Method for separating single tocopherol from mixed tocopherol

A technology for separating tocopherols, which is applied in the field of separating single tocopherols, and achieves the effects of high degree of production automation, simple process and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

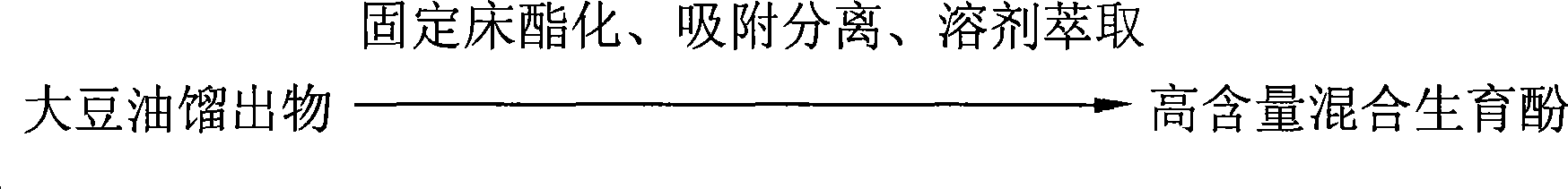

Problems solved by technology

Method used

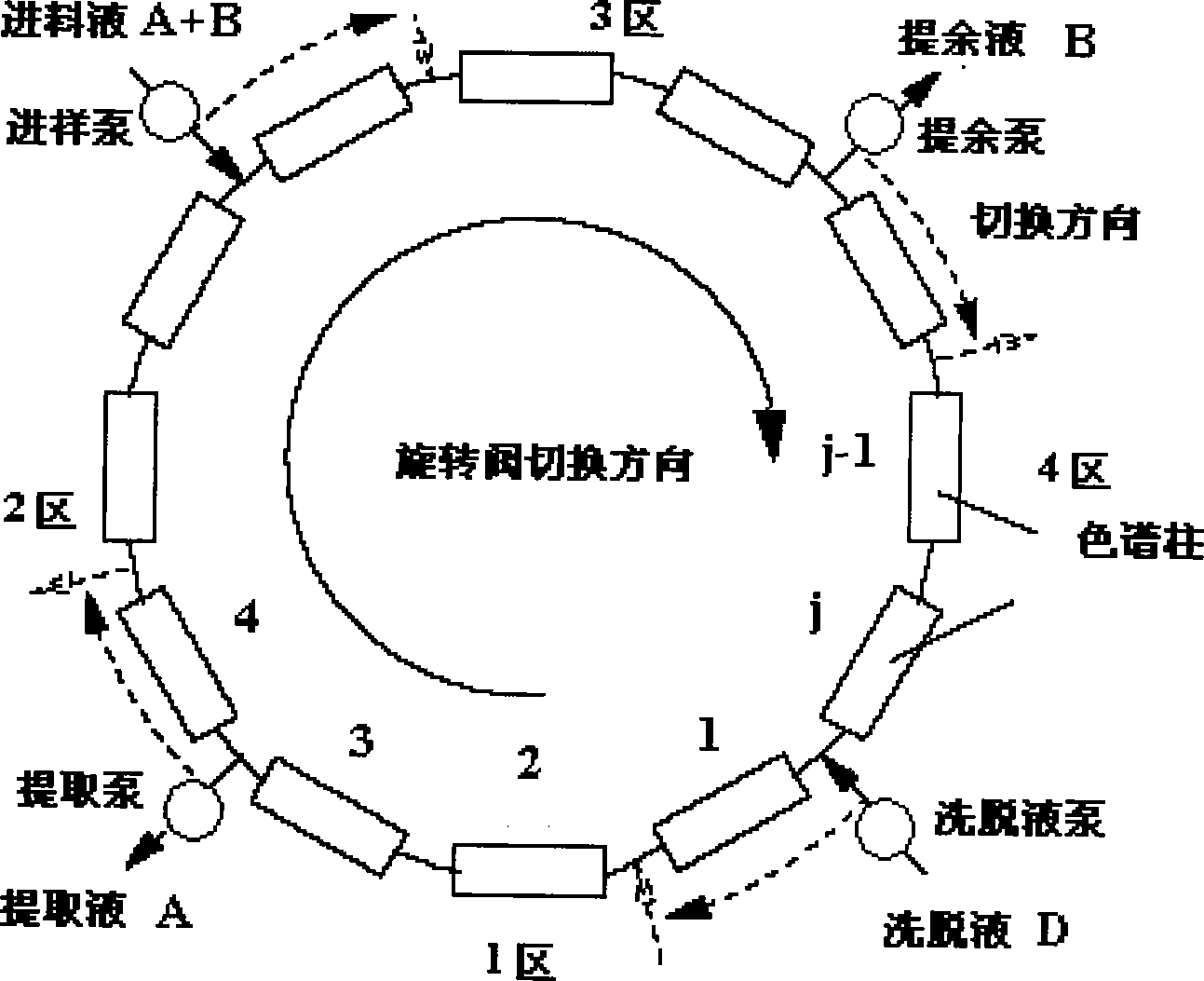

Image

Examples

Embodiment 1

[0033] Simulated moving bed system CSEP _ 916 (Norr, Germany), equipped with 8 chromatographic columns (ID2×10cm), 2 in each zone, the chromatographic columns are filled with silica gel, and the columns are packed by high-pressure wet method. The mobile phase was n-hexane / ethanol solution (99.5 / 0.5, v / v), and the temperature was 30°C. The purity of the mixed tocopherols used for feeding is 97.5%, which contains 22.8% of α-tocopherol, 2.8% of β-tocopherol, 34.7% of γ-tocopherol and 37.2% of δ-tocopherol. mg / ml feed solution.

[0034] a. Operating conditions

[0035] Injection liquid flow rate: U F =1ml / min

[0036] Eluent flow rate: U D =2.8ml / min

[0037] Raffinate flow rate: U R =2.0ml / min

[0038] Extraction flow rate: U E =1.8ml / min

[0039] Zone 1 velocity: U E =6.4ml / min

[0040] Switching time: t s =757s

[0041] b. Finished product analysis

[0042] The composition of raffinate and extract was analyzed by silica gel column. The purity and yield of δ-toco...

Embodiment 2

[0044] Simulated moving bed system CSEP_ 916 (Norr, Germany), equipped with 8 chromatographic columns (ID2×10cm), 2 in each zone, the chromatographic columns are filled with powdered activated carbon, and packed by high-pressure wet method. The mobile phase was n-hexane / methanol solution (99.5 / 0.5, v / v), and the temperature was 30°C. The purity of the mixed tocopherols used for feeding is 97.5%, which contains 22.8% of α-tocopherol, 2.8% of β-tocopherol, 34.7% of γ-tocopherol and 37.2% of δ-tocopherol. mg / ml feed solution.

[0045] a. Operating conditions

[0046] Injection liquid flow rate: U F =1ml / min

[0047] Eluent flow rate: U D =2.6ml / min

[0048] Raffinate flow rate: U R =1.8ml / min

[0049] Extraction flow rate: U E =2.0ml / min

[0050] Zone 1 velocity: U E =6.7ml / min

[0051] Switching time: t s =720s

[0052] b. Finished product analysis

[0053] The composition of raffinate and extract was analyzed by silica gel column. The purity and yield of δ-tocoph...

Embodiment 3

[0055] Simulated moving bed system CSEP _ 916 (Noel, Germany), equipped with 8 chromatographic columns (ID2×10cm), 2 in each zone, the chromatographic columns are filled with activated alumina, and the columns are packed by high-pressure wet method. The mobile phase was n-hexane / acetone solution (99 / 1, v / v), and the temperature was 30°C. The purity of the mixed tocopherols used for feeding is 97.5%, which contains 22.8% of α-tocopherol, 2.8% of β-tocopherol, 34.7% of γ-tocopherol and 37.2% of δ-tocopherol. mg / ml feed solution.

[0056] a. Operating conditions

[0057] Injection liquid flow rate: U F =1ml / min

[0058] Eluent flow rate: U D =3.1ml / min

[0059] Raffinate flow rate: U R =2.2ml / min

[0060] Extraction flow rate: U E =1.9ml / min

[0061] Zone 1 velocity: U E =6.9ml / min

[0062] Switching time: t s =708s

[0063] b. Finished product analysis

[0064] The composition of raffinate and extract was analyzed by silica gel column. The purity and yield of δ-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com