Patents

Literature

40results about How to "Better even distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-wear-resistant zinc-aluminum alloy and preparation thereof

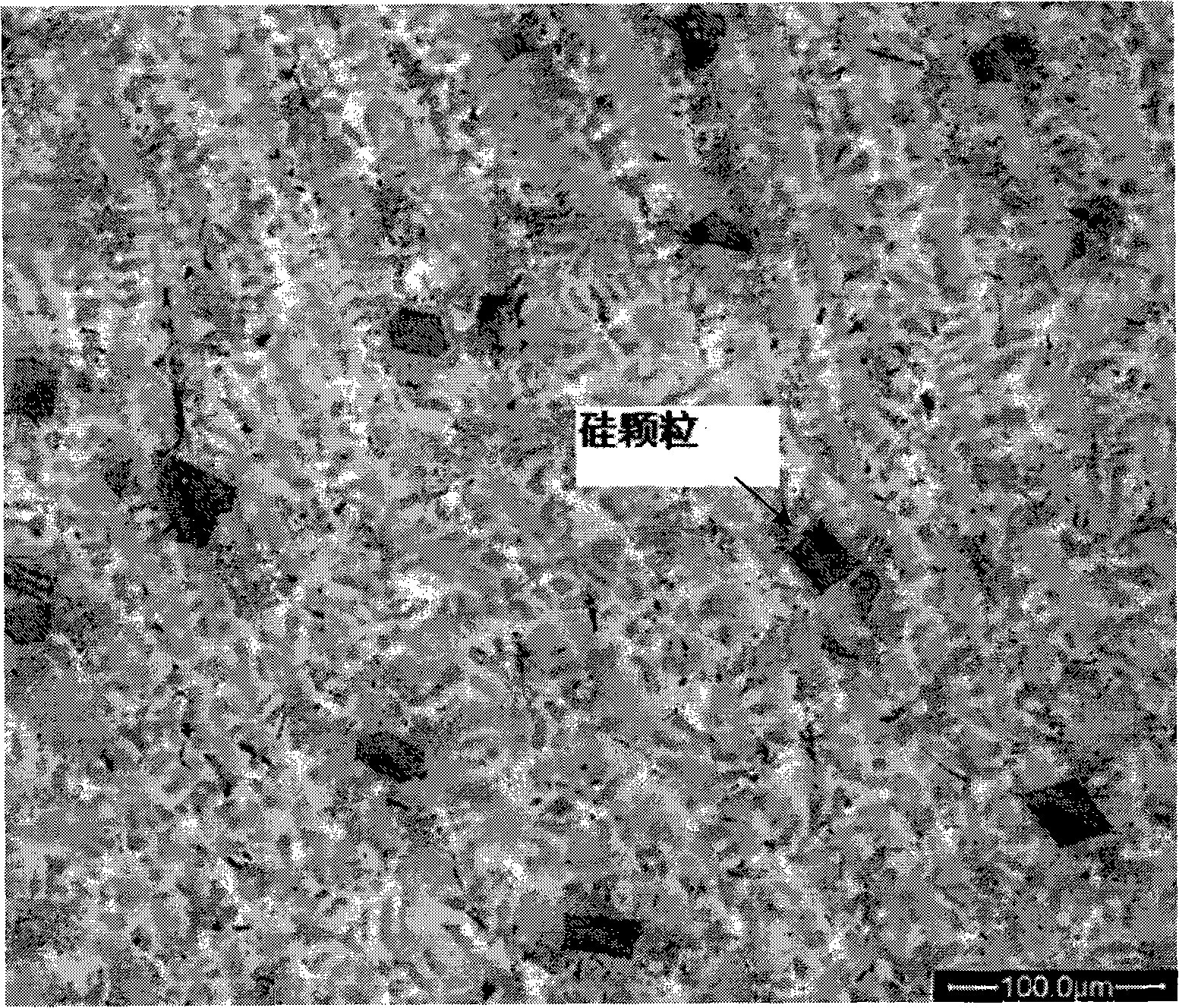

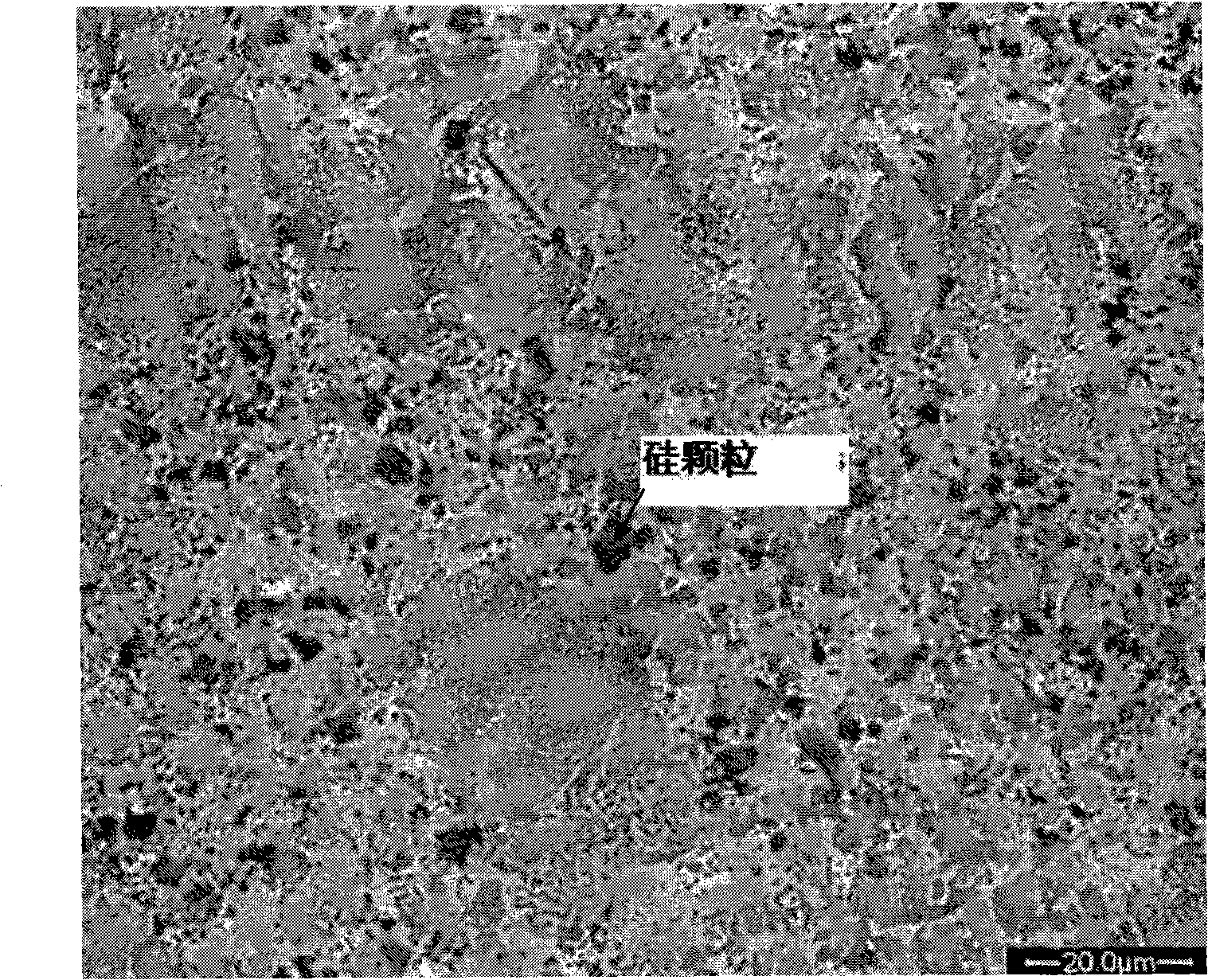

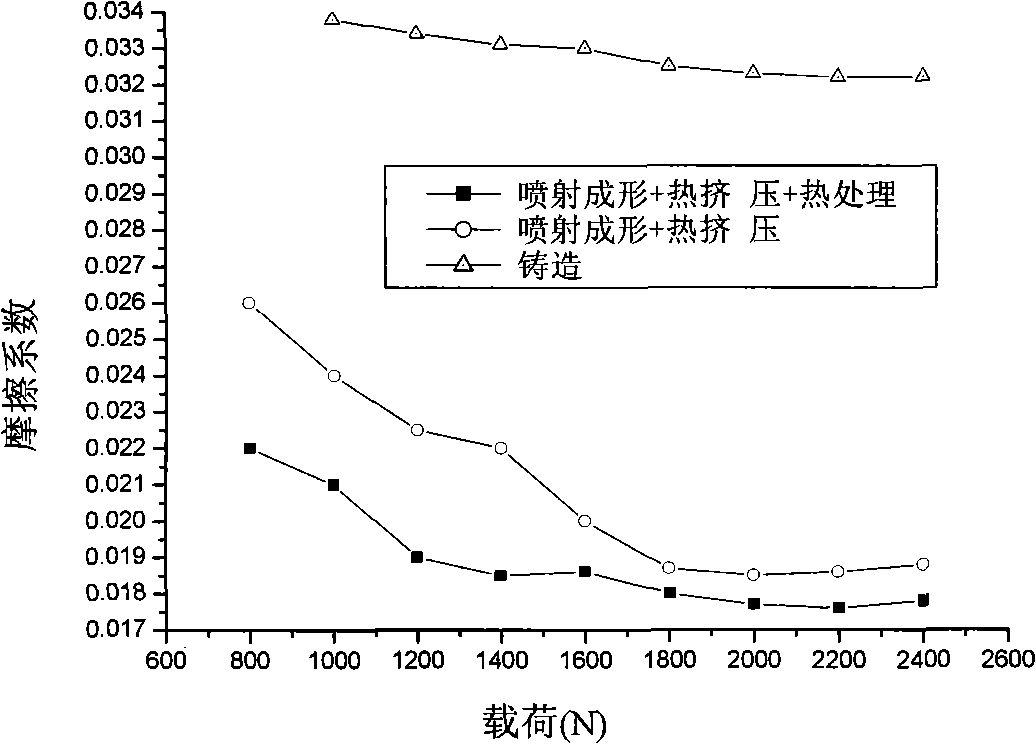

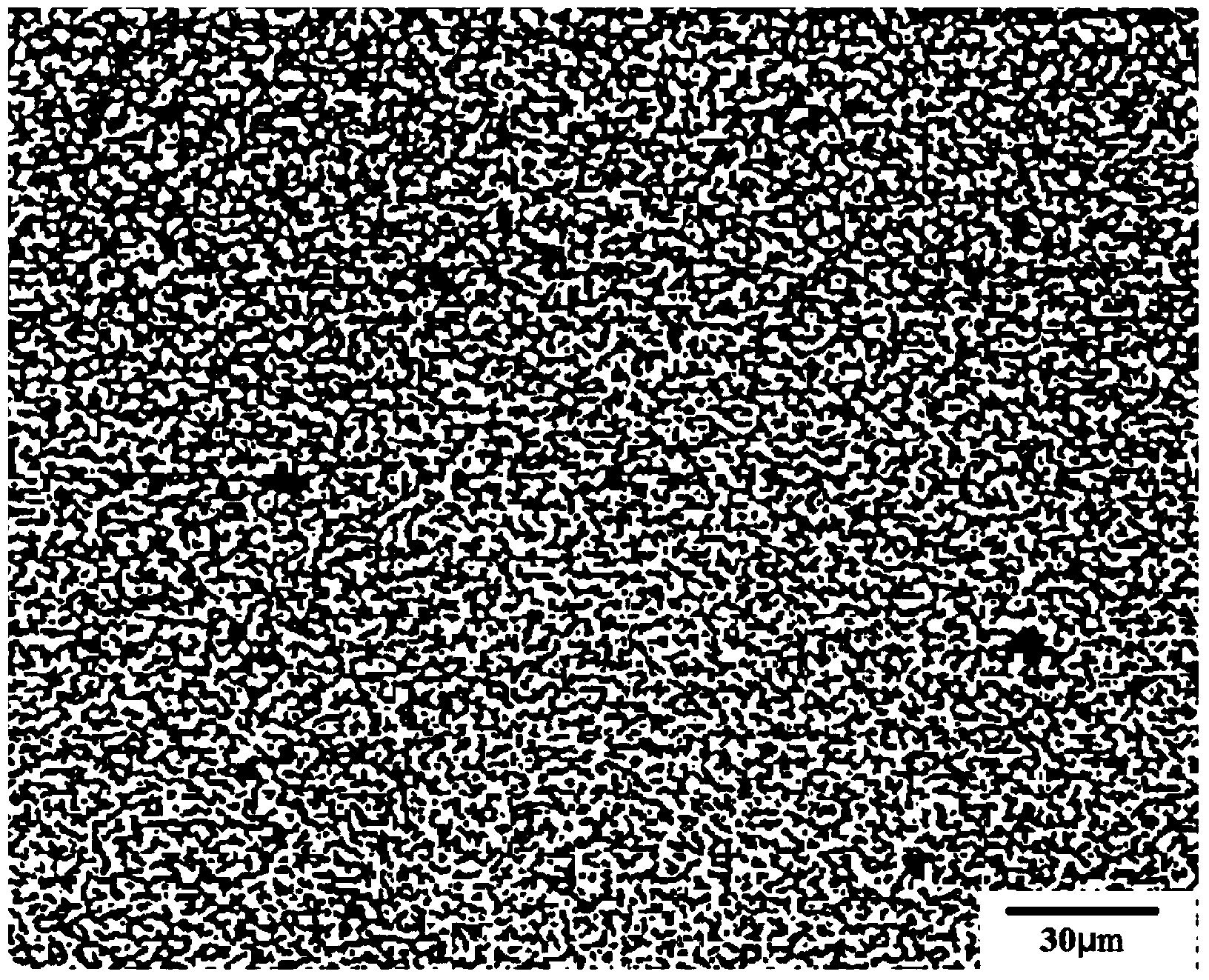

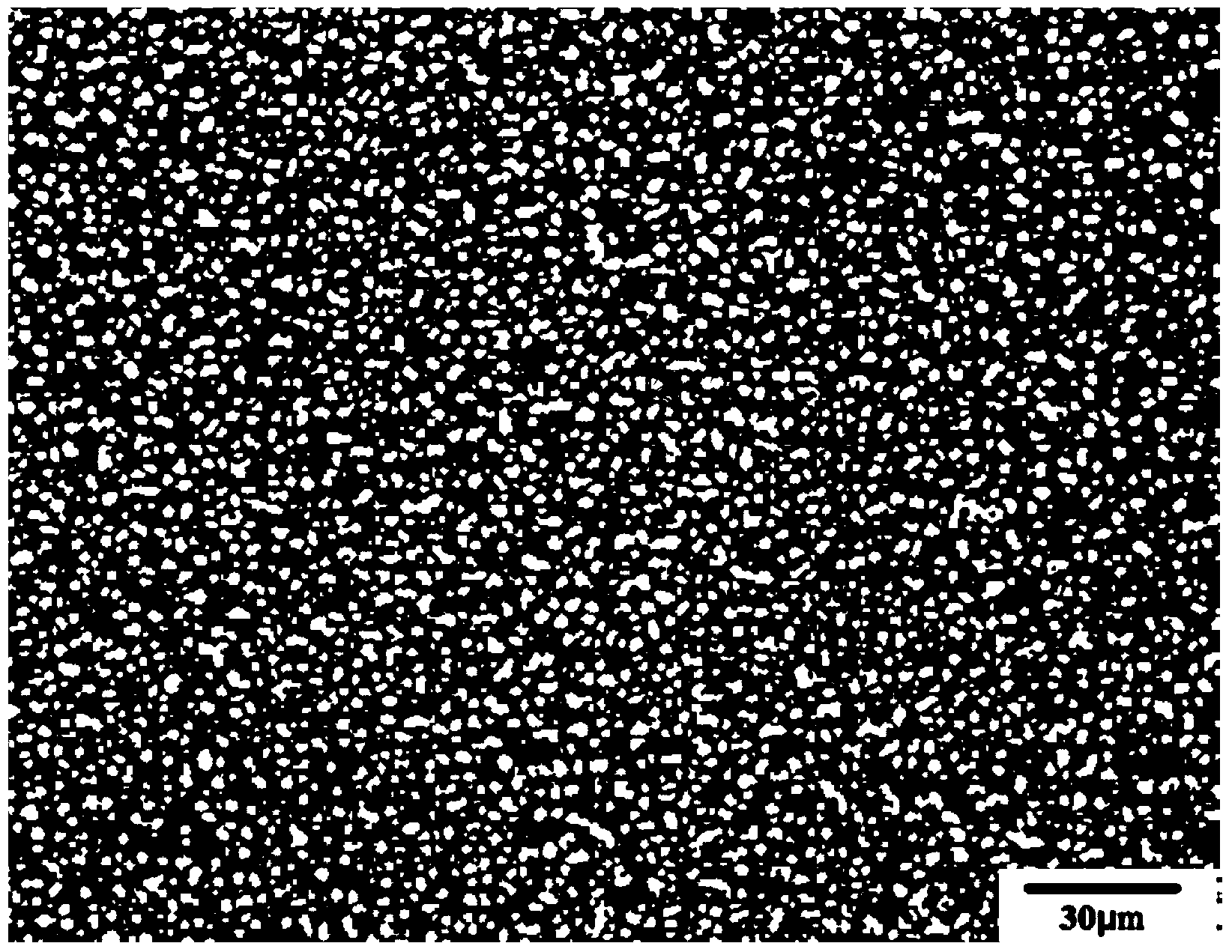

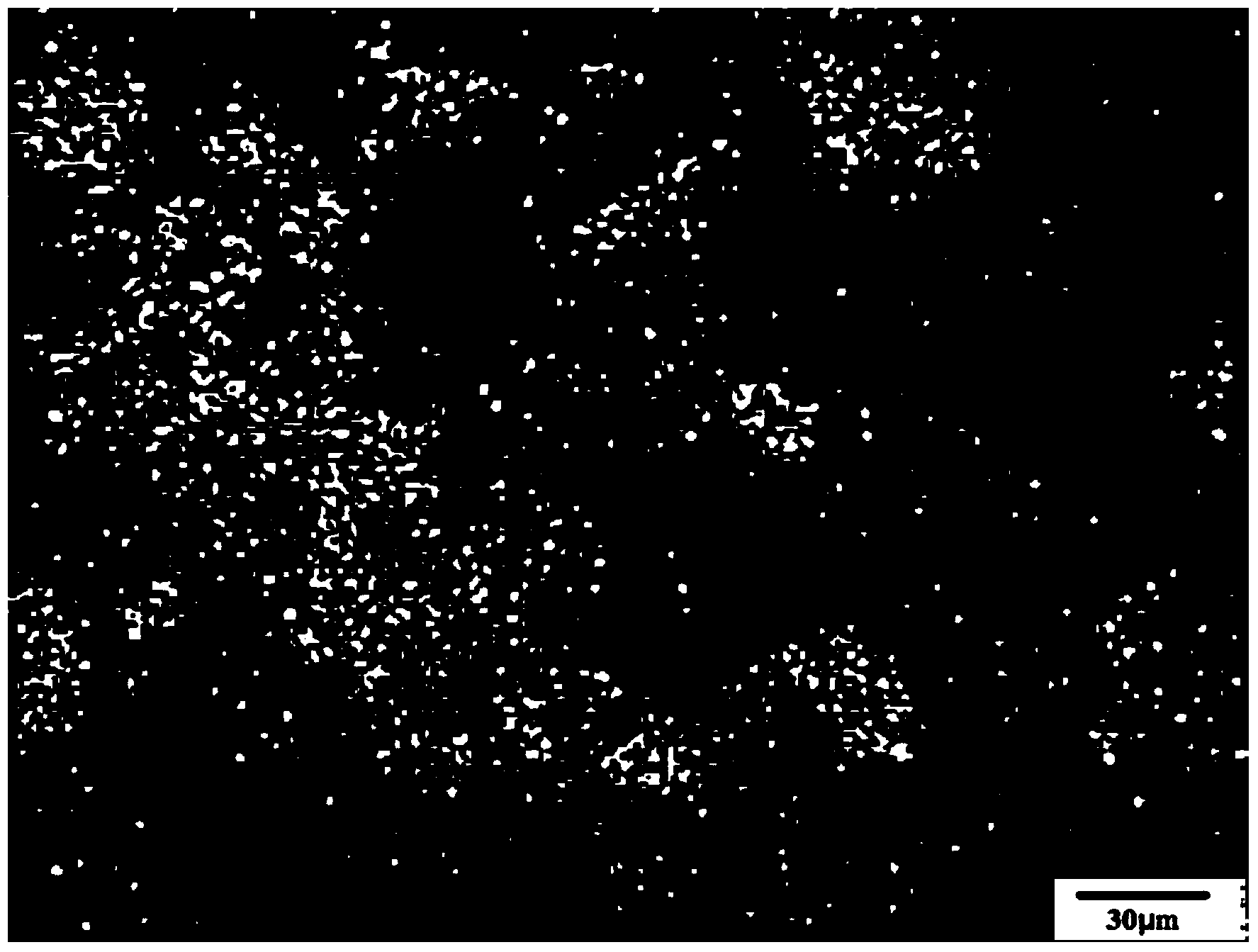

The invention discloses highly wear-resistant allumen. The invention is characterized in that according to the weight percentage, the allumen comprises the following components: 25 to 40 percent of Al, 1 to 5 percent of Cu, 1 to 10 percent of Si, and Zn as the residual. In the invention, spray forming and the hot extrusion method of multi-step accumulated deformation are utilized to achieve small size and even distribution of silicon grains which can not be achieved through common casting, and thereby the Zn-Al-Cu-Si alloy with good wear resistant property can be obtained.

Owner:TONGJI UNIV

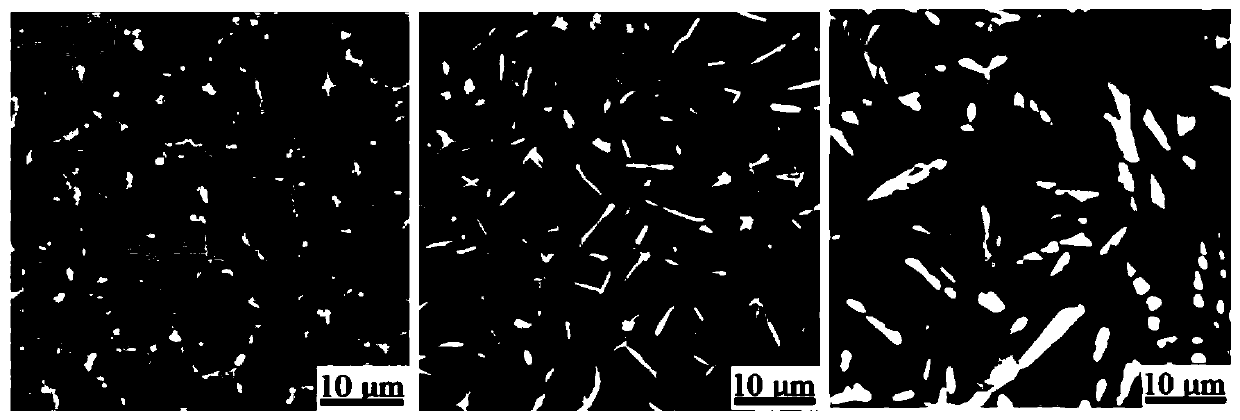

Large-sized ruthenium-based alloy sputtering target and preparation method thereof

ActiveCN104032270AUniform phase distributionSmall grain sizeVacuum evaporation coatingSputtering coatingAlloy elementCoating

The invention discloses a large-sized ruthenium-based alloy sputtering target and a preparation method thereof. The ruthenium-based alloy target comprises one or more of Al, Co, Cr and the like and the balance of Ru and is in a cake shape, wherein the diameter of the target is not less than 100mm, the density is not less than 99.5%, the density difference between the central zone and the marginal zone of the target does not exceed 0.3%, and a second phase formed by the Ru and other alloy elements is uniformly distributed in an Ru matrix phase. The preparation method for the ruthenium-based alloy sputtering target comprises the steps of preparing brittle phase ruthenium-based alloy powder with relatively low melting point through a gas atomization method, treating the brittle phase through an air-current mill to obtain fine and uniform alloy powder, and sintering the powder to obtain the ruthenium-based alloy target of which the diameter is more than 100mm. The alloy target is low in impurity content, high and uniform in density, uniform in component distribution and fine and uniform in grains, a coating sputtered by using the target is uniform in thickness and stable in performance, and the phenomena of abnormal discharge and the like in the sputtering process are reduced.

Owner:SINO PLATINUM METALS CO LTD

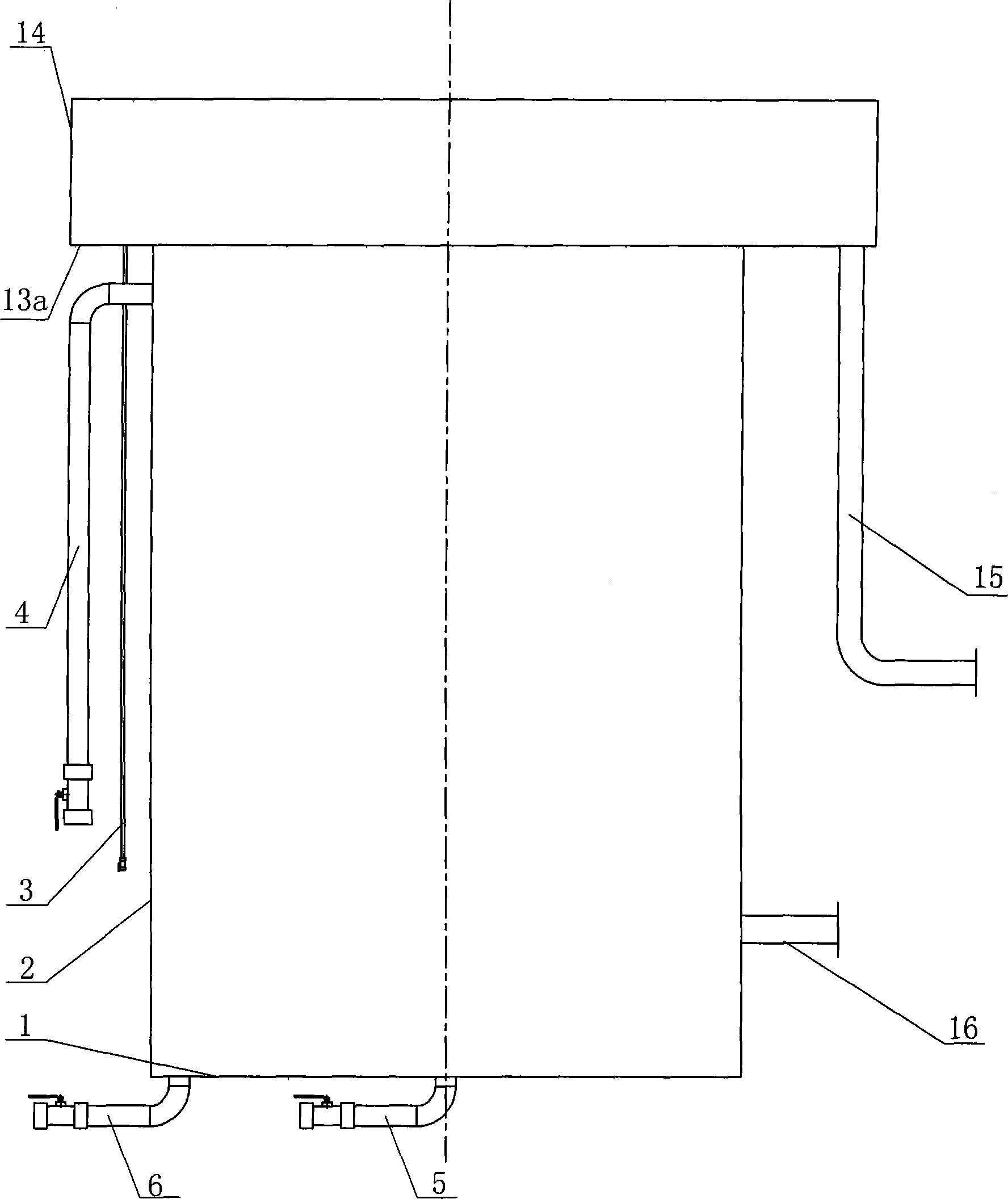

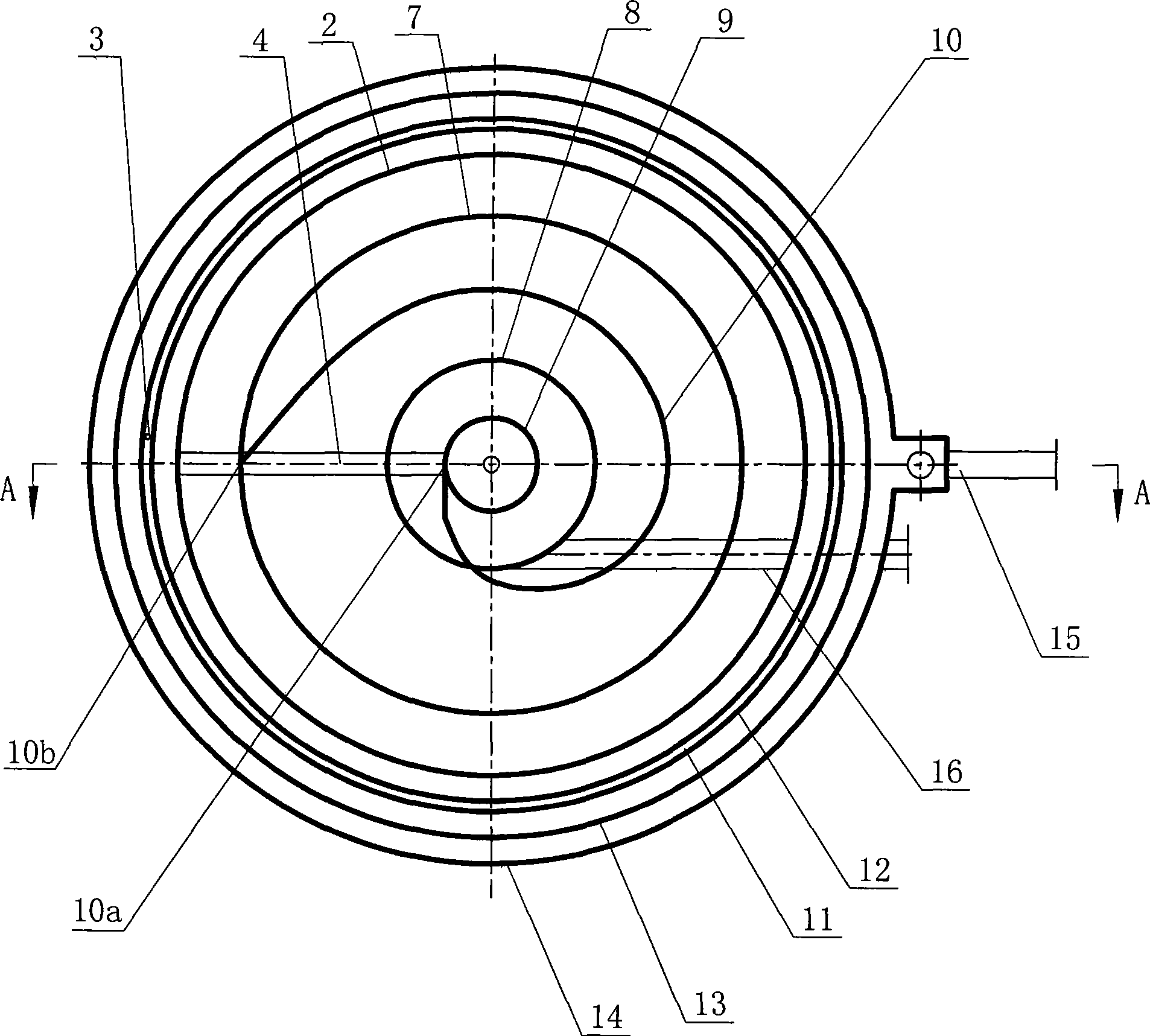

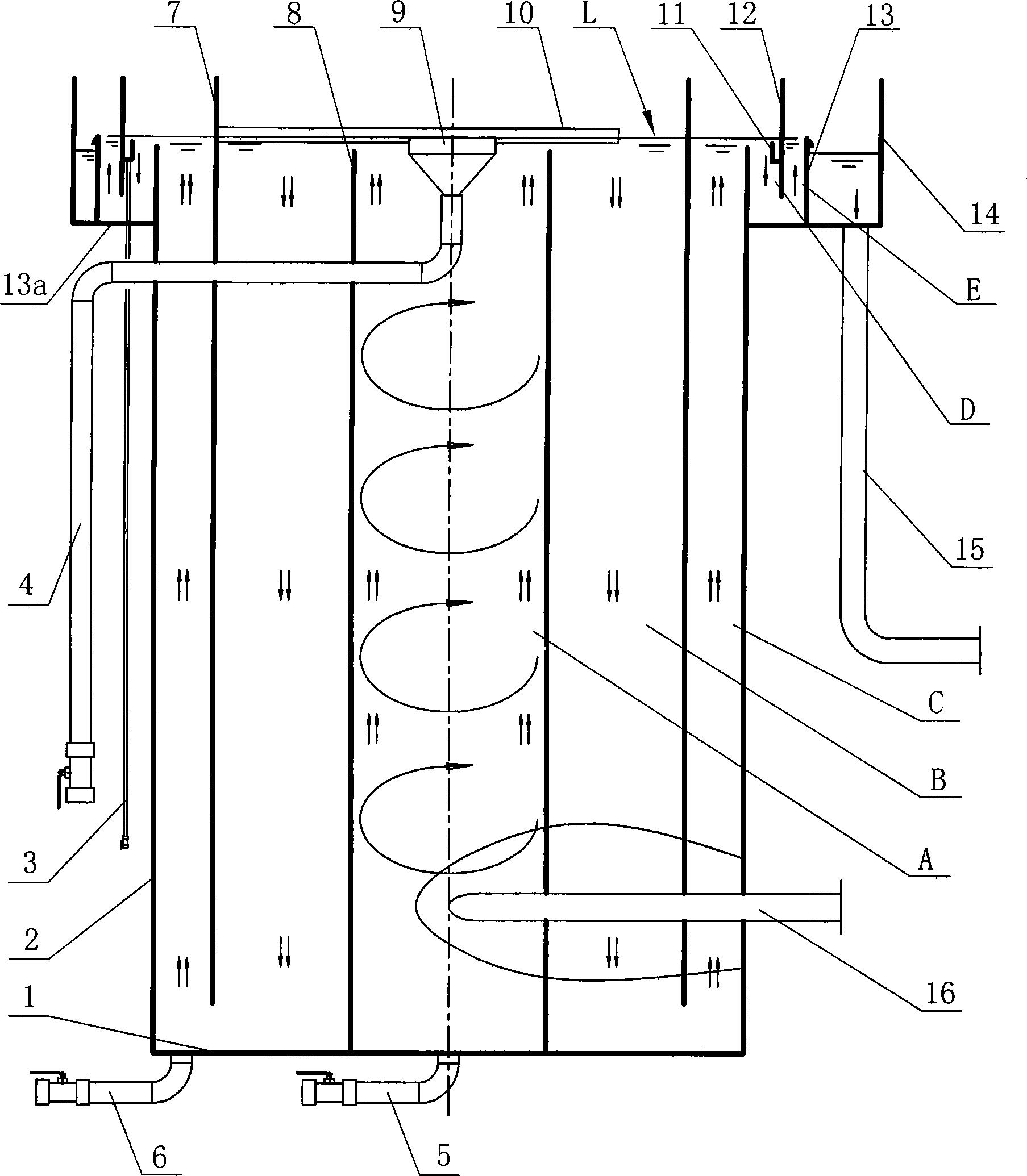

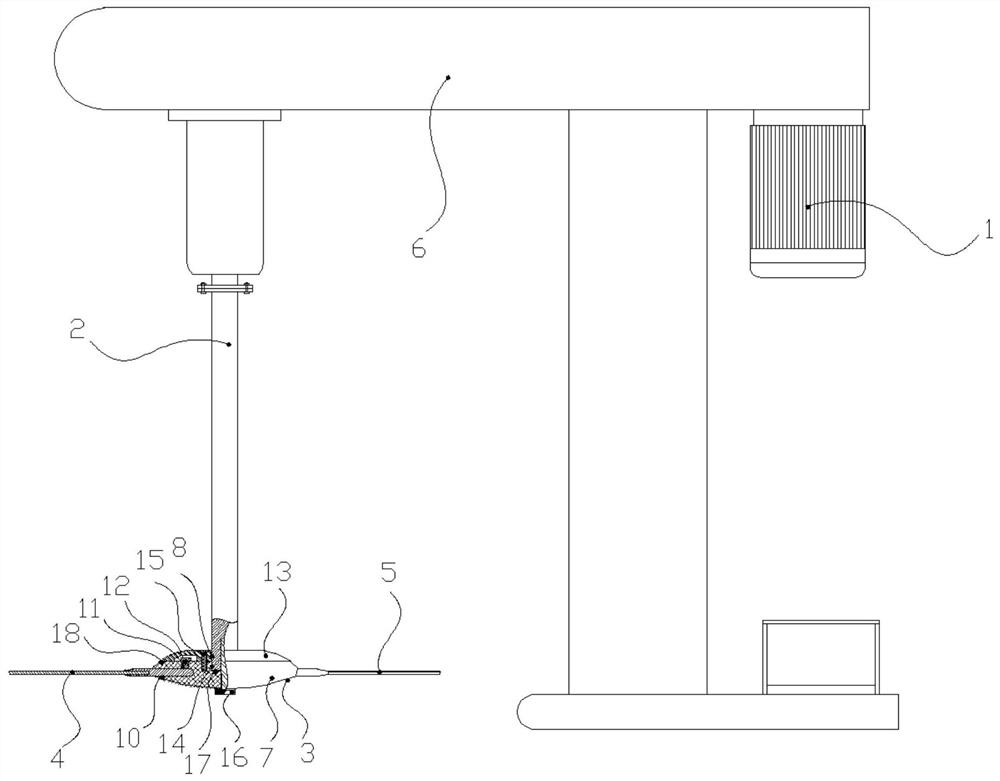

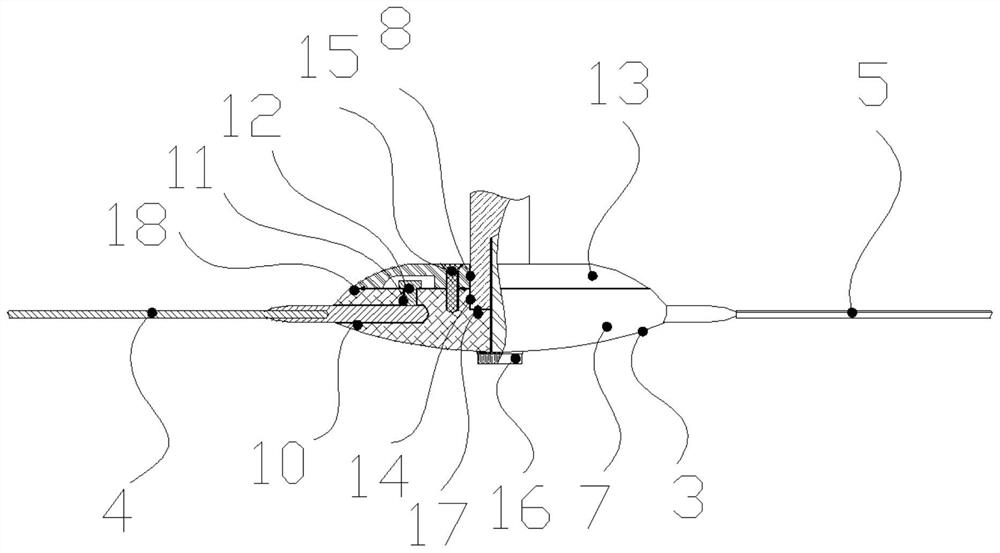

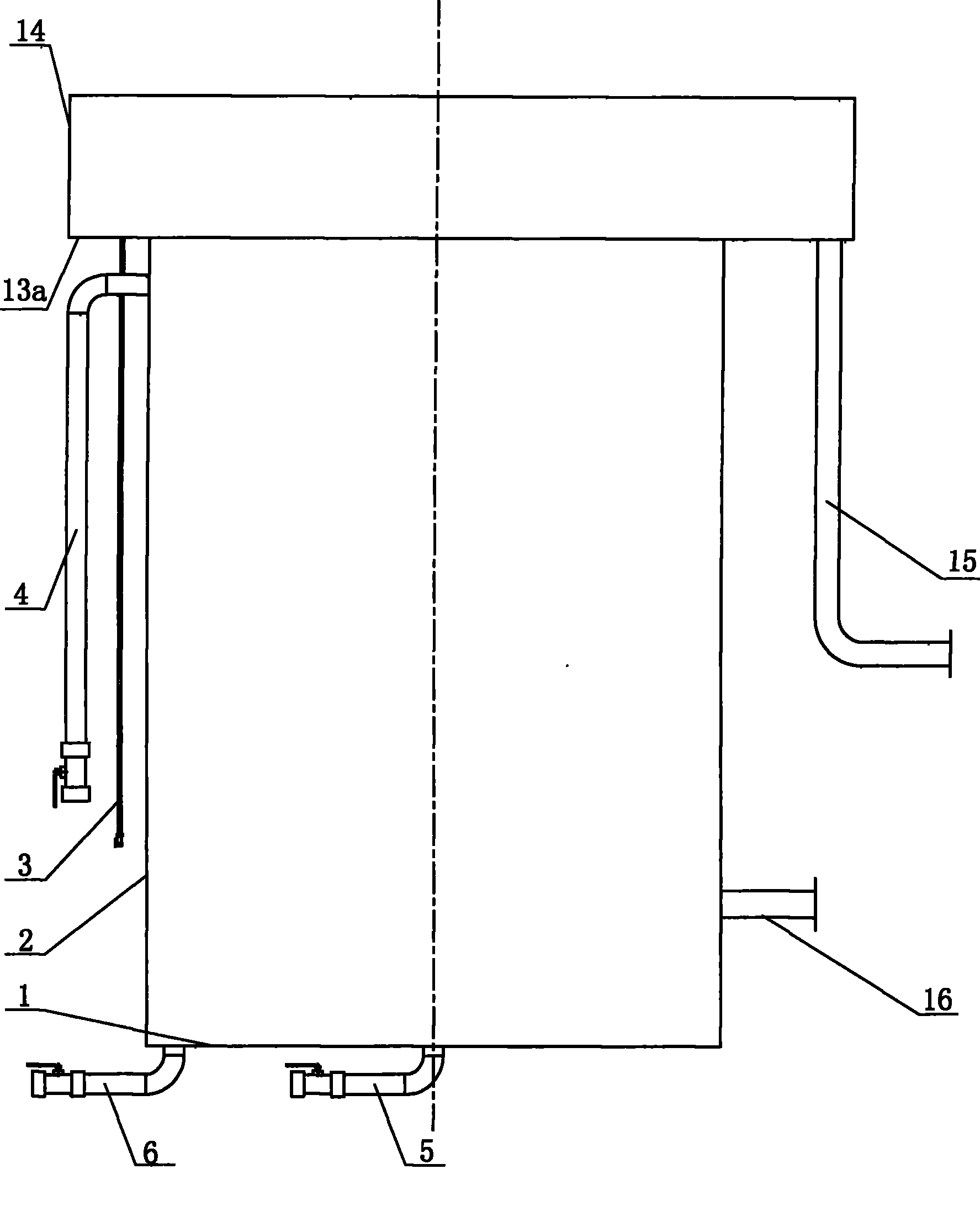

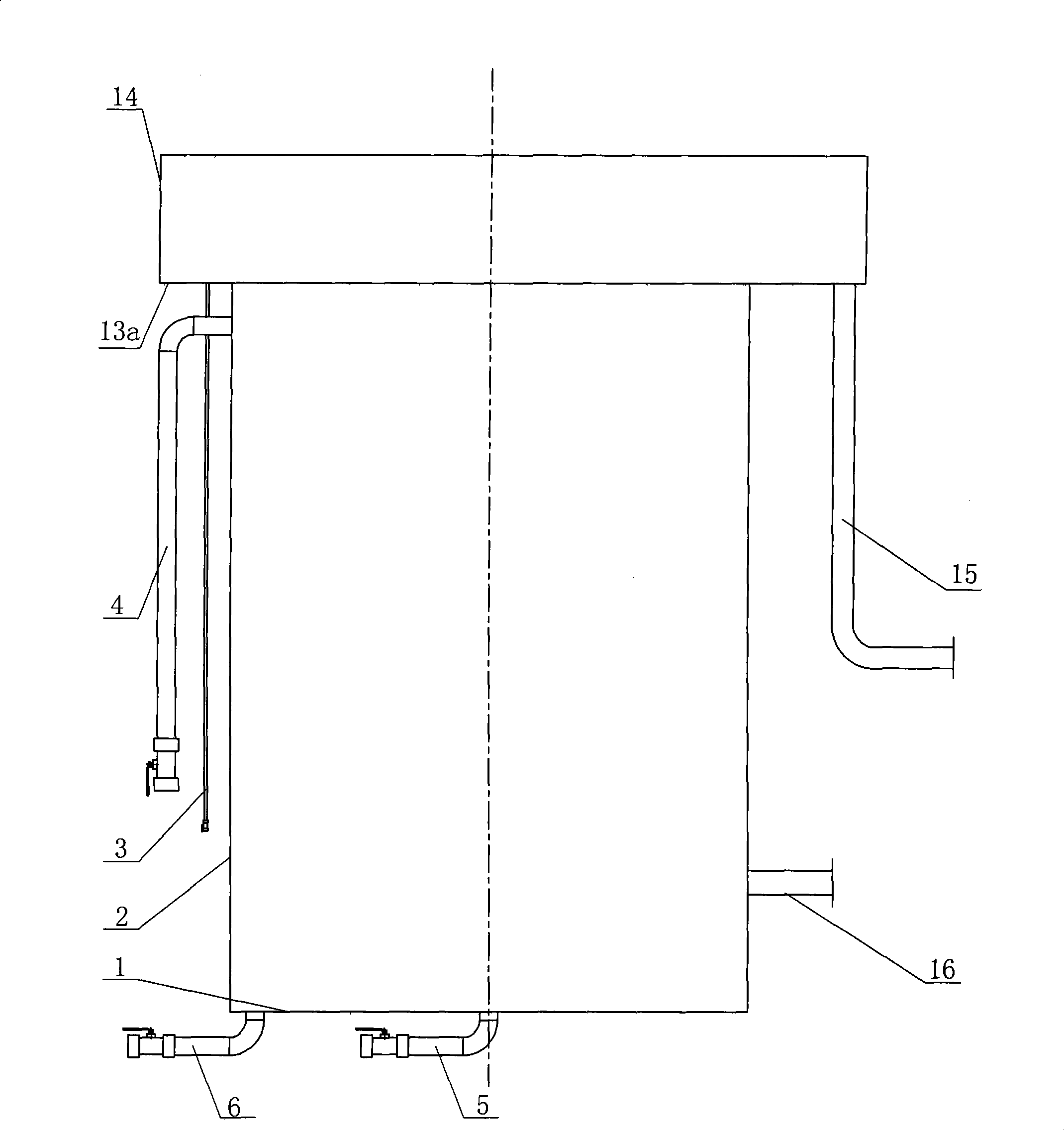

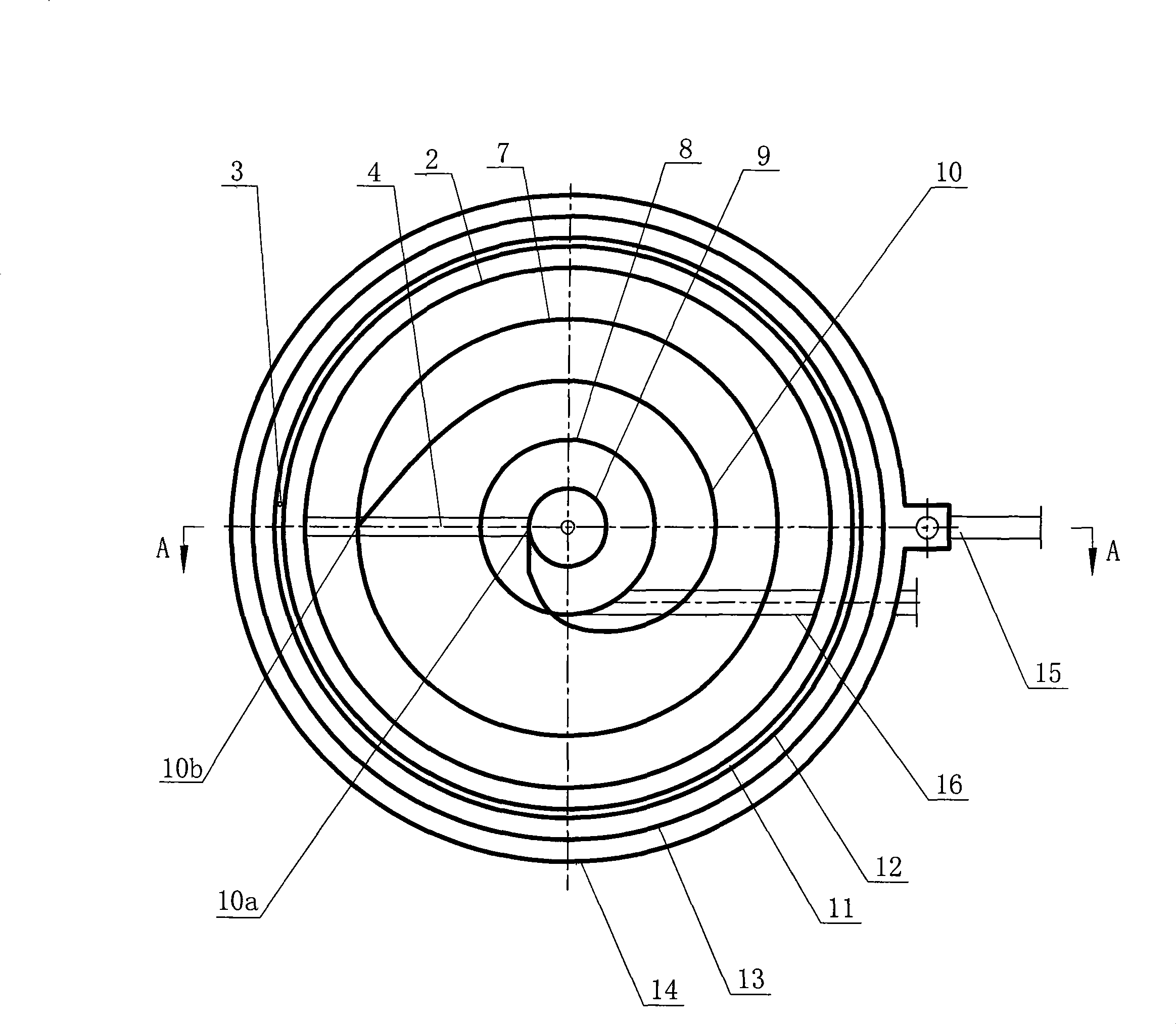

Gas floatation separation device

InactiveCN101417184ALong-term continuous stable distributionBetter even distributionFlotationLiquid separationExternal energyMicrobubbles

The invention discloses an air flotation separation device, comprising an external cylinder (2), a rotational flow mixed cylinder (8), a first slag-retaining cylinder (7), a first scum drainage pipe (4) and a scum collecting guide plate (10); wherein, the bottom end of the first slag-retaining cylinder (7) and the bottom of the external cylinder (2) have spacing so as to form a water passage; the bottom of the side wall of the rotational flow mixed cylinder (8) is connected with a water inlet pipe (16) which enters in tangent direction; the periphery of the top of the external cylinder (2) is provided with a clean water collecting trench (14); and the scum collecting guide plate (10) is a strip-typed plate in an involute shape, with the involute direction right opposite to the water rotational flow direction in the rotational flow mixed area (A). Compared with the prior art, the air flotation separation device does not need to add external energy cleaning systems, achieves the object of long-term continuously and stably running, and ensures that the requirement that the micro air bubbles adhere to the dispersed oil, emulsified oil and dissolved oil of small particle size as much as possible is met, thus achieving the object of high-efficiency separation of oil from water. The air flotation separation device is especially suitable for low-consistency water containing oil.

Owner:宁波威瑞泰默赛多相流仪器设备有限公司

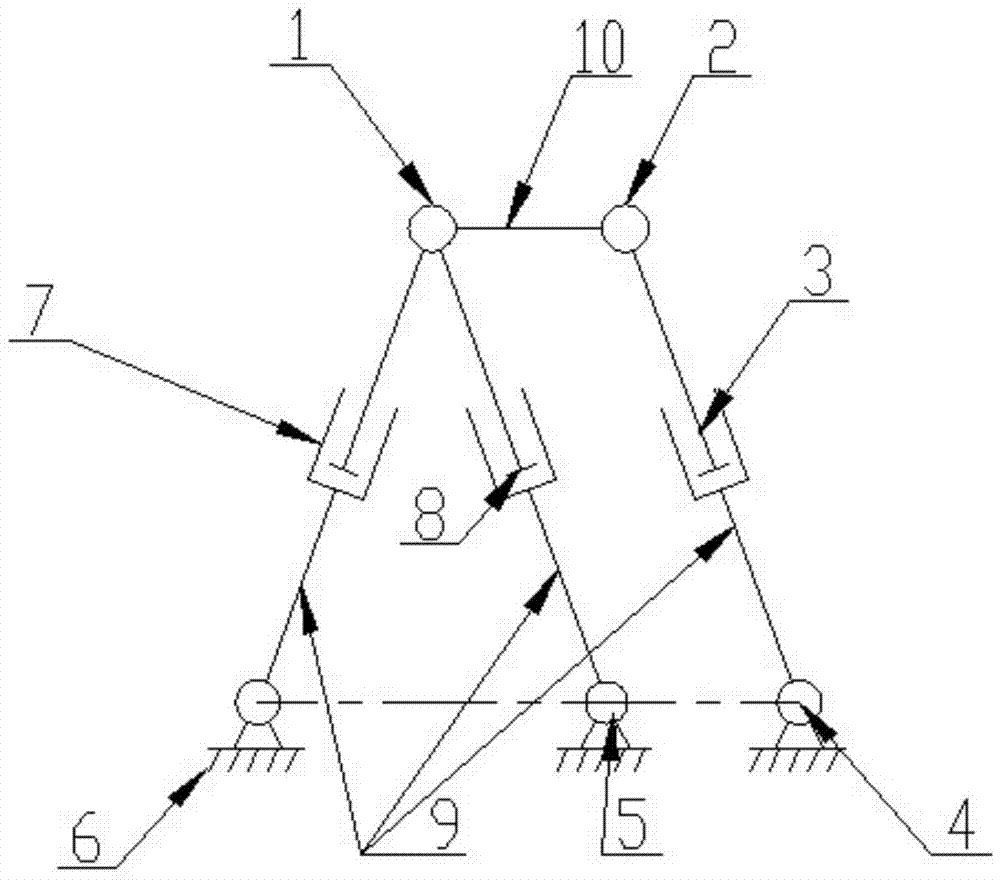

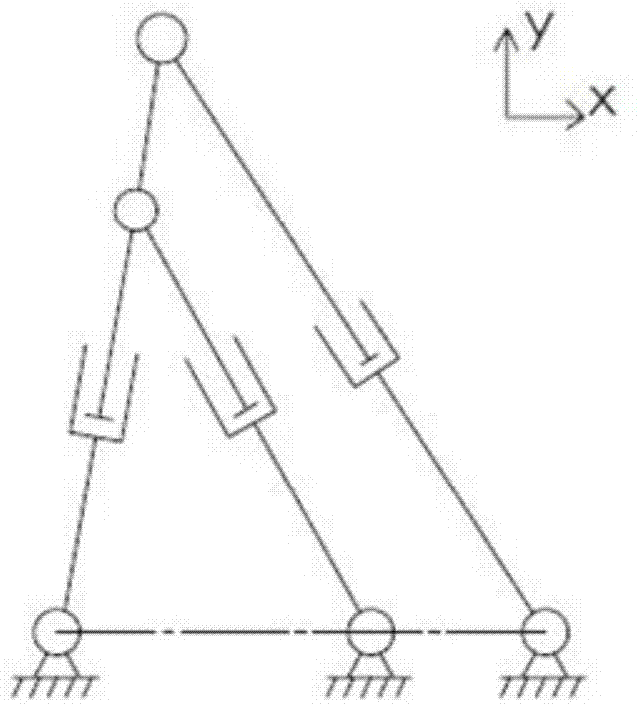

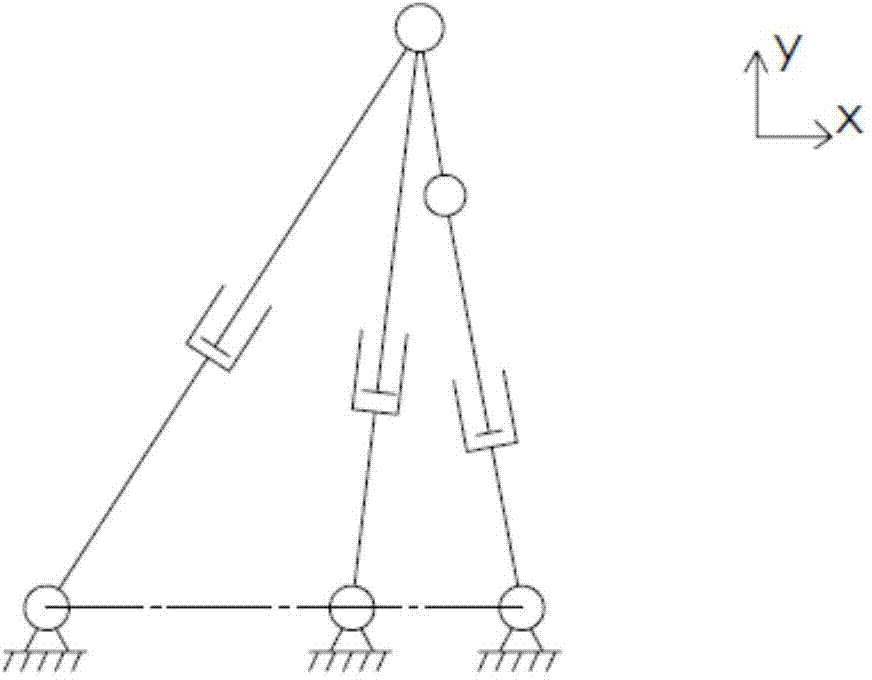

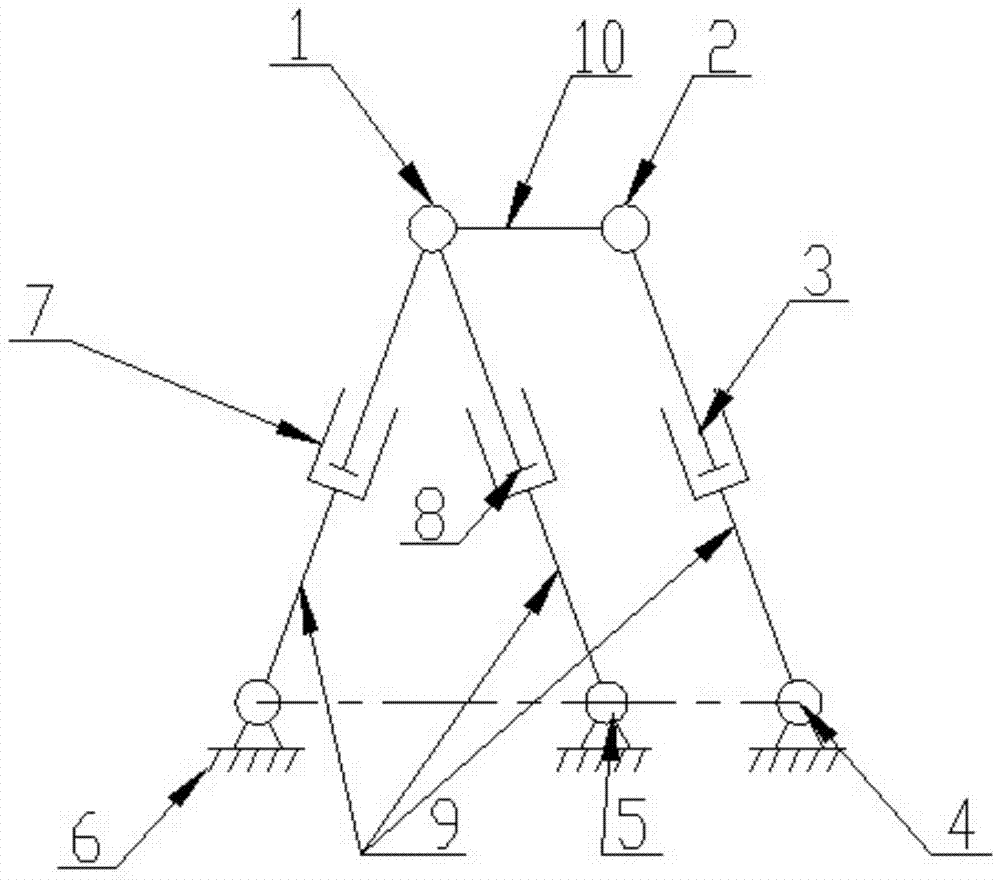

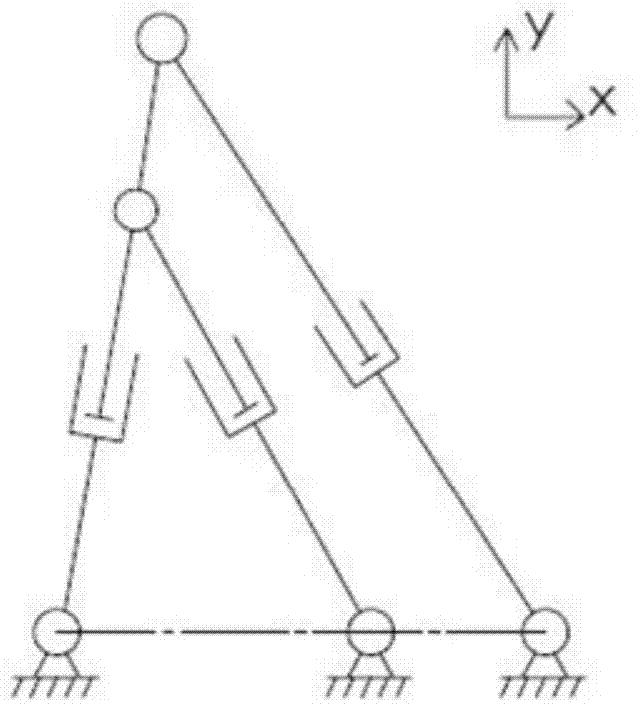

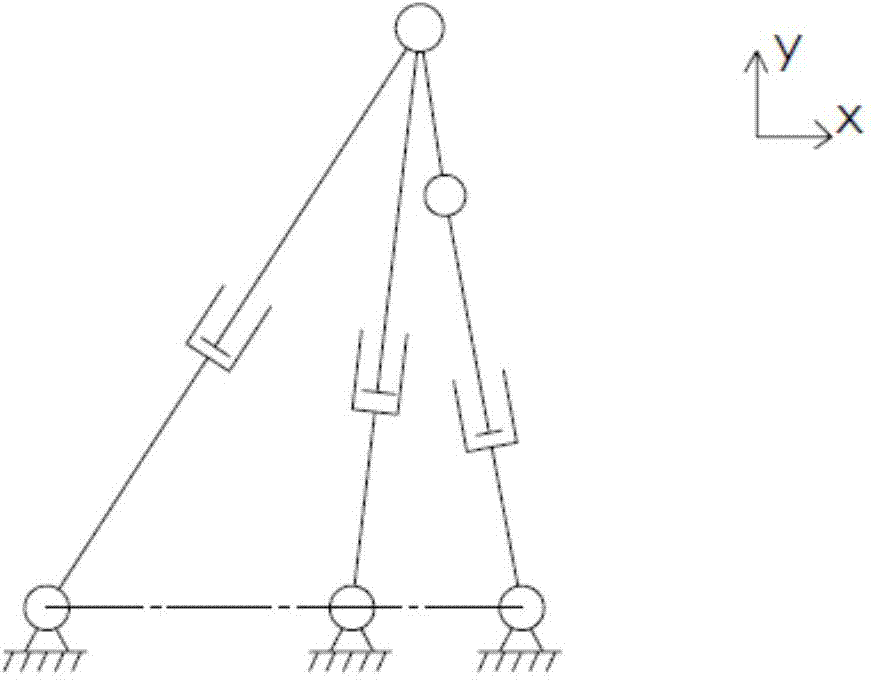

Planar three-freedom-degree parallel mechanism driven by three linear drivers and application thereof

InactiveCN103495973ASimple structureLow costProgramme-controlled manipulatorCookerElectrical and Electronics engineering

The invention relates to a planar three-freedom-degree parallel mechanism driven by three linear drivers. The planar three-freedom-degree parallel mechanism comprises the three linear drivers and five hinges, wherein two of the five hinges are upper hinges, the other three hinges are lower hinges, the three lower hinges are all fixed to the ground or a device rack, the lower hinges are connected with the linear drivers respectively, the upper ends of the two linear drivers with the lower ends connected with the lower hinges on the outer sides are connected with the upper hinges on the same sides respectively, the upper end of the linear driver with the lower end connected with the middle lower hinge is connected with the upper hinge on any side, and the two upper hinges are connected with each other through an output connecting rod. The parallel mechanism is used as a stir-fry mechanism of an automatic cooker or a vibrating screen or a vibration test table or a transmission mechanism or a parallel robot. The planar three-freedom-degree parallel mechanism driven by the three linear drivers is reasonable in design, ingenious in structure, convenient to install, easy to obtain and wide in application range, and when the parallel mechanism is used, even distribution of driving force can be ensured, stable output can be ensured and the structure of the whole device can be simplified.

Owner:XINXIANG UNIV

Sintered magnetic composite material and preparation method thereof

InactiveCN108335819AInhibit growthEliminate direct contactInorganic material magnetismCopper alloyRaw material

The invention discloses a sintered magnetic composite material and a preparation method thereof. The magnetic composite material is prepared by mixing and sintering a material A, a material B, a material C and a copper alloy D, and the weight ratio of the material A, the material B, the material C to the copper alloy D is 0.05:(1-1.3):(0.003-0.008):(0.05-0.09). The sintered magnetic composite material is simple and convenient in preparation technology and simple in process, raw materials for preparation are low in cost, the produced alloy has good performance, industrial production is facilitated, and the prepared permanent magnet material is applicable to electrical equipment industry.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

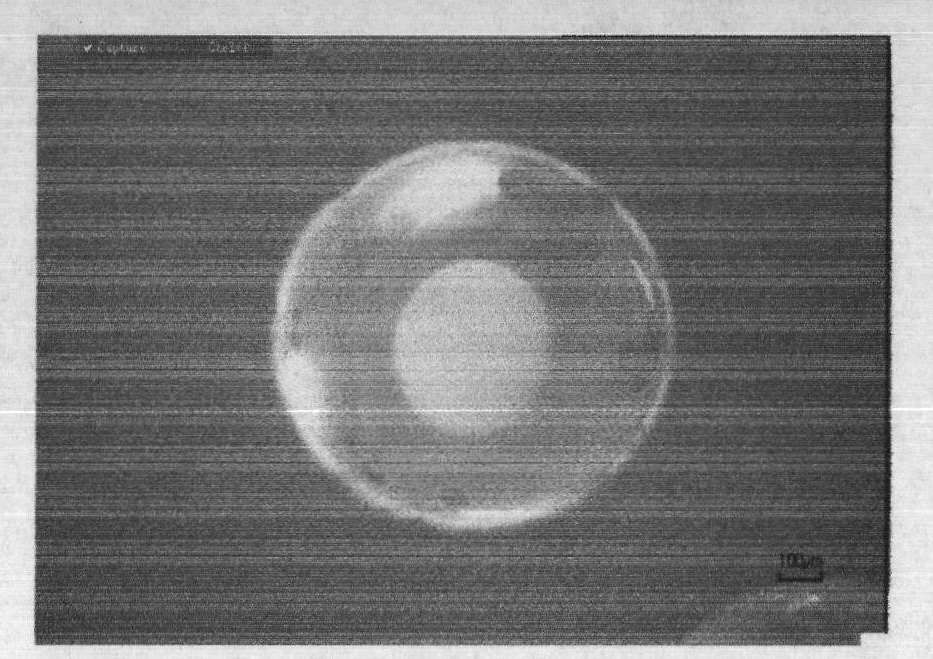

Process for preparing expandable polystyrene/silica airgel core-shell composite particle

The invention relates to a process for preparing an expandable polystyrene / silica airgel core-shell composite particle, which comprises the following steps of preparing an aqueous phase solution; preparing an oil phase solution; and after the temperature inside a reaction kettle reaches 60 DEG C, introducing the oil phase solution into the aqueous phase solution by a core-shell droplet generator, setting the temperature of the reaction kettle to be 90 DEG C, realizing the control of core-shell ratio of the composite particle by controlling the flow rate of a styrene monomer in the core-shell droplet generator, after the temperature of the reaction kettle reaches 90 DEG C, starting to time, adding pentane after 2.5 hours, after the temperature reaches 100 DEG C, keeping the temperature for 3 hours, cooling to 40 DEG C and discharging. The silica airgel / polystyrene composite heat insulation material designed by the invention simultaneously has the characteristics of low density, good mechanical properties, good flame resistance, low thermal conductivity and the like, and the heat insulation of the prepared polystyrene / silica airgel composite heat insulation board is increased by 65.4% compared with the current EPS (expandable polystyrene) board for heat insulation of buildings.

Owner:陕西得波材料科技有限公司

Freeze drying preparation method for ultra-fine tungsten-doped yttrium oxide composite powder

The invention provides a freeze drying preparation method for ultra-fine tungsten-doped yttrium oxide composite powder. According to the freeze drying preparation method, a surface-active agent polyethylene glycol (PEG), polyvinylpyrrolidone (PVP) or polyoxyethylene lauryl ether are added on the basis of freeze drying for in-situ preparing of about 10 nm of ultra-fine nanometer W-Y2O3 composite powder. The freeze drying preparation method comprises the steps that ammonium meta-tungstate, yttrium nitrate hexahydrate and a surface-active agent are dissolved into water and are fully dispersed anddissolved through ultrasonic treatment; then a mixture is placed in a refrigerator to be pre-frozen for a period of time; after being pre-frozen, the mixture is put into a freeze dryer to be subjected to freeze drying; a freeze-dried loose structure is ground and calcined in air so as to remove the surface-active agent, and thus WO3-Y2O3 composite powder is obtained; and finally, two-step reduction is conducted through hydrogen, and thus the ultra-fine tungsten-doped yttrium oxide composite powder is obtained. The powder, with the surface-active agent being added, prepared through the freezedrying method is small in particle aggregation, the average grain size reaches about 10 nm, granularity distribution of grains is extremely narrow, and second-phase Y2O3 is distributed quite evenly.

Owner:TIANJIN UNIV

Doping modified sodium vanadium fluorophosphates positive electrode material and preparation method thereof

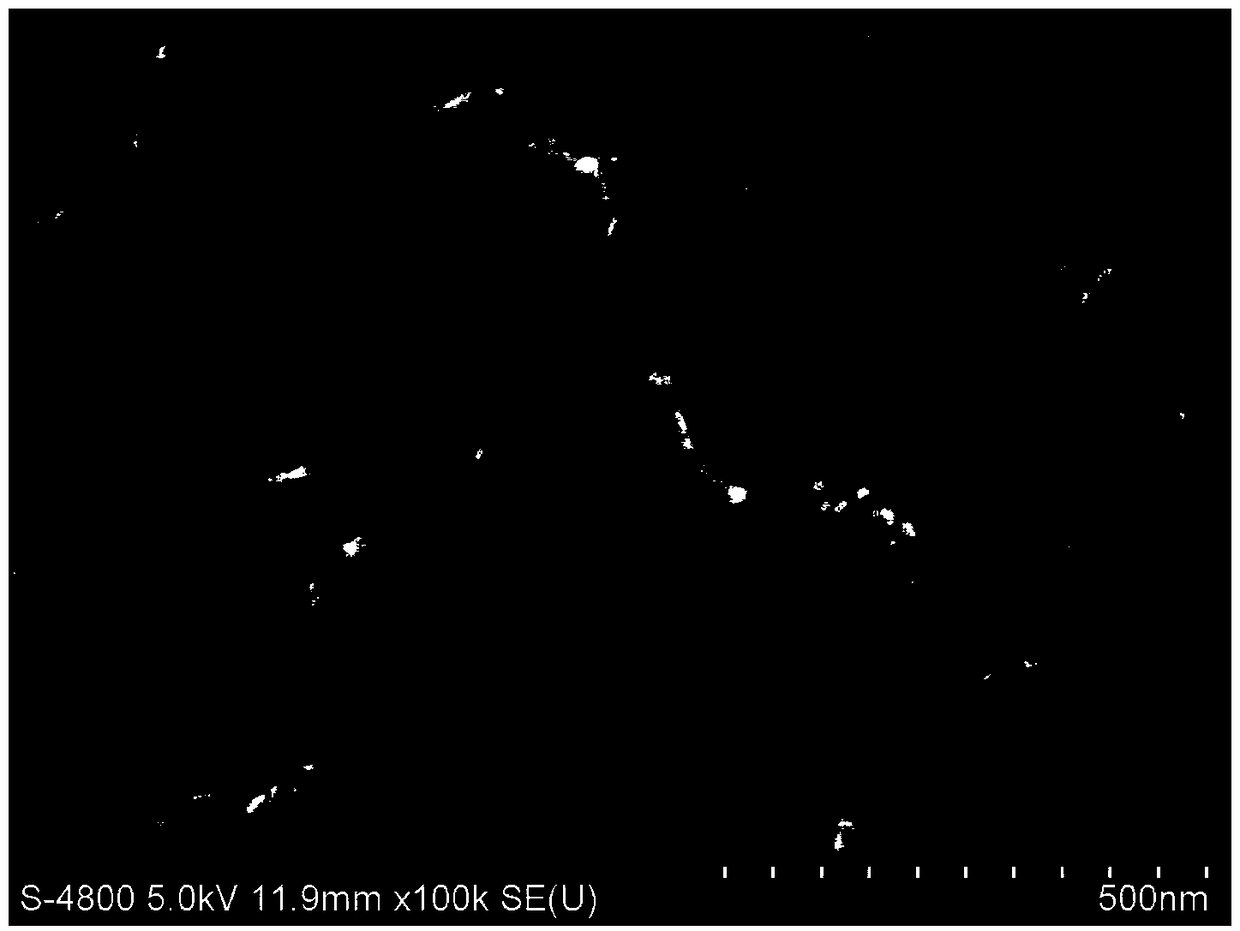

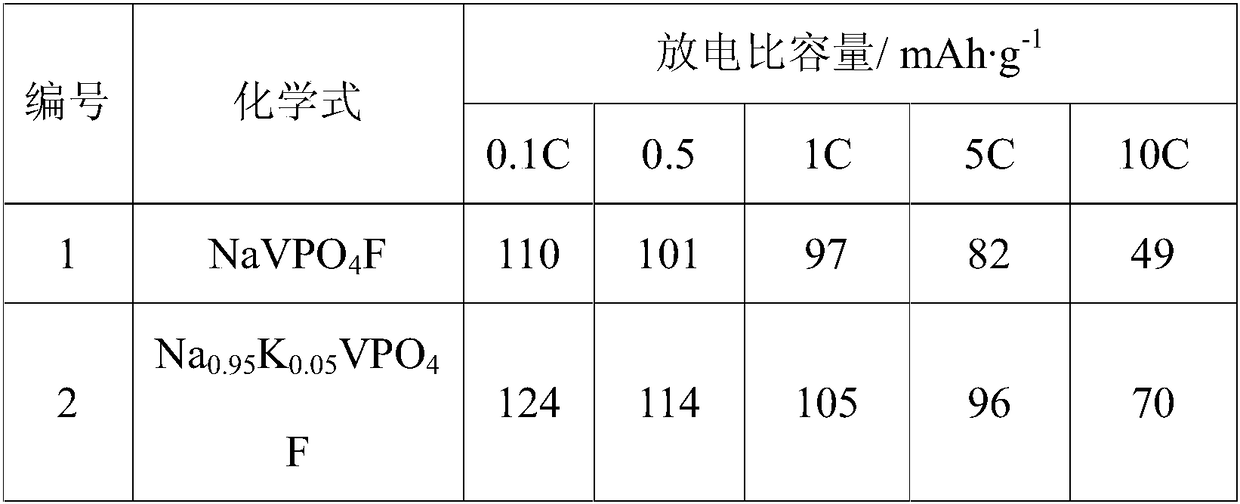

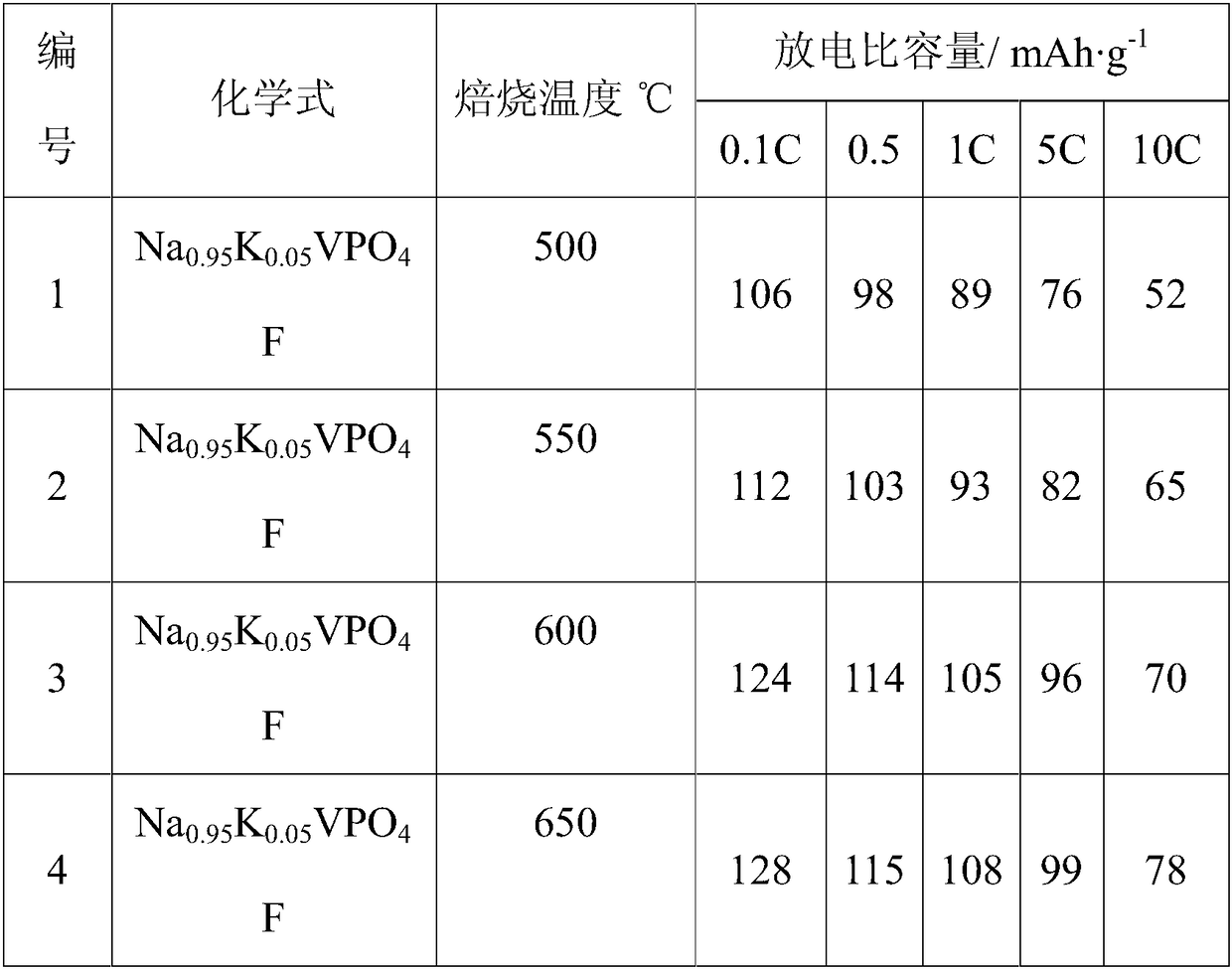

InactiveCN108899505AHigh purityImprove charge and discharge performanceCell electrodesSecondary cellsFreeze-dryingPotassium

The invention provides a doping modified sodium vanadium fluorophosphates positive electrode material and a preparation method thereof. The positive electrode material is represented by a general formula of Na(1-x)KxVPO4F, wherein x is more than or equal to 0 and less than or equal to 0.15. The preparation method disclosed by the invention comprises the following steps: mixing and dissolving various raw materials into deionized water to realize uniform mixing on a molecular level; freezing, and performing freeze-drying treatment to prepare a powdered material having the characteristics of excellent dispersion property, light particle aggregation and the like; and calcining twice at a medium temperature and a high temperature, thereby obtaining the doping modified sodium vanadium fluorophosphates positive electrode material with the advantages of being loose and porous, fine and uniformly distributed in particle system, high in purity and excellent in charge and discharge performance.

Owner:CENT SOUTH UNIV

Method for producing industrial phosphoric acid by tunnel kiln

The invention discloses a method for producing technical grade of phosphoric acid in tunnel kilns. The method comprises the steps of pulverizing phosphorite, silica and anthracite; mixing phosphorite powder, silica powder and anthracite cuff uniformly in proportion; adding a cementing agent to prepare material lumps; coating the material lumps with a wrapping agent and baking; conducting tunnel kiln reduction: introducing the material lumps into a tunnel kiln, heating, and pushing waste materials from the kiln after the phosphor element is basically released from the material lumps; hydrating: introducing a gas from the tunnel kiln into a hydrated tower to conduct hydration absorption so as to obtain crude acid, and preparing the technical grade of phosphoric acid after the crude acid is purified. By using the method, the technical grade of phosphoric acid is produced by adopting the tunnel kiln, and the reduction reaction is conducted mainly in the tunnel kiln, thereby improving the reduction efficiency, saving fuels, reducing production cost, reducing corrosion to devices and mechanical consumption, being in accordance with the main trend of energy conservation, environmental friendliness, and recycling utilization, and having wide promotion and application space.

Owner:GUIYANG JINGZHENG TECH MANAGEMENT

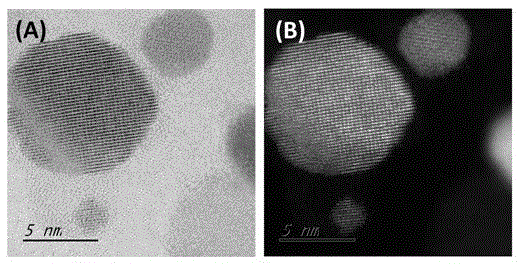

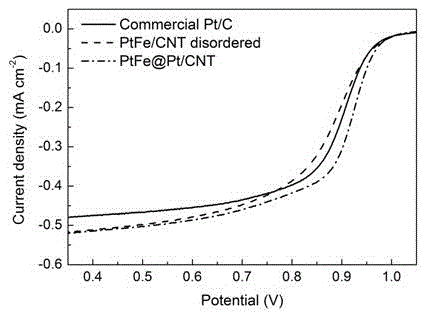

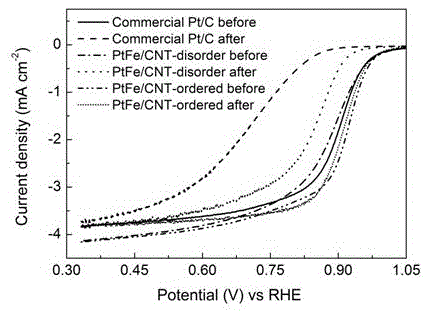

Carbon-nanotube-loaded platinum-iron superlattice alloy nanoparticles and preparation method therefor

ActiveCN105489907ASimple processOperational securityMaterial nanotechnologyCell electrodesPtru catalystNanoparti cles

The invention relates to carbon-nanotube-loaded platinum-iron superlattice alloy nanoparticles used for an oxygen reduction reaction of a proton film fuel cell negative electrode, and a preparation method for the nanoparticles. Chloroplatinic acid and ferrous nitrate are used as a precursor; carbon-nanotube-loaded platinum-iron alloy nanoparticles are obtained by adopting a sodium borohydride reduction method implemented in an ethylene glycol solution; then the carbon-nanotube-loaded alloy nanoparticles are subjected to thermal annealing processing in an inert gas atmosphere to convert the carbon-nanotube-loaded alloy nanoparticles into the carbon-nanotube-loaded platinum-iron superlattice alloy nanoparticles. The method is simple in process, safe in operation, free of reduction gas in the thermal annealing process, and high in controllability; and the activity and the stability of the catalyst oxidization reduction reaction of the obtained product catalyst are both improved at a relative high degree.

Owner:BEIJING UNIV OF CHEM TECH +1

Continuous casting process for producing high-titanium wear-resisting steel on straight arc slab continuous casting machine

The invention relates to a continuous casting process for producing high-titanium wear-resisting steel on a straight arc slab continuous casting machine. The continuous casting process comprises the following steps of: adopting full-protection casting for continuous casting, adopting long nozzle shielding argon gas casting from a steel ladle to a tundish and adopting immersion type water gap protection casting from the tundish to a crystallizer, wherein molten steel in the tundish adopts an alkaline covering agent and a tundish slag double-layer covering agent; adopting an eddy current probe to detect the liquid surface of the crystallizer in a fully-automatic manner in a casting process, and automatically controlling continuous-casting speed according to degree of superheat of the tundish; enabling protective slag on the surface of the crystallizer to be adaptive to high-titanium molten steel; and adopting a mode of quickly cooling the front part and slowly cooling the middle part and the rear part for a secondary cooling region of the crystallizer. According to the continuous casting process, secondary oxidization of molten steel in the casting process can be effectively prevented, stability of titanium in the molten steel is guaranteed, and the protective slag is prevented from being denatured; and meanwhile, separation of large-particle titanium compounds in steel can be restrained by optimizing and cooling, so that the problems that titanium compound particles in die casting are relatively great and are not even in distribution are solved, and the titanium compounds in the steel are guaranteed to be fine and uniformly distributed.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

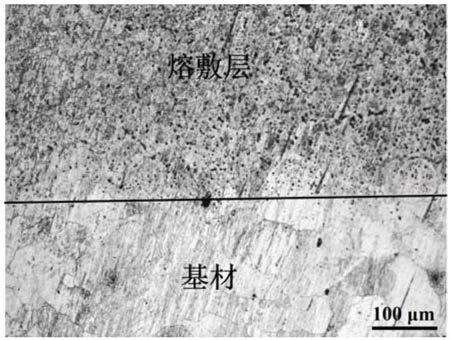

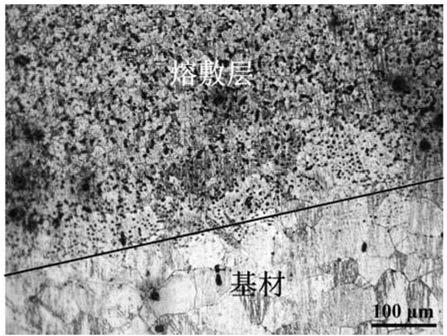

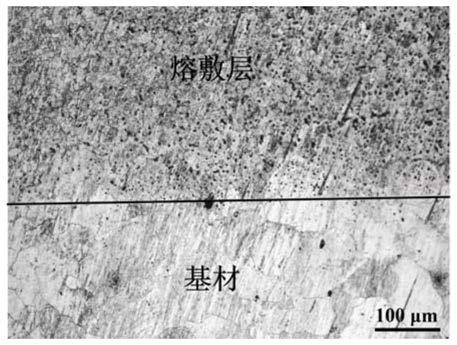

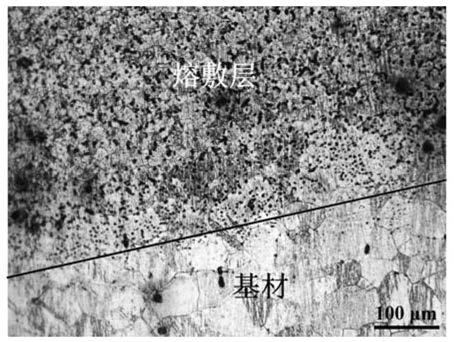

Method for improving magnesium alloy welded joint through surface microalloying

ActiveCN108977805AHigh yield strengthHigh tensile strengthMetallic material coating processesRare-earth elementWeld seam

The invention discloses a method for improving a magnesium alloy welded joint through surface microalloying, and belongs to the technical field of welding technologies in material processing. Mixed powder composed of metal powder including Al, Ti, Cr, Mn and Ni and rare earth element powder including Sc and Nd is developed, and a laser microalloying technology is used for conducting surface modification on a magnesium alloy welding seam area to improve the comprehensive performance of the magnesium alloy welded joint, wherein the power comprises the components in percentage by mass: 9.1%-9.4%of Al, 5.4-5.8% of Ti, 4.1-4.3% of Cr, 0.05-0.2% of Mn, 0.03-0.2% of Sc, 0.8%-2.2% of Nd and the balance Ni, and the grain size of laser microalloyed powder is 100-300 meshes. The laser microalloyingtechnology is adopted to obtain a nanophase-containing cladding layer good in performance on the surface of the magnesium alloy welded joint, and rare earth elements, the other alloy elements and a Mgalloy substrate molten layer can generate a large number of alloy compound wild phases and can effectively refine a microstructure of the cladding layer, improve the mechanical performance of the magnesium alloy welded joint and greatly improve the corrosion resistance performance of the magnesium alloy welded joint.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI +1

Composite material of magnesium alloy and method for preparing the same

The invention discloses a magnesium alloy composite material comprising powdered alloy and nano particles of carbide and oxide, wherein the composite material powdered alloy includes (by weight portions) Al 2-10 parts, Zn 0.1-1 part, Mn 0.02-0.4 part, Mg 88.60-97.88 parts.

Owner:CHONGQING UNIV

A large-scale ruthenium-based alloy sputtering target and its preparation method

ActiveCN104032270BLow impurity contentHigh densityVacuum evaporation coatingSputtering coatingRutheniumAbnormal discharge

The invention discloses a large-sized ruthenium-based alloy sputtering target and a preparation method thereof. The ruthenium-based alloy target comprises one or more of Al, Co, Cr and the like and the balance of Ru and is in a cake shape, wherein the diameter of the target is not less than 100mm, the density is not less than 99.5%, the density difference between the central zone and the marginal zone of the target does not exceed 0.3%, and a second phase formed by the Ru and other alloy elements is uniformly distributed in an Ru matrix phase. The preparation method for the ruthenium-based alloy sputtering target comprises the steps of preparing brittle phase ruthenium-based alloy powder with relatively low melting point through a gas atomization method, treating the brittle phase through an air-current mill to obtain fine and uniform alloy powder, and sintering the powder to obtain the ruthenium-based alloy target of which the diameter is more than 100mm. The alloy target is low in impurity content, high and uniform in density, uniform in component distribution and fine and uniform in grains, a coating sputtered by using the target is uniform in thickness and stable in performance, and the phenomena of abnormal discharge and the like in the sputtering process are reduced.

Owner:YUNNAN PRECIOUS METALS LAB CO LTD

Preparation method of aluminum-silicon alloy

The invention discloses a preparation method of an aluminum-silicon alloy. The preparation method comprises the steps: heating blocky silicon to 1300-1400 DEG C to ensure that the blocky silicon is melted to molten silicon, controlling the temperature of the molten silicon to 760-770 DEG C, and mixing the molten silicon with molten aluminum under a high-purity nitrogen or argon protection atmosphere to prepare molten aluminum-silicon alloy. The prepared molten aluminum-silicon alloy is thin and uniform in silicon phase and uniform in distribution. Silicon is remarkably refined, and crystalline grains are smaller.

Owner:CITIC DICASTAL

A kind of high-quality mirror aluminum alloy material and preparation method thereof

The invention discloses a high-quality mirror aluminum alloy material and a preparation method thereof. The alloy is composed of the following components: Si: 0.45-0.55%, Cu: 0.15-0.25%, Mg: 0.75-0.95%, Cr: 0.12 ~0.22%, Ag: 0.02~0.20%, Pb: 0.03~0.15%, Fe≤0.08%, Mn≤0.1%, Zn≤0.05%, Ti≤0.04%, the balance is Al and unavoidable impurities. The preparation method includes: melting and casting, solid solution treatment, low-temperature cold deformation at -200--150°C, and vibration aging treatment in the sub-resonant frequency range. The invention optimizes the alloy components and the preparation process, effectively controls the quantity, distribution and shape of unfavorable second phases, recrystallization and residual crystalline phases, improves the surface activity, light absorption, optical reflectivity and machining adaptability of the matrix tissue, and effectively Improve the mirror precision machining yield of aluminum alloy materials and the adaptability to the surface coating process; finally obtain high-quality mirror aluminum alloy materials.

Owner:湖南卓创精材科技股份有限公司

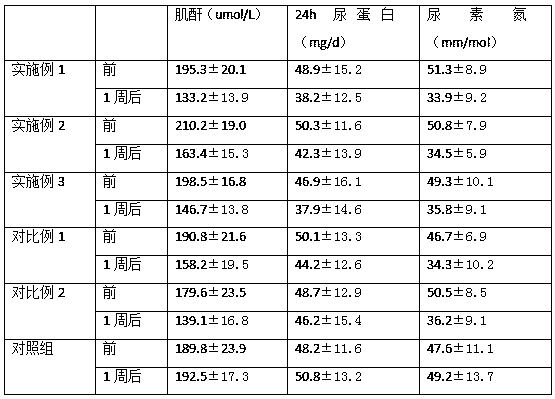

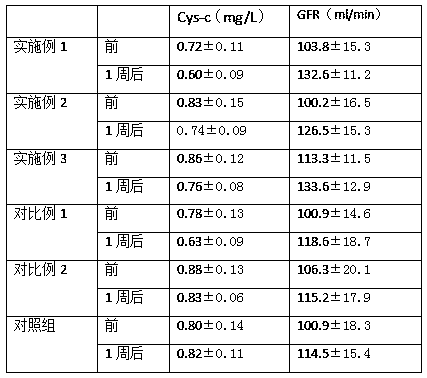

Full-nutrition food formula for adult chronic kidney disease non-dialysis patients, and preparation method thereof

InactiveCN110226743AIncrease profitPromote digestion and absorptionDough treatmentFood ingredient functionsDietary fiberDialysis patients

The present invention belongs to the field of special medical food and particularly relates to a full-nutrition food formula for adult chronic kidney disease non-dialysis patients, and a preparation method thereof. The full-nutrition food formula provides energy of 565.7 Kcal / 100 g and contains 40 g / 100 g of proteins providing energy of 162.6 Kcal / 100 g, 30 g / 100 g of carbohydrates providing energy of 121.9 Kcal / 100 g, 25 g / 100g of fat providing energy of 221.1 Kcal / 100 g, and 30 g / 100 g of dietary fibers providing energy of 60.1 Kcal / 100 g. The provided food is high in raw material utilization rate, relieves malnutrition symptoms of the adult chronic kidney disease non-dialysis patients, and is high in quality, convenient to carry and suitable for industrial production.

Owner:UNIV OF JINAN

Preparation method of in-situ particle reinforced metal-based composite material

ActiveCN114250379AUniversalImprove mechanical propertiesIncreasing energy efficiencyNitrogen gasMetal matrix composite

The invention discloses a preparation method of an in-situ particle reinforced metal matrix composite, and belongs to the field of powder metallurgy. Titanium powder, a reinforcing body X and a binding agent M are evenly mixed according to a certain proportion, after pressing forming is conducted, the two-step sintering technology of nitrogen sintering and high-temperature sintering is adopted, and the high-performance in-situ particle reinforced metal-based composite material is obtained. In the method, fine and uniform TiC, TiB, TiN or Ti (C, N) strengthening phase particles are generated by utilizing in-situ reaction between titanium powder and nitrogen, C, B or B4C. And meanwhile, Fe, Ni and Co serve as binders to increase wettability between a strengthening phase and a binding phase, metallurgical bonding of strengthening particles and a metal matrix is achieved, and therefore the toughness of the metal matrix composite is improved, full compactness is achieved, and residual pores are eliminated. The metal-based composite material is prepared through the powder metallurgy process, in-situ particle strengthening can be achieved, the process is simple, the raw material utilization rate is high, the material shape is complex and changeable, the production efficiency is high, and the method is suitable for large-scale industrial production.

Owner:UNIV OF SCI & TECH BEIJING +1

An expandable polystyrene/sio 2 Preparation Technology of Airgel Core-Shell Composite Particles

A preparation process of expandable polystyrene / SiO2 airgel core-shell composite particles, first prepare the water phase solution; then prepare the oil phase solution; when the temperature in the reaction kettle reaches 60°C, the oil phase solution The shell droplet generator is introduced into the aqueous solution, and the temperature of the reactor is set at 90°C. By controlling the flow rate of styrene monomer in the core-shell droplet generator, the control of the core-shell ratio of the composite particles is realized. When the temperature of the reactor reaches After 90°C, start timing, add pentane after 2.5 hours, wait until the temperature reaches 100°C, keep it warm for 3 hours, cool down to 40°C and discharge. The invention designs the SiO2 airgel / polystyrene composite thermal insulation material to have the characteristics of small density, good mechanical properties, good flame retardancy and low thermal conductivity, etc., and prepares the thermal insulation performance of the polystyrene / SiO2 airgel composite thermal insulation board It is 65.4% higher than the current EPS board for building insulation.

Owner:陕西得波材料科技有限公司

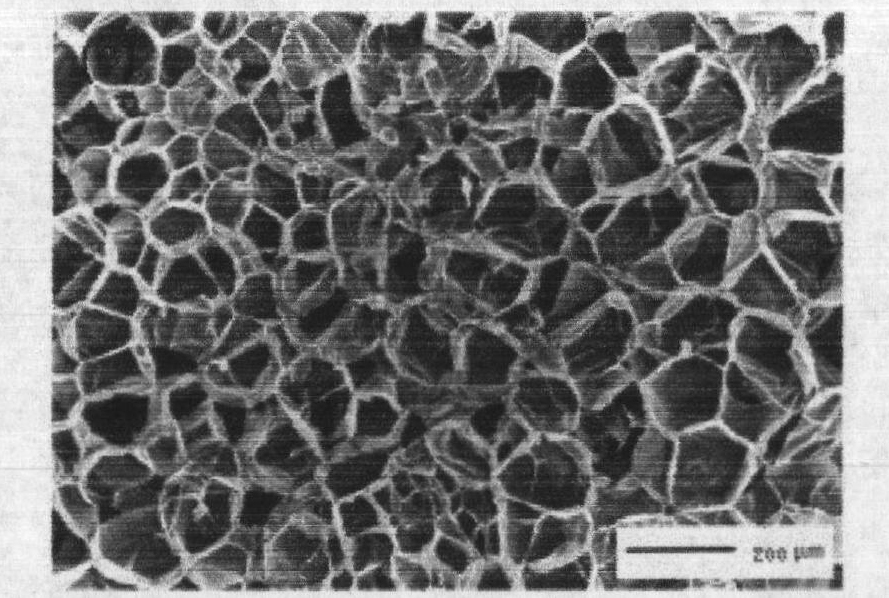

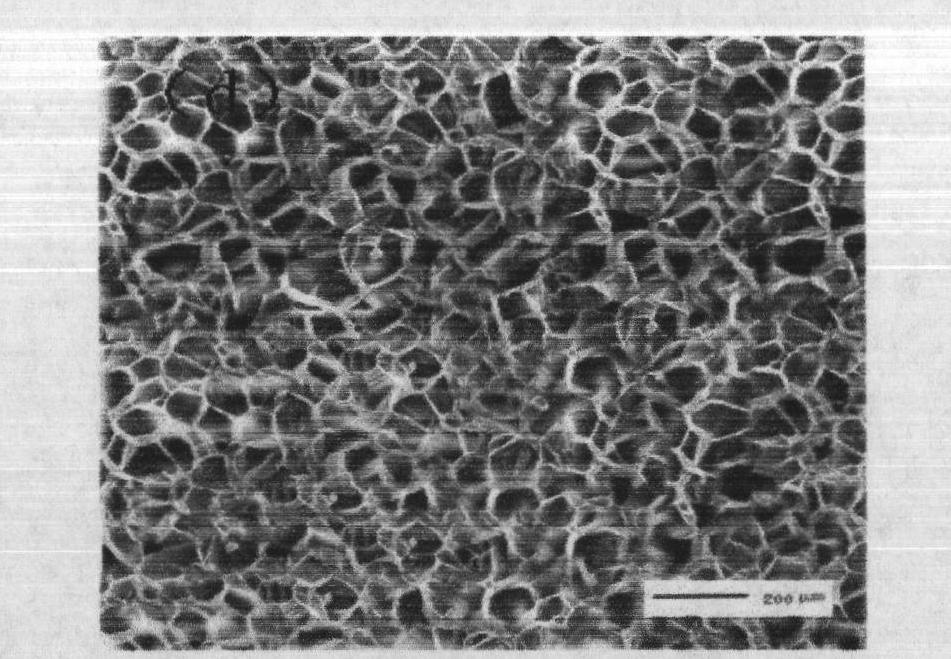

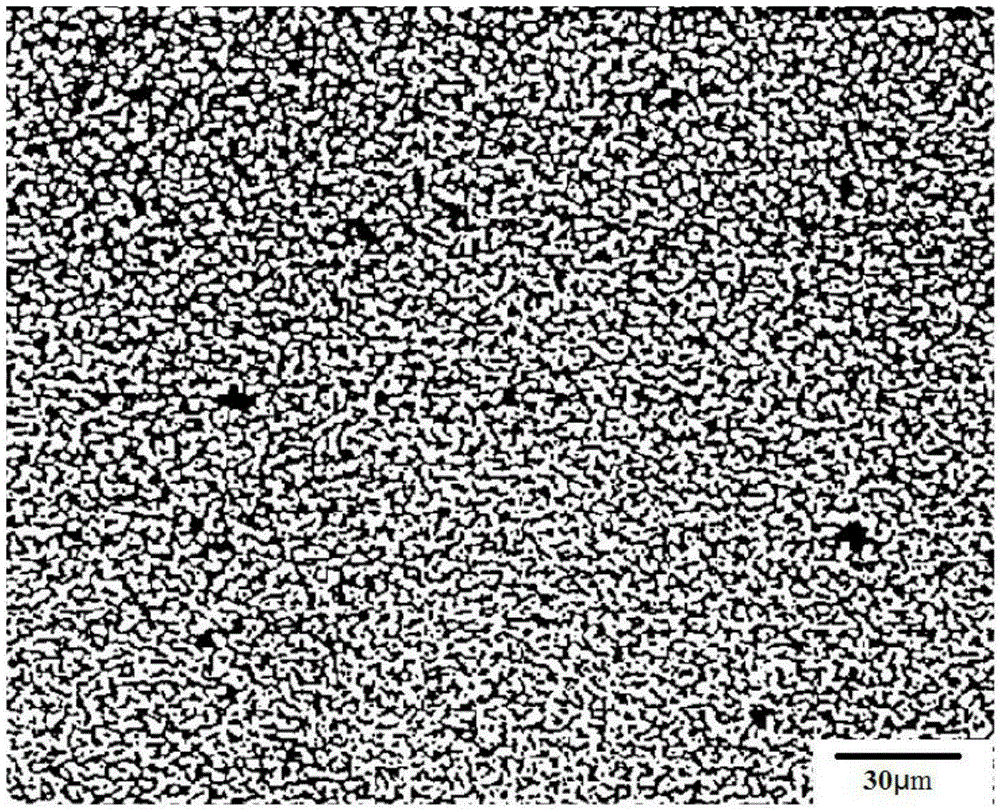

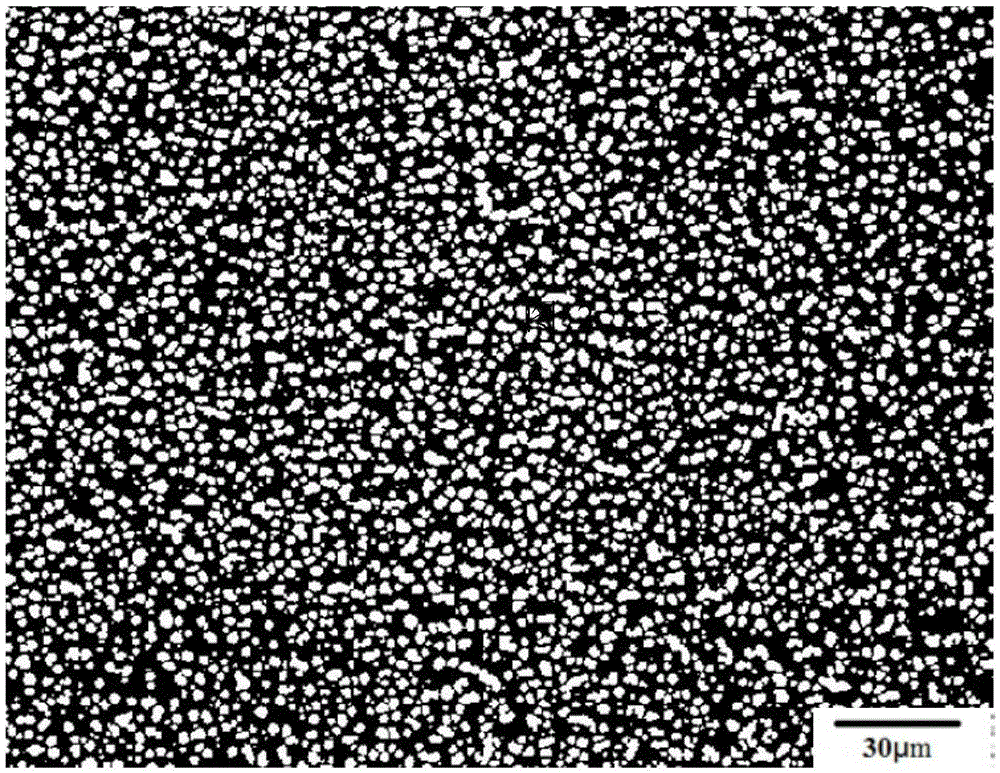

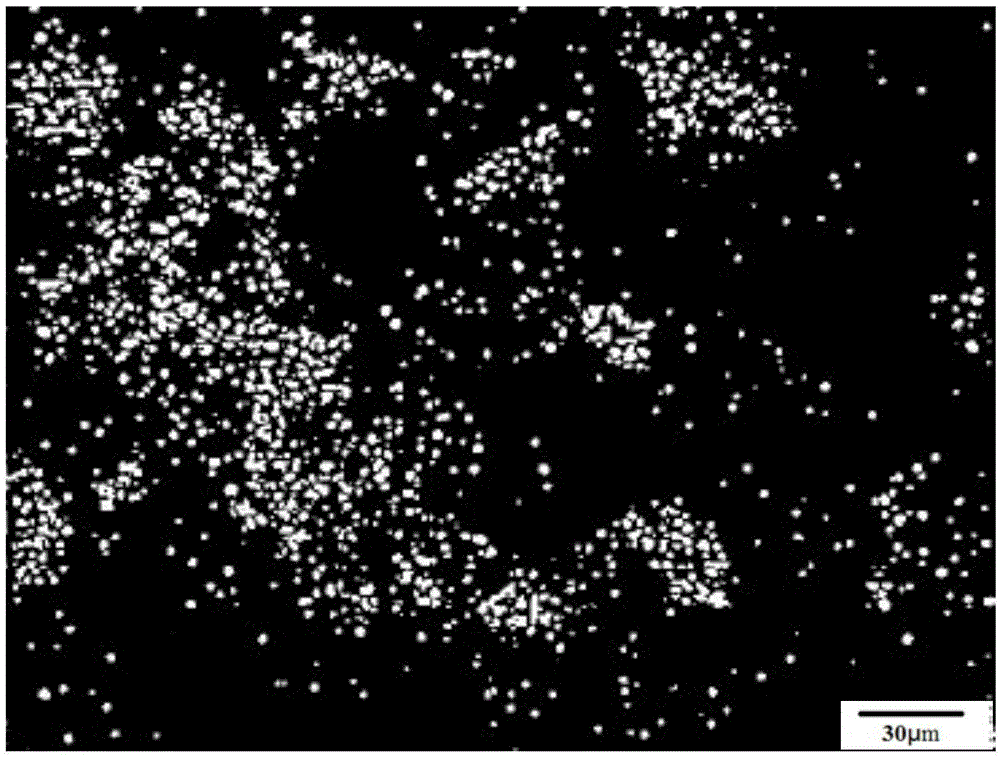

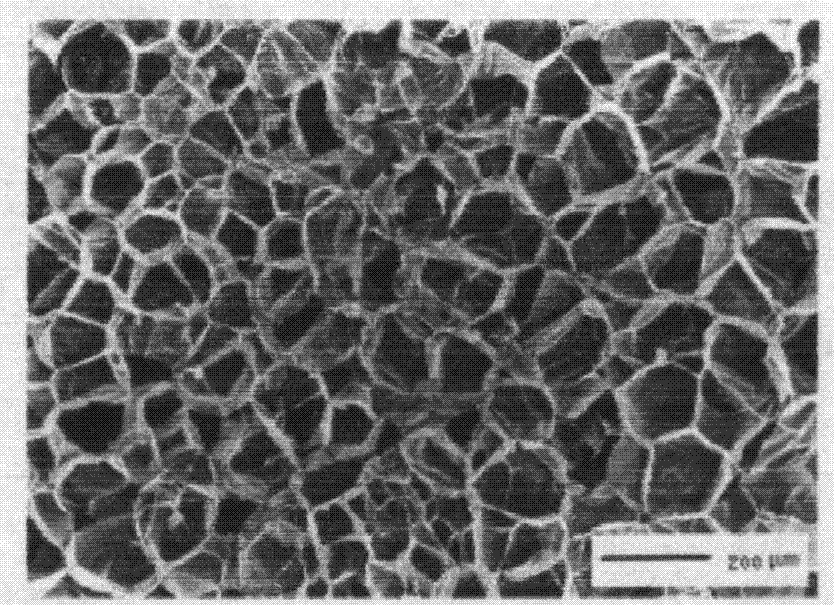

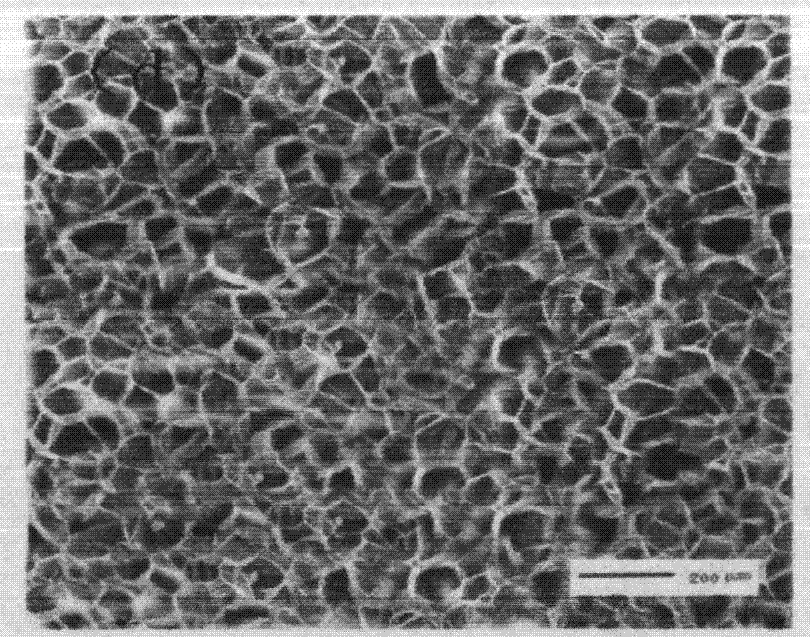

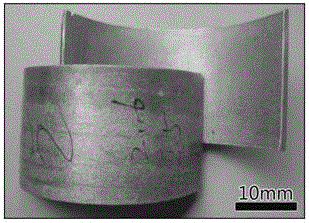

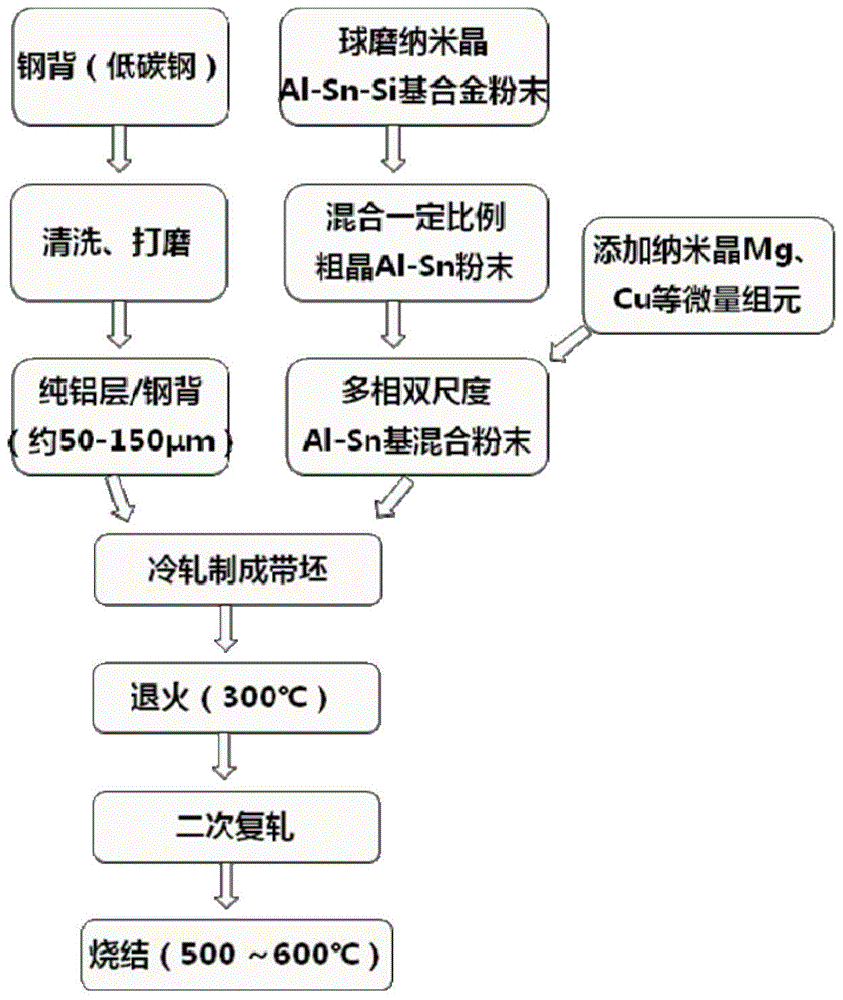

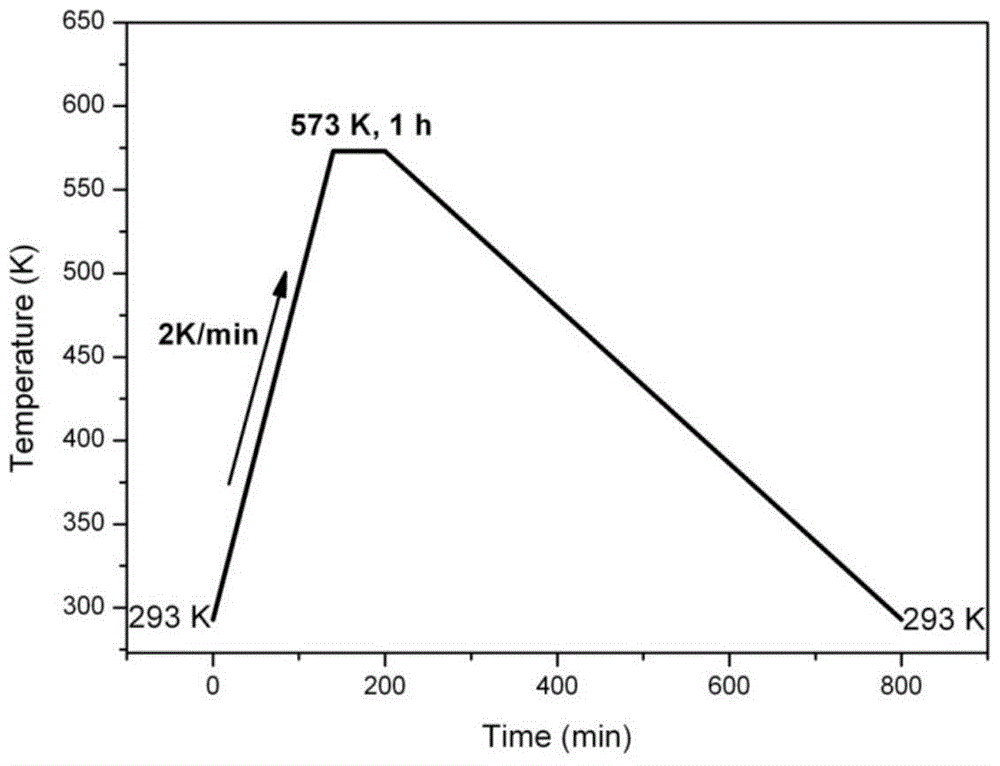

Multi-phase dual-scale structure aluminum-tin-based composite bearing strip and its preparation method

ActiveCN104589726BImprove fatigue strengthHigh densityMolten spray coatingLamination ancillary operationsScale structureAlloy

The invention provides a multi-phase dual-scale structure Al-Sn-based alloy powder / pure aluminum / steel back composite bearing pad strip, which comprises an upper multi-phase dual-scale structure Al-Sn-based alloy layer, a middle transition pure A three-layer structure consisting of an Al layer and a lower carbon steel back layer; the Al-Sn-based alloy layer is prepared by mechanical alloying and has a multi-phase dual-scale structure Al-Sn-Si-Mg-Cu mixed The powder is composed of: nanocrystalline Al-Sn-Si alloy powder + micron coarse-grained Al-Sn alloy powder + nanocrystalline Cu, Mg, Si and other trace components. The present invention also provides a preparation method of a multi-phase double-scale aluminum-tin-based alloy powder / pure aluminum / steel back composite bearing strip. Preparation of scale alloy powder, surface treatment of steel back, primary rolling compound, annealing, secondary rolling and sintering and other processes. It solves the problems arising in the industrial application process of Al-Sn-based bearing alloy prepared by mechanical alloying in the bearing bush strip, and realizes industrial production.

Owner:SOUTH CHINA UNIV OF TECH

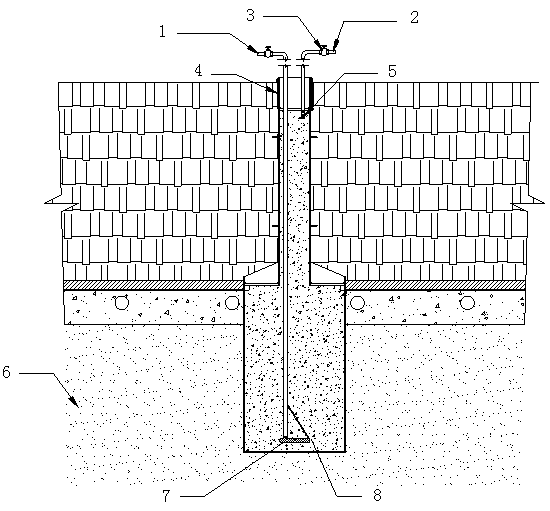

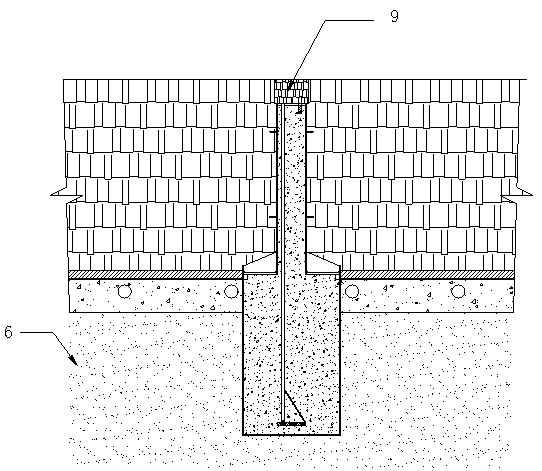

Deep foundation pit underground drainage pre-buried well grouting plugging construction method

InactiveCN110863503ASimple structureEasy to operateFoundation engineeringSteel platesGround water level

The invention discloses a deep foundation pit underground drainage pre-buried well grouting plugging construction method. The method is characterized by comprising the following steps of a, manufacturing a plugging circular steel plate according to an inner diameter of the pre-buried well, welding a drain pipe, and making a grouting pipe; b, winding an isolation filler around the outer edge of anupper opening of the pre-buried well; c, adding gravel in a pre-buried well, installing a grouting pipe and gravel to a predetermined position; d, installing the plugging circular steel plate, and welding the plugging circular steel plate to the grouting pipe, the pre-buried pipe; e, the grouting pipe and the drain pipe to be high in height to the underground water level equilibrium position; f, grouting, secondary grouting; g, cutting the grouting pipe, the drain pipe, the pre-buried pipe spare section, roughening the edge structure concrete; and h, and pouring concrete for the second time. The drainage pre-buried well plugging system has the advantages that the structure is simple, the operation is convenient, the engineering quality is safe and reliable, the grouting floral pipe is horizontally positioned at the grouting part of the pre-buried well bottom hole, the average distribution of the slurry during grouting is facilitated, the isolation filling material is arranged, when thespare section steel manufacturing facility is removed, the whole structure of the secondary filling concrete is completely combined after roughed.

Owner:CHINA MCC20 GRP CORP

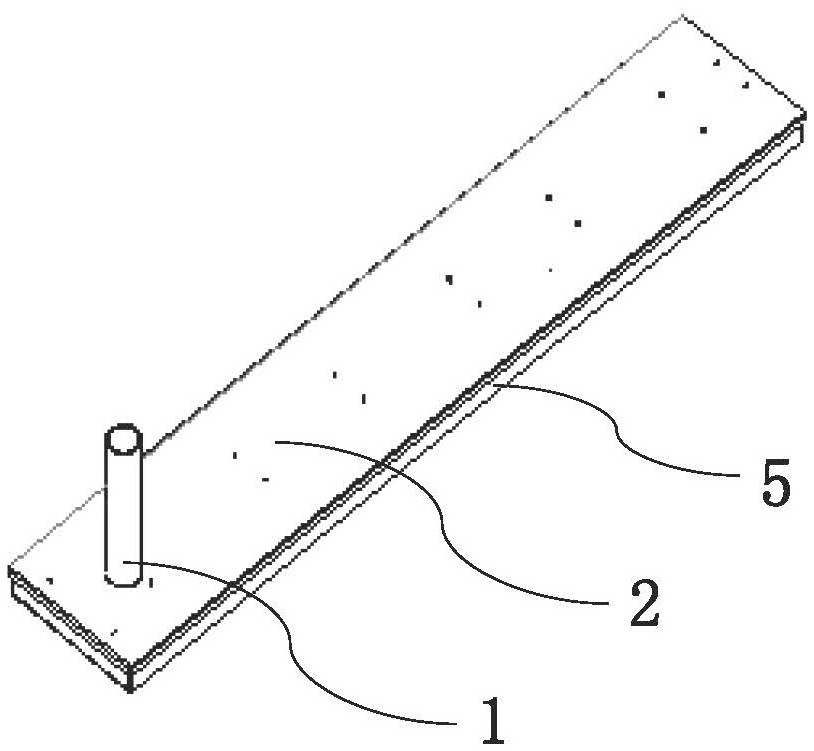

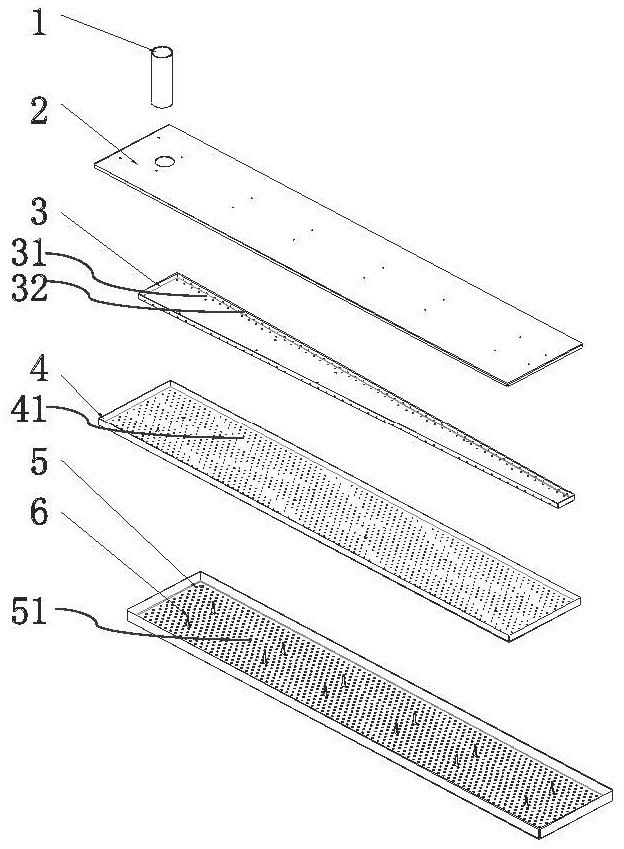

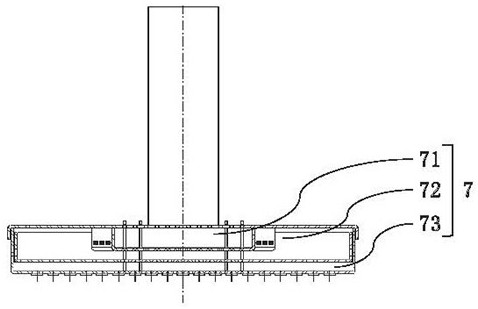

Liquid distributor of falling film evaporator and manufacturing method thereof

ActiveCN112856861AEvenly distributedBetter even distributionGeneral water supply conservationEvaporators/condensersEngineeringRefrigerant

The invention provides a liquid distributor of a falling film evaporator and a manufacturing method thereof. The liquid distributor comprises a bottom-layer liquid distribution plate and a top cover plate covering the bottom-layer liquid distribution plate, the bottom-layer liquid distribution plate and the top cover plate jointly define a liquid distribution cavity, an upper-layer liquid distribution plate and a middle-layer liquid distribution plate are arranged in the cavity in the height direction, a first-layer liquid distribution area, a second-layer liquid distribution area and a third-layer liquid distribution area are separated, the top cover plate is provided with an inlet connecting pipe communicating with the first-layer liquid distribution area, the edge of the upper-layer liquid distribution plate is bent and erected to form a side wall, vertical distribution holes and horizontal distribution holes are formed in the plate face and the side wall of the upper-layer liquid distribution plate correspondingly, through distribution holes are formed in the middle-layer liquid distribution plate, and the bottom-layer liquid distribution plate is provided with flanging stretching holes communicating with the third-layer liquid distribution area. When a certain pressure is applied to a refrigerant, the refrigerant is pressed into the first-layer liquid distribution area through the inlet connecting pipe, then is sprayed to the second-layer liquid distribution area at a high speed through the vertical distribution holes and the horizontal distribution holes of the upper-layer liquid distribution plate, and then sequentially passes through the middle-layer liquid distribution plate and the bottom-layer liquid distribution plate in a deceleration manner, so that fine and uniform distribution of the refrigerant is realized.

Owner:ZHEJIANG KING CO LTD

A method for preparing needle-like second phases to improve the degradation resistance of medical magnesium alloys

ActiveCN110722168BReduce transfer rateHigh affinityAdditive manufacturingTransportation and packagingImplantGalvanic corrosion

Owner:CENT SOUTH UNIV

Water-in-water artistic coating fine granulation device

PendingCN111905648AImprove covering abilityReduce consumptionArtist's paintsGranulation in stationary drums/troughsEngineeringMechanical engineering

The invention relates to the field of water-in-water multicolor coating treatment, in particular to a water-in-water artistic coating fine granulation device which comprises a high-speed power mechanism, a transmission shaft is fixed to the power output end of the high-speed power mechanism, and a granulation mechanism is arranged at the other end of the transmission shaft and comprises a dispersion disc with the outer surface of a curved surface structure. At least two dispersing blades used for color point granulation are evenly arranged on the side wall of the periphery of the dispersing disc, knife edges are arranged on the front side walls, in the length extending direction, of the dispersing blades, and the included angle between the outer side walls of the knife edges is smaller than 90 degrees. According to the invention, high-efficiency and large-scale granulation can be achieved to obtain color points with good uniformity and particle size of less than 3mm; in addition, onlyone-time granulation is needed, granulation with the color point particle size smaller than 3 mm can be completed within 10 min no matter how many batches are, efficient granulation can be achieved, it can be guaranteed that the color point with the particle size smaller than 3 mm obtained through granulation can reach 99%, and the granulated color point is fine in particle size and good in uniformity.

Owner:CHONGQING YIPU BAISHAN MUD BUILDING MATERIALS

A Method of Surface Microalloying to Improve Magnesium Alloy Welded Joints

ActiveCN108977805BHigh yield strengthHigh tensile strengthMetallic material coating processesRare-earth elementWeld seam

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI +1

Gas floatation separation device

InactiveCN101417184BBetter even distributionEfficient separationFlotationLiquid separationExternal energyMicrobubbles

The invention discloses an air flotation separation device, comprising an external cylinder (2), a rotational flow mixed cylinder (8), a first slag-retaining cylinder (7), a first scum drainage pipe (4) and a scum collecting guide plate (10); wherein, the bottom end of the first slag-retaining cylinder (7) and the bottom of the external cylinder (2) have spacing so as to form a water passage; thebottom of the side wall of the rotational flow mixed cylinder (8) is connected with a water inlet pipe (16) which enters in tangent direction; the periphery of the top of the external cylinder (2) isprovided with a clean water collecting trench (14); and the scum collecting guide plate (10) is a strip-typed plate in an involute shape, with the involute direction right opposite to the water rotational flow direction in the rotational flow mixed area (A). Compared with the prior art, the air flotation separation device does not need to add external energy cleaning systems, achieves the object of long-term continuously and stably running, and ensures that the requirement that the micro air bubbles adhere to the dispersed oil, emulsified oil and dissolved oil of small particle size as much as possible is met, thus achieving the object of high-efficiency separation of oil from water. The air flotation separation device is especially suitable for low-consistency water containing oil.

Owner:宁波威瑞泰默赛多相流仪器设备有限公司

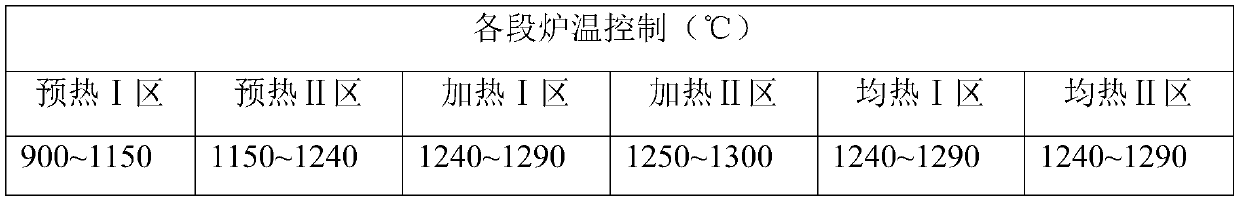

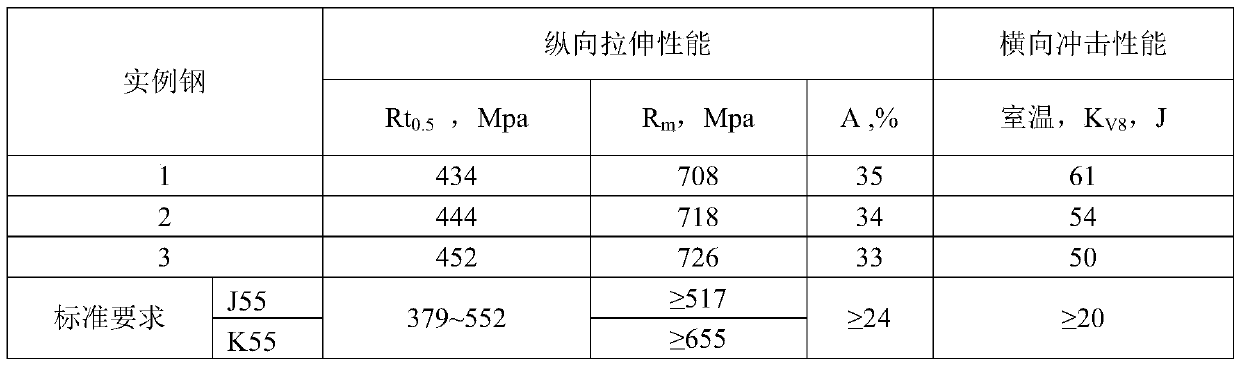

Method for improving impact power of JK55 steel grade oil well pipe by treating alloy steel with micro titanium

The invention provides a method for improving impact power of a JK55 steel grade oil well pipe by treating alloy steel with micro titanium. An alloy pipe is treated by 0.010%-0.040% Ti, the method comprises electric furnace smelting, LF furnace refining, pipe billet continuous casting, pipe billet heating at 1240-1290 DEG C, two-roller cross piercing at 1150-1210 DEG C, rolling into a pierced billet by a PQF continuous mill at 1050-1160 DEG C, sizing rolling, blowing and cooling by a cooling bed fan, and forming. According to the invention, the method has the following beneficial effects: thetensile strength of the oil pipe is more than or equal to 700 MPa, the yield strength is more than or equal to 430 MPa, the elongation percentage is more than or equal to 33%, the transverse impact power at a room temperature is more than or equal to 50 J, and the structure is ferrite plus pearlite; the composition design is reasonable, the operation and control are simple and convenient, and thecost is low; the impact toughness is good, the product performance meets the requirements of J55 and K55 steel grades, and the product can be used for oil casing and an oil pipe.

Owner:TIANJIN PIPE GROUP CORP

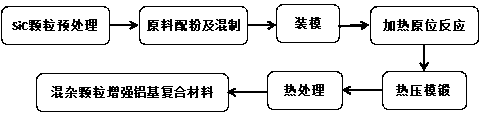

A method for preparing hybrid particle reinforced aluminum matrix composite material by composite strengthening method

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Planar three-freedom-degree parallel mechanism driven by three linear drivers and application thereof

The invention relates to a planar three-freedom-degree parallel mechanism driven by three linear drivers. The planar three-freedom-degree parallel mechanism comprises the three linear drivers and five hinges, wherein two of the five hinges are upper hinges, the other three hinges are lower hinges, the three lower hinges are all fixed to the ground or a device rack, the lower hinges are connected with the linear drivers respectively, the upper ends of the two linear drivers with the lower ends connected with the lower hinges on the outer sides are connected with the upper hinges on the same sides respectively, the upper end of the linear driver with the lower end connected with the middle lower hinge is connected with the upper hinge on any side, and the two upper hinges are connected with each other through an output connecting rod. The parallel mechanism is used as a stir-fry mechanism of an automatic cooker or a vibrating screen or a vibration test table or a transmission mechanism or a parallel robot. The planar three-freedom-degree parallel mechanism driven by the three linear drivers is reasonable in design, ingenious in structure, convenient to install, easy to obtain and wide in application range, and when the parallel mechanism is used, even distribution of driving force can be ensured, stable output can be ensured and the structure of the whole device can be simplified.

Owner:XINXIANG UNIV

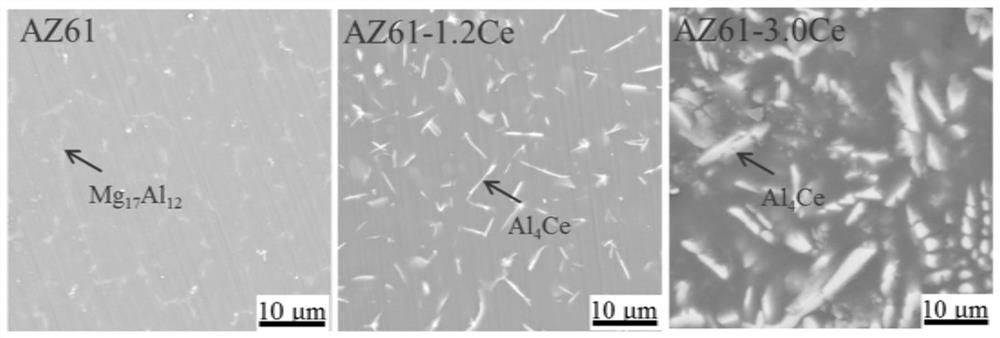

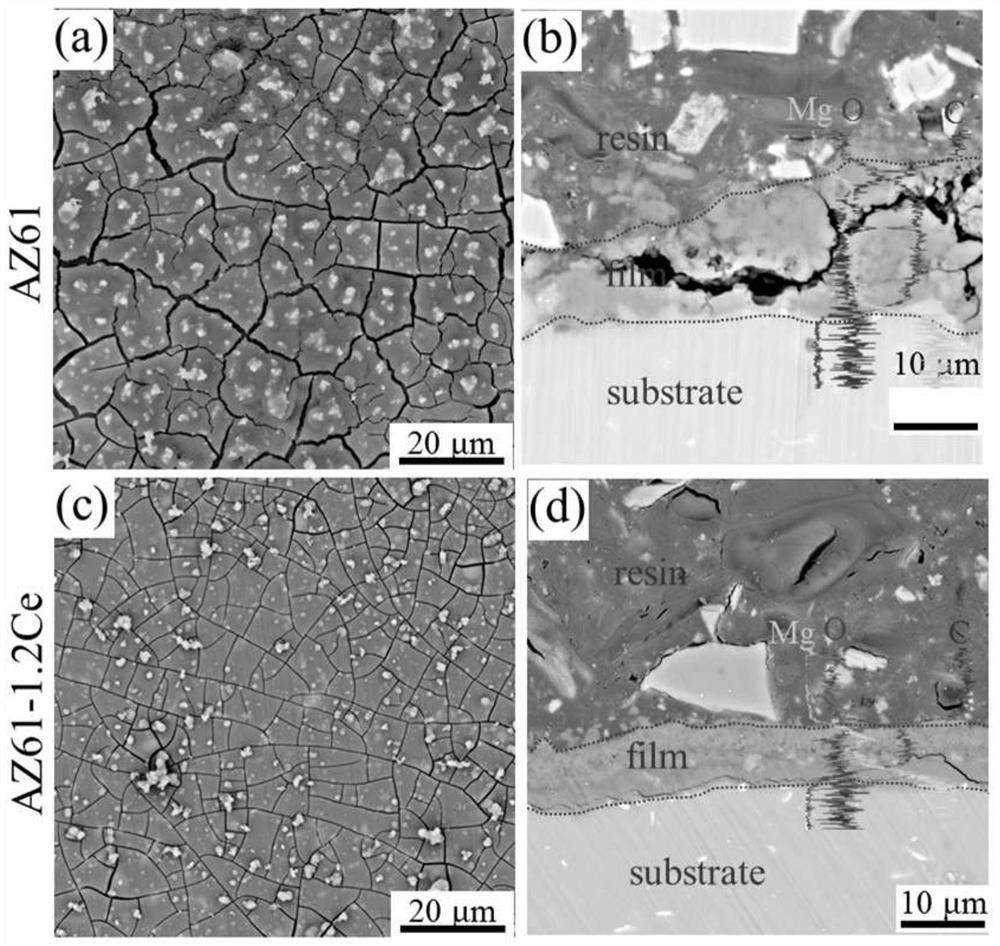

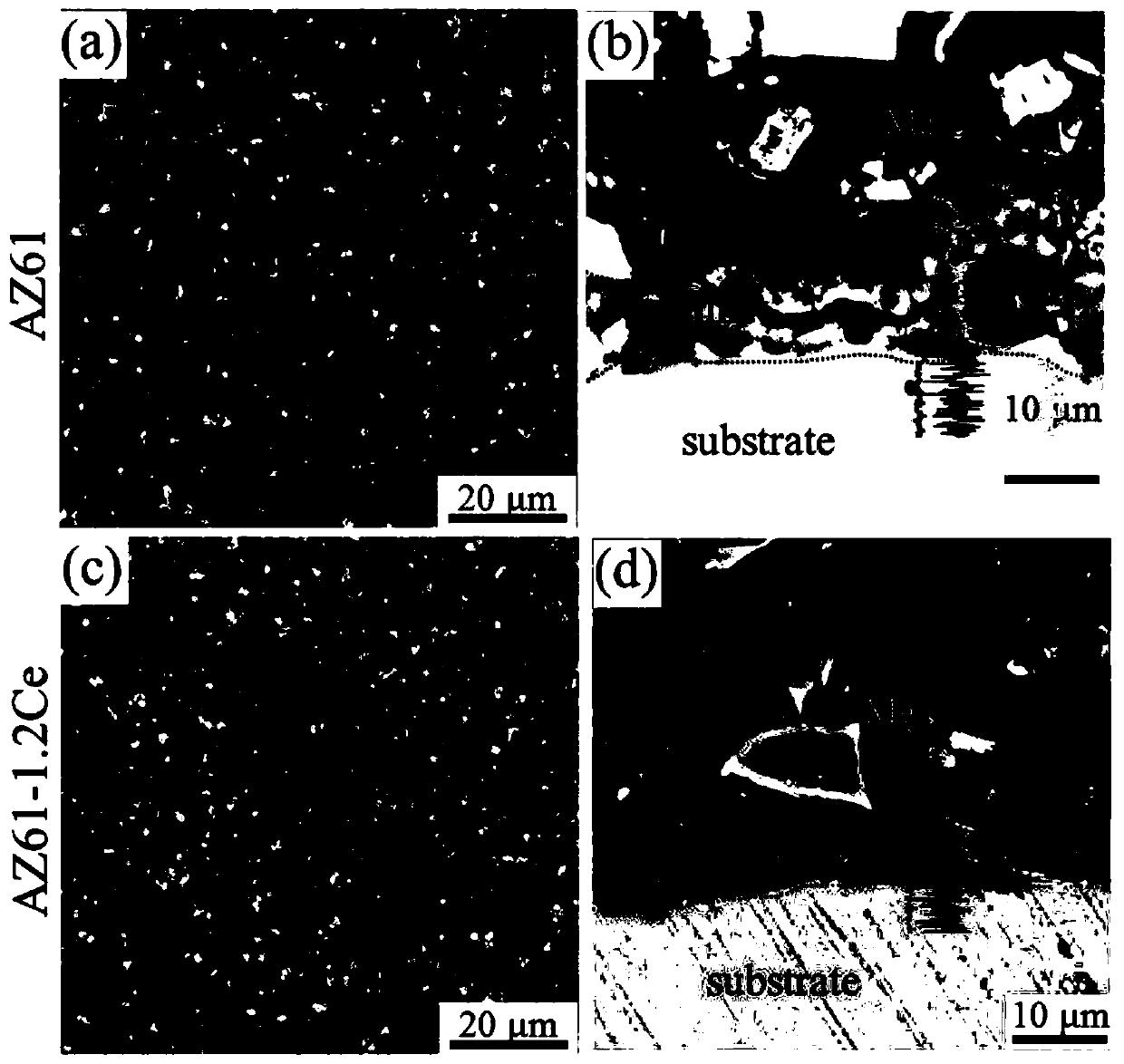

Method of preparing needle-shaped second phase for improving degradation resistance of medical magnesium alloy

ActiveCN110722168AImprove resistance to degradationReduce potential differenceAdditive manufacturingTransportation and packagingImplantMaterials science

The invention relates to a method of preparing a needle-shaped second phase for improving degradation resistance of a medical magnesium alloy. The magnesium alloy includes an AZ61 matrix and needle-shaped Al4Ce phases uniformly distributed in the matrix. The preparation method includes the steps that Ce powder and AZ61 powder are subjected to ball milling to obtain mixed powder, and then the magnesium alloy containing the needle-shaped Al4Ce phases is prepared by SLM. According to the method, on the one hand, matrix grains and the needle-shaped Al4Ce phase structures can be obviously refined,on the other hand, the solid solubility of solute elements is increased, and precipitation of the second phase of Mg17Al12 is inhibited; the formed needle-shaped Al4Ce phases have both smaller potential differences and greater resistance from the matrix, and galvanic corrosion can be inhibited; and during formation of Al4Ce, Al in the alloy is consumed, an original Mg17Al12 phase in the alloy canalso be reduced and refined, thus galvanic corrosion is reduced, degradation resistance of the magnesium alloy is improved through combined action of the two effects, and thus application of the magnesium alloy to degradable implantation materials is promoted.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com