Patents

Literature

95results about How to "No chemical reactions involved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

G-C3N4 nanosheet with monodisperse structure and preparation method of g-C3N4 nanosheet

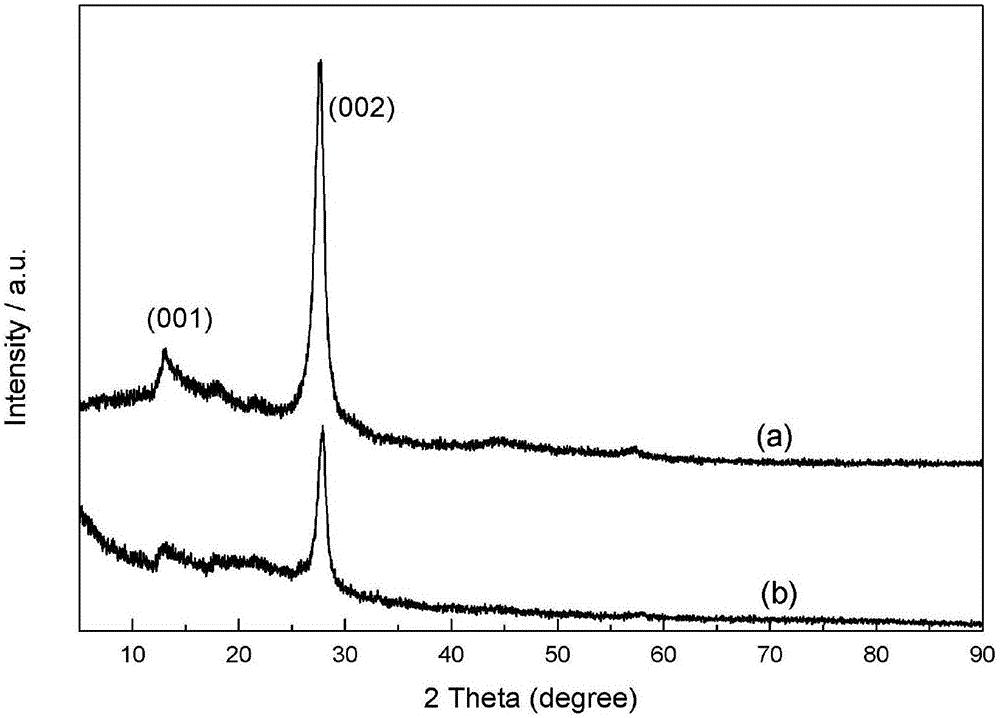

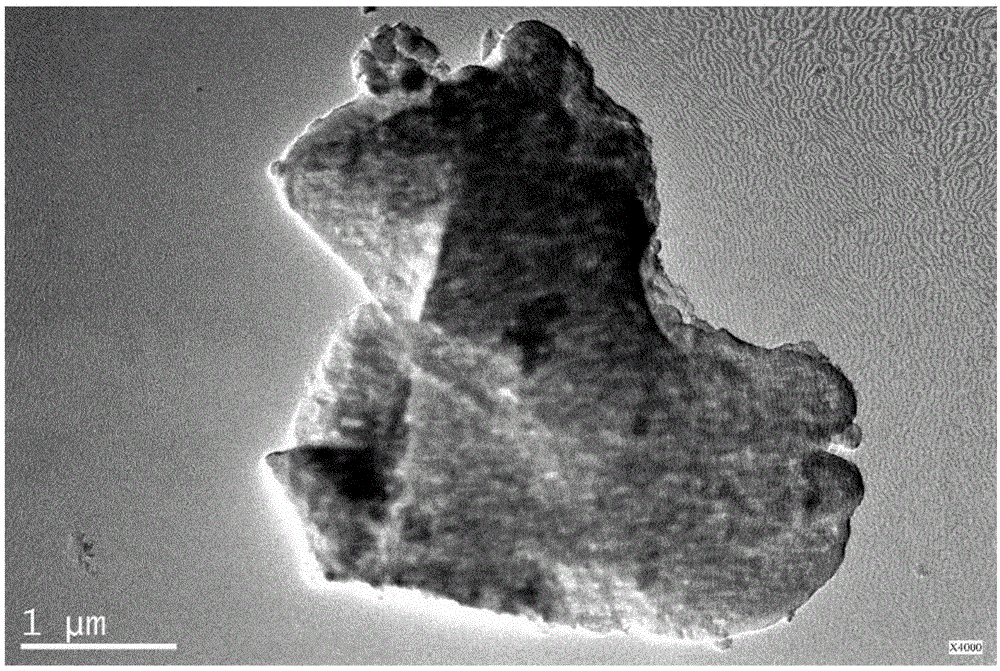

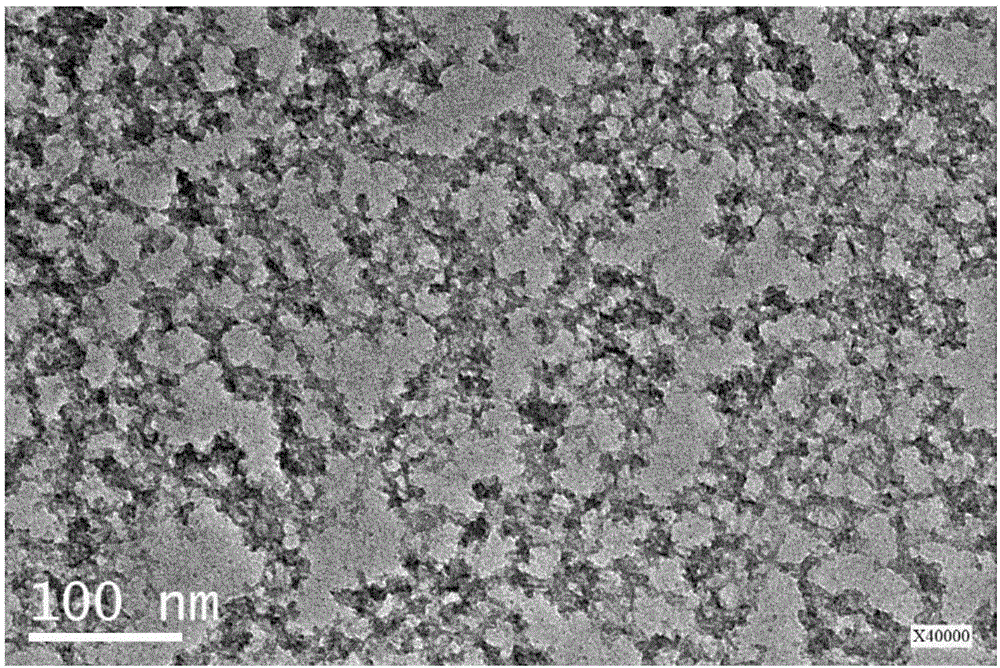

InactiveCN106629638AUniform particle distributionNo agglomerationMaterial nanotechnologyNitrogen and non-metal compoundsMicro nanoDispersity

The invention relates to the technical fields of micro-nano structures and photocatalysis, in particular to a g-C3N4 nanosheet with a monodisperse structure and a preparation method of the g-C3N4 nanosheet. The size of the g-C3N4 nanosheet with the monodisperse structure is 10 to 50nm; particles are uniformly distributed, so that the agglomeration phenomenon is avoided. The g-C3N4 nanosheet is prepared by a secondary calcination method under the condition of water vapor atmosphere, is mild in preparation conditions and can be prepared in macroscopic quantity; the g-C3N4 nanosheet with the monodisperse structure is large in specific surface area and good in dispersity, has higher reactive sites, and can be effectively applied to photocatalytic degradation of organic matters and production of hydrogen by water photodecomposition.

Owner:HEFEI UNIV OF TECH

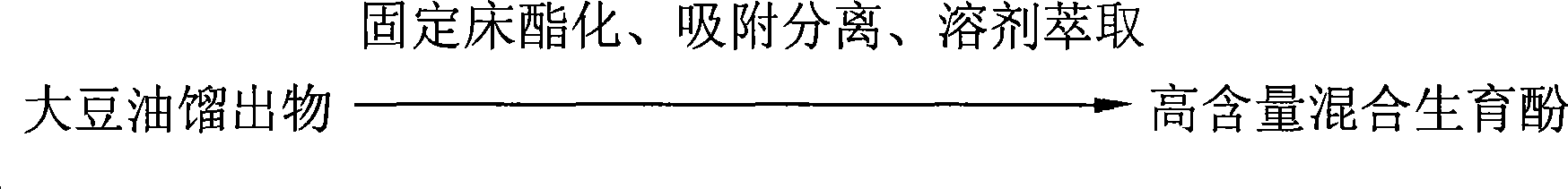

Method for separating single tocopherol from mixed tocopherol

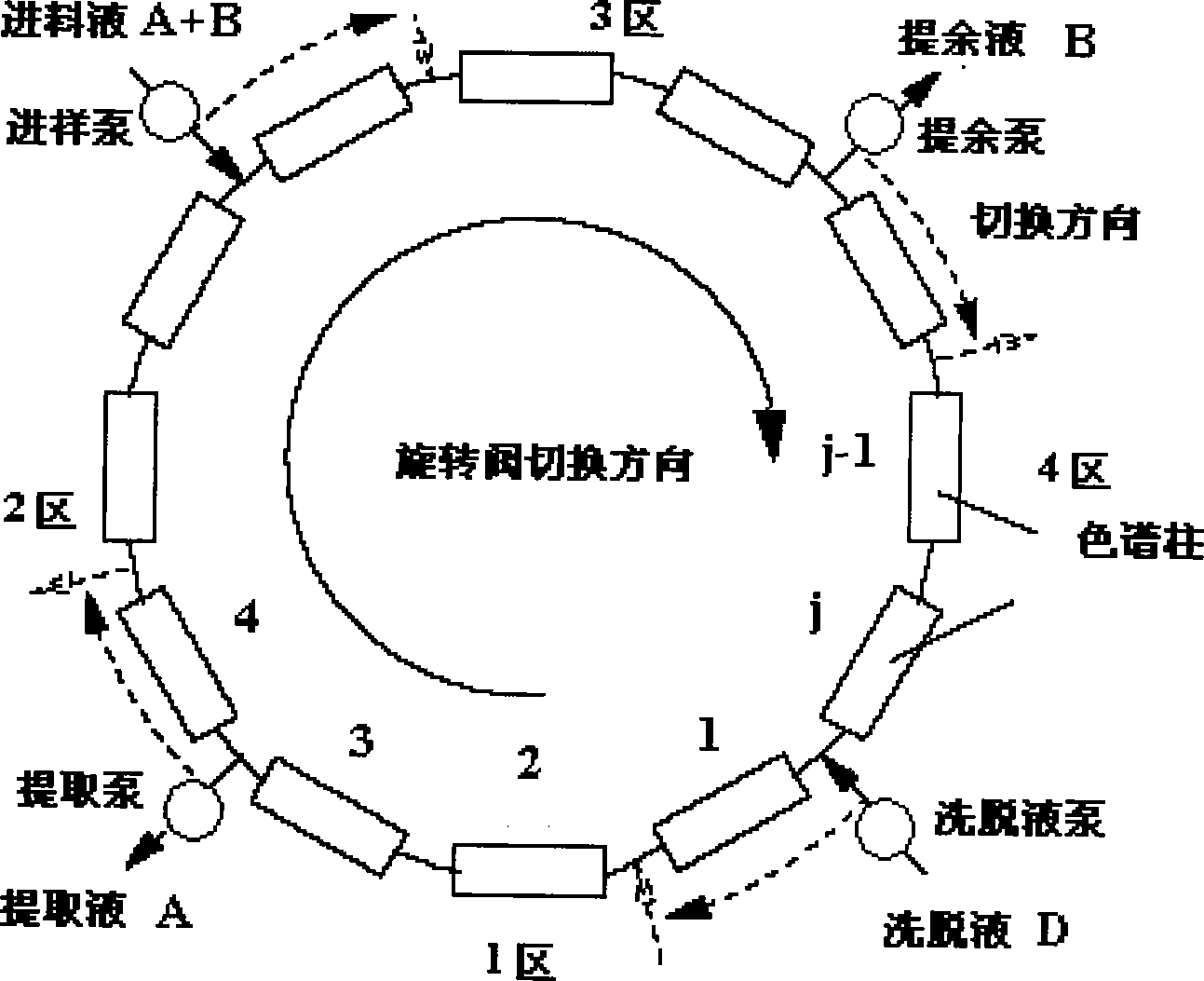

InactiveCN101220018AReduce consumptionHigh purityOrganic chemistryChemical reactionSimulated moving bed

The invention relates to a method for separating single tocopherol from mixed tocopherol, which takes the mixed tocopherol with a content of 50 percent to 100 percent as a raw material and adopts a four-area simulated moving bed chromatography system to separate a d-alpha-tocopherol, a d-beta-tocopherol, a d-gamma-tocopherol and a d-delta tocopherol with the purity and yield all more than 98 percent. As the simulated moving bed chromatography separation is a continuous process, the method has the advantages of high degree of production automation, simple technique, high production efficiency, continuous production and stable product quality. As an adsorbent and a solvent have low consumption, the whole separating device does not relate to chemical reactions.

Owner:ZHEJIANG UNIV

Method for preparing polymer film with continuous nanometer pore channels

The invention relates to a method for preparing polymer film with continuous nanometer pore channels, which comprises the following steps: preparing block copolymer solution in which a block copolymer consists of a block A and a block B; smearing the prepared block copolymer solution on a substrate and volatilizing solvent to form film; immersing the substrate coated with polymer film in the solvent having the effect of selectively swelling one block of the block copolymer; and taking out the substrate coated with the polymer film from the solvent, drying the substrate and obtaining the polymer film with continuous pore channels. The method has the advantages of no relation to chemical reaction, convenience, controllability, simple steps, capability of preparing porous polymer film in large area and good prospects for mass production.

Owner:NANJING UNIV OF TECH

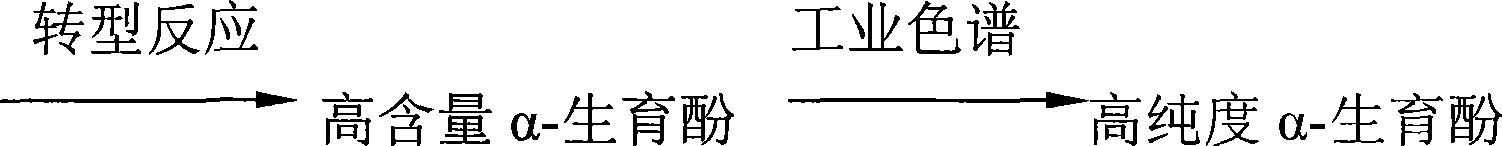

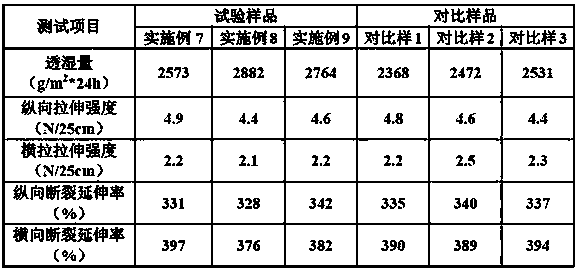

Highly-antibacterial air-permeable film

The present invention relates to a kind of highly antibacterial gas permeable film, it is the PE antibacterial gas permeable film formed by the modified porous graphene composite antibacterial material evenly distributed in it in PE matrix material, and its component and parts by weight are as follows: PE 40-70 parts 0.5-10 parts of modified porous graphene antibacterial masterbatch; 28-55 parts of inorganic filler; 0.5-5 parts of auxiliary agent A. Wherein, the modified porous graphene masterbatch is made of 5-60 parts of carrier resin, 1-12 parts of modified porous graphene antibacterial powder, auxiliary agent B, and is extruded and granulated by screw after blending. The pores of porous graphene are loaded with antibacterial plant extracts, or antibacterial plant extracts and antibacterial materials prepared by loading organic rare earth salts, wherein the antibacterial plant extracts are such as camellia oil, tea polyphenols, and aloe oil. Porous graphene is one or both of porous graphene oxide and porous reduced graphene, and the inorganic filler is CaCO3 or / and Na2SO4.

Owner:XIAMEN YUANCHUANGLI TECH SERVICE CO LTD

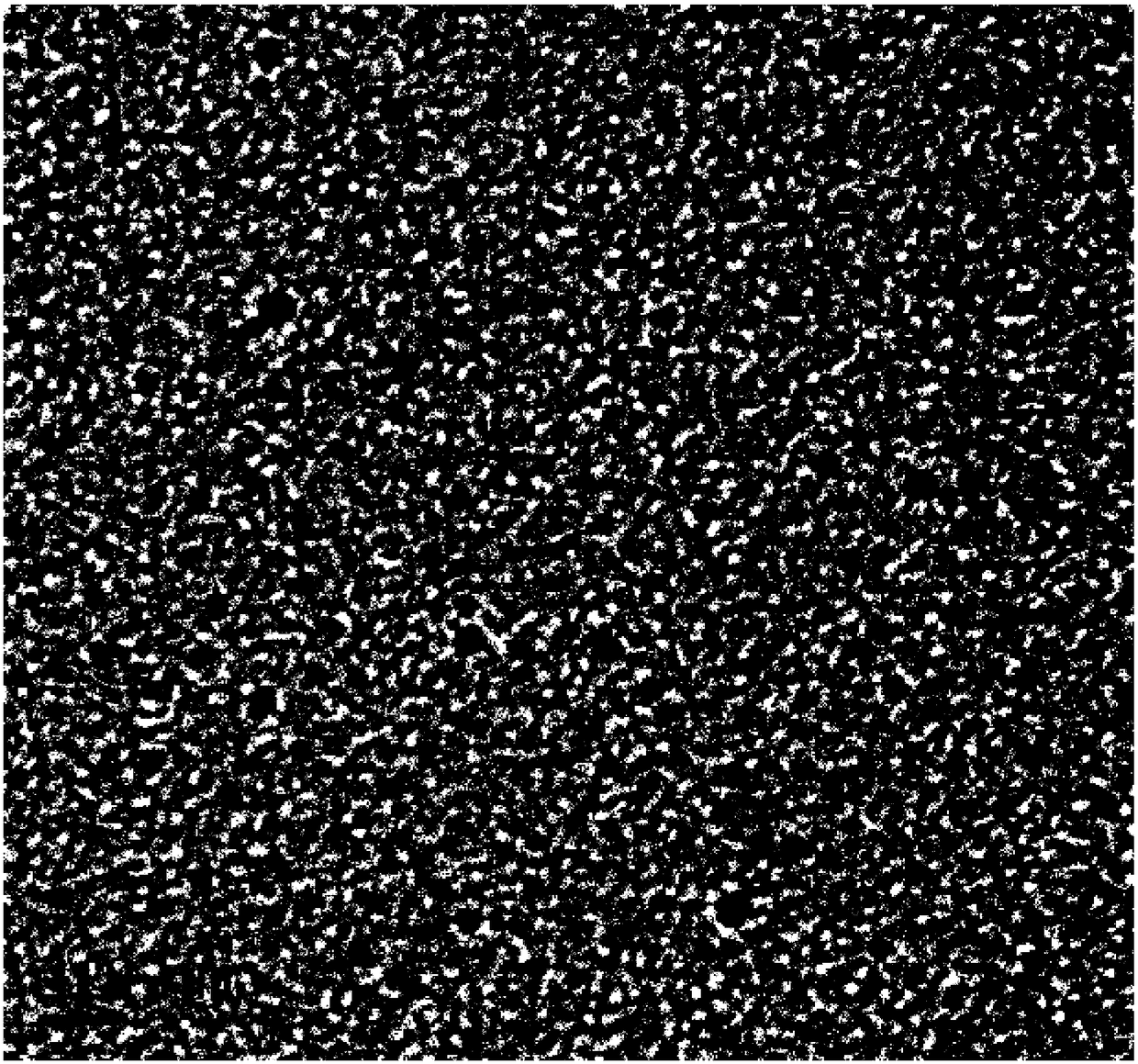

Preparation method of porous film with regular vertical pores

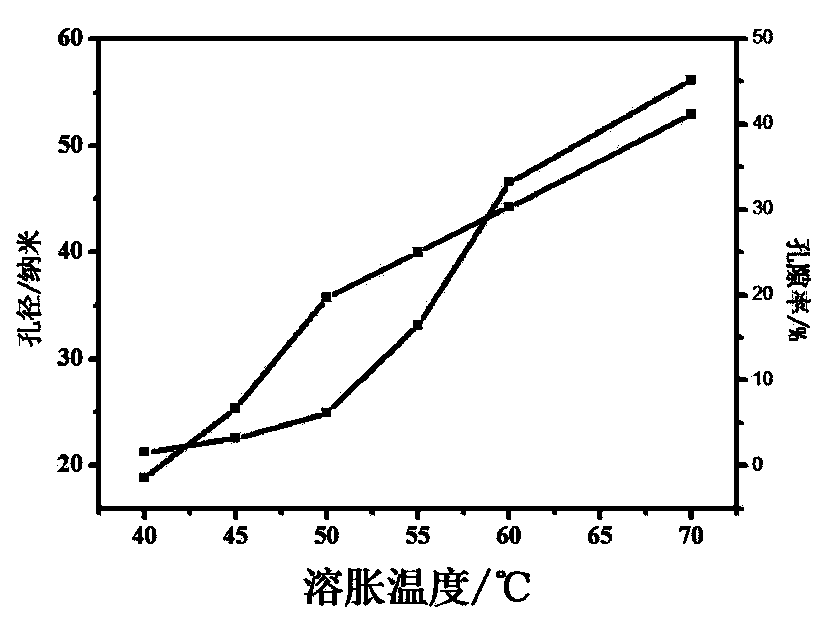

The invention relates to a preparation method of a porous film with regular vertical pores. The preparation method comprises the following steps of: firstly, annealing a block copolymer film by using a solvent, inducing the block copolymer to generate phase separation so as to form a vertically oriented micro-phase structure; and then performing selective swelling on dispersed phases of the block copolymer by using a swelling agent, and changing a dispersed structure into a pore structure so as to form a porous film with a highly-ordered vertical pore structure. The film prepared by the method has a vertically-oriented cylindrical pore structure, the sizes of the pores are highly uniform, the arrangement is highly regular, and the pore diameter is adjustable. The preparation method is extremely simple and convenient to operate, and is controllable without chemical reactions, so that the preparation method has a wide application prospect in the fields of separation films, nano etching and the like.

Owner:NANJING UNIV OF TECH

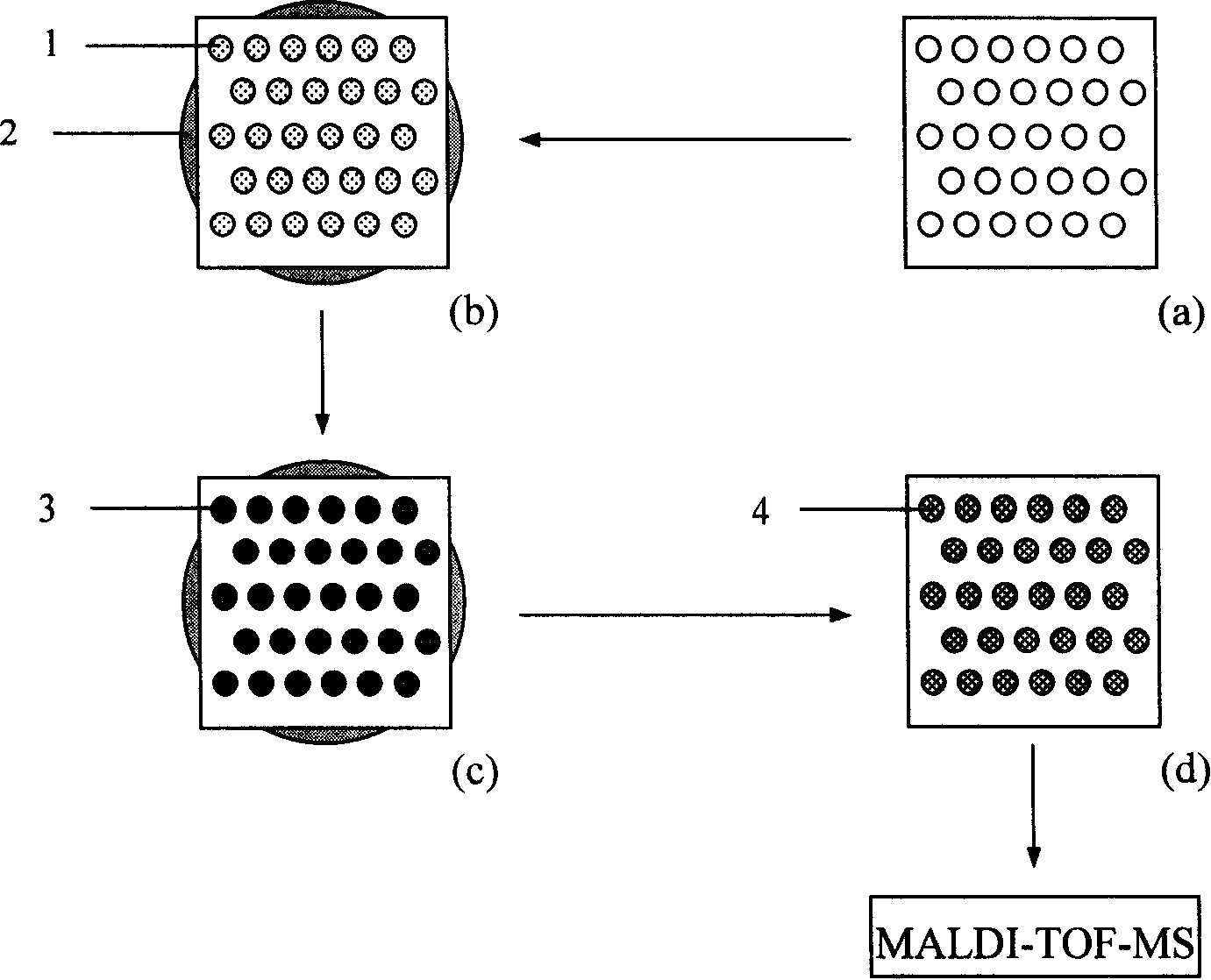

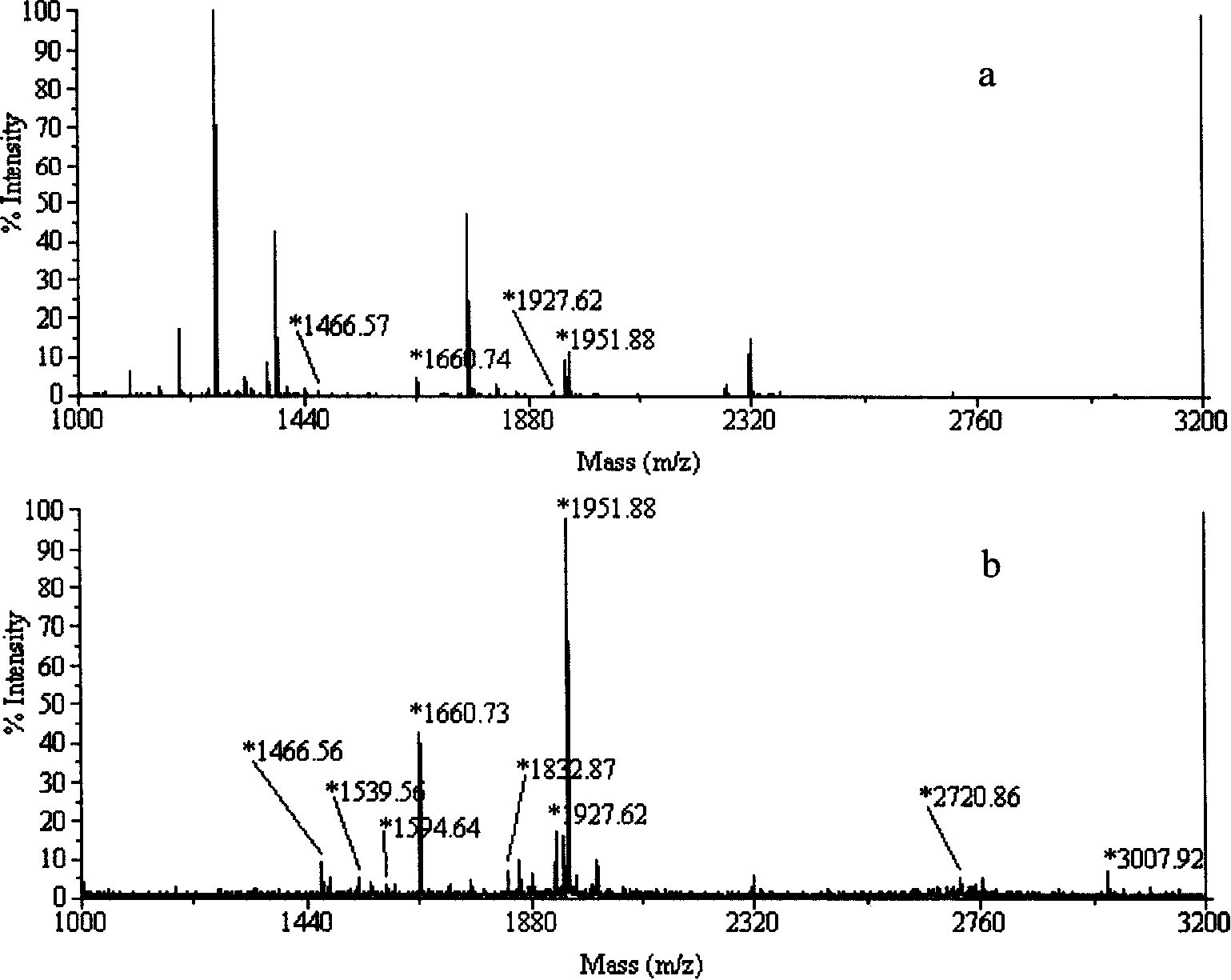

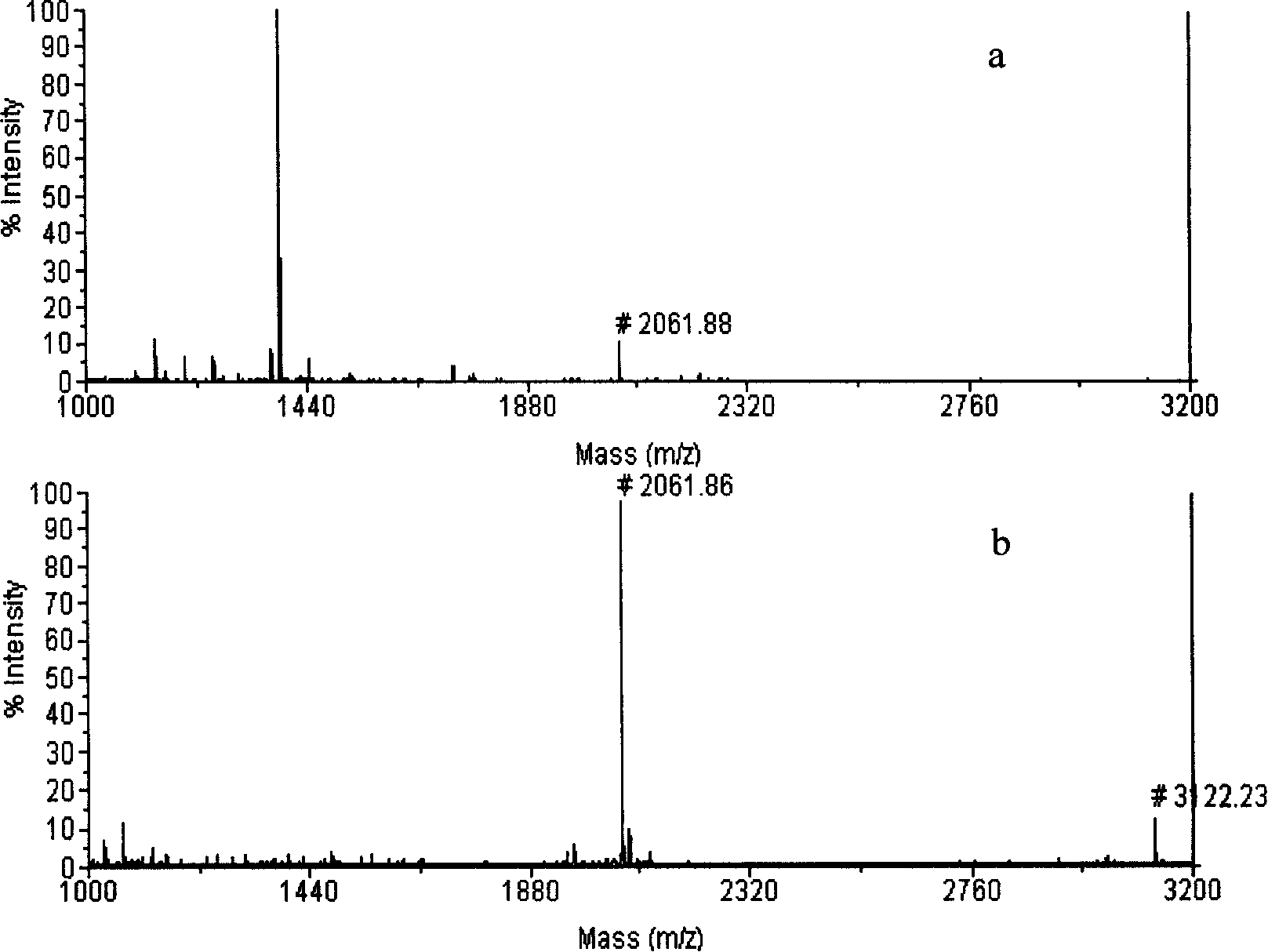

Method for fast enriching and appraising phosphopeptide on MALDI-TOF-MS sample target

InactiveCN101196527AFast grooming processSimple and fast operationComponent separationBiological testingChemical reactionDesorption

The invention relates to a method of fast enrichment and fast identification on the phosphoeptide of the modificatory sample target by the matrix-assisted laser-desorption / time-of-flight mass spectrometry (MALDI-TOF-MS), which is to physically adsorb the fine magnetic nano particle onto the sample target, wash the sample after the sample is loaded to remove the non phosphoeptide and phosphate, add the matrix to make cocrystallization with the phosphoeptide absorbed on the sample target and then conduct the MALDI-TOF-MS analysis. The method does not relate to the chemical reaction without pre-processing to the target, which can modify the target MALDI made of different substrate materials; A plurality of samples complete their enrichment at the same time on the modified target MALDI; There are no sample transfer in the whole process from the sample loading to the mass spectrometric analysis. The invention is easy, fast and sensitive to operate, which has a good application value in the large-scale analysis of the phosphoproteome.

Owner:INST OF RADIATION MEDICINE ACAD OF MILITARY MEDICAL SCI OF THE PLA

Preparation method for temperature-sensitive separation membrane with nanometer ordered aperture

InactiveCN103464015AUniform pore size distributionArranged in orderSemi-permeable membranesSurface layerSpins

A new preparation technology, which is a segmented-copolymer selective swelling pore-forming method, is utilized for preparation of a temperature-sensitive membrane with nanometer ordered aperture, and a composite membrane with a temperature-responding surface is prepared by coating or spin coating of the temperature-sensitive membrane on a conventional basic membrane material. The temperature-sensitive membrane has uniform membrane aperture dimension, and consistent content and distribution of aperture surface PNIPAAm, and is capable of effectively improving response performance of the temperature-sensitive membrane. The preparation method of the temperature-sensitive membrane mainly comprises the following steps: synthesizing a segmented copolymer PS-b-PNIPAAm by utilizing an atom transfer free-radical method, dissolving SP-b-PNIPAAm and performing spin coating on SP-b-PNIPAAm on the surface of a clean glass sheet, drying, performing solvent annealing, placing the annealed glass sheet in ethanol or water for swelling pore-forming to obtain the polymer membrane with nanometer ordered aperture. The PS-b-PNIPAAm / PP(PVDF) composite membrane with a surface layer possessing a nanometer porous temperature-responding functional layer is obtained by utilizing the method which comprises that a commercial basic membrane (PP / PVDF) is coated by the PS-b-PNIPAAm solution by a spin mode.

Owner:TIANJIN POLYTECHNIC UNIV

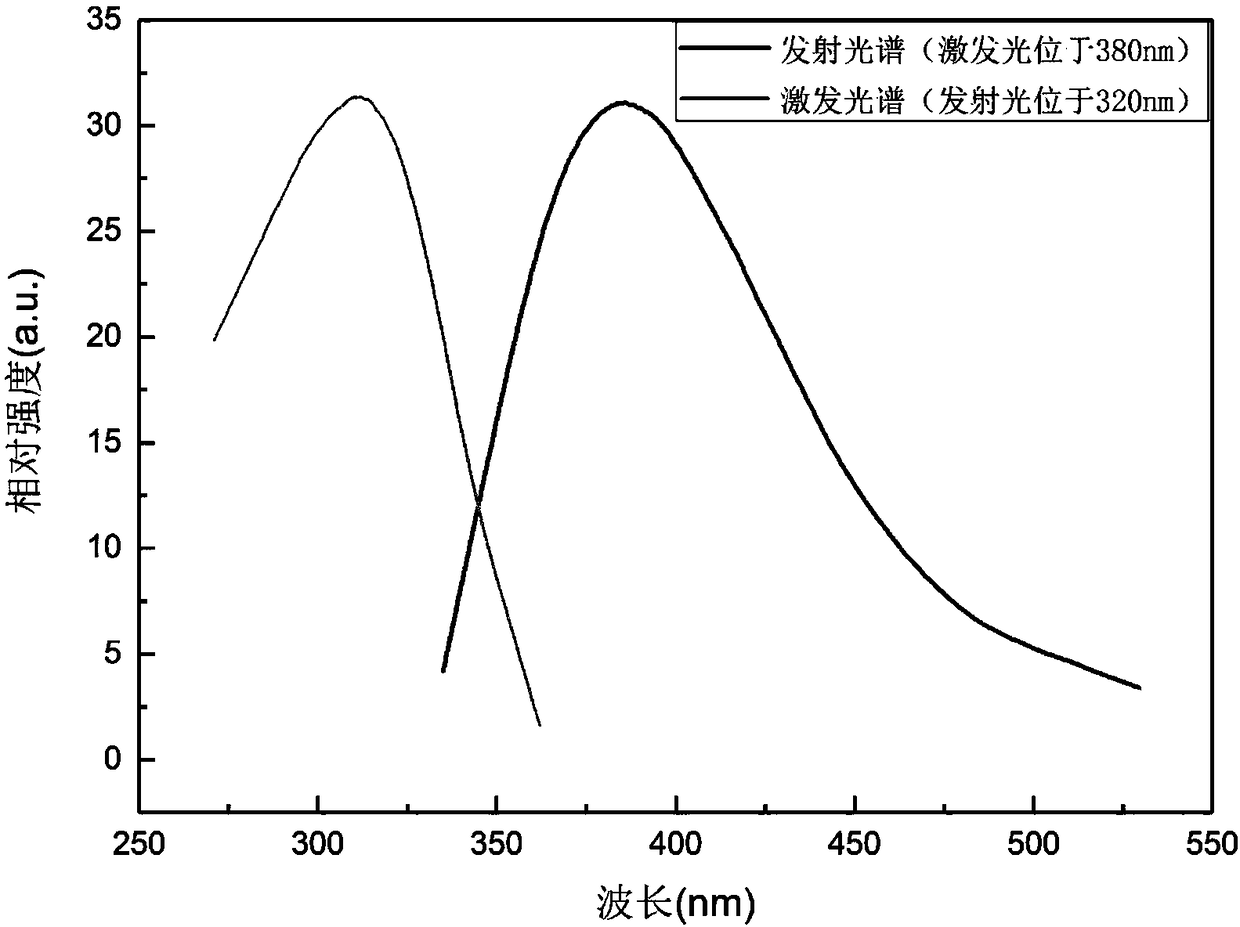

Green preparation method for carbon dots used for biological imaging

ActiveCN108424769AEasy to manufactureFluorescence enhancementLuminescent compositionsBiological imagingBiocompatibility Testing

Carbon dots are a novel fluorescent material with high light stability and good biocompatibility and have great application potential in fields like biological imaging; however, conventional preparation methods for carbon dots are complicated, consume a large amount of energy consumption or need dangerous chemical reagents, so carbon dots are difficult to prepare and apply in large scale. The invention provides a green preparation method for carbon dots to overcome the above-mentioned disadvantages; and the green preparation method is greatly simplified, ensures low toxicity and good biocompatibility of carbon dots from the source, and allows prepared carbon dots to be more applicable to biological imaging. The green preparation method comprises the following steps: (1) preparation of rawmaterials: selecting raw materials rich in phenolic substances, wherein bulk raw materials should be pulverized and sieved; (2) extraction of the phenolic substances: extracting the prepared raw materials with a solvent to obtain a solution of the phenolic substances; and (III) separation of carbon dots: separating the solution of the phenolic substances by using physical methods such as centrifugation and dialysis to obtain the dispersion liquid of carbon dots. The dispersion liquid of carbon dots is subjected to pressure-reduced drying and dispersion with normal saline or the like before applied to biological imaging.

Owner:NORTHEAST FORESTRY UNIVERSITY

Anti-pollution aromatic polyamide composite reverse osmosis membrane and preparation method thereof

InactiveCN110038446AWater molecule mass transfer resistance is lowReduce mass transfer resistanceMembranesReverse osmosisUltrafiltrationPolyamide

The invention relates to an anti-pollution aromatic polyamide composite reverse osmosis membrane and a preparation method thereof. The preparation method of the reverse osmosis membrane comprises thefollowing steps of: soaking a cleaned polysulfone ultrafiltration membrane in a water phase monomer solution, taking out the polysulfone ultrafiltration membrane, airing the polysulfone ultrafiltration membrane, soaking one side of the polysulfone ultrafiltration membrane in an oil phase monomer solution, reacting for a period of time, taking out the polysulfone ultrafiltration membrane to completely volatilize an organic solvent to obtain a nascent state reverse osmosis membrane; coating the surface of nascent state reverse osmosis membrane with a layer of anti-pollution functional layer precursor solution, and performing heat treatment and rinsing to obtain the anti-pollution aromatic polyamide composite reverse osmosis membrane. A mixed matrix anti-pollution functional layer is constructed by a one-step method, the permeability of the functional layer is improved based on the design of the mixed matrix membrane, covalent bond fixation of the mixed matrix functional layer on the surface of the membrane is realized through chemical grafting and chemical crosslinking, and finally the anti-pollution reverse osmosis membrane with excellent long-term stability is obtained.

Owner:自然资源部天津海水淡化与综合利用研究所

Method for marble processing through marble leftover material

ActiveCN104526887AHigh strengthRetain glossStone-like material working toolsEngineeringUltimate tensile strength

The invention discloses a method for marble processing through marble leftover material. The method includes the following steps of firstly, cutting the marble leftover material according to drawing requirements; secondly, grinding female lines and male lines of the cut marble leftover material on a line machine; thirdly, splicing and arranging the marble leftover material according to the female lines and the male lines; fourthly, filling glue to obtain a formed marble plate piece; fifthly, setting the thickness; sixthly, brushing with surface glue; seventhly, conducting coating and brushing with waterproof back glue, and laying a back net; eighthly, conducting polishing and cutting. By means of the method, the obtained marble is higher in strength, better in glossiness and lower in production cost while the marble leftover material is recycled.

Owner:BEICHUAN XIANFENG STONE PROD

Nano-composite biological scaffold with multi-stage controllable through hole structure, and preparation method and application thereof

ActiveCN107115570ARealize the combinationSimple preparation processTissue regenerationProsthesisPickering emulsionOil phase

The invention discloses a nano-composite biological scaffold with multi-stage controllable through hole structure, and a preparation method and application thereof. The preparation method is combined with a water-in-oil type Pickering high internal phase emulsion template method and a 3D printing technology, the Pickering emulsion template takes an organic solution containing biodegradable polyester and hydrophobic modified silicon dioxide nanoparticles as an oil phase and deionized water as an aqueous phase, the oil phase and the aqueous phase are mixed and emulsified to form water-in-oil type Pickering emulsion, the emulsion is printed and formed by the 3D printing technology, and the nano-composite biological scaffold with the multi-stage controllable through hole structure is obtained. The preparation method provided by the invention is simple in operation, mild in preparation condition, low in requirement on equipment and suitable for industrialized production, the hole structure of the porous scaffold can be adjusted conveniently and rapidly by changing the preparation condition of the emulsion, the scaffold structure is regulated and controlled by writing different printing programs, and design and implementation of the hole structure are unified.

Owner:SOUTH CHINA UNIV OF TECH

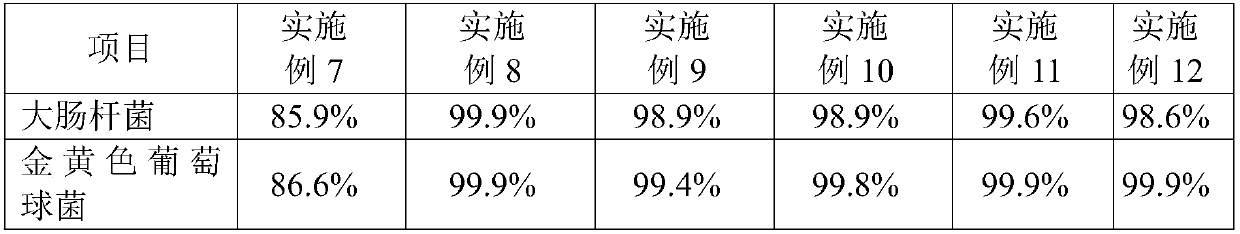

Graphene antimicrobial composition as well as preparation method and application thereof

ActiveCN107951902ADeveloped and connected nanoporous structureImprove adsorption capacityAntibacterial agentsOrganic active ingredientsPorous grapheneCerium

The invention relates to a graphene antimicrobial composition. With modified porous graphene which has interpenetrated pore structures as a carrier, the graphene antimicrobial composition is an antimicrobial material which is prepared by loading an antimicrobial plant extract in pores of the modified porous graphene; and the graphene antimicrobial composition consists of the following components in percentage by mass: 20-80% of the modified porous graphene and 20-80% of the antimicrobial plant extract, and preferably, the graphene antimicrobial composition further consists of organic rare-earth salt; and the graphene antimicrobial composition consists of the following components in percentage by mass: 20-70% of the modified porous graphene, 20-80% of the antimicrobial plant extract and 1-5% of the organic rare-earth salt. The antimicrobial plant extract is any one or any combinations of camellia oleosa seed oil, tea polyphenol and aloe oil; and the organic rare-earth salt is any one orany combinations of lanthanium stearate, cerium stearate, lanthanium laurate and cerium laurate.

Owner:XIAMEN YUANCHUANGLI TECH SERVICE CO LTD

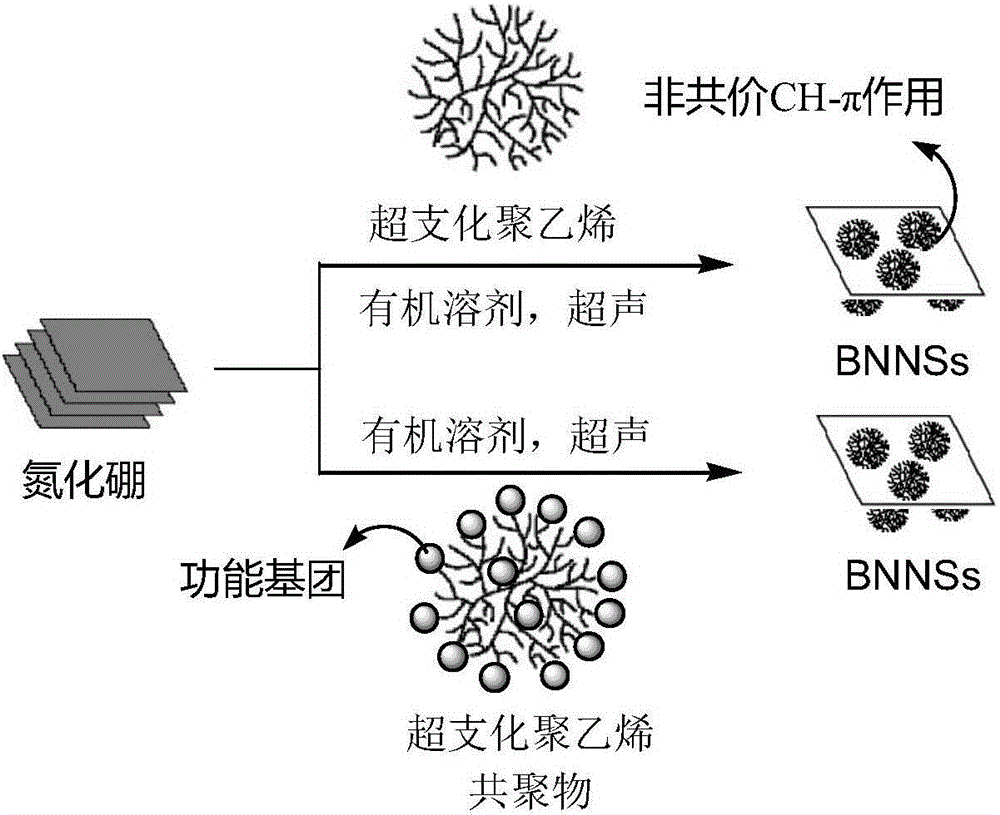

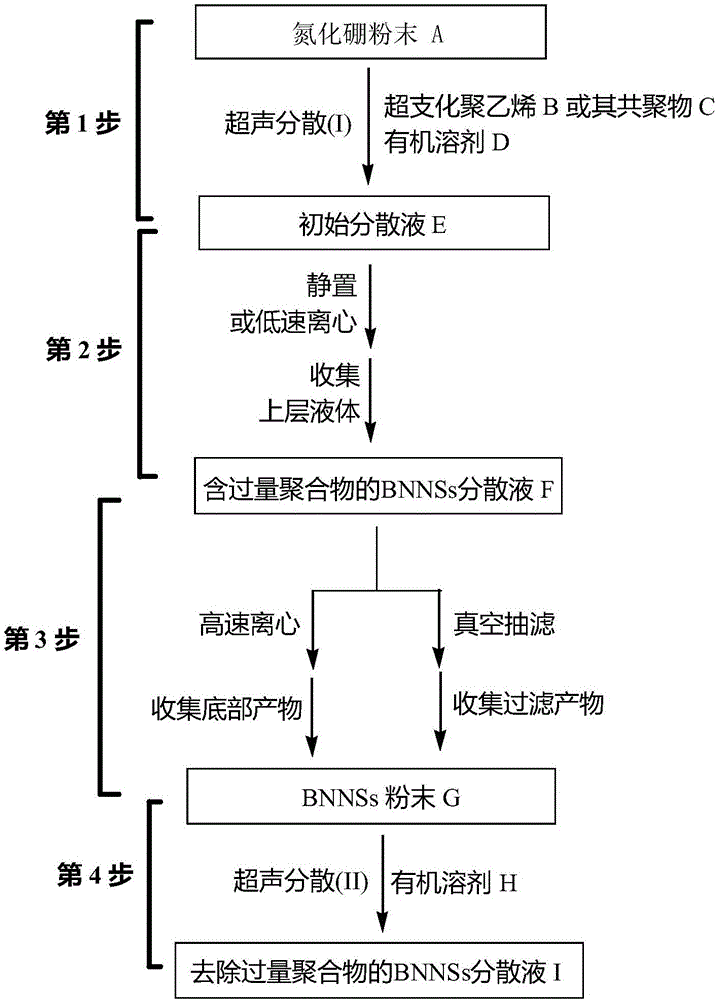

Efficient preparation method of boron nitride nanosheet and organic dispersion liquid thereof

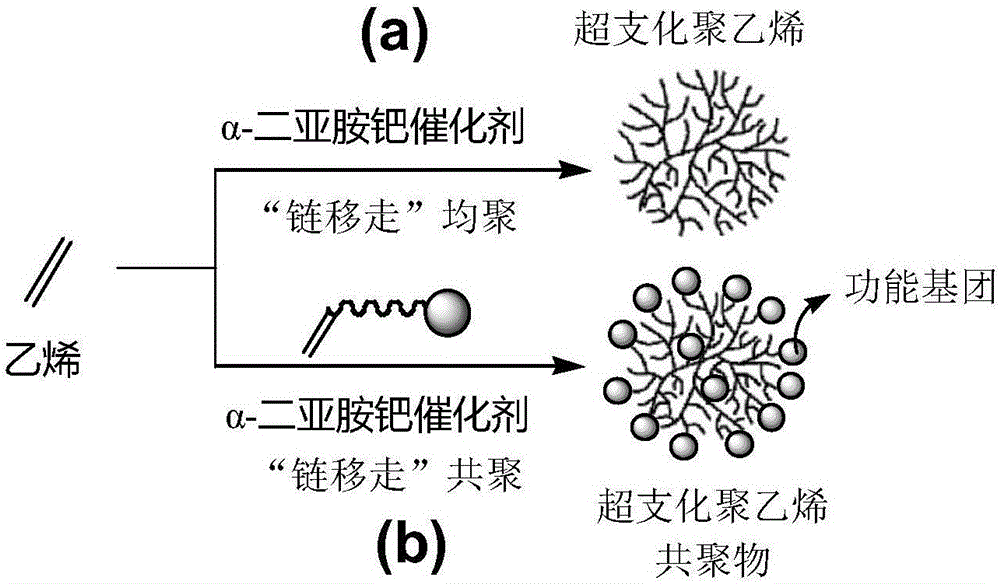

ActiveCN106586979AGuaranteed structural integrityNo chemical reactions involvedNitrogen compoundsChemistryBoron nitride

The invention provides an efficient preparation method of a boron nitride nanosheet and organic dispersion liquid thereof. The efficient preparation method comprises the following steps: a first step, adding boron nitride powder A, polymer and an organic solvent D in proportion, sealing, and then carrying out ultrasonic treatment to obtain initial dispersion liquid E, wherein the polymer is at least one of hyperbranched polyethylene B and hyperbranched polyethylene copolymer C; a second step, fully standing or centrifuging the initial dispersion liquid E obtained from the step 1 at low speed to obtain BNNSs dispersion liquid F containing excessive polymer; a third step, carrying out high-speed centrifuging or vacuum suction filtration and drying on the BNNSs dispersion liquid F containing the excessive polymer obtained from the step 2 to obtain a boron nitride nanosheet G; and a fourth step, adding the boron nitride nanosheet powder G and an organic solvent H which are obtained from the step 3 in the container, sealing and then carrying out ultrasonic treatment to obtain the boron nitride nanosheet dispersion liquid. By the efficient preparation method of the boron nitride nanosheet and the organic dispersion liquid thereof, the low-defect boron nitride nanosheet and the dispersion liquid thereof are effectively prepared controllably at low cost.

Owner:ZHEJIANG UNIV OF TECH

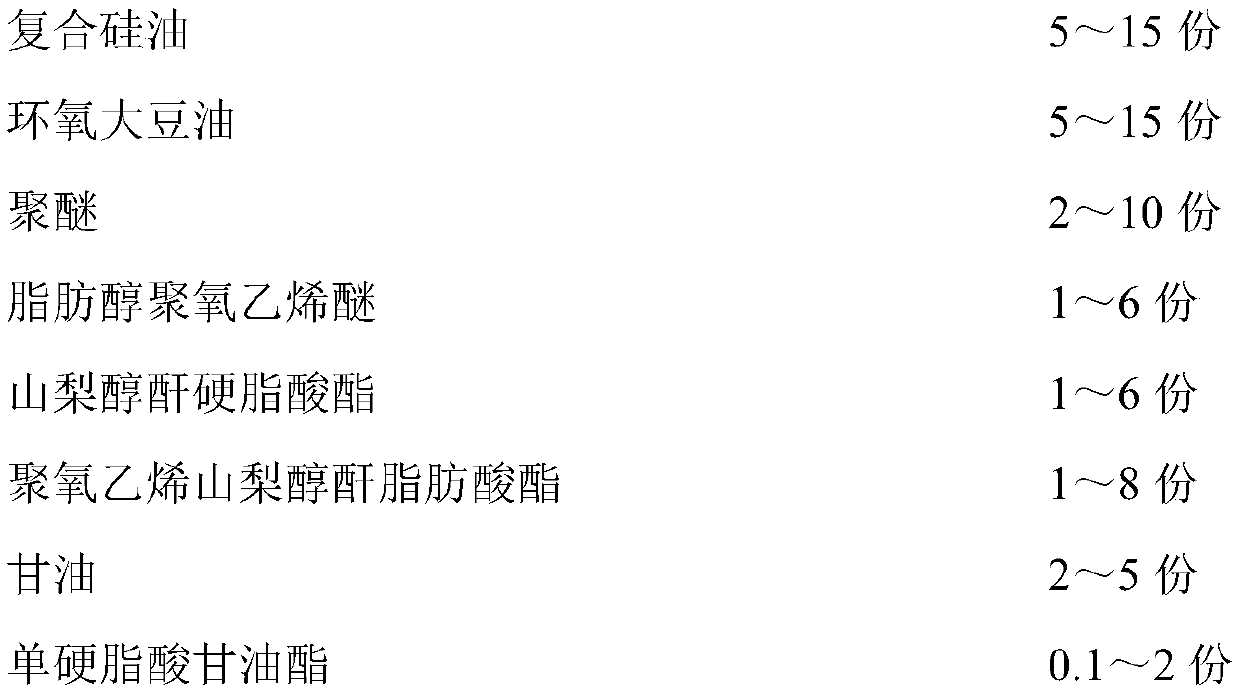

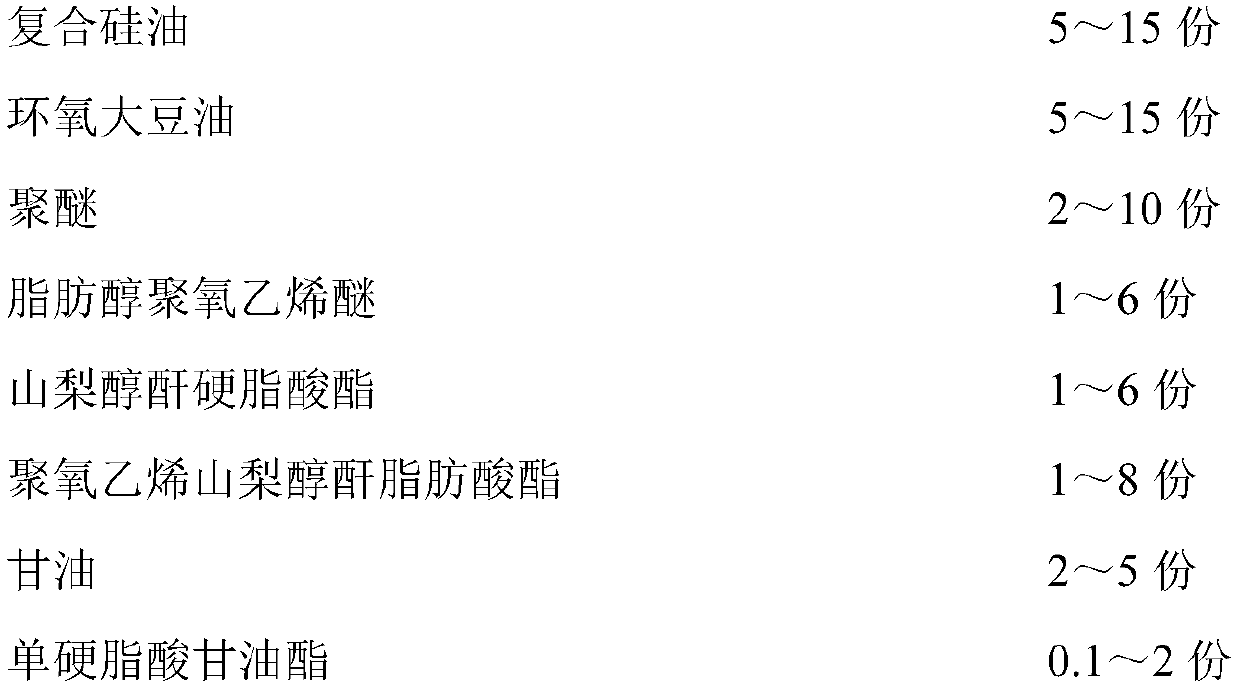

Defoamer containing silicone oil and epoxidized soybean oil and preparation method thereof

ActiveCN110075573AGood defoamingExcellent foam suppressionFoam dispersion/preventionFatty alcoholSilicone oil

The invention discloses a defoamer containing silicone oil and epoxidized soybean oil. The defoamer has excellent defoaming, foam inhibition and anti-shearing performances. The defoamer containing silicone oil and epoxidized soybean oil, taking 100 parts as a baseline, comprises the following components in parts by mass: 5 to 15 parts of compound silicone oil, 5 to 15 parts of epoxidized soybean oil, 2 to 10 parts of polyether, 1 to 6 parts of fatty alcohol-polyoxyethylene ether, 1 to 6 parts of sorbitan tristearate, 1 to 8 parts of polyoxyethylene sorbitan fatty acid ester, 2 to 5 parts of glycerinum, 0.1 to 2 parts of glycerin monostearate and the balance of deionized water.

Owner:江苏长丰有机硅有限公司

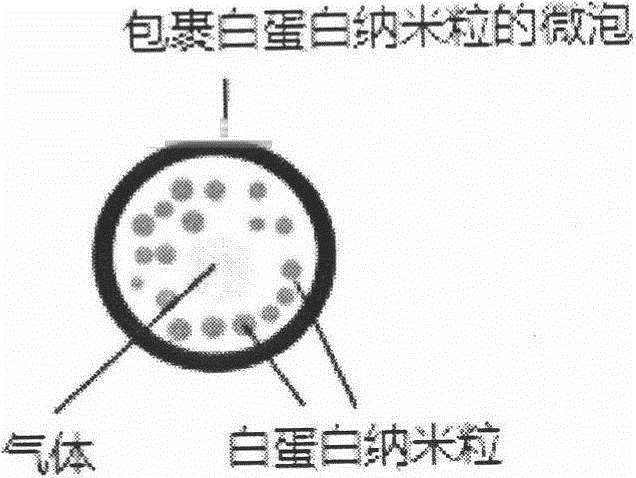

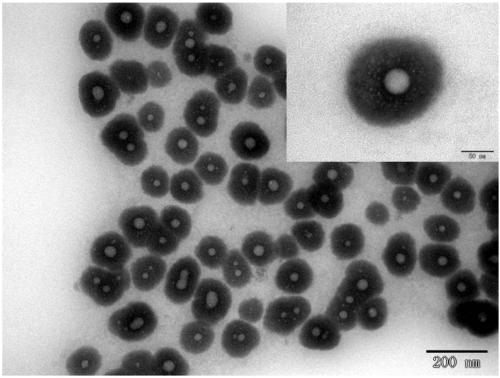

Ultrasound lipid microbubble wrapping drug-carrying albumin nanoparticles and preparation method thereof

InactiveCN104096245ASimple preparation processEasy to industrializeEchographic/ultrasound-imaging preparationsMacromolecular non-active ingredientsDiseaseCarrying capacity

The invention discloses an ultrasound lipid microbubble wrapping drug-carrying albumin nanoparticles and a preparation method thereof. The drug-carrying albumin nanoparticles comprise drugs and albumin. An ultrasound lipid microbubble membrane material mainly comprises phospholipid components and can wrap gas and the drug-carrying albumin nanoparticles simultaneously to form a composite structure with the gas and the nanoparticles in the middle. According to the ultrasound lipid microbubble wrapping the drug-carrying albumin nanoparticles and the preparation method thereof, the drug-carrying capacity of the microbubble is high, the preparation technology is simple, the production cost is low, and the ultrasound lipid microbubble is prone to industrial production, not only can be taken as an ultrasound developer for disease diagnosis, but also can be taken as a drug-carrying preparation for disease treatment.

Owner:CHONGQING MEDICAL UNIVERSITY

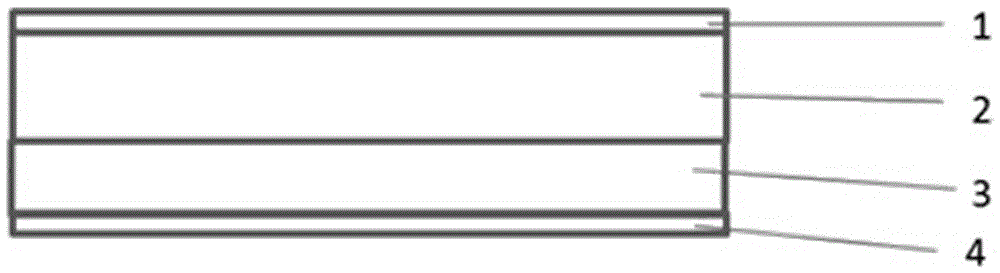

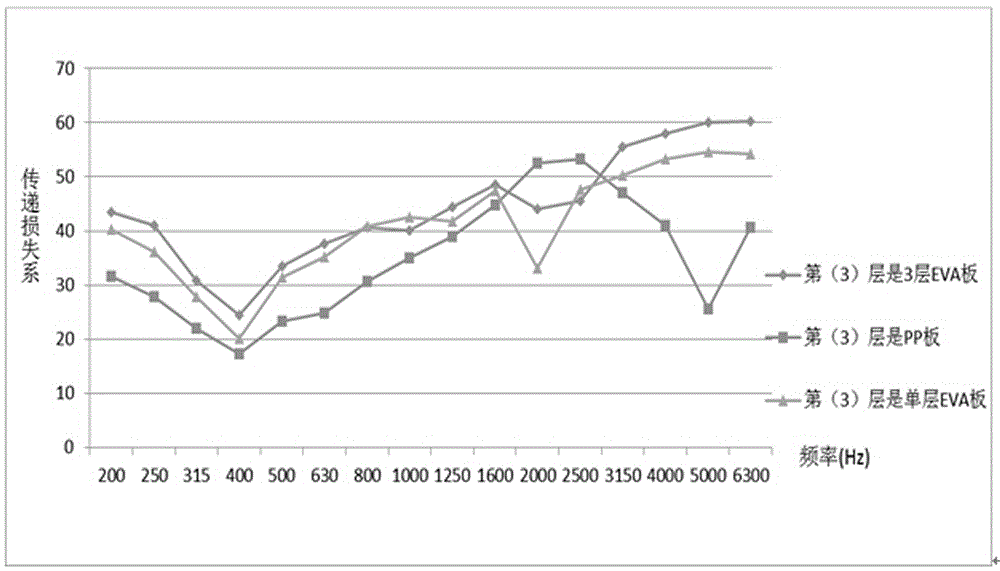

Composite material for automotive wheel cover

ActiveCN105818500AResolve rockingSolve the problem of water hammerLayered product treatmentSynthetic resin layered productsNonwoven fabricMacromolecule

The invention discloses a composite material for an automotive wheel cover. The composite material comprises a first non-woven fabric layer, a sound-absorbing cotton layer, a macromolecular resin composite sheet layer and a second non-woven fabric layer which are superposed from top to bottom in sequence; the macromolecular resin composite sheet layer is formed by superposing more than one layer of EVA sheet and a PP sheet and / or a PET sheet. As the macromolecular resin composite sheet layer formed by superposing the more than one layer of EVA sheet and the PP sheet and / or the PET sheet is selected, the composite material for the automotive wheel cover, disclosed by the invention, solves the problems that as an existing automotive wheel cover is obtained by hot-press forming of thermoplastic resin fibers, the sound insulation effect is worse, and the obvious sound transmission loss coefficient trough occurs in the wheel cover obtained by hot-press forming after a plate is extruded by PP+EPDM or PE blending injection or blending; the average sound transmission loss coefficient of the obtained composite material for the automotive wheel cover reaches 44 db, the sound reflectivity is high within a medium-high frequency scope, no obvious sound transmission loss trough occurs, and the noise problems caused by stone attack and water attack when an automobile travels at a high speed are effectively solved.

Owner:广州泰力高汽车零部件有限公司

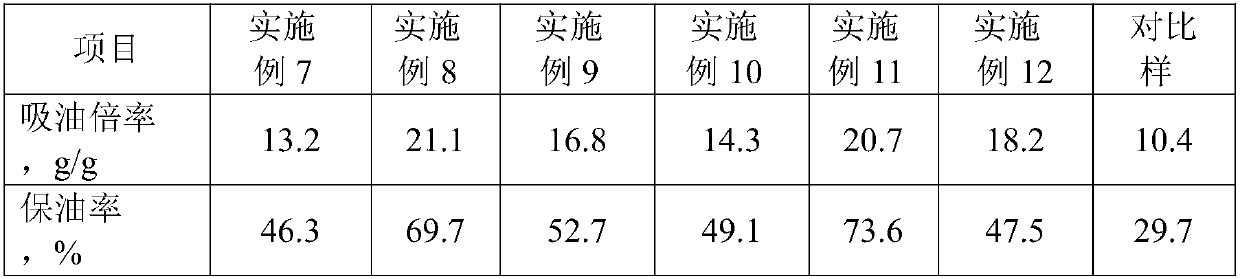

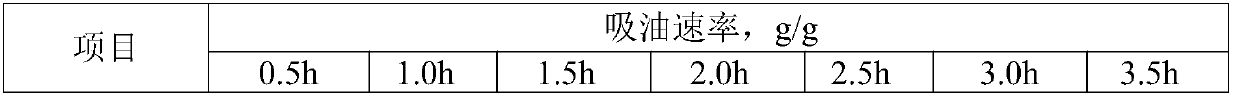

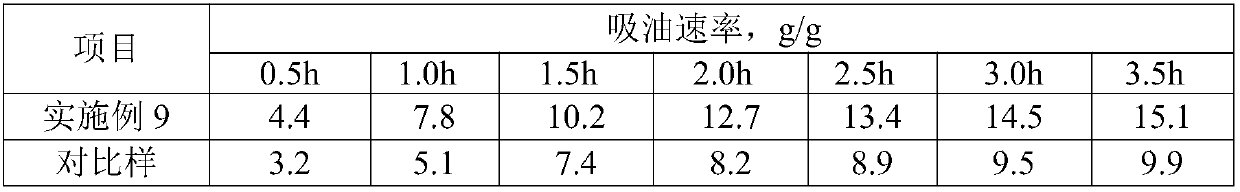

Method for preparing graphene high-oil absorption resin

ActiveCN107617427AExcellent hydrophobic and lipophilic propertiesHigh oil absorption rateOther chemical processesLiquid separationIonCvd graphene

The invention relates to a method for preparing a graphene high-oil absorption resin. The method comprises the following steps: 1, putting modified porous graphene or modified porous graphene antibacterial composition into deionized water, and performing ultrasonic dispersion for 1-24 hours so as to obtain a modified porous graphene suspension; 2, stirring deionized water and an emulsifier in a reaction container, sufficiently dissolving, and adding an acrylic monomer so as to obtain a stable emulsion; 3, putting the modified porous graphene suspension into the emulsion in the step 2, performing continuous stirring emulsification for 30-60 minutes, further adding a chemical cross-linking agent and a pore-forming agent, and continuously stirring for 10-30 minutes; 4, heating to 40-70 DEG C,performing a reaction for 2-20 hours with an initiator so as to obtain porous high-oil absorption resin gel; 5, pelletizing the porous high-oil absorption resin gel, and drying in an oven at 105-180DEG C till a constant weight, so as to obtain the graphene high-oil absorption resin.

Owner:浙江卫星新材料科技有限公司

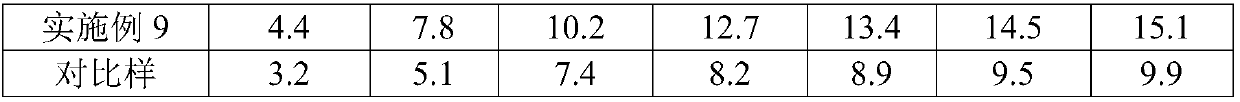

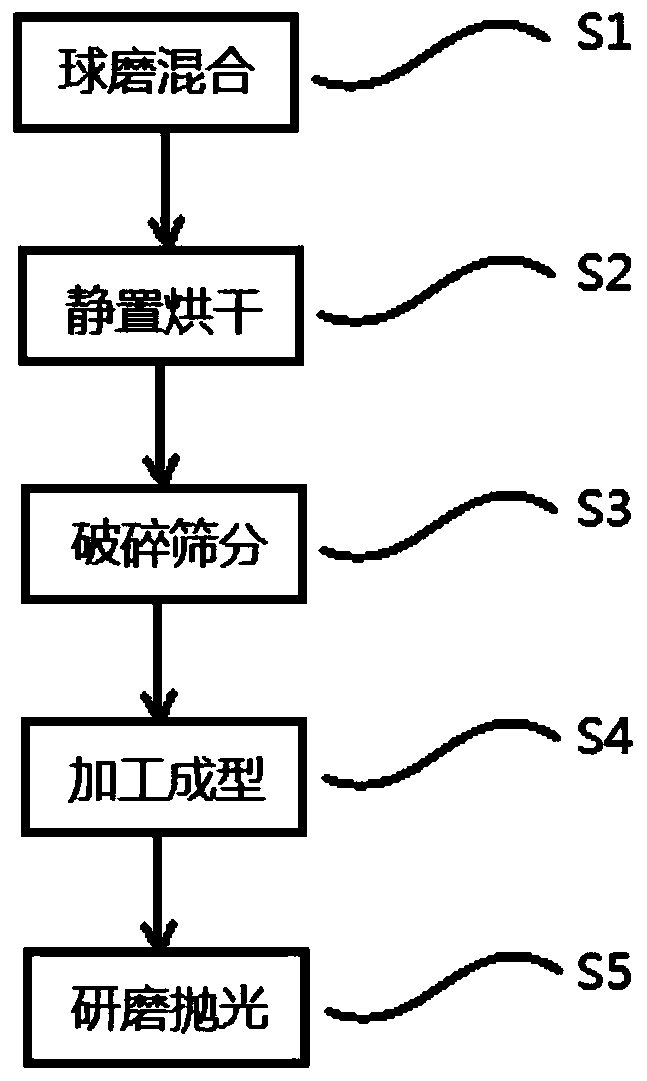

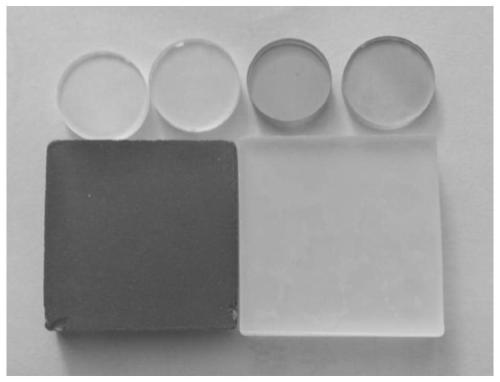

Preparation method of transparent ceramic

InactiveCN110183223AImprove the sintering processGood optical performanceBall millHot isostatic pressing

The invention discloses a preparation method of a transparent ceramic. The preparation method includes the following steps: to-be-obtained transparent ceramic powder and a sintering assistant are fully mixed through a planetary ball milling process; after ball milling is performed for a given time, drying is performed; the dried powder is pulverized and screened, and then sequentially subjected toprepressing, cold isostatic pressing, high temperature sintering and grinding / polishing steps; a transparent ceramic sample is obtained through preparation. Through the preparation method of the invention, the compound sintering assistant is adopted to effectively promote the sintering process of the ceramic; the sintering temperature is reduced; the transparency of the transparent ceramic is increased.

Owner:深圳市丁鼎陶瓷科技有限公司

Immobilization acetylcholinesterase tablet and matched substrate tablet, preparation method and use for the same

InactiveCN101054573ARapid Pesticide Residue TestGood reproducibilityImmobilised enzymesHydrolasesPesticide residueThymol blue

The present invention provides a immobilized acetylcholine esterase sheet and matched matrix sheet and their preparation method and uses. The immobilized acetylcholine esterase uses qualitative filter paper as carrier and is adsorbed in filter paper. The immobilized acetylcholine esterase sheet uses crucian brain as source of acetylcholine esterase and qualitative filter paper as fixed carrier by physical adsorption method. The matched matrix sheet is prepared using the following method : mixing thymol blue alcohol solution of weight percentage 0.1-1% and 0.1-0.5mol / L -1acetylcholine according to volume ratio 1:1-1:5, titrating with 0.05-0.2mol / L-1 sodium hydroxide to make the color changing from red to blue, stop titration instantly, adding it to culture dish, filter paper is added and then matrix sheet is obtained. The inventive enzyme sheet reproduce well, has high enzyme activity. The enzyme sheet is easy to store and can be used for detecting carbamate pesticide, especially in quick agricultural pesticide residue detection.

Owner:HUAZHONG AGRI UNIV +2

Color transparent ceramic and preparation method thereof

InactiveCN110204327AImprove the sintering processLower sintering temperatureColoring agentsTransparent ceramics

The invention discloses a color transparent ceramic and a preparation method thereof. The preparation method comprises: completely mixing the power of a to-be-obtained color transparent ceramic, a coloring agent and a sintering aid by using a planetary ball milling process, carrying out ball milling for a predetermined time, drying, carrying out breaking screening on the dried powder, and sequentially carrying out pre-pressing molding, cold isostatic pressing treatment, high-temperature sintering and grinding / polishing to prepare the color transparent ceramic sample. According to the present invention, the color transparent ceramic can be prepared; by using the composite sintering aid, the sintering process of the ceramic is effectively promoted, the sintering temperature is reduced, and the light transmittance of the transparent ceramic is improved; and the preparation process is simplified by adding the coloring agent at one time.

Owner:深圳市丁鼎陶瓷科技有限公司

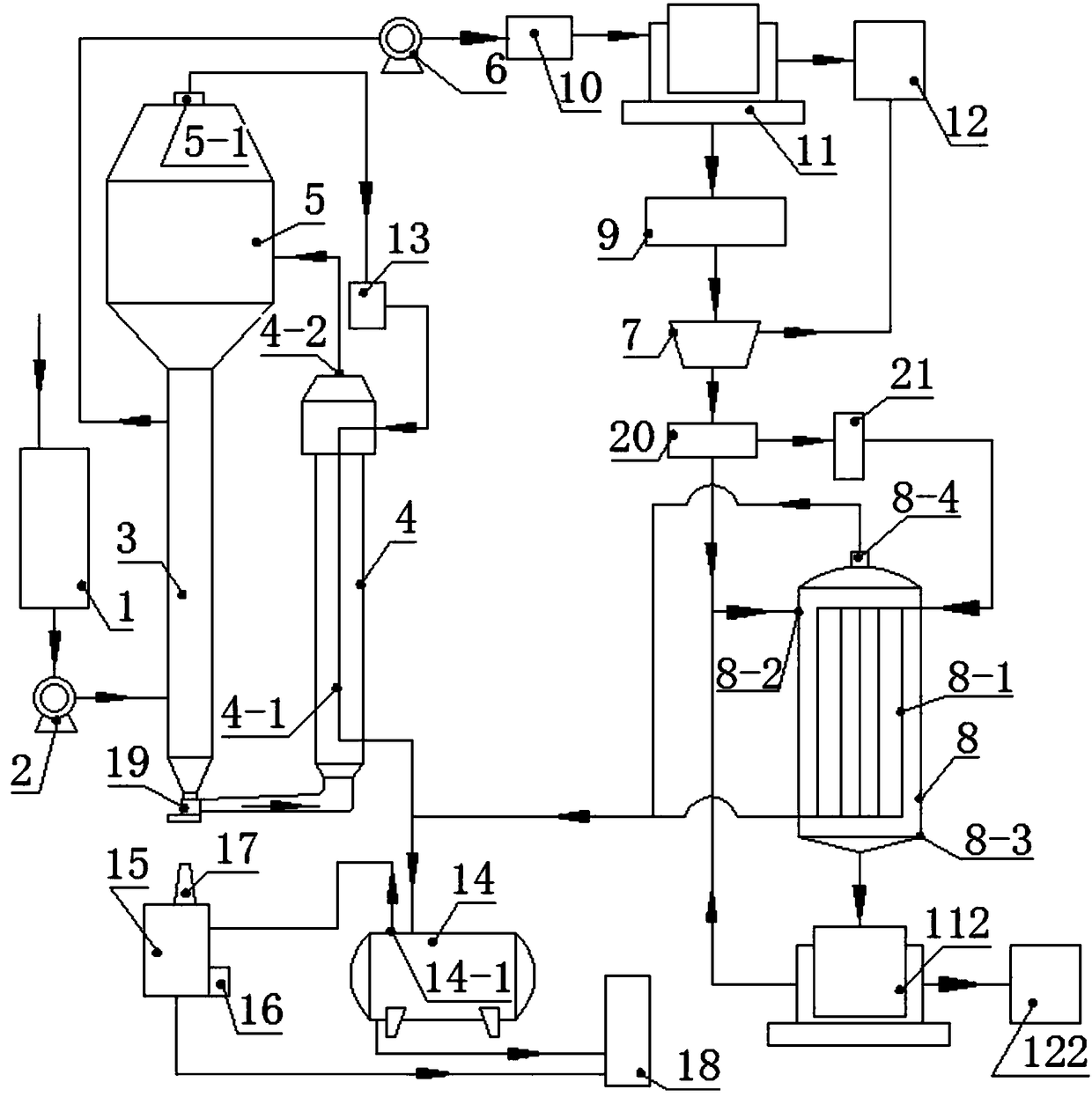

High salinity organic wastewater treatment equipment

PendingCN108178410ASimple processReduce energy consumptionWater/sewage treatment by centrifugal separationWater contaminantsNanofiltrationMulti effect

The invention discloses high salinity organic wastewater treatment equipment. The equipment consists of a raw water tank, a feeding pump, an MVR evaporator, a discharge pump, a magma tank, a centrifuge A, a refrigeration tank, a filter, a nanofiltration membrane separation instrument, a fluidized bed boiler, a vacuum evaporator and a centrifuge B. The raw water tank is connected to the MVR evaporator, the water outlet of the MVR evaporator is connected to the magma tank, the discharge port of the magma tank is connected to the centrifuge A, the liquid discharge port of the centrifuge A is connected to the refrigeration tank, the refrigeration tank is connected to the nanofiltration membrane separation instrument through the filter, the organic wastewater outlet of the nanofiltration membrane separation instrument is connected to the fluidized bed boiler, the vacuum evaporator is internally equipped with a heating pipeline, the vacuum evaporator is provided with a water inlet, a discharge port and a secondary steam outlet, and the steam outlet of the fluidized bed boiler is connected to the heating pipeline. The high salinity organic wastewater treatment equipment provided by the invention employs the novel MVR evaporator to replace the traditional multi-effect evaporator, combines the evaporation process with refrigeration process, combines vacuum evaporation for salt making with high temperature incineration of organic matters, simplifies the process, and reduces the energy consumption.

Owner:山东特保罗环保节能科技有限公司

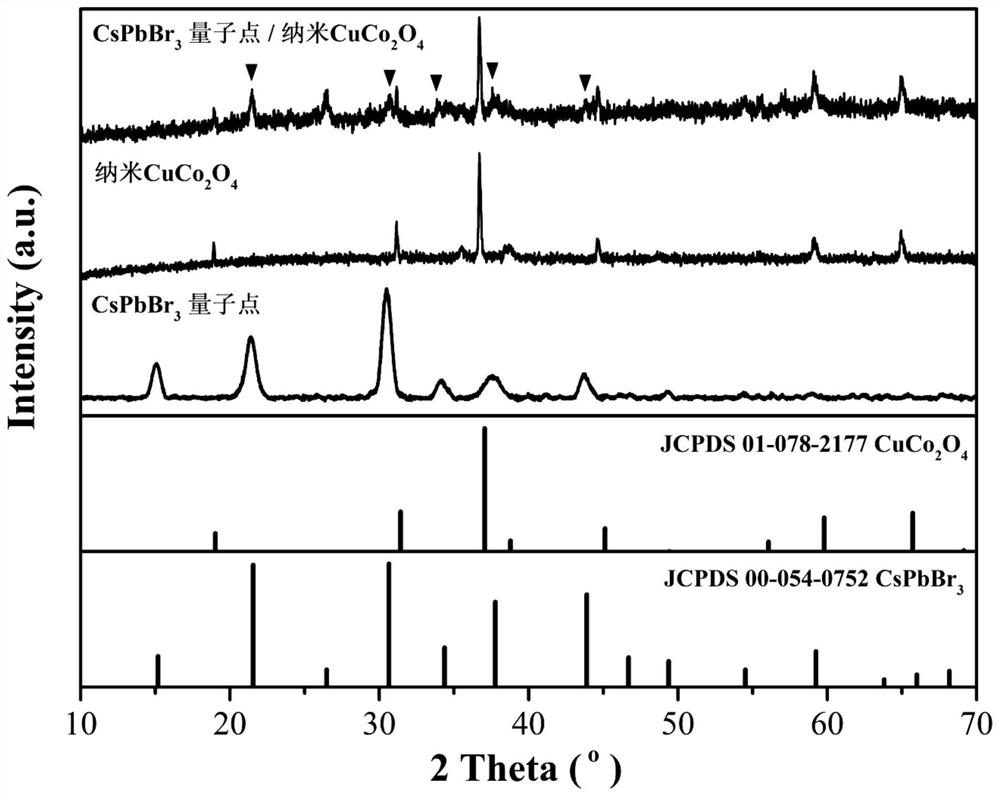

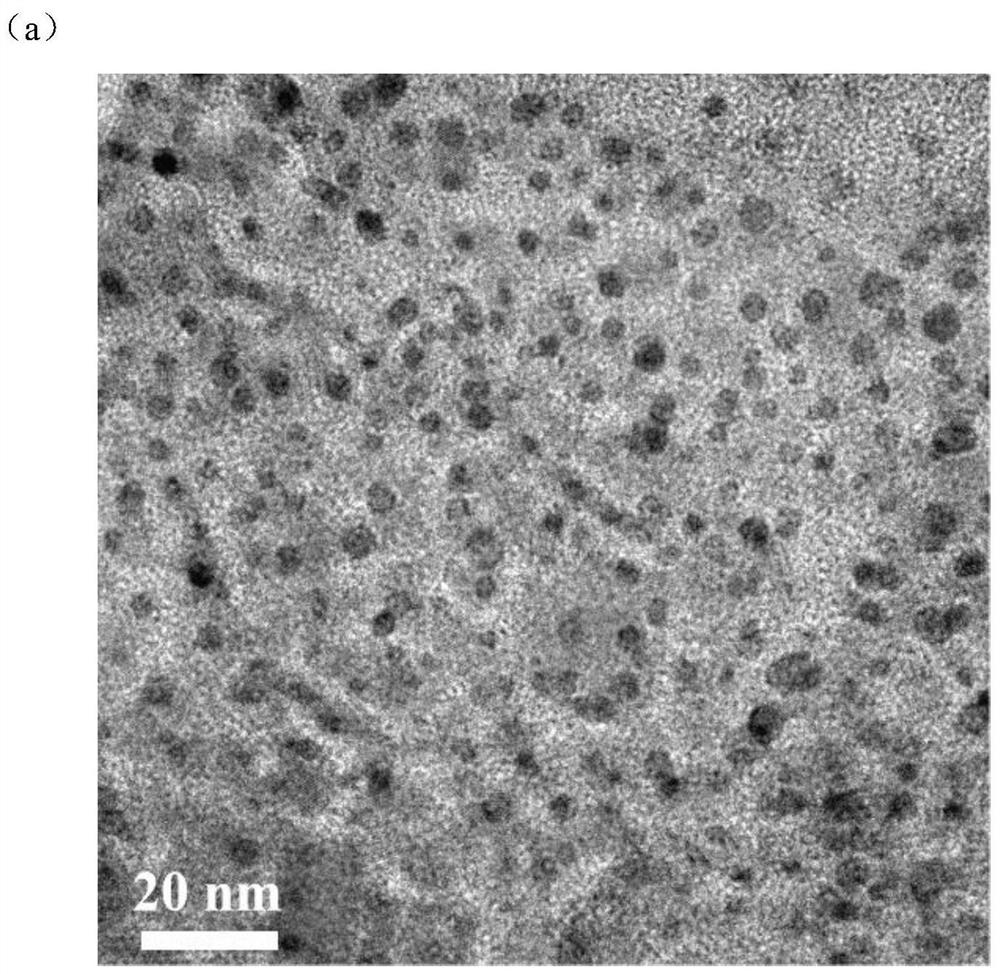

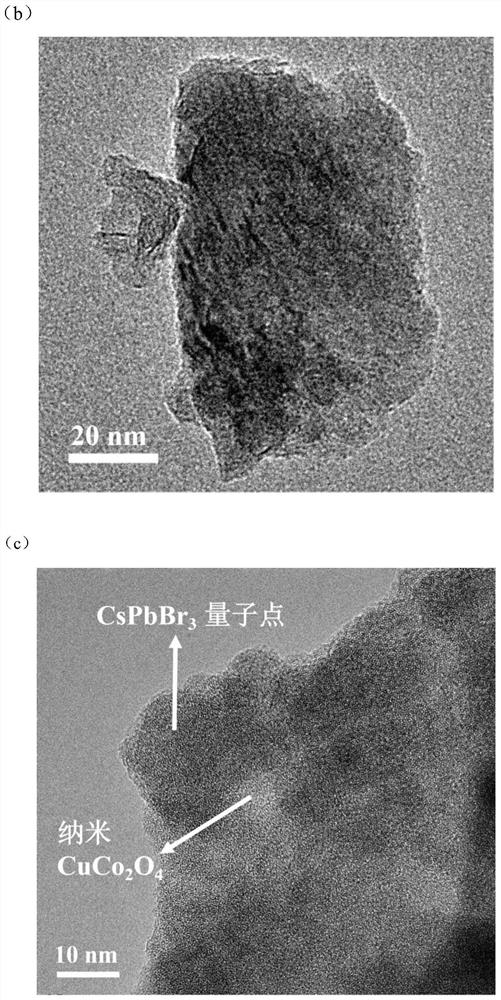

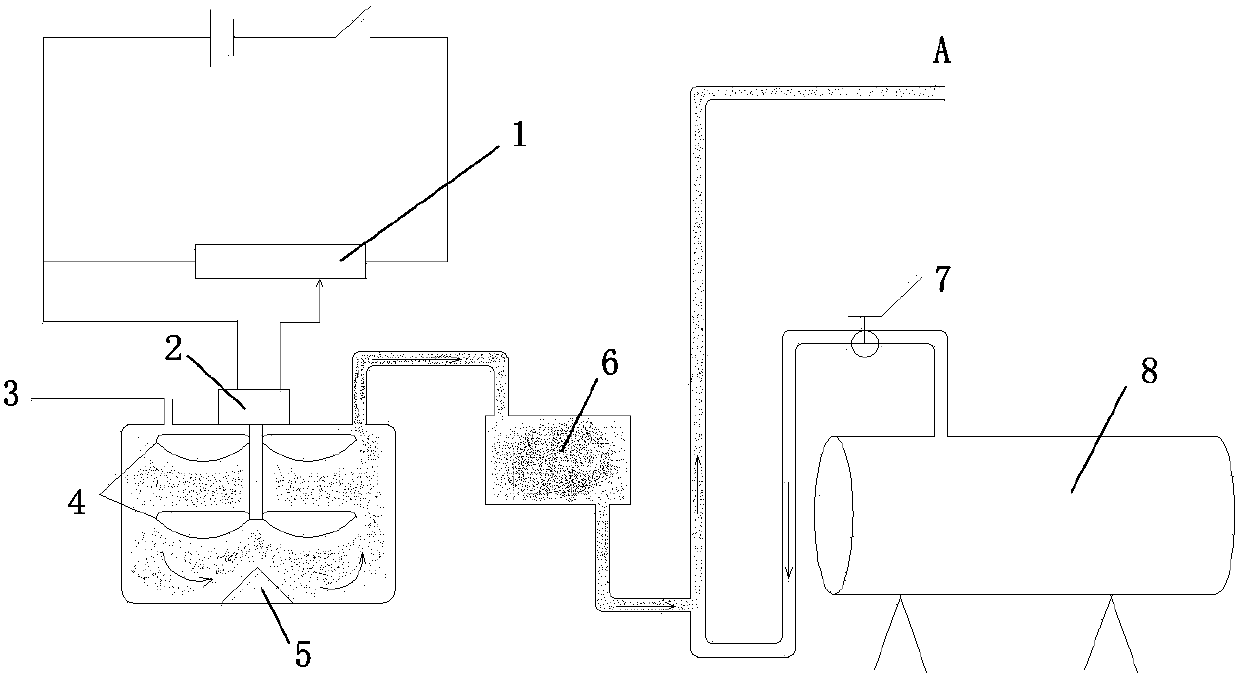

CsPbBr3 quantum dot/nano CuCo2O4 composite photocatalyst for CO2 reduction and preparation method of CsPbBr3 quantum dot/nano CuCo2O4 composite photocatalyst

ActiveCN113145141AGood monodispersityHigh utilization rate of visible lightCatalyst activation/preparationCarbon monoxideChemical physicsChemical reaction

The invention relates to a CsPbBr3 quantum dot / nano CuCo2O4 composite photocatalyst for CO2 reduction, the CsPbBr3 quantum dot / nano CuCo2O4 composite photocatalyst comprises CsPbBr3 quantum dots and nano CuCo2O4, and the ratio of the CsPbBr3 quantum dots to the nano CuCo2O4 is (0.2-2) mmol: (4-40) mg; and the invention further relates to a preparation method of the CsPbBr3 quantum dot / nano CuCo2O4 composite photocatalyst for CO2 reduction. The CsPbBr3 quantum dot / nano CuCo2O4 composite photocatalyst has the advantages of being high in visible light utilization rate and excellent in photocatalytic performance, CsPbBr3 quantum dots and nano CuCo2O4 are compounded through continuous ultrasonic treatment, sound waves of high-frequency vibration are transmitted to the surfaces of the CsPbBr3 quantum dots and the surfaces of the nano CuCo2O4, atoms on the surface layers of the CsPbBr3 quantum dots and the surfaces of the nano CuCo2O4 rub against one another, the key point of the method lies in the combination of atomic layers on the surfaces of the two materials, so that the CsPbBr3 quantum dots embedded into the CuCo2O4 nanosheets are not easy to fall off; the method does not involve chemical reaction, so that other impurities are not introduced; and the method is simple in process, good in reproducibility and low in cost, and meets environmental requirements.

Owner:WUHAN UNIV OF TECH

Auxiliary powder adding device and processing method for functional rotor spinning yarns

The invention provides an auxiliary powder adding device for functional rotor spinning yarns. The auxiliary powder adding device is mounted in rear of a rotor spinning machine and comprises a static bin. A pipeline of the static bin is connected with an air compressor through a valve. One end of the static bin is connected with the tail end of a rotor of the rotor spinning machine through a pipeline. The other end of the static bin is connected with a tapered body through a pipeline. Fan blades are arranged in the tapered body, an air vent is arranged on the tapered body, and the tapered body is connected with the output end of a motor. A slide rheostat is arranged on the motor. The rotor spinning machine is simply modified, the auxiliary powder adding device is connected with the tail end of the hollow-shaft rotor, and powder with a certain function is input into the rotor by the auxiliary powder adding device during rotor spinning to be twisted with fibers into the yarns, so that the functional rotor spinning yarns containing the powder can be acquired directly.

Owner:ZHONGYUAN ENGINEERING COLLEGE

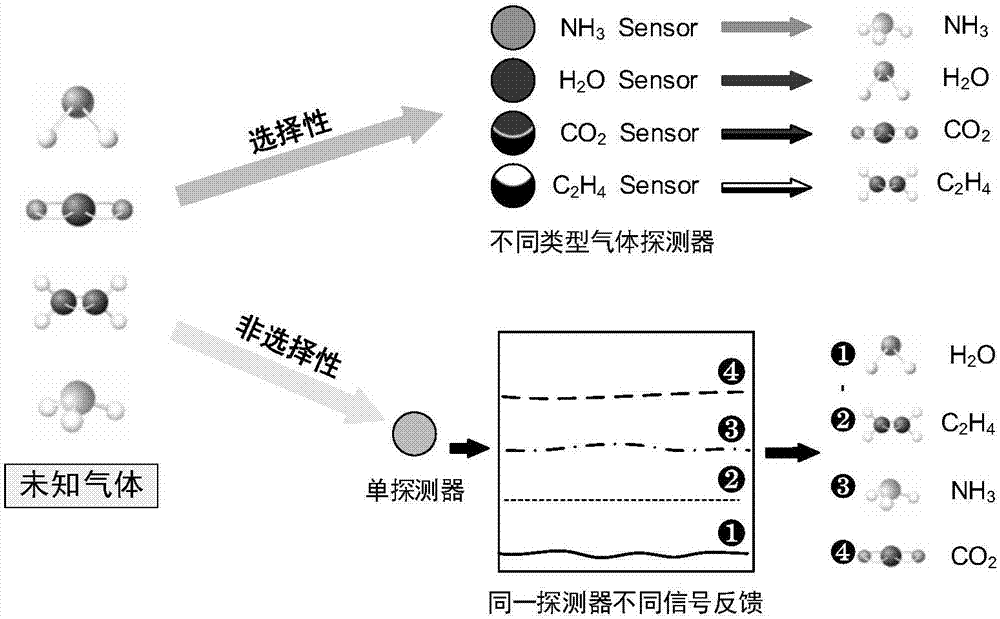

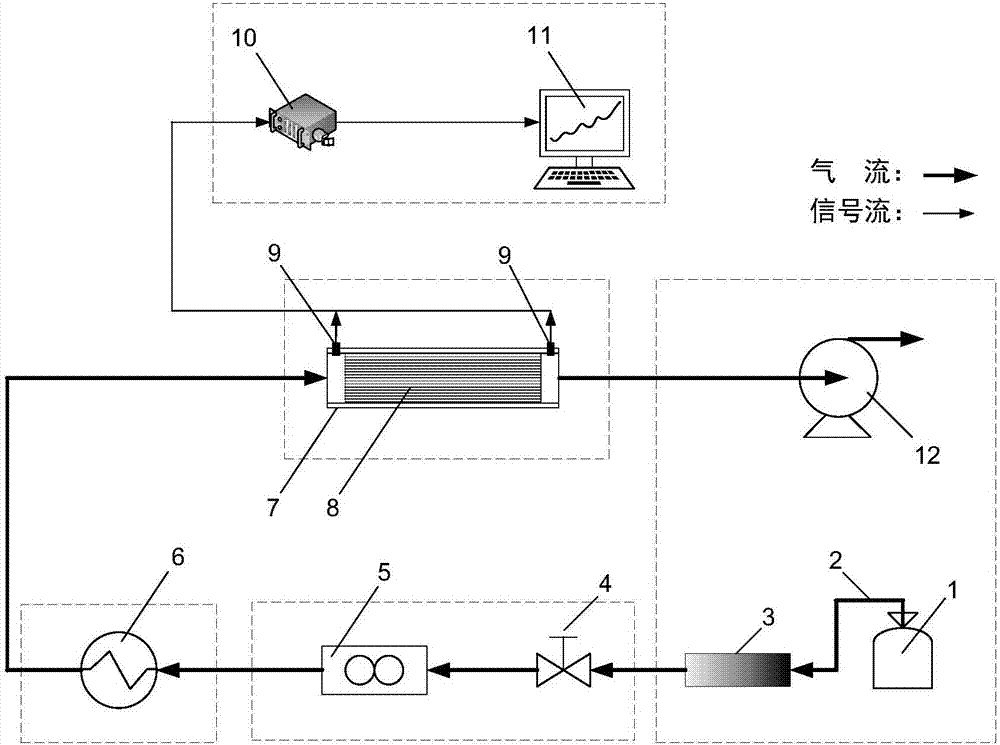

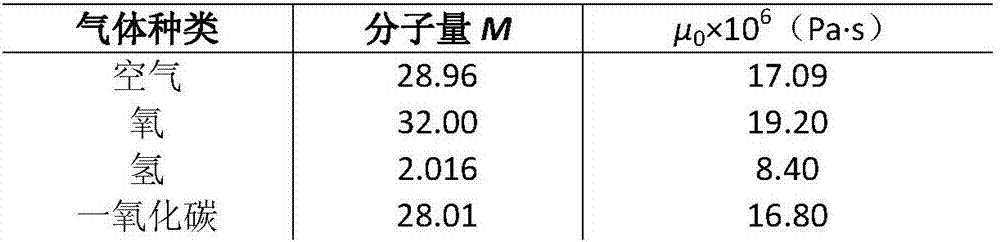

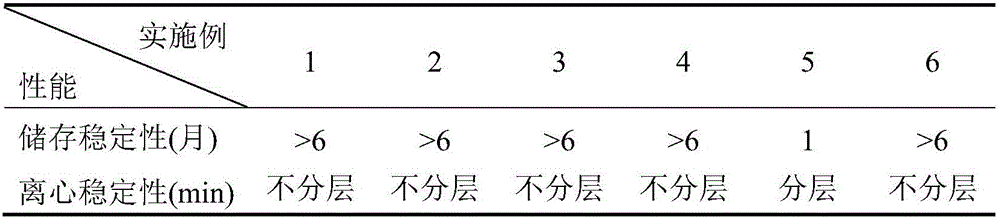

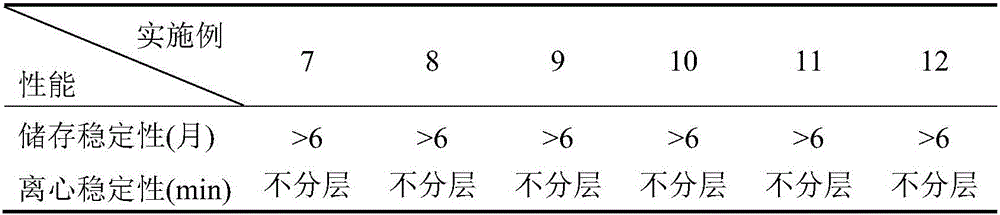

Non-selective fire gas detection device based on viscosity properties

InactiveCN107976381AEfficient identificationNo chemical reactions involvedFlow propertiesTemperature controlCombustion

The invention discloses a non-selective fire gas detection device based on viscosity properties. The device comprises a sampling unit, a flow velocity control unit, a constant temperature control unit, a detection and identification unit and a data recording and analysis unit, wherein the sampling unit is used for extracting a gas sample generated due to leakage or combustion in the environment tobe detected by means of a vacuum pump, and the extracted gas sample sequentially enters the flow velocity control unit and the constant temperature control unit through a sampling pipe after passingthrough a sampling end filter screen and a drying agent; the flow velocity control unit consists of a flow-limiting valve and a flow meter, and can realize the accurate adjustment of the flow velocityof gas flowing through the flow velocity control unit so as to enable the flow velocity of the gas to be detected to meet the detection requirement; the constant temperature control unit comprises atemperature adjustment part and an electric heating coil, and can be used for rapidly heating the gas, flowing through the temperature adjustment part, up to set temperature; the detection and identification unit comprises a cylindrical porous media and a sleeve; two micro pressure differential sensors are respectively arranged at the two ends of the detection and identification unit and are usedfor acquiring and analyzing the pressure loss of the gas after the gas flows through the porous media; the data recording and analysis unit can be used for collecting and recording the signal responseof the micro pressure differential sensors, and further identifies the type of the gas by comparing the obtained differential pressure with characteristic differential pressure of a standard gas sample.

Owner:HUAIHAI INST OF TECH

High-performance water-based epoxy resin automobile paint and preparation method thereof

InactiveCN105885628ALow VOC contentReduce environmental pollutionAnti-corrosive paintsEpoxy resin coatingsIonSolvent

The invention discloses a high-performance water-based epoxy resin automobile paint and a preparation method thereof. The automobile paint comprises the following components in parts by weight: 30-60 parts of component A and 30-90 parts of component B. The component A comprises 30-60 parts of epoxy resin M, 1-10 parts of emulsifier X, 1-10 parts of cosolvent and 30-60 parts of deionized water. The component B comprises 0-30 parts of pigment, 10-30 parts of amine curing agent, 30-60 parts of deionized water, 0.1-3 parts of organosilicon leveling agent, 0.1-3 parts of polylol wetting agent, 1-5 parts of dispersing agent, 0.1-2 parts of preservative, 0.5-2 parts of emulsifier Y, 0.2-2 parts of pH regulator and 0.2-2 parts of defoaming agent. The whole paint uses water as the medium and only needs a small amount of cosolvent, so the VOC (volatile organic compound) content is greatly lowered, and the environmental pollution is small. The phase-reversal method used for preparing the water-based epoxy resin emulsion directly adopts mechanical dispersion without chemical reaction, and thus, has the advantages of simple equipment and low cost.

Owner:HUBEI JIAJI SYNTHESIS MATERIALS CO LTD +1

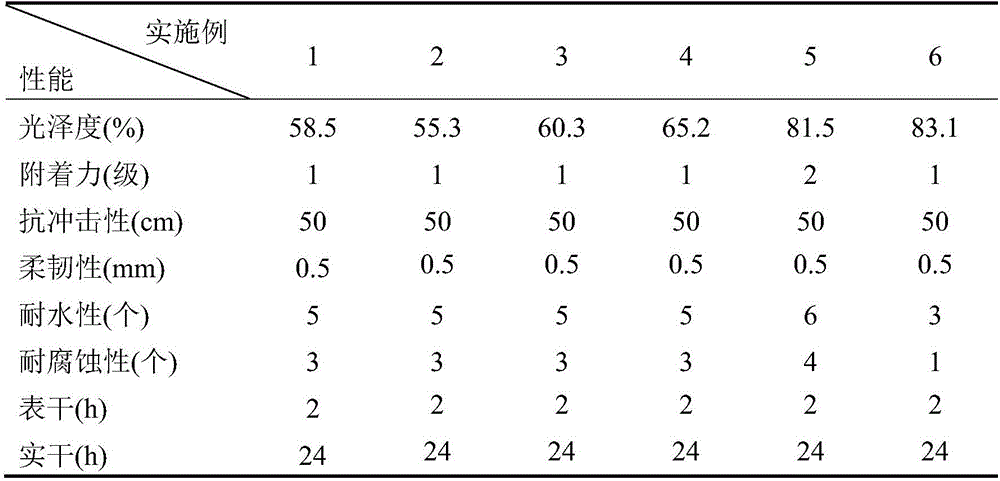

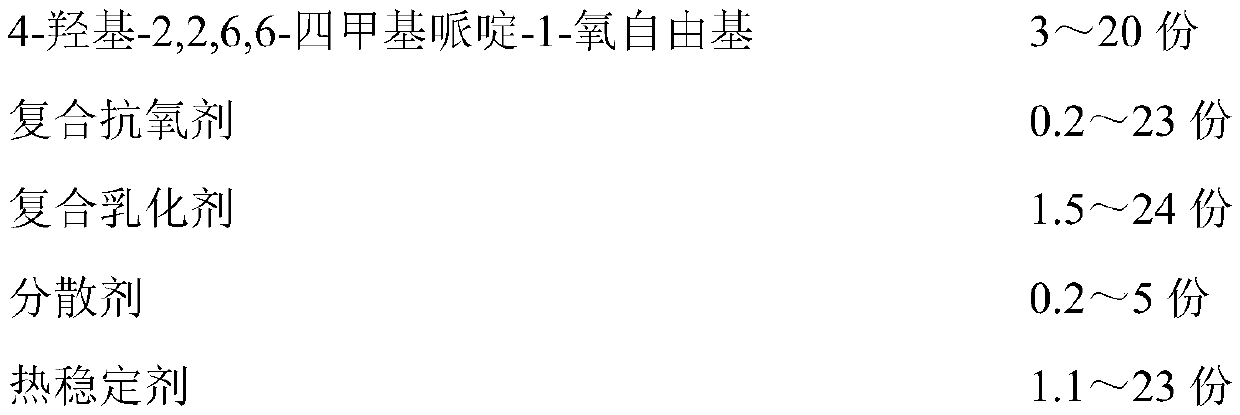

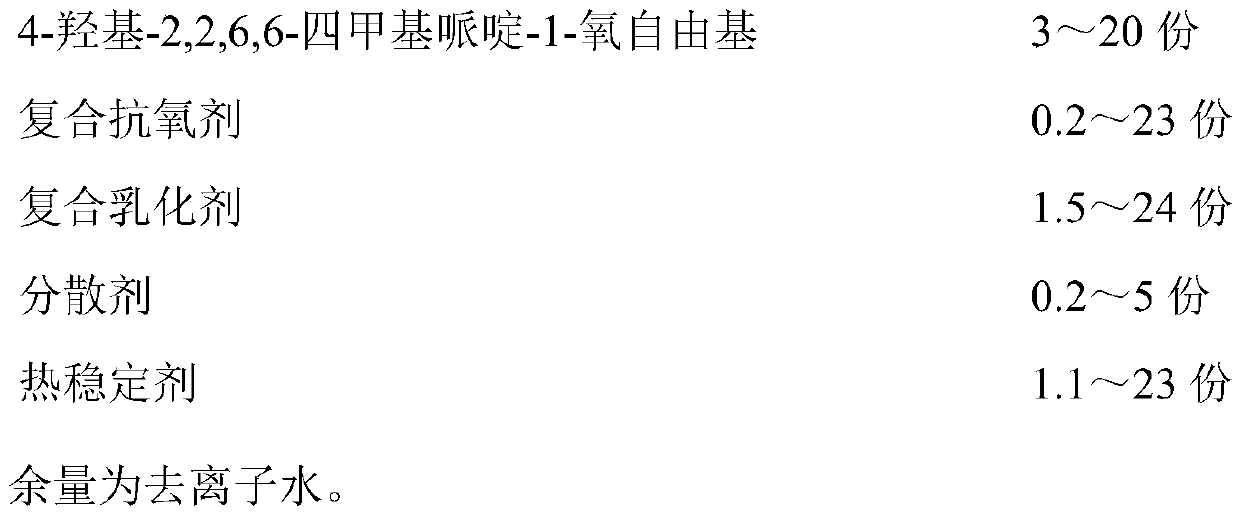

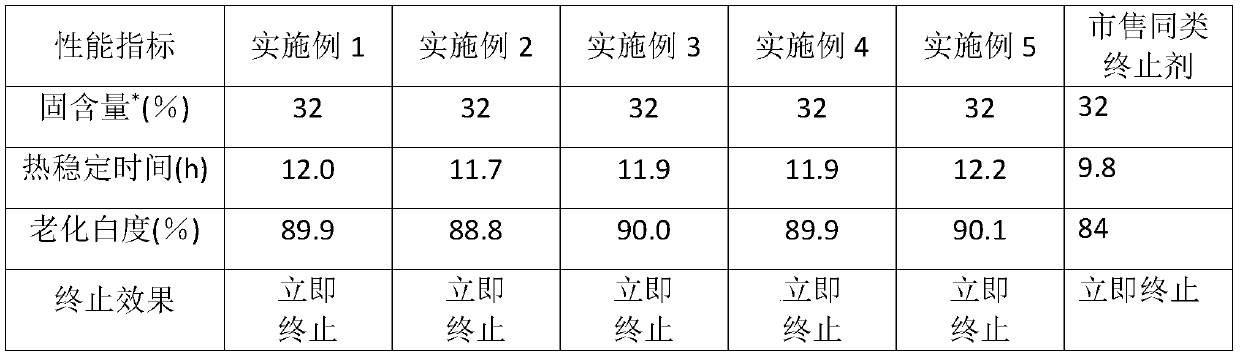

An aqueous emulsion type terminator for PVC resin and vinyl chloride-vinyl acetate copolymer and a preparation method thereof

An aqueous emulsion type terminator for PVC resin and vinyl chloride-vinyl acetate copolymer is provided. The terminator is good in emulsion stability and high in terminating efficiency, and producedresin has high ageing whiteness that can be 88 or above. The terminator includes, based on 100 parts by mass, 3-20 parts of 4-hydroxy-2,2,6,6-tetramethylpiperidinooxy, 0.2-23 parts of a composite antioxidant, 1.5-24 parts of a composite emulsifier, 0.2-5 parts of a dispersant and 1.1-23 parts of a thermal stabilizer, with the balance being deionized water.

Owner:江苏长丰有机硅有限公司

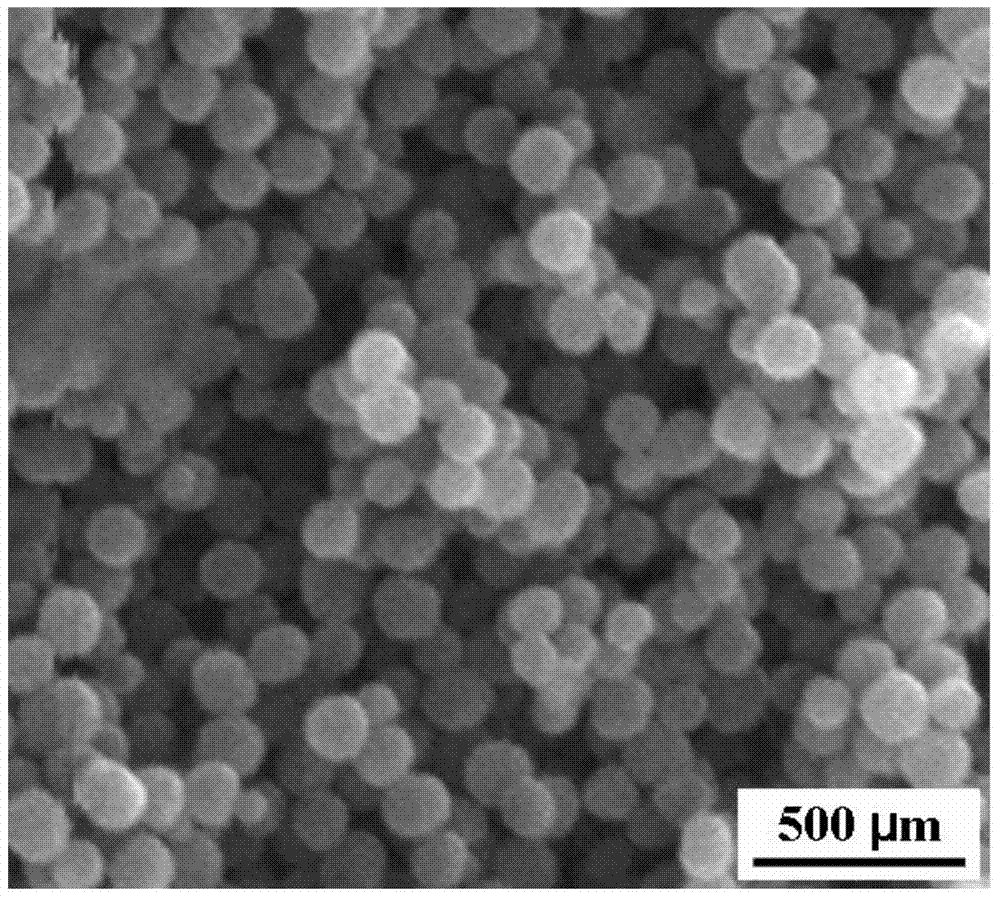

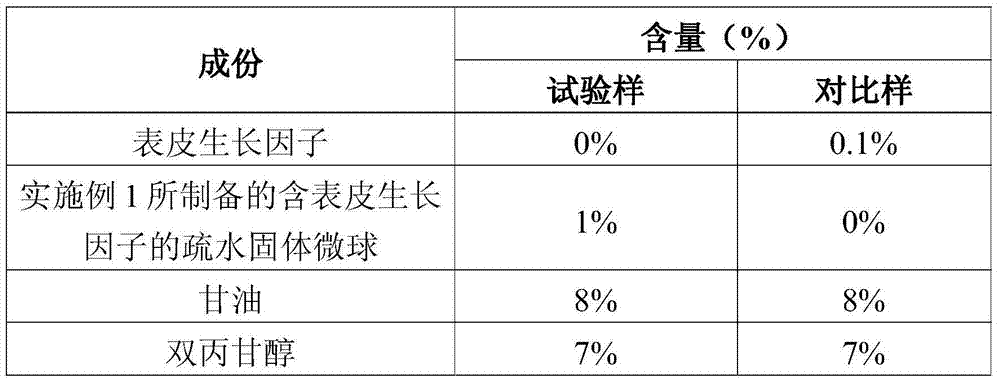

Hydrophobic solid microspheres containing epidermal growth factors and preparation method and application of microspheres

ActiveCN103860392ANon-irritatingGood water solubilityCosmetic preparationsToilet preparationsEnvironmental resistanceChemical reaction

The invention discloses hydrophobic solid microspheres containing epidermal growth factors and a preparation method and application of the microspheres. The preparation method comprises the following steps: with polyethylene glycol porous microspheres as a protective agent, loading the epidermal growth factors; and protecting the polyethylene glycol porous microspheres loading the epidermal growth factors by paraffin through fusing and spraying. The preparation method provided by the invention has the advantages and effects that (1) polyethylene glycol with the molecular weight from 2000 to 20000 is selected as the protective agent for the epidermal growth factors; (2) the epidermal growth factors are protected by solid paraffin, and polyethylene glycol freezed powder isolates water; (3) the preparation process is simple and does not refer to chemical reactions, and is free of the generation of the three wastes and green and environment-friendly; (4) the contained epidermal growth factors are acid-resistant, alkali-resistant, light-resistant, waterproof and high-temperature-resistant; and (5) the hydrophobic solid microspheres are simple and convenient to use, and can serve as a functional additive which is added into various emulsions and cream or frost-like cosmetics by being slightly squeezed.

Owner:GUANGDONG VOCATIONAL & TECHNICAL COLLEGE

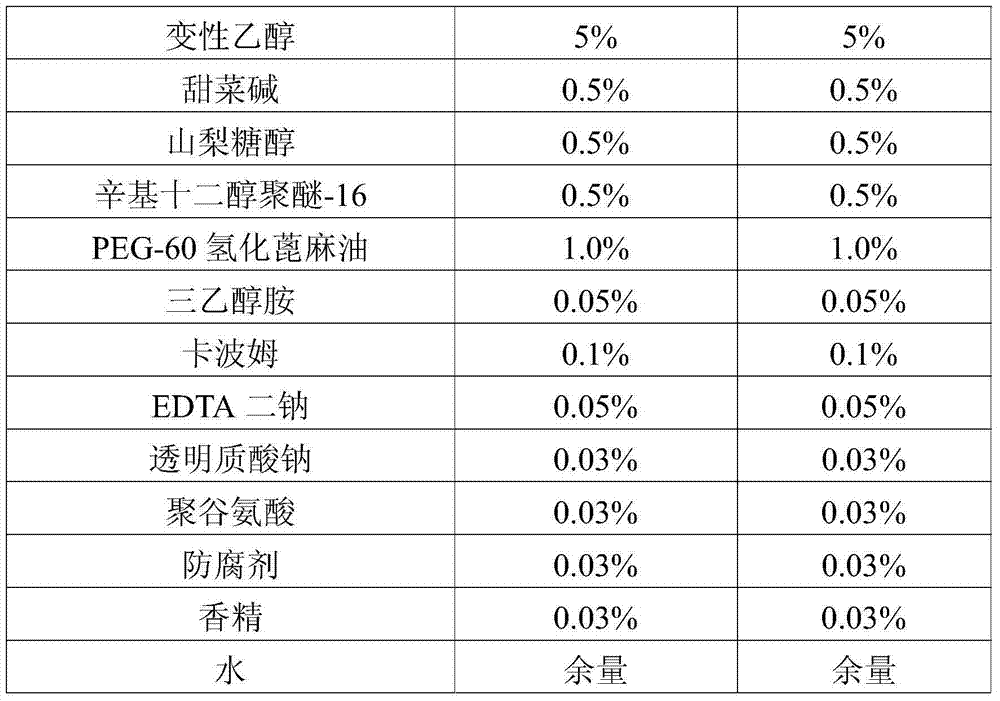

Light sensitive material/calcium alginate core-shell nanocapsule dispersoid and preparation method thereof

ActiveCN111358711AImprove protectionPlay a protective effectCosmetic preparationsToilet preparationsCALCIUM LACTOBIONATEOil phase

The invention provides a light sensitive material / calcium alginate core-shell nanocapsule dispersoid and a preparation method thereof. By the method, light sensitive materials can be made into the light sensitive material / calcium alginate core-shell nanocapsule dispersoid, and the light sensitive materials can be subjected to stabilization and controlled release, and have the characteristics of being simple in technology and safe and reliable. The preparation method provided by the invention comprises the following steps of (1) adding an oil phase solution to an aqueous phase solution, and performing emulsifying to obtain emulsion, wherein the oil phase solution contains the light sensitive materials; or directly adding purely light sensitive materials to the aqueous phase solution, and performing emulsifying so as to obtain the emulsion, wherein the aqueous phase solution is obtained through enabling sodium alginate and / or modified sodium alginate and an emulsifying agent to dissolvein water, and is used as a wall material solution; and (2) adding a curing agent aqueous solution to the emulsion, and performing gel coagulation for obtaining shells of the sodium alginate so as to obtain the light sensitive material / calcium alginate core-shell nanocapsule dispersoid, wherein the curing agent aqueous solution is selected from calcium lactate and / or a calcium chloride aqueous solution.

Owner:WANHUA CHEM GRP CO LTD

Graphene based super oil-absorbable and antibacterial oil-absorbable resin and application thereof

ActiveCN107641171AHigh oil absorption rateImprove lipophilicityNon-miscible liquid separationPorous grapheneSurface layer

The invention relates to graphene based super oil-absorbable and antibacterial oil-absorbable resin. The super oil-absorbable and antibacterial oil-absorbable resin is a porous material formed after expanded and foamed, and has a mutually communicated and developed pore structure, wherein the super oil-absorbable and antibacterial oil-absorbable resin takes super oil-absorbable resin as a matrix material, and modified porous graphene or a modified porous graphene antibacterial composition is combined inside the matrix material or / and between molecular structures of a surface layer of the matrix material. The graphene based super oil-absorbable and antibacterial oil-absorbable resin comprises the following components in parts by weight: 100 parts of an acrylate monomer, 0.5 to 5 parts of anemulsifier, 1 to 20 parts of modified porous graphene or a modified porous graphene antibacterial composition, 0.5 to 5 parts of a crosslinking agent, 0.05 to 2 parts of an initiator and a pore-forming agent. The modified porous graphene is formed by using polydimethylsiloxane to modify porous graphene through vapor deposition, and the modified porous graphene antibacterial composition is prepared by loading natural antibacterial agents in pores of the modified porous graphene.

Owner:浙江卫星新材料科技有限公司

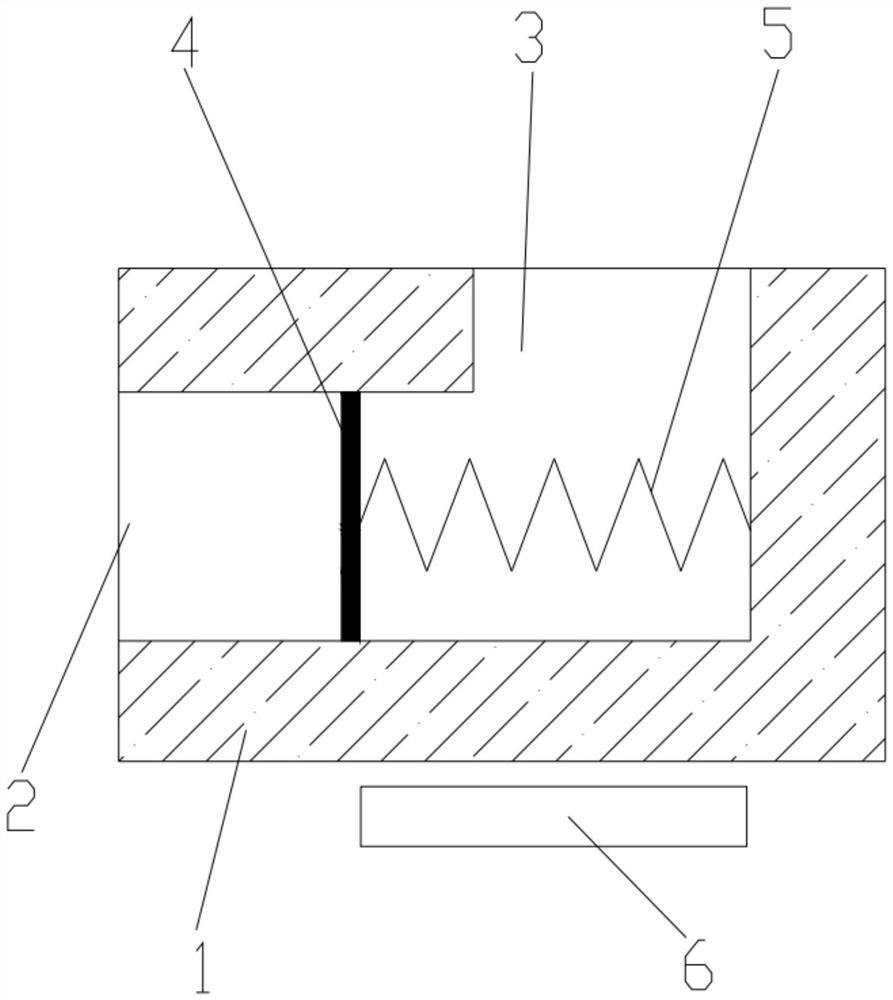

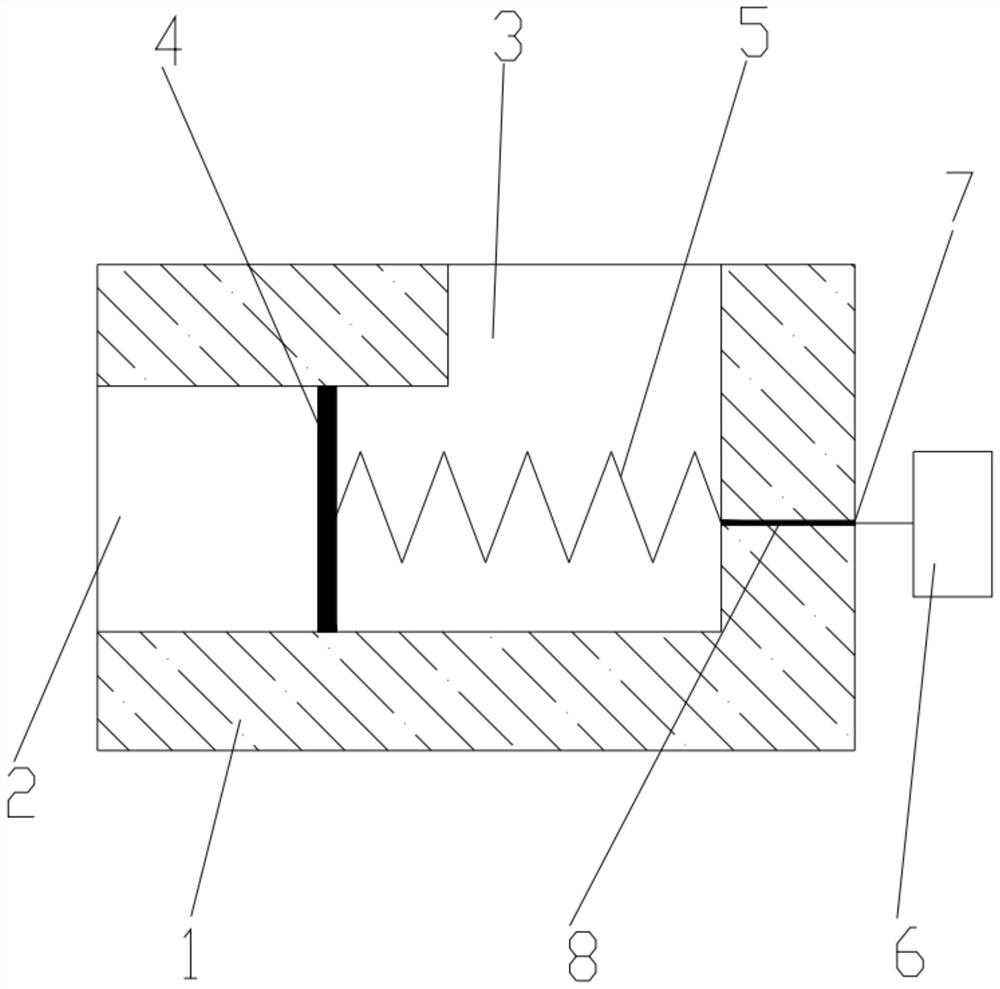

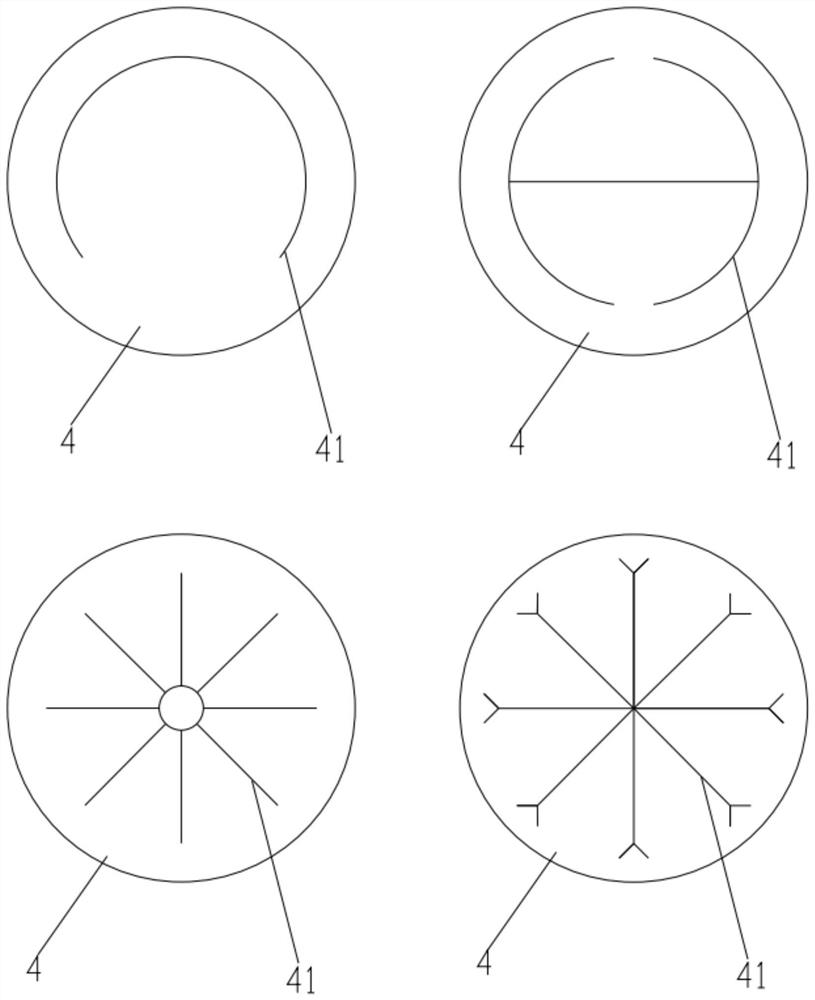

Shape memory alloy isolating valve

PendingCN111623157APlay the role of isolationImprove securityOperating means/releasing devices for valvesEqualizing valvesIsolation valveShape-memory alloy

The invention discloses a shape memory alloy isolating valve which comprises a valve body internally provided with a channel. An isolating membrane for isolating the channel is arranged in the channel, a spring is arranged on one side of the isolating membrane, the other end of the spring is connected with the valve body, and the spring is made of a shape memory alloy. According to the shape memory alloy isolating valve, the isolating membrane for isolating the channel is arranged in the channel, the isolating membrane can block distribution of fluid in the channel and play an isolating role,the isolating valve is in a closed state when the isolating membrane is intact, when the spring is heated, the spring can deform due to the physical property of the shape memory alloy, the spring extends forwards, the forward elastic force borne by the isolating diaphragm and coming from the spring is gradually increased, when the forward elastic force borne by the isolating diaphragm and appliedby the spring reaches a certain value, the isolating diaphragm can be broken and damaged, at the moment, the channel is not blocked by the isolating diaphragm, and the isolating valve can be in an open state.

Owner:西安空天引擎科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com