Gas floatation separation device

A technology of air flotation separation and separation area, which is applied in the direction of solid separation, liquid separation, separation methods, etc. It can solve problems such as affecting production efficiency, complicated maintenance operations, and clogging of releasers, and achieves complete oil-water separation, high separation efficiency, and low cost. economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the embodiments of the drawings.

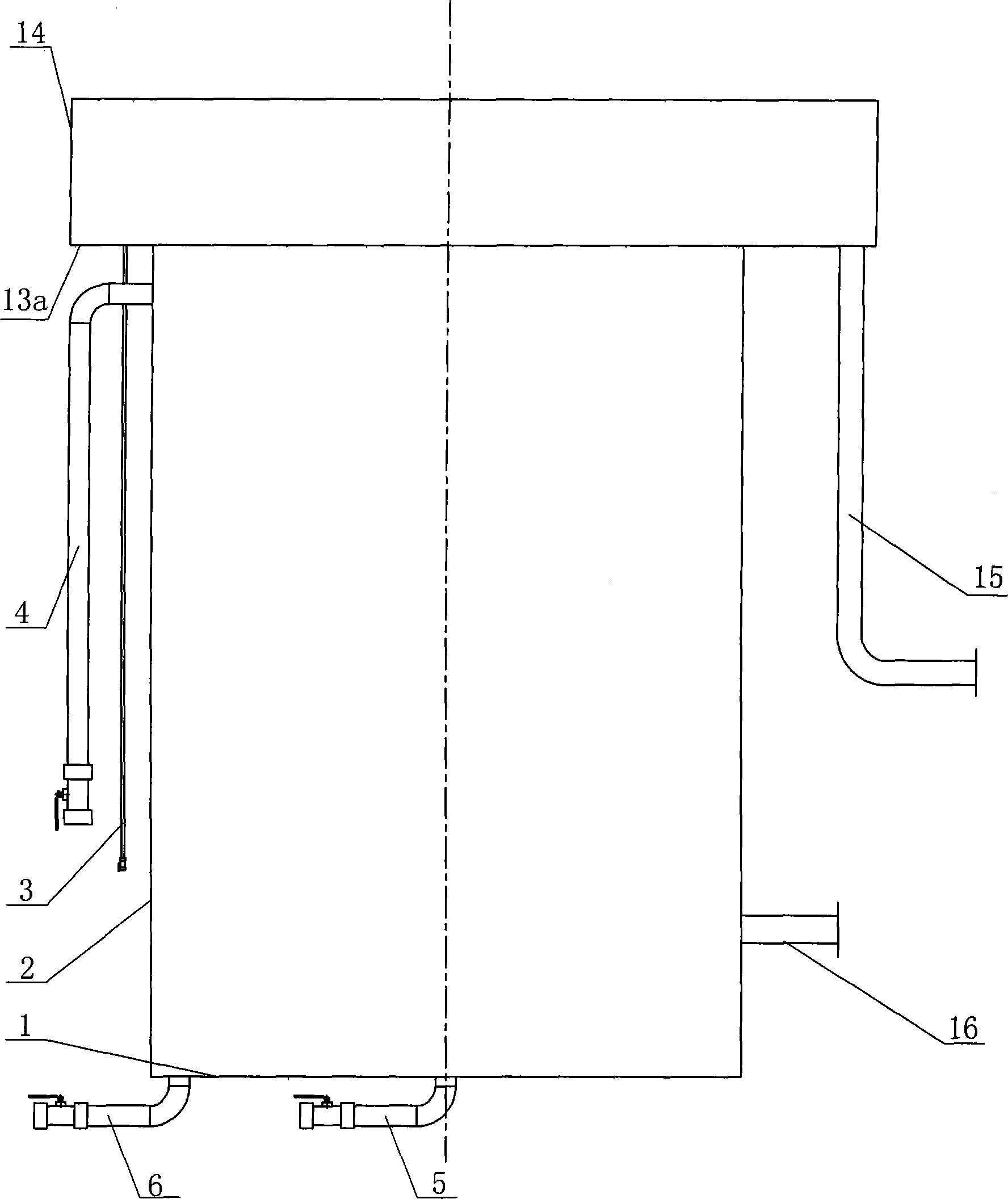

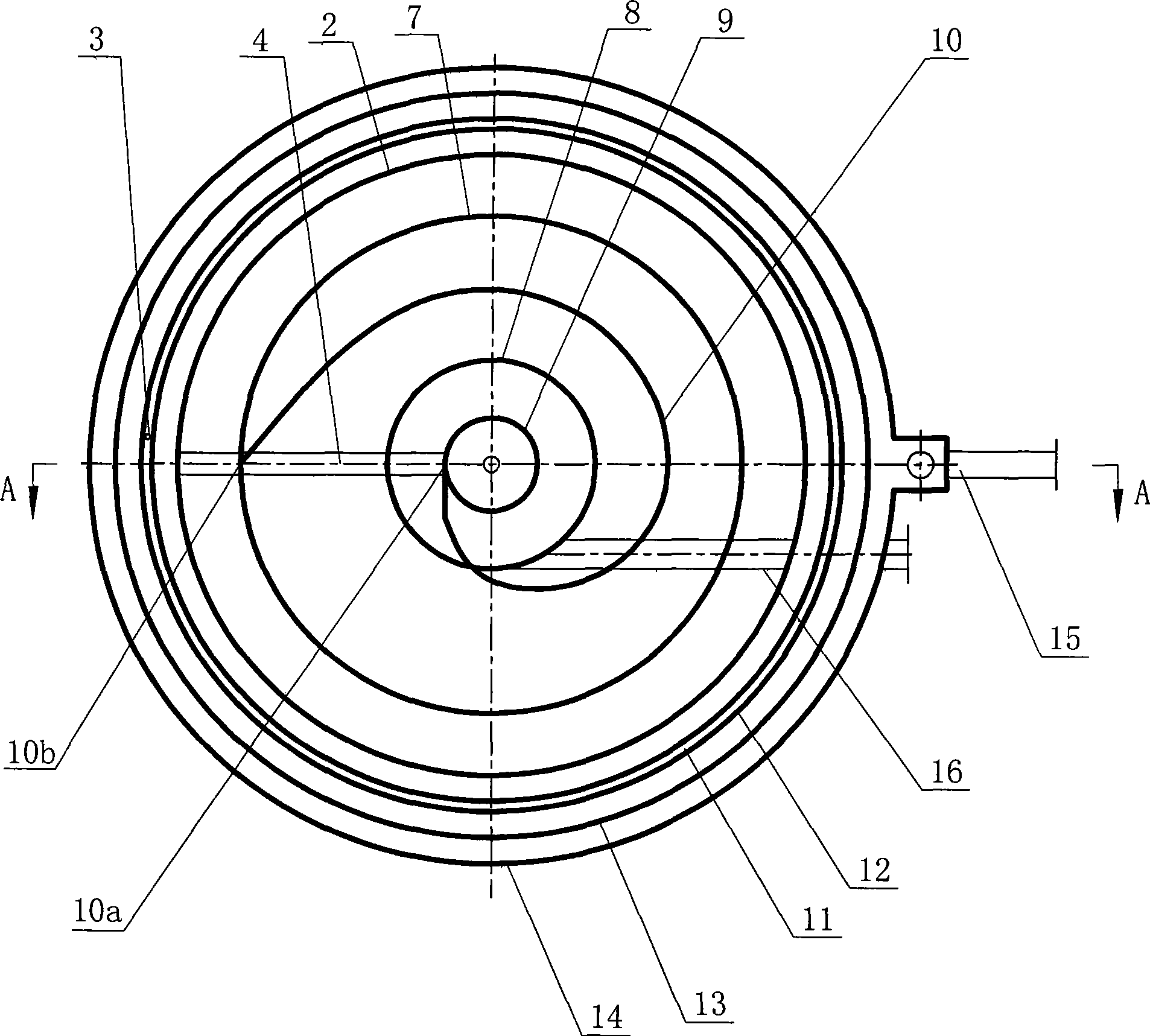

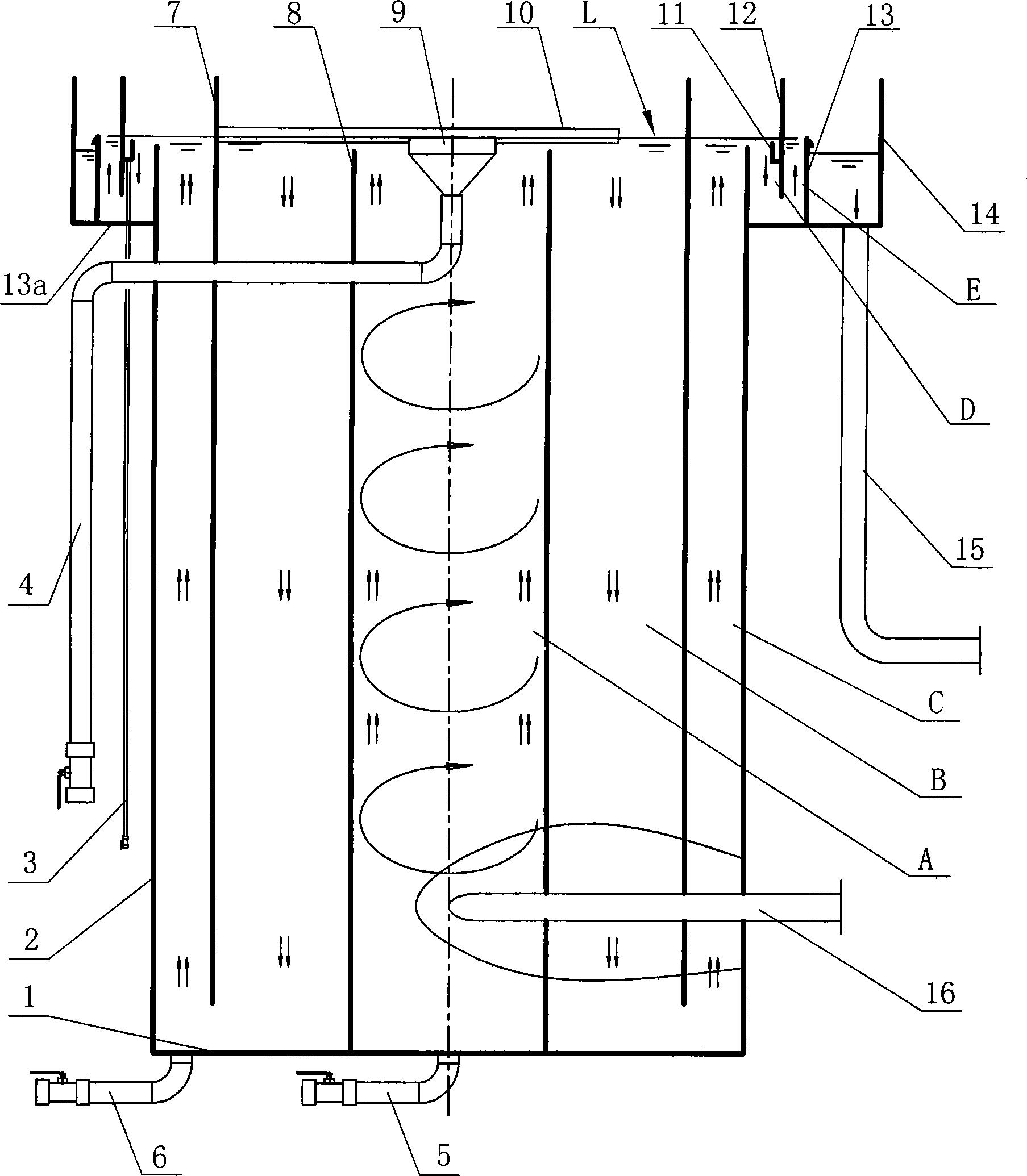

[0030] Such as Figure 1 ~ Figure 3 As shown, the air flotation separation device includes an outer cylinder 2, a swirling mixing cylinder 8 arranged in the center of the outer cylinder 2, and a first slag stopper 7 arranged between the outer cylinder 2 and the swirling mixing cylinder 8. , The three have the same centerline;

[0031] Wherein, the outer cylinder body 2 and the swirling mixing cylinder 8 both have a closed bottom. In this embodiment, the bottom of the swirling mixing cylinder 8 is overlapped on the bottom 1 of the outer cylinder 2 so that the bottoms of the two are connected as a whole. There is a distance between the bottom end of the first slag blocking cylinder 7 and the bottom 1 of the outer cylinder 2 to form a water flow channel. The swirl mixing cylinder 8 and the first slag blocking cylinder 7 on the periphery thereof separate the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com