A kind of forsterite-carbon gunning material for non-ferrous smelting furnace

A technology of forsterite and forsterite sand, which is applied in the field of lining gunning materials for non-ferrous smelting furnaces, can solve the problems of loss of kiln service life, spalling of refractory lining structure, and delay in production, so as to prolong service life and improve sintering process , the effect of fluidity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

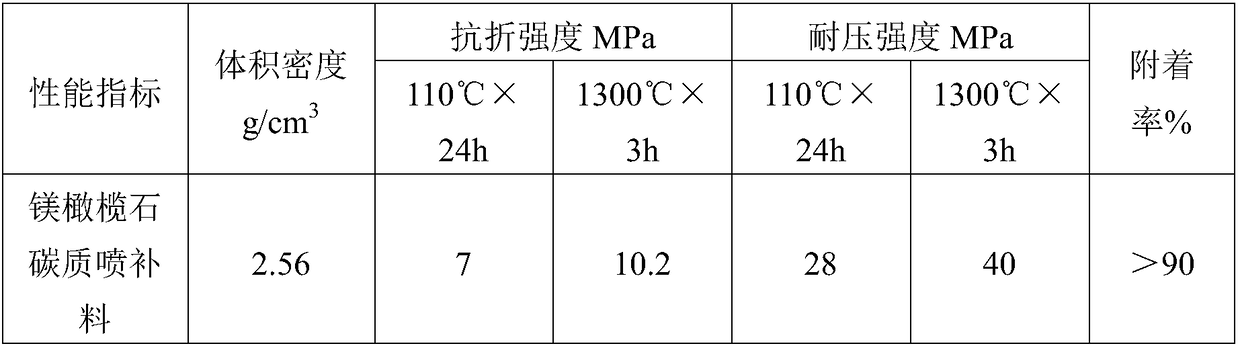

Embodiment 1

[0031] Forsterite-carbon gunning material for non-ferrous smelting furnaces of the present invention, represented by weight percent, consists of 60% of synthetic forsterite sand with a particle size of 0-3mm, and 15% of mid-range magnesia with a particle size of 2-4mm. , composed of 10% fused magnesia with a particle size of <0.088mm, 5% binder and 10% additives;

[0032] The synthetic forsterite sand is prepared by the following method:

[0033] a. First, place magnesite tailings, quartz powder and light-burned magnesium powder in a ball mill to grind them to <0.044mm;

[0034] b. Add 70wt% of tailings powder, 15wt% of quartz powder and 15wt% of light-burned magnesium powder into the three-dimensional mixer, fully mix evenly, and the mixing time is 10 minutes ;

[0035] c. Press the homogeneously mixed powder mixture in step b into a spherical solid billet, the bulk density of the solid billet>2.30g / cm 3 ; The solid billet is dried naturally, and the ball is obtained after...

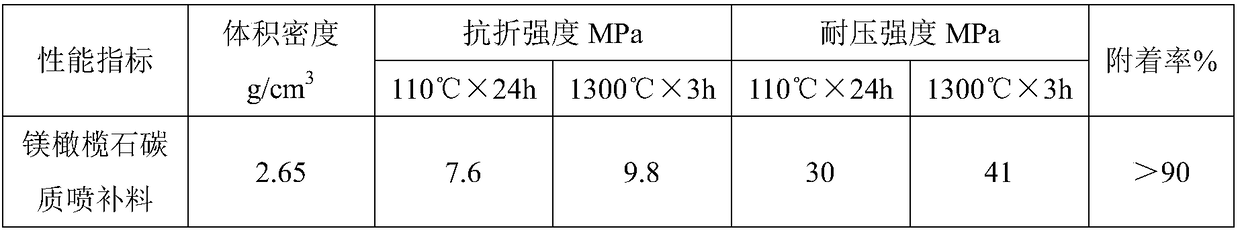

Embodiment 2

[0044] Forsterite-carbon gunning material for non-ferrous smelting furnaces of the present invention, represented by weight percent, consists of 50% of synthetic forsterite sand with a particle size of 0-3mm, and 20% of mid-range magnesia with a particle size of 2-4mm. , composed of 15% fused magnesia with particle size <0.088mm, 9% binder and 6% additive;

[0045] The synthetic forsterite sand is prepared by the following method:

[0046] a. First, place magnesite tailings, quartz powder and light-burned magnesium powder in a ball mill to grind them to <0.044mm;

[0047] b. Add 75wt% of tailings powder, 17wt% of quartz powder and 8wt% of light-burned magnesium powder into the three-dimensional mixer, and mix well for 15 minutes. ;

[0048] c. Press the homogeneously mixed powder mixture in step b into a spherical solid billet, the bulk density of the solid billet>2.30g / cm 3 ; The solid billet is dried naturally, and the ball is obtained after drying;

[0049] d. Put the b...

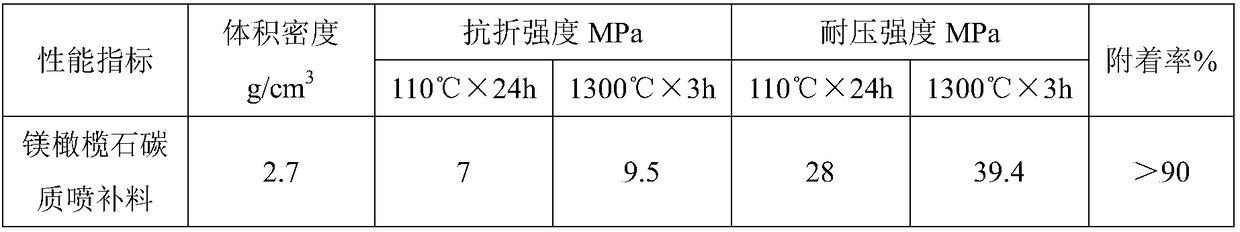

Embodiment 3

[0057] Forsterite-carbon gunning material for non-ferrous smelting furnaces of the present invention, represented by weight percent, consists of 40% of synthetic forsterite sand with a particle size of 0-3mm, and 25% of mid-range magnesia with a particle size of 2-4mm. , composed of 20% fused magnesia with a particle size of <0.088mm, 8% binder and 7% additives;

[0058] The synthetic forsterite sand is prepared by the following method:

[0059] a. First, place magnesite tailings, quartz powder and light-burned magnesium powder in a ball mill to grind them to <0.044mm;

[0060] b. Add 62wt% of tailings powder, 25wt% of quartz powder and 13wt% of light-burned magnesium powder into the three-dimensional mixer, mix well and evenly, and the mixing time is 20 minutes ;

[0061] c. Press the homogeneously mixed powder mixture in step b into a spherical solid billet, the bulk density of the solid billet>2.30g / cm 3 ; The solid billet is dried naturally, and the ball is obtained aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com