Preparation method of transparent ceramic

A technology for transparent ceramics and powders, applied in the field of ceramic materials, can solve the problems of generating chloride ions and nitrate ions, the process does not have environmental protection requirements, and increasing production costs, achieving low cost of raw materials, shortening sintering time, and improving sintering. effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention will be further described below in conjunction with more specific embodiments, but it should be pointed out that the transparent ceramic and its preparation method of the present invention are not limited to this specific form or steps. Those skilled in the art can obviously understand that the following explanations can be directly applied to other similar compounds or preparation methods not specified herein even without any adjustment or modification.

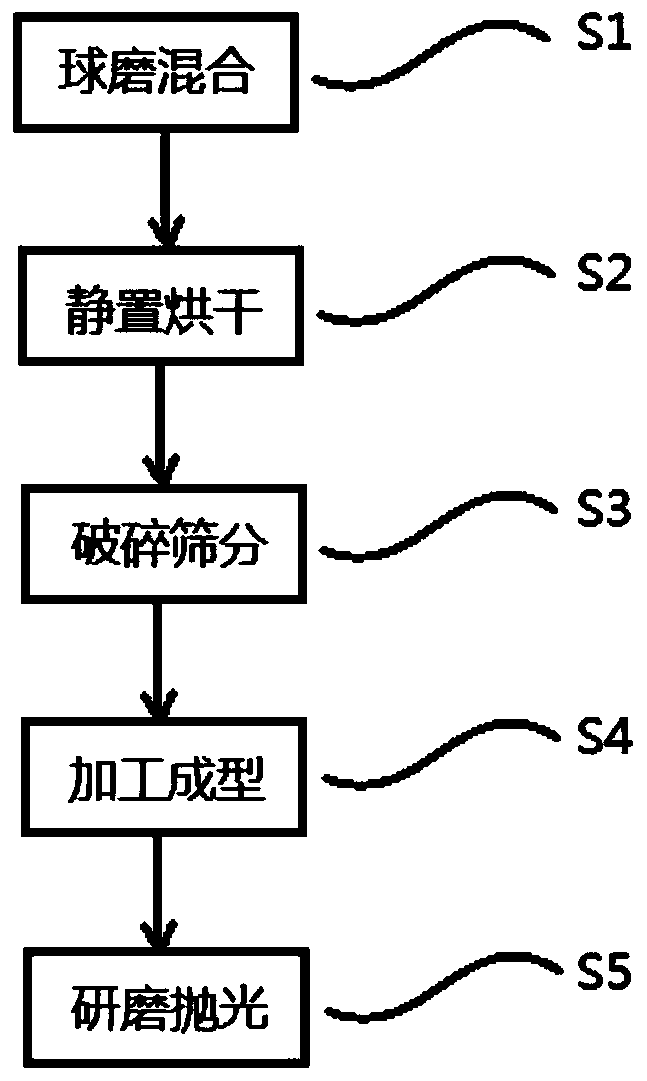

[0027] Such as figure 1 Shown, the preparation method of transparent ceramic of the present invention comprises the following steps:

[0028] S1: Put the oxide powder and sintering aid in a ball milling tank at a certain weight percentage, add an appropriate amount of deionized water or absolute ethanol at the same time, and use a planetary ball mill to continuously ball mill at room temperature for 2-12 hours;

[0029] Among them, the oxide powder can be Y 2 o 3 、Al 2 o 3 、Sc 2 o 3 、Lu 2...

Embodiment 1

[0043] S1: To 10kg of yttrium aluminum garnet (Y 3 al 5 o 12 ) Add 0.05kg of LiF and 0.05kg of SiO to the powder 2 As a sintering aid, put the resulting mixture into a nylon ball mill jar, and put alumina balls and deionized water at the same time; make the weight ratio of the aforementioned powder mixture to the alumina balls 1:20, and the added deionized water The amount of ionic water is just enough to submerge the powder and balls; the powder is ball milled with a planetary ball mill, the speed of the ball mill is 200 rpm, and the ball milling time is 12 hours.

[0044] S2: After the ball milling, transfer the ball-milled slurry to a glass vessel of appropriate size, and place it in a drying oven for drying treatment. The drying temperature is 90° C. and the drying time is 2 hours.

[0045] S3: The dried powder has agglomeration and needs to be crushed; use the corresponding crushing method according to the degree of agglomeration; the crushed powder is then passed thro...

Embodiment 2

[0052] S1: To 1kg yttrium aluminum garnet (Y 3 al 5 o 12 ) in the powder, add 0.01kg of LiF and 0.01kg of MgO as sintering aids, put the obtained mixture into a nylon ball mill jar, put alumina balls and deionized water into it simultaneously; make the powder mixture and alumina mill The weight ratio of the balls is 1:15, and the amount of deionized water added is just enough to submerge the powder and the balls; the powder is milled with a planetary ball mill, the speed of the ball mill is 180 rpm, and the milling time is 10 hours.

[0053] S2: After the ball milling, transfer the ball-milled slurry to a glass petri dish of appropriate size, and place it in a drying oven for drying treatment. The drying temperature is 90° C. and the drying time is 4 hours.

[0054] S3: The dried powder has agglomeration and needs to be crushed; use the corresponding crushing method according to the degree of agglomeration; the crushed powder is then passed through a 200-400 mesh sieve.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com