Preparation method of titanium nitride-ferrous metal ceramics

A technology of iron metal and titanium nitride, applied in the field of cermet materials and preparation, can solve the problems of TiN denitrification, reduction of material strength and hardness, etc., and achieve the effects of high density, uniform distribution of each phase, and uniform powder particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

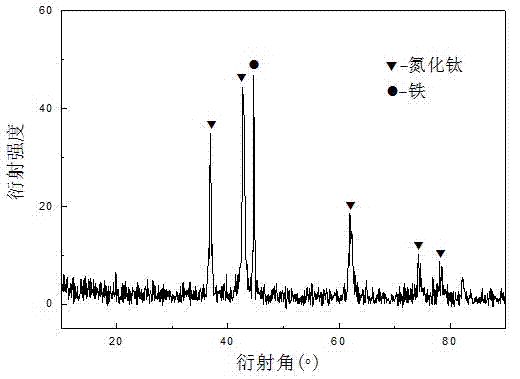

[0021] 10g of iron block and 90g of titanium sponge were weighed according to the proportion of 10% Fe mass fraction, mixed uniformly to make alloy masterbatch, and the masterbatch was prepared into alloy ingot by vacuum smelting method. The alloy ingot was cut into slices, and placed in a tubular atmosphere furnace for hydrogenation embrittlement with high-purity hydrogen. The hydrogenation temperature was 650°C, the heating rate was 10°C / min, and the hydrogenation time was 3h. After the hydrogenated alloy is preliminarily crushed, it is placed in a stainless steel ball mill tank for high-energy ball mill crushing. The mass ratio of the ball to material is 8:1, and the TiH is obtained by ball milling for 6 hours. x -Fe composite powder. Then, the composite powder was placed in a tube-type atmosphere furnace for dehydrogenation treatment under the protection of argon flow. The dehydrogenation temperature was 620°C, the heating rate was 10°C / min, and the dehydrogenation time wa...

Embodiment 2

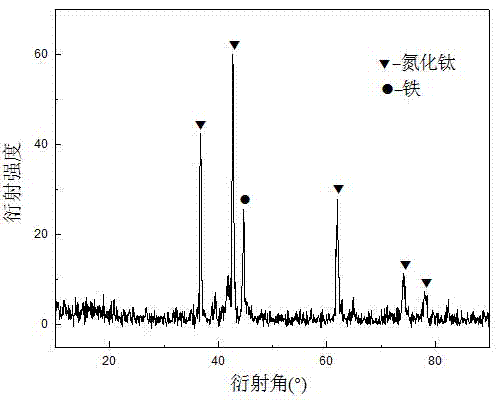

[0024] 15g of iron block and 85g of titanium sponge were weighed according to the proportion of 15% Fe mass fraction, mixed uniformly to make alloy masterbatch, and the masterbatch was prepared into alloy ingot by vacuum smelting method. The alloy ingot was cut into slices, and placed in a tubular atmosphere furnace for hydrogenation embrittlement by high-purity hydrogen. The hydrogenation temperature was 680 °C and the heating rate was 10 o C / min, the hydrogenation time is 3h. After the hydrogenated alloy is preliminarily crushed, it is placed in a stainless steel ball mill tank for high-energy ball mill crushing. The mass ratio of the ball to material is 8:1, and the TiH is obtained by ball milling for 4 hours. x -Fe composite powder. Then, the composite powder was placed in a tubular atmosphere furnace and dehydrogenated under the protection of argon flow. The dehydrogenation temperature was 640°C, the heating rate was 10°C / min, and the dehydrogenation time was 2.5h to obt...

Embodiment 3

[0026] 20g of iron block and 80g of titanium sponge were weighed according to the proportion of 20% Fe mass fraction, mixed evenly to make alloy masterbatch, and the masterbatch was prepared into alloy ingot by vacuum smelting method. The alloy ingot was cut into slices, and placed in a tubular atmosphere furnace for hydrogenation embrittlement with high-purity hydrogen. The hydrogenation temperature was 700°C, the heating rate was 10°C / min, and the hydrogenation time was 4h. After the hydrogenated alloy is preliminarily crushed, it is placed in a stainless steel ball mill tank for high-energy ball mill crushing. The mass ratio of the ball to material is 8:1, and the TiH is obtained by ball milling for 6 hours. x -Fe composite powder. Then, the composite powder was placed in a tubular atmosphere furnace and dehydrogenated under the protection of argon flow. The dehydrogenation temperature was 650°C, the heating rate was 10°C / min, and the dehydrogenation time was 3h to obtain T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com