removal of molybdenum on the ion-exchanged liquid on the APT production line, and concentrate until the specific gravity of the solution is 1.40g / cm 3 ;According to the ratio of 10% and 10‰ of the volume of ammonium tungstate solution, respectively add polyethylene glycol aqueous solution and n-butanol with a concentration of 10% by weight, and stir for 30 minutes to mix evenly; adopt the GZ-50 type whose inner wall is lined with polytetrafluoroethylene The high-speed centrifugal spray drying equipment performs rapid crystallization and drying on the ammonium tungstate solution after the above-mentioned dispersion treatment. The inlet air temperature is 300°C, the outlet air temperature is 100°C, the feed rate is 20L / h, and the rotational speed of the centrifugal disc is 15,000 rpm. ~50μm, hollow thin-walled spherical ammonium tungstate crystals with a wall thickness of 2.0~5.0μm, the particle morphology is as follows Figure 3-a S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com