A Method of Surface Microalloying to Improve Magnesium Alloy Welded Joints

A technology of welding joints and microalloying, which is applied in the coating process and coating of metal materials, can solve the problems of difficult welding of magnesium alloys, restrictions on the engineering application of magnesium alloys, and large residual stress, etc., and achieve the use of raw materials and equipment The effect of low cost, easy control of process parameters and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Firstly, automatic argon arc butt welding is performed on AZ61 magnesium alloy rolled plates:

[0039] 1) The thickness of AZ61 magnesium alloy rolled plate is 5mm, and the size is 60×120mm;

[0040] 2) After welding, use sandpaper and steel brush to remove the oxide layer on the surface of the plate to be welded, and then clean the surface of the plate with acetone to remove various impurities;

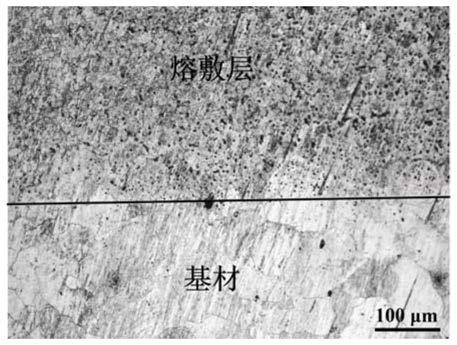

[0041] 3) if figure 1 The laser microalloying surface modification is carried out on the weld seam and heat affected zone of AZ61 magnesium alloy welding joint as shown in the figure. The surface distance of the material is 2.5cm, the powder feeding diameter is 2.5mm, the angle between the powder feeding nozzle and the base metal is 65°, argon is used for carrier gas and gas protection, and the flow rates of carrier gas and protective gas are 7L / min and 10L / min respectively. min. The defocus of the laser is 10mm, the laser power is 1700W, the laser spot is 2.5mm, and the sc...

Embodiment 2

[0047] Firstly, laser butt welding is carried out on the AM30 magnesium alloy rolled plate:

[0048] 1) The thickness of AM30 magnesium alloy rolled plate is 6mm, and the size is 60×120mm;

[0049] 2) After welding, use sandpaper and steel brush to remove the oxide layer on the surface of the plate to be welded, and then clean the surface of the plate with acetone to remove various impurities;

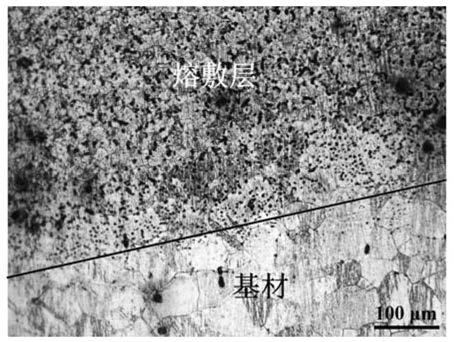

[0050] 3) if figure 1 The laser microalloying surface modification is performed on the weld seam and heat-affected zone of the AM30 magnesium alloy welding joint shown in the figure. The surface distance of the material is 1.5cm, the powder feeding diameter is 3.5mm, the angle between the powder feeding nozzle and the base metal is 55°, argon is used for carrier gas and gas protection, and the flow rates of carrier gas and shielding gas are 8L / min and 11L / min respectively. min. The defocus of the laser is 13mm, the laser power is between 1900W, the laser spot is 3mm, and the scannin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com