Preparation method of porous film with regular vertical pores

A technology of vertical channels and porous membranes, which is applied in the field of preparation of porous membranes with regular vertical channels, which can solve the problems of wide distribution of pore size and disordered channels, and achieve the effect of simple method, easy operation and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (a) Use a balance to weigh 0.06 g of a block copolymer of polystyrene and poly(2-vinylpyridine) (the volume ratio of poly(2-vinylpyridine) is 20%, and the total molecular weight is 362,000 Daltons) , be dissolved in 2.0 grams of chloroform, be mixed with the solution that polymer mass fraction is 4%;

[0030] (b) After the polymer is completely dissolved, filter the solution with a PTFE filter head to remove large aggregates, and then coat the polymer solution on the silicon substrate on a spin coater at 2000 rpm;

[0031] (c) Transfer the film to a small bottle with chloroform at the bottom of the bottle, anneal the film in the vapor of chloroform for 10 minutes, take it out, and dry it naturally in the air;

[0032] (d) The annealed film was immersed in ethanol at different temperatures (40, 45, 50, 55, 60, 70°C) to swell for 3 hours and then taken out, and the ethanol was allowed to evaporate and dry naturally in the air.

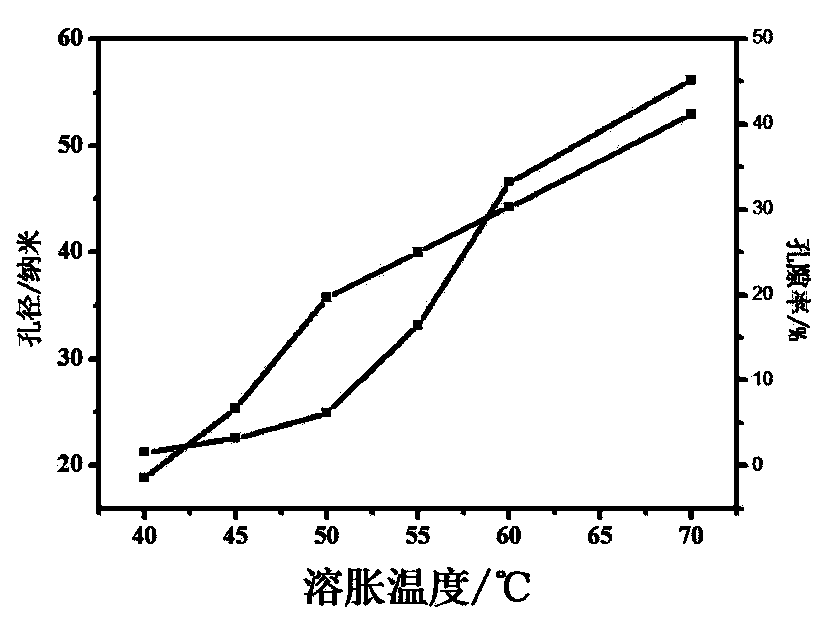

[0033] It can be seen from Figure (1) that...

Embodiment 2

[0036] (a) Weigh 0.06 g of block copolymer of polystyrene and polyacrylic acid (polyacrylic acid) with a volume ratio of 25% and a total molecular weight of 66,500 Daltons) with a balance, dissolve it in 3.0 g of tetrahydrofuran, and prepare a polymerized The substance mass fraction is 2% solution;

[0037] (b) After the polymer is completely dissolved, filter the solution with a PTFE filter head to remove large aggregates, and then coat the polymer solution on the silicon substrate on a spin coater at 3000 rpm;

[0038] (c) Transfer the film to a small bottle with toluene at the bottom of the bottle, anneal the film in toluene vapor for 40 seconds, take it out, and dry it naturally in the air;

[0039] (d) After the annealed film was immersed in ethylene glycol at 30°C and swelled for 12 hours, it was taken out, and the ethylene glycol was allowed to evaporate and dry naturally in the air.

[0040] It can be seen from Figure (4a) that after swelling, a pore structure with un...

Embodiment 3

[0042] (a) Weigh 0.06 g of polyacrylonitrile and polyoxyethylene block copolymer (polyoxyethylene) with a volume ratio of 10% and a total molecular weight of 90,000 Daltons) with a balance, dissolve it in 0.6 g of toluene, and prepare Become the solution that polymer mass fraction is 10%;

[0043] (b) After the polymer is completely dissolved, filter the solution with a PTFE filter head to remove large aggregates, and then coat the polymer solution on the silicon substrate on a spin coater at 3000 rpm;

[0044] (c) Transfer the film to a small bottle with tetrahydrofuran at the bottom of the bottle, anneal the film in the steam of tetrahydrofuran for 1 hour, take it out, and dry it naturally in the air;

[0045] (d) After the annealed film is immersed in water at 80°C and swelled for 72 hours, it is taken out, and the water is allowed to evaporate and dry naturally in the air.

[0046] From the SEM image, it can be seen that a regular hexagonal circular channel structure is f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com