Large-sized ruthenium-based alloy sputtering target and preparation method thereof

A technology of ruthenium-based alloy and sputtering target, which is applied in the field of large-scale ruthenium-based alloy sputtering target and preparation, to achieve the effects of improving film thickness uniformity, uniform composition, and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

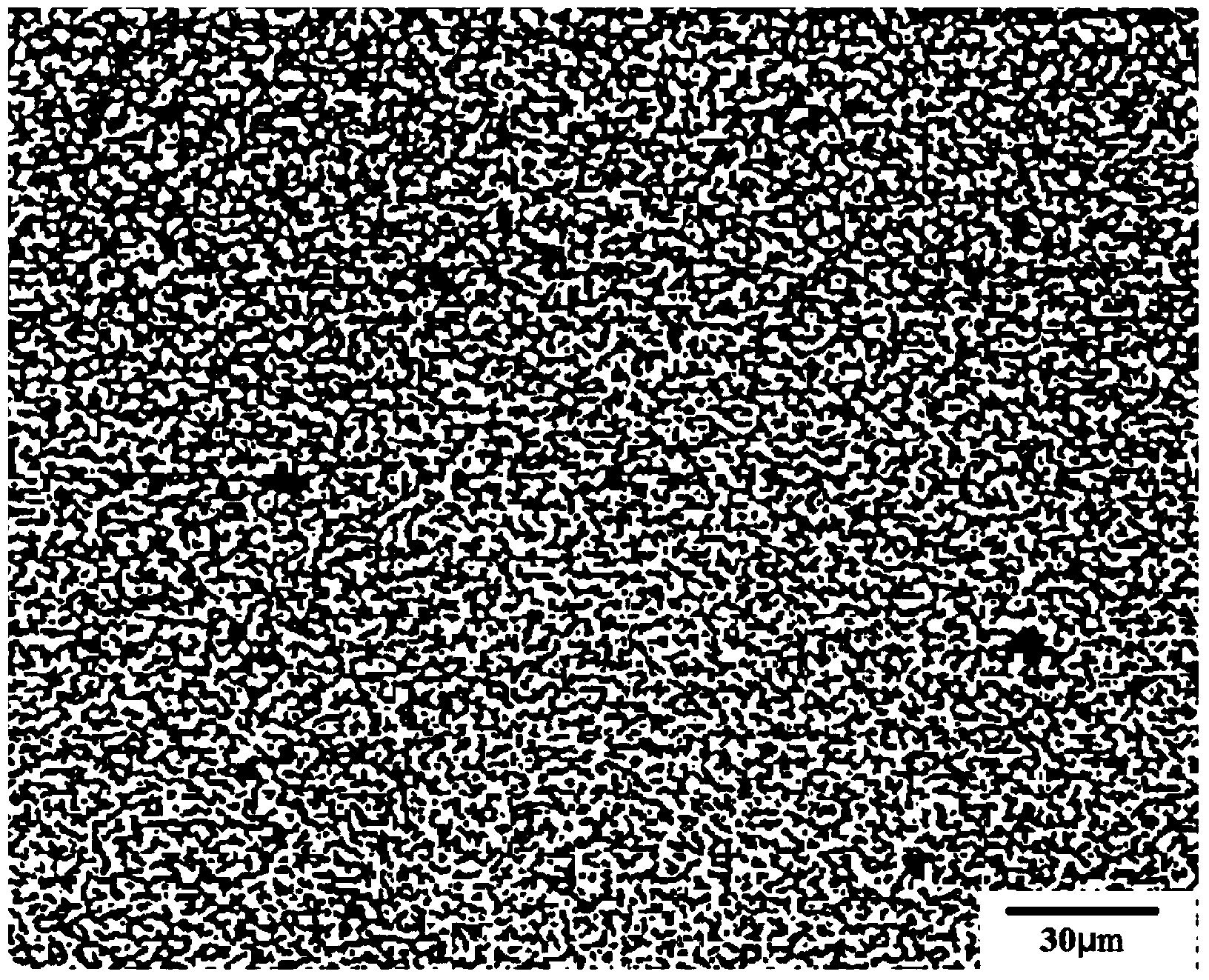

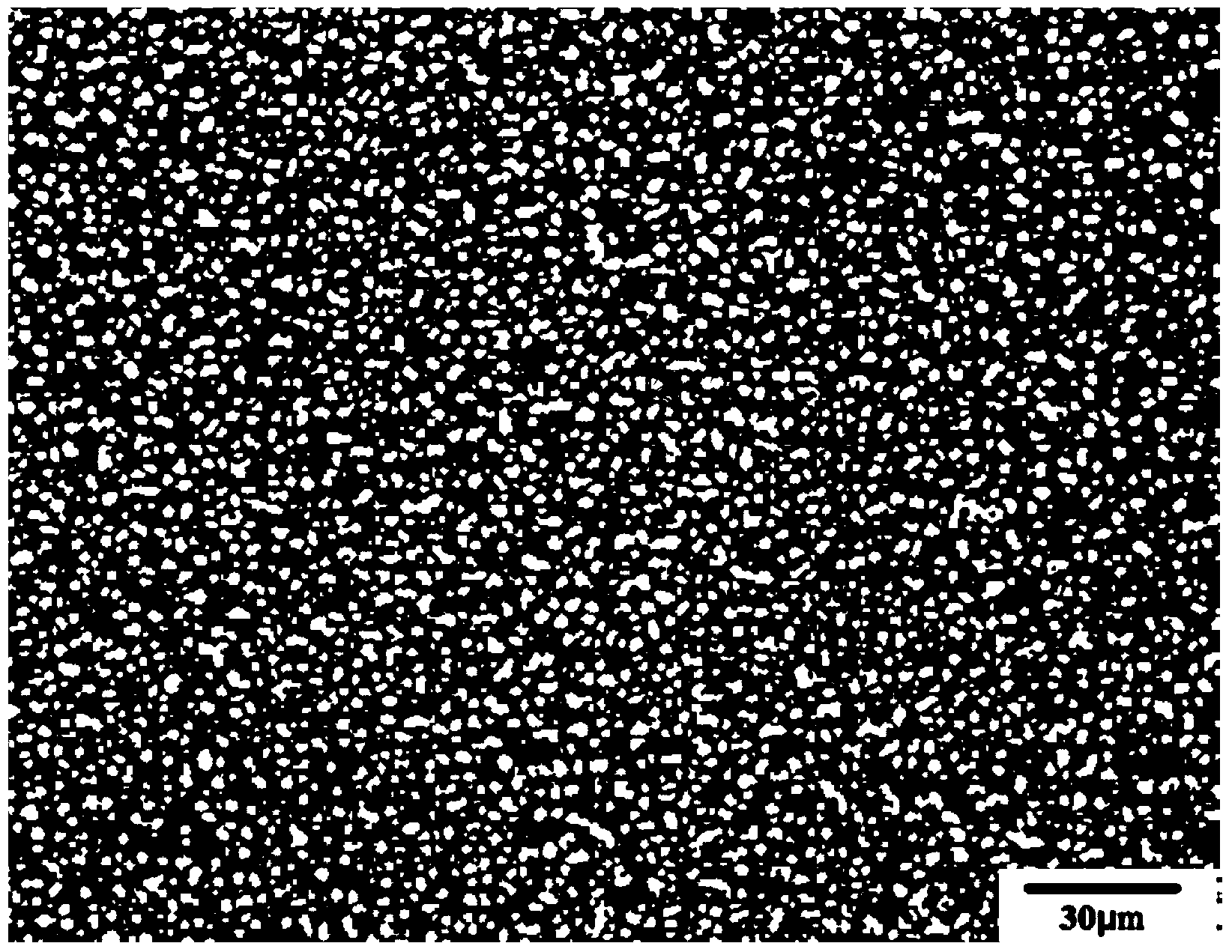

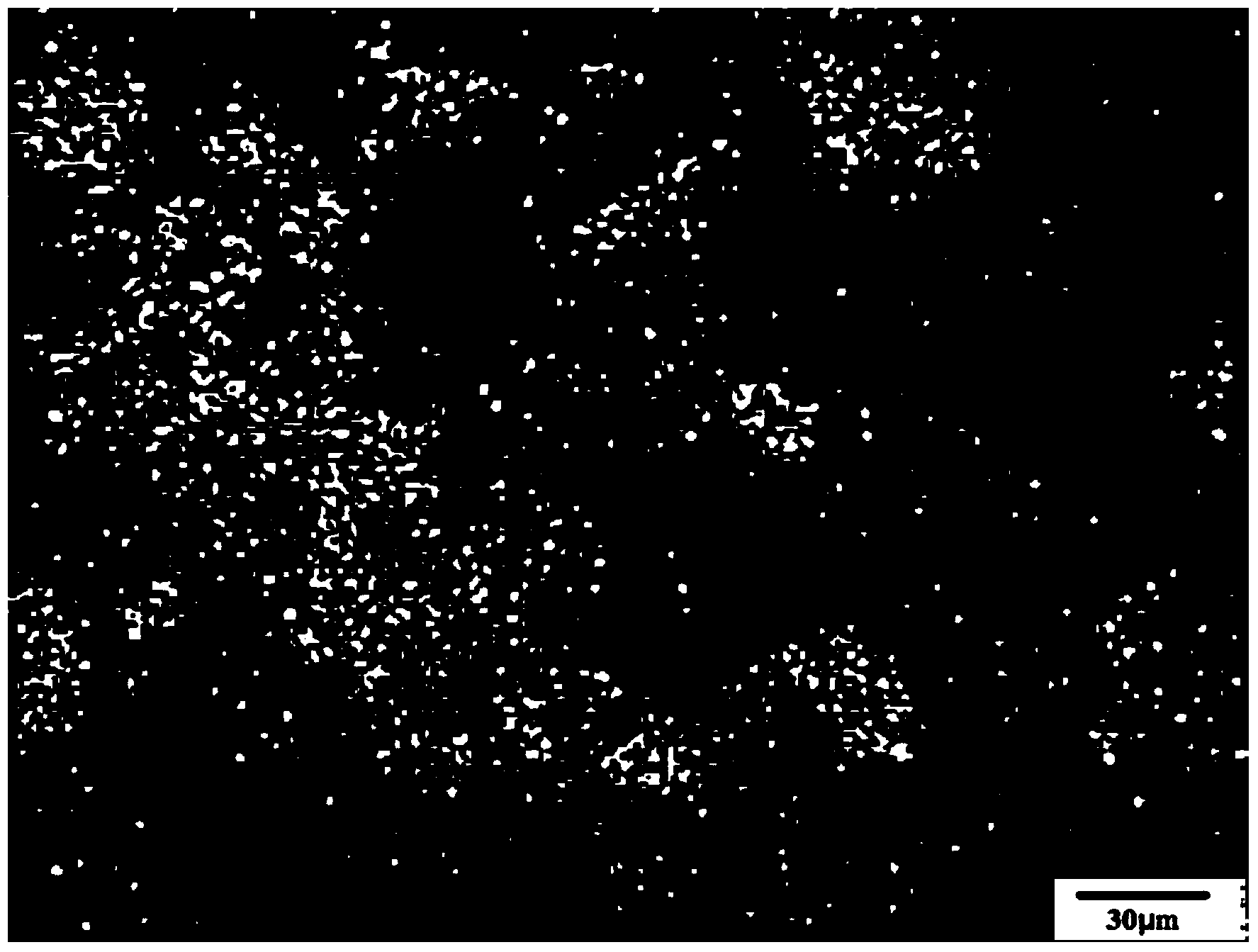

Image

Examples

Embodiment 1

[0034] Ru of the present invention 51 Al 49 Alloy targets are prepared by the following methods:

[0035] (1) Raw material preparation: choose Ru and Al above 3N5 as raw materials;

[0036] (2) Preparation of alloy powder: according to Al 6 Ru or Al 13 Ru 4 The stoichiometric ratio of the intermetallic compound is 10-20Kg, and the vacuum gas atomization method is used to prepare the alloy powder. The material is melted in a vacuum medium frequency induction melting furnace, and the melting temperature is 1000-1600 ° C. The alloy solution is transferred into the tundish to start the gas Atomization, the atomization pressure is 5-8MPa. In order to avoid the introduction of impurities during the atomization process, high-purity argon gas above 4N is selected as the atomization gas. After the atomization is completed, it is sieved by a standard sieve, and the alloy powder below 100 μm is selected;

[0037] (3) Jet mill treatment: The atomized powder is subjected to jet mill ...

Embodiment 2

[0041] The difference from Example 1 is that the ruthenium-based alloy target is Ru 51 co 49 , the raw materials are Ru and Co above 3N5, and the stoichiometric ratio of the alloy powder is Ru in the hexagonal close-packed phase 3 co 7 , the melting temperature is 1600-1800°C, Ru 3 co 7 It is mixed with Ru powder according to the ratio of Ru51Co49, and the sintering temperature is 1100-1300°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com