Heterojunction solar cell taking silicon nanorod array as substrate and fabrication method of heterojunction solar cell

A technology of silicon nanopillars and solar cells, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as reducing reflection, achieve the effects of reducing reflection, increasing effective area, and easy control of aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

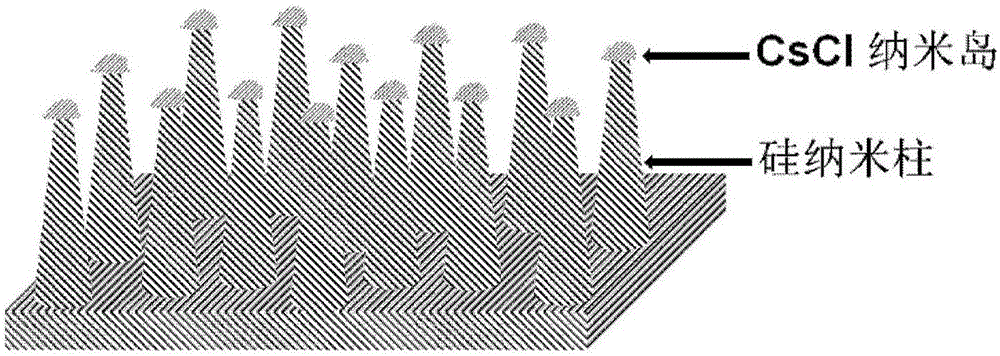

[0038] The invention provides a heterojunction solar cell with a large aspect ratio silicon nano column array as a substrate and a preparation method thereof. This type of heterojunction solar cell is based on a P-type silicon nano-pillar array with a large aspect ratio, and an N-type thin film material is wrapped on the surface of the nano-pillar array to form a heterojunction. The manufacturing method includes: first, prepare a large aspect ratio nano-pillar array on the surface of the P-type silicon wafer; then prepare an aluminum back field on the back; then, use magnetron sputtering to wrap zinc oxide on the surface of the silicon nano-pillar array. N-type material layer such as cadmium sulfide; in the next step, a transparent conductive layer of ITO is covered on the surface of the N-type material layer; finally, a titanium silver electrode is prepared on the upper surface.

[0039] The present invention proposes to apply the self-assembly technology of cesium chloride nano...

Embodiment example

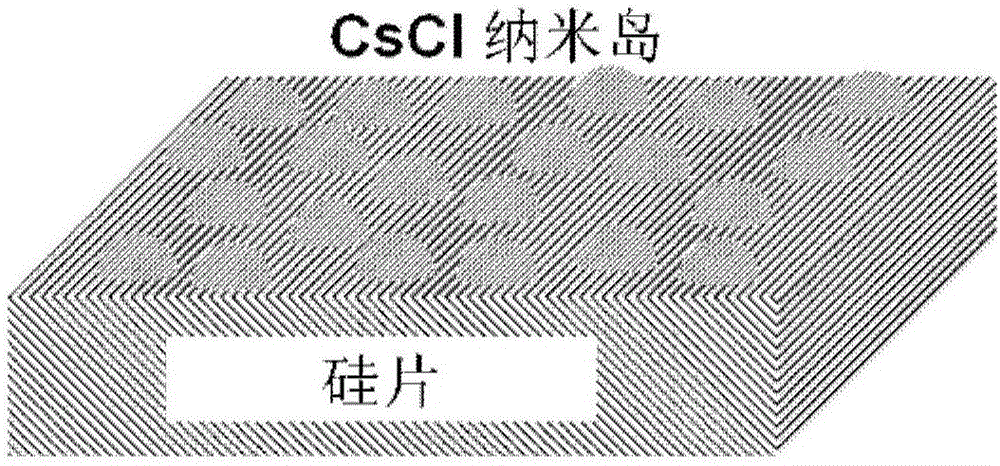

[0049] Step 1: The silicon wafer is selected as P-type doped, single-sided polishing, Crystal orientation, thickness is 400 microns, resistivity is 1-5 ohm. The cesium chloride film was prepared by thermal evaporation method on the polished surface with a thickness of 200 nanometers.

[0050] Step 2: Put the silicon wafer plated with cesium chloride film in step 1 into a ventilated chamber with a humidity of 40%. The humidity is controlled by the flow of moist gas flowing into the chamber. Development is carried out for 30 minutes under this humidity condition. The cesium chloride film agglomerates into a nano-island structure, forming a cesium chloride nano-island structure on the surface of the silicon wafer. The average diameter of cesium chloride nano islands is 400 nanometers.

[0051] Step 3: Put the silicon wafer with the cesium chloride island structure on the surface in step 2 into the etching chamber of the plasma etching machine, the etching process parameters are pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com