Auxiliary powder adding device and processing method for functional rotor spinning yarns

A technology of rotor spinning and auxiliary devices, which is applied in the field of textile processing, can solve problems such as complicated procedures, and achieve the effects of short production process, increased product added value, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

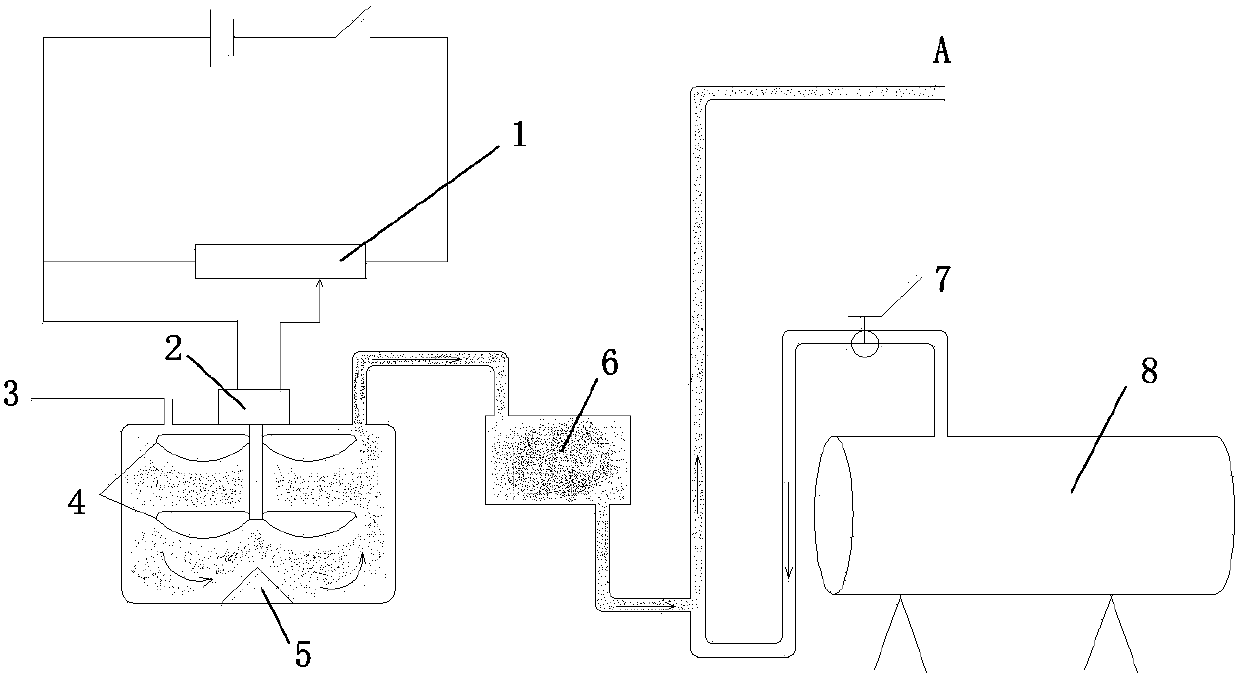

[0015] A powder application auxiliary device for functional rotor spinning yarn, the powder application auxiliary device is installed at the rear of the rotor spinning machine, the powder application auxiliary device includes a static chamber 6, the pipeline of the static chamber and the air compressor 8 pass through The valve 7 is connected, and the other end A of the static chamber is connected to the end of the rotor cup of the rotor spinning machine through a pipeline. The pipeline is connected with the cone body 5, the fan blade 4 is arranged in the cone body, the air vent 3 is arranged on the cone body, the cone body is connected with the output end of the motor 2, and the sliding rheostat 1 is arranged on the motor.

[0016] The processing method of the functional rotor spinning yarn, its steps are as follows: Use a high-energy impact mill to grind the sandalwood fragments into powder, put the powder into the powder application auxiliary device, and the powder enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com