Planar three-freedom-degree parallel mechanism driven by three linear drivers and application thereof

A linear drive, linear drive technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems affecting the normal and smooth operation of the overall equipment, uneven distribution of driving force, and easy entanglement of movements, so as to ensure normal and smooth operation. , conducive to even distribution, the effect of less invalid load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

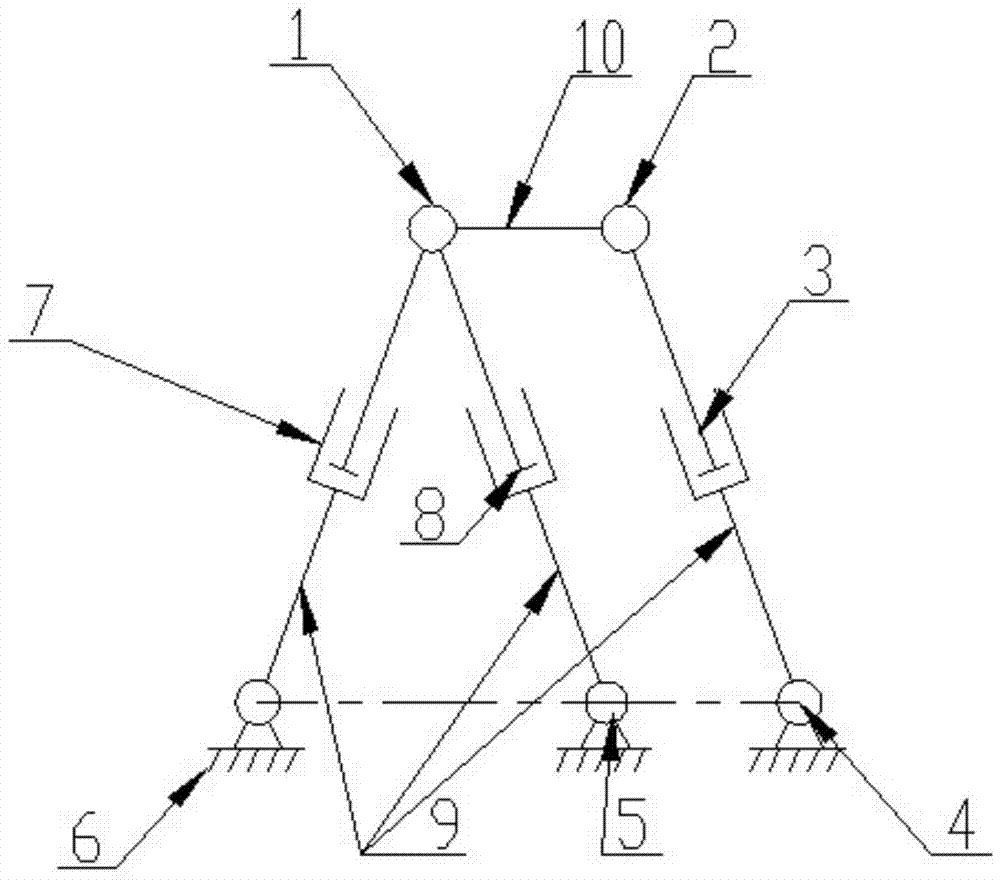

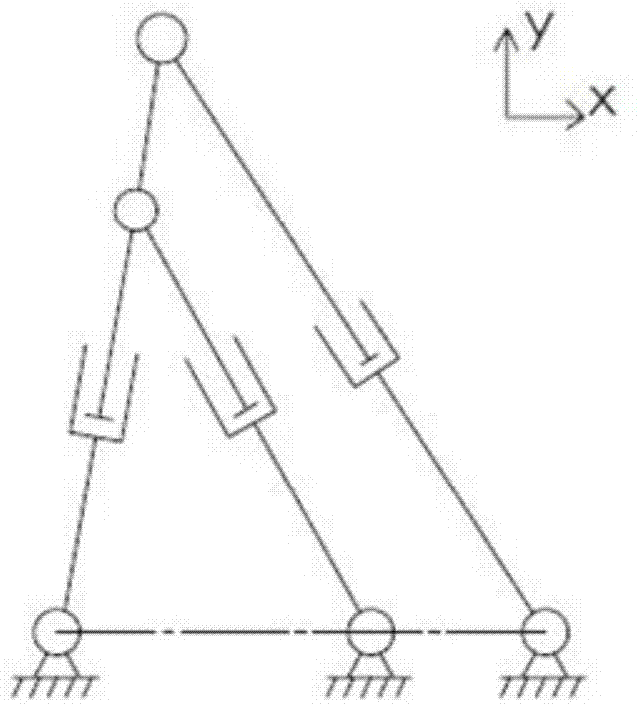

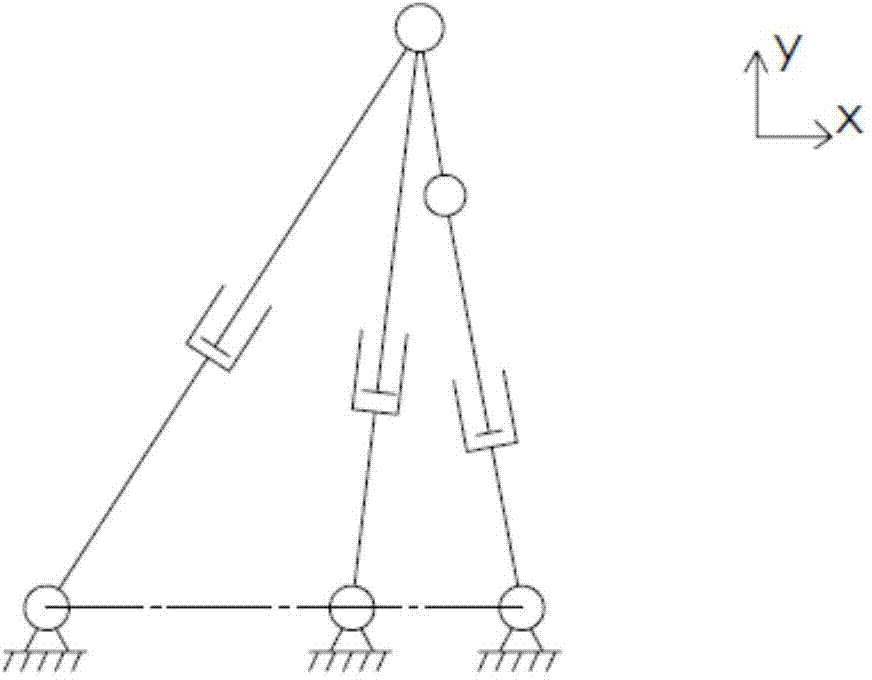

[0022] A planar three-degree-of-freedom parallel mechanism with three linear drives, including three linear drives 3, 7, 8 and five hinges, two of which are upper hinges 1, 2, and three hinges are lower hinges 4, 5, 6 , the three lower hinges are all fixed on the ground or the equipment frame, and the axes of the three lower hinges are located on the same axis.

[0023] Each lower hinge is connected to a linear driver, and its specific structure is: each lower hinge is hinged with a lower link 9, and each lower link is connected to the lower end of the respective linear driver. The linear drive is a linear cylinder or a hydraulic cylinder or an electric push rod or an electric cylinder or other linear drive devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com