Freeze drying preparation method for ultra-fine tungsten-doped yttrium oxide composite powder

A technology of composite powder and yttrium oxide, which is applied in the field of freeze-drying preparation of ultrafine yttrium oxide-doped tungsten composite powder, can solve the problems of serious grain agglomeration, particle size, precursor powder segregation, and grain growth, etc., to achieve Uniform distribution, low cost, small distribution and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

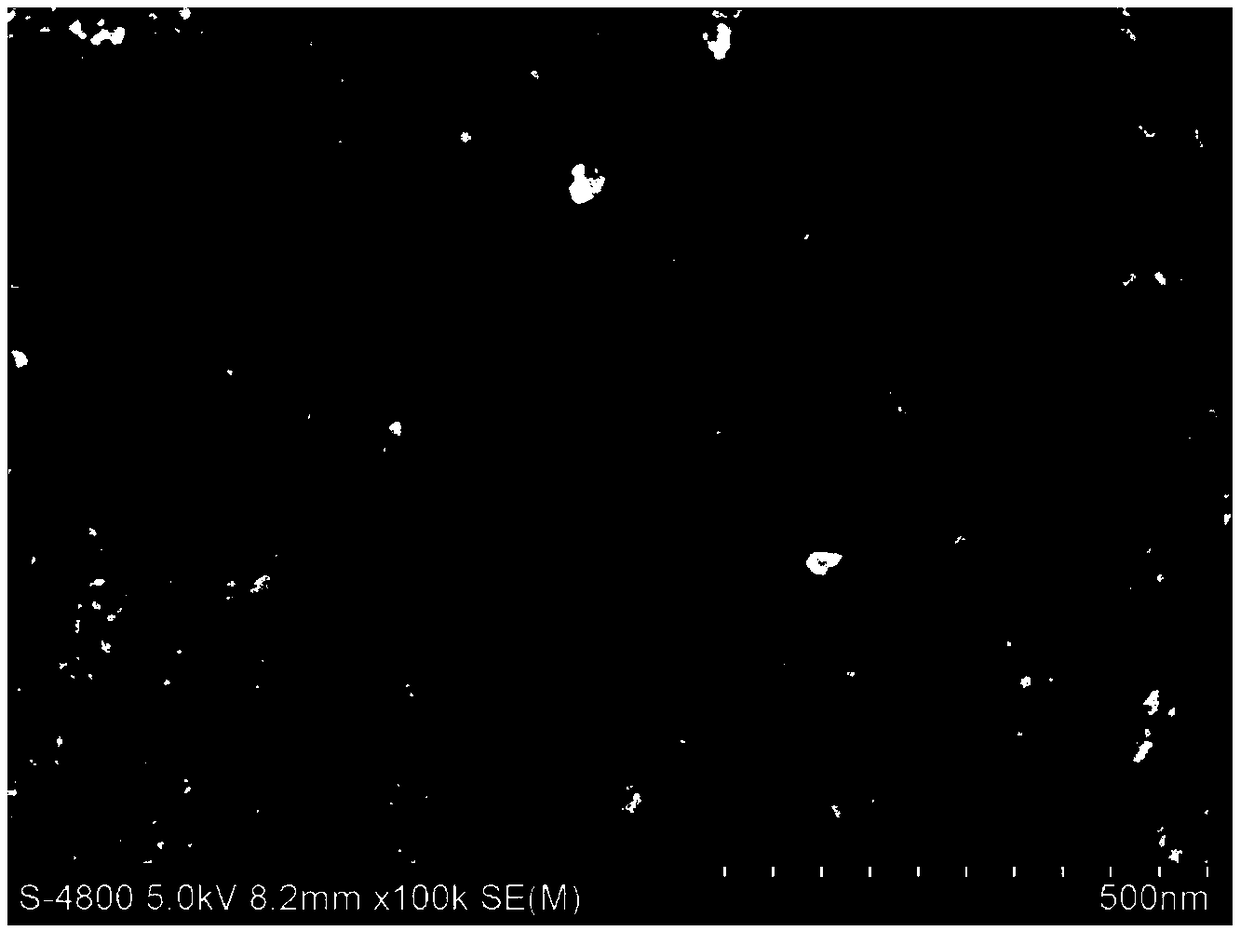

[0037](1) Dissolve 2g of AMT and 0.1332g of yttrium nitrate hexahydrate in 100mL of deionized water, then dissolve 0.1g of PVP k-12 in it, and finally add to 200ml with deionized water (the concentration of AMT is 0.01g / mL, The mass of yttrium nitrate hexahydrate is 6.66% of the mass of ammonium metatungstate), and it is fully dissolved and dispersed by ultrasonic treatment (ultrasonic treatment power is 60W, ultrasonic time is 3h) to obtain a mixed solution.

[0038] (2) Then pour it into a watch glass and put it in the refrigerator, the pre-freezing temperature is -60°C, and pre-freeze for 8 hours.

[0039] (3) After the temperature of the lyophilizer reaches the freezing temperature of -60°C and stabilizes, put the pre-frozen watch glass into the lyophilizer, turn on the vacuum pump and maintain a vacuum of 1.0 Pa, and freeze-dry for 18 hours.

[0040] (4) Calcining the freeze-dried powder in air at 450° C. for 1.5 h to obtain a composite oxide powder.

[0041] (5) The com...

Embodiment 2

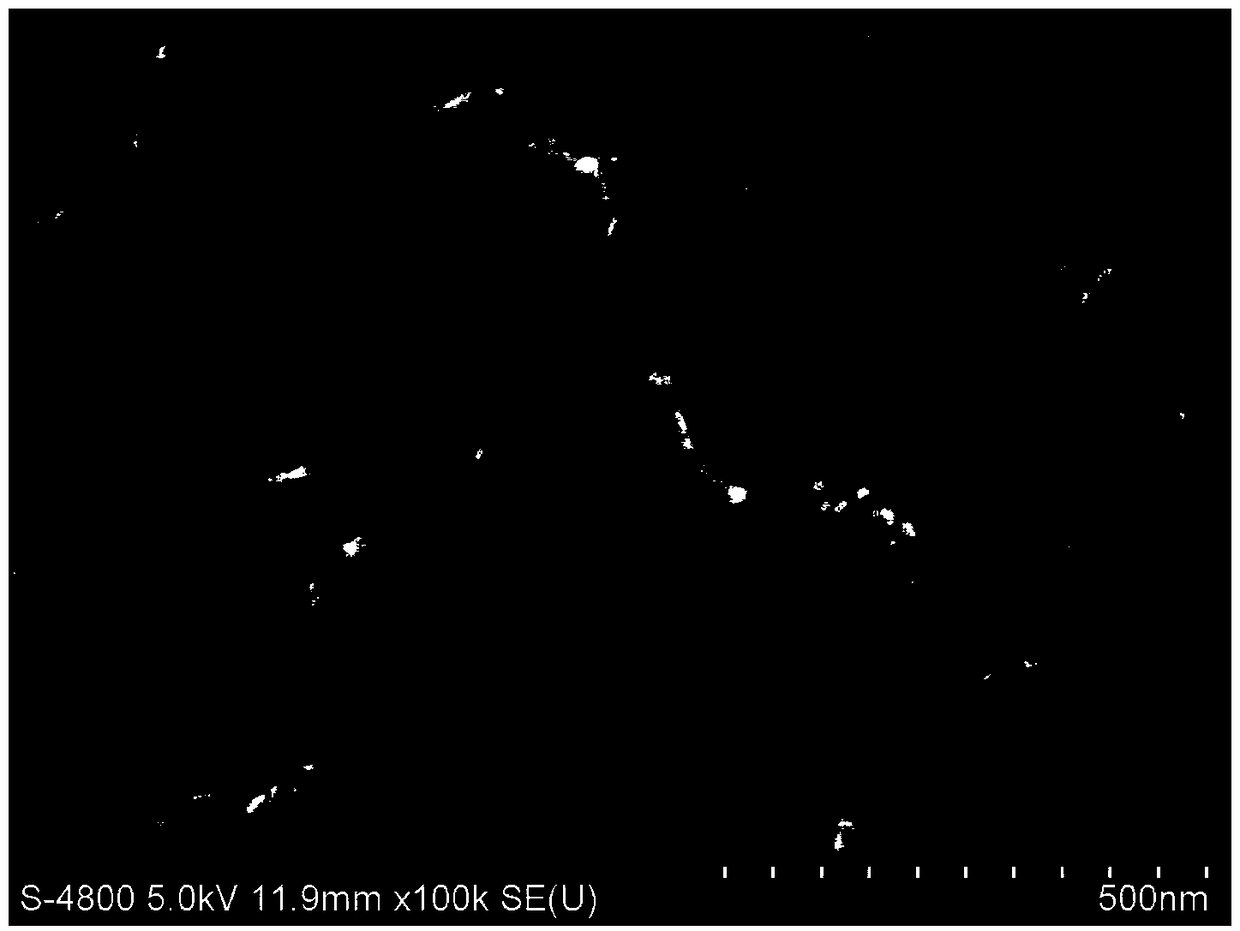

[0043] (1) Dissolve 2g of AMT and 0.1332g of yttrium nitrate hexahydrate in 4mL of deionized water, then dissolve 0.05g of PVP k-30 in it, and finally add to 8ml with deionized water (the concentration of AMT is 0.25g / mL, nitric acid The mass of yttrium hexahydrate is 6.66% of the mass of ammonium metatungstate), and it is fully dissolved and dispersed by ultrasonic treatment (ultrasonic treatment power is 300W, ultrasonic treatment time is 1h) to obtain a mixed solution.

[0044] (2) Then pour it into a watch glass and place it in the refrigerator at -60°C for 6 hours.

[0045] (3) After the temperature of the lyophilizer reaches the freezing temperature of -40°C and stabilizes, put the pre-frozen watch glass into the lyophilizer, turn on the vacuum pump and maintain a vacuum of 20 Pa, and freeze-dry for 48 hours.

[0046] (4) Calcining the freeze-dried powder in air at 500° C. for 0.5 h to obtain a composite oxide powder.

[0047] (5) The composite oxide powder is subjected...

Embodiment 3

[0049] (1) Dissolve 2g of AMT and 0.0533g of yttrium nitrate hexahydrate in 25mL of deionized water, then dissolve 0.3g of PVP k-60 in it, and finally add to 50ml with deionized water (the concentration of AMT is 0.04g / mL, nitric acid The mass of yttrium hexahydrate is 2.66% of the mass of ammonium metatungstate), and it is fully dissolved and dispersed by ultrasonic treatment (ultrasonic treatment power is 100W, ultrasonic time is 2h) to obtain a mixed solution.

[0050] (2) Then pour it into a watch glass and place it in the refrigerator at -30°C for 12 hours.

[0051] (3) After the temperature of the lyophilizer reaches the freezing temperature of -55°C and stabilizes, put the pre-frozen watch glass into the lyophilizer, turn on the vacuum pump and maintain a vacuum of 8 Pa, and freeze-dry for 12 hours.

[0052] (4) Calcining the freeze-dried powder in air at 400° C. for 1.8 h to obtain a composite oxide powder.

[0053] (5) The composite oxide powder is subjected to two-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com