Method of preparing linoleate isomerase micro-capsules on the basis of polyelectrolyte layer-by-layer self-assembly technology

A technology of linoleic acid isomerase and layer-by-layer self-assembly, which is applied in the same direction fixed on/in the organic carrier to achieve the effect of controllable wall thickness and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

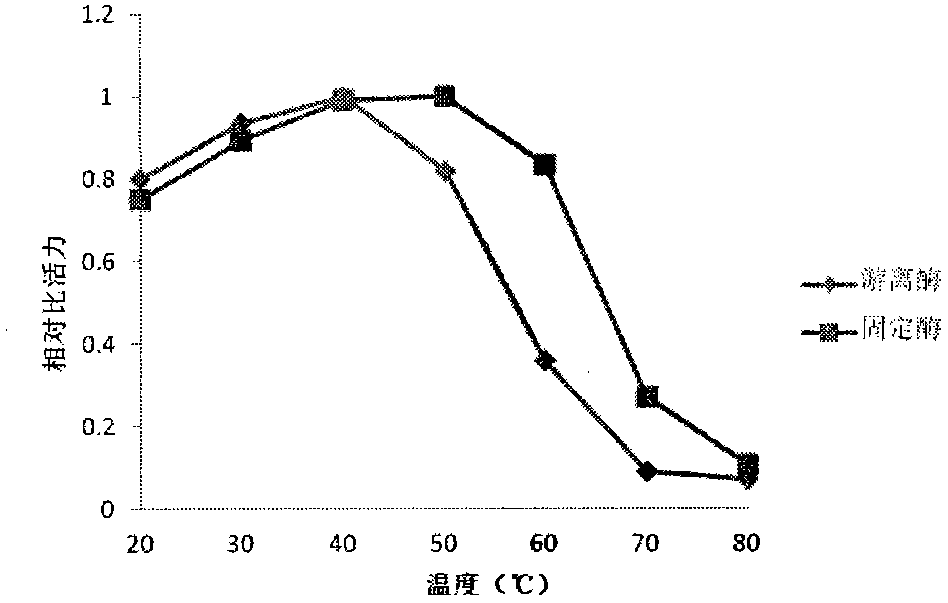

[0027] Example 1: Effect of temperature on enzymatic reactions

[0028] The linoleic acid isomerase microcapsules and free linoleic acid isomerase were reacted at 20, 30, 40, 50, 60, 70, and 80°C respectively, and the enzyme specific activity was determined; the highest enzyme specific activity is 100%, the ratio of the enzyme specific activity under other temperatures to the highest enzyme specific activity is the relative specific activity, and the relative specific activity of linoleic acid isomerase microcapsules and free linoleic acid isomerase is shown in Table 1 under each temperature condition and figure 1 shown.

[0029] The influence of table 1 temperature on enzymatic reaction

[0030] Tab.1Effect of temperature on the enzymatic reaction

[0031]

[0032] From Table 1 and figure 1 It can be seen that the optimum reaction temperature of free linoleic acid isomerase is 40°C, the optimum reaction temperature of linoleic acid isomerase microcapsules is 50°C, and ...

example 2

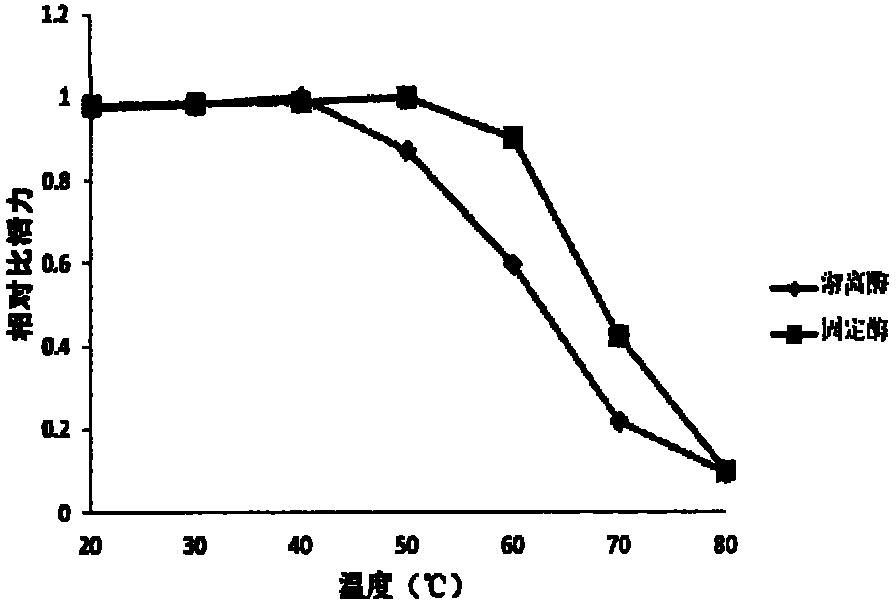

[0033] Example 2: Comparison of thermal stability of linoleic acid isomerase microcapsules and free linoleic acid isomerase

[0034] Incubate linoleic acid isomerase microcapsules and free linoleic acid isomerase at 20, 30, 40, 50, 60, 70, and 80°C for one hour, and then carry out at 37°C after the incubation. Enzyme-catalyzed reaction, measure the enzyme specific activity; take the highest enzyme specific activity as 100%, the ratio of the enzyme specific activity at other temperatures to the highest enzyme specific activity is the relative specific activity, the linoleic acid isomerase microcapsules under each heat preservation condition and the relative specific activity of free linoleic acid isomerase as table 2 and figure 2 shown.

[0035] Table 2 Comparison of thermal stability of linoleic acid isomerase microcapsules and free linoleic acid isomerase

[0036] Tab.2 Comparison of the thermal stability of the microcapsule and free LAI

[0037]

[0038] From Table 2 ...

example 3

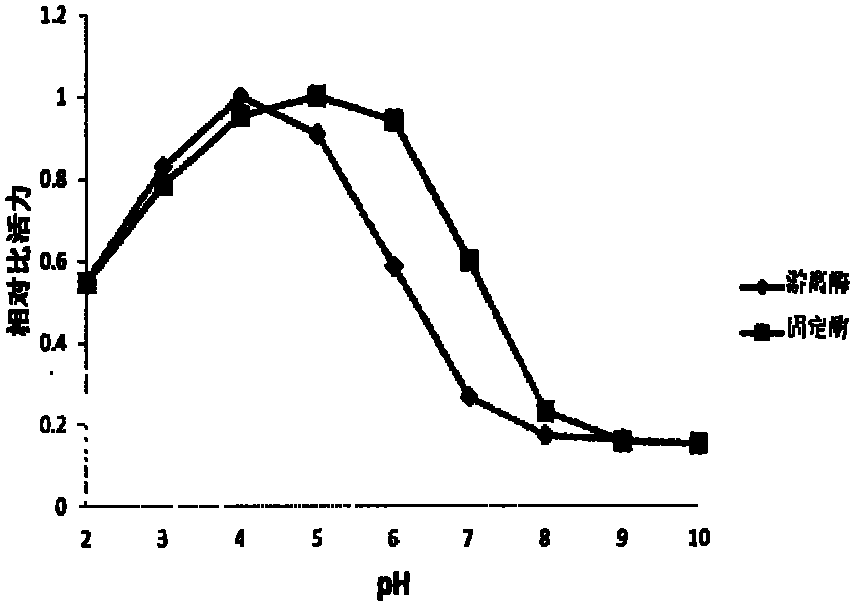

[0039] Example 3: Effect of pH on Enzymatic Reactions

[0040] The linoleic acid isomerase microcapsules and free linoleic acid isomerase were respectively reacted under the pH conditions of 2, 3, 4, 5, 6, 7, 8, 9, and 10, and the enzyme specific activity was determined; The enzyme specific activity is 100%. The ratio of the enzyme specific activity at other temperatures to the highest enzyme specific activity is the relative specific activity. The relative specific activity of linoleic acid isomerase microcapsules and free linoleic acid isomerase under various pH conditions as table 3 and image 3 shown.

[0041] The influence of table 3pH on enzymatic reaction

[0042] Tab.3Effect of pH on the enzymatic reaction

[0043]

[0044] From Table 3 and image 3 It can be seen that the optimum reaction pH of free linoleic acid isomerase is 4, the optimum reaction pH of linoleic acid isomerase microcapsules is 5, and the optimum reaction pH of microencapsulated linoleic acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com