Shape memory alloy isolating valve

A technology of memory alloy and isolation valve, which is applied in valve details, safety valves, balance valves, etc., can solve the problems of valve shell structure damage and sealing, task failure, failure, etc., and achieve high working reliability, high structural reliability, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

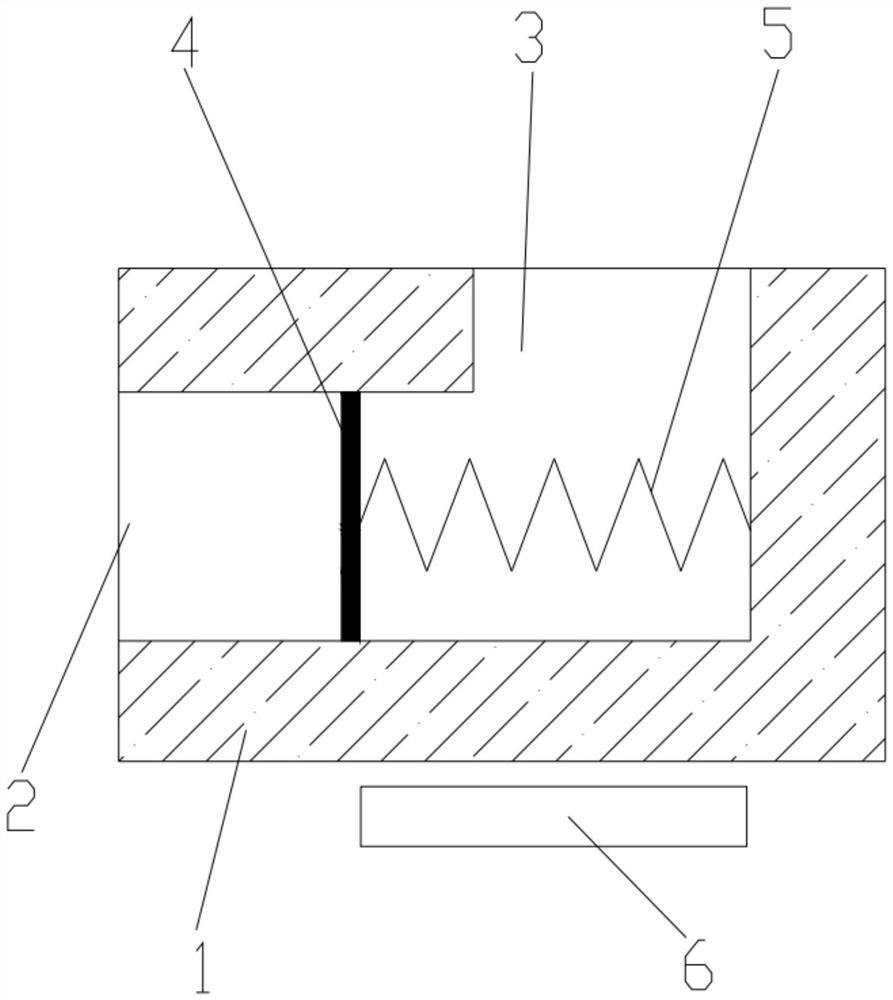

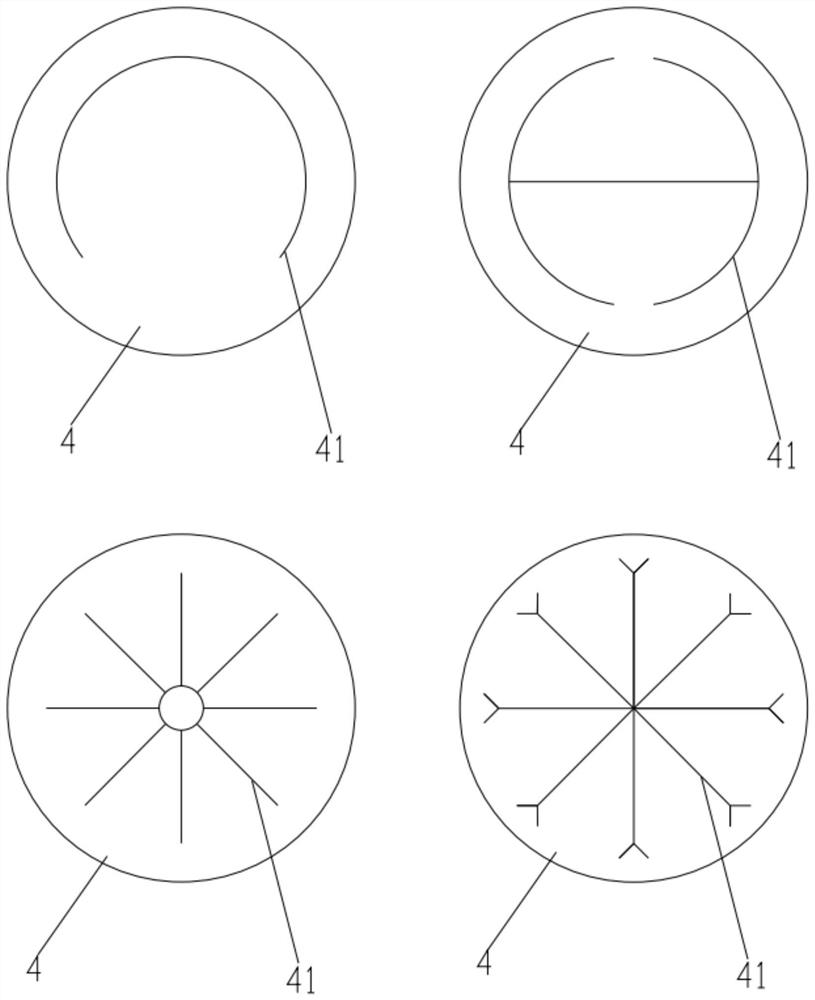

[0024] Such as figure 1 and image 3 As shown, a shape memory alloy isolation valve shown in this embodiment includes a valve body 1 with a channel inside, a channel inlet 2 and a channel outlet 3 are respectively provided at the front and rear ends of the channel, and a channel is provided in the channel The partitioned isolation diaphragm 4 is provided with a spring 5 on the side of the isolation diaphragm 4 close to the channel outlet 3, the material of the spring 5 is a shape memory alloy, and the other end of the spring 5 is connected to the inner wall of the valve body 1; In the structure, the isolation diaphragm 4 can block the flow of fluid in the channel and play the role of isolation. At this time, the isolation valve is in a closed state. Due to the physical characteristics of the shape memory alloy, the spring 5 has a shape memory effect. When the spring 5 is heated , the physical properties of the shape memory alloy can lead to deformation of the spring 5, the sp...

Embodiment 2

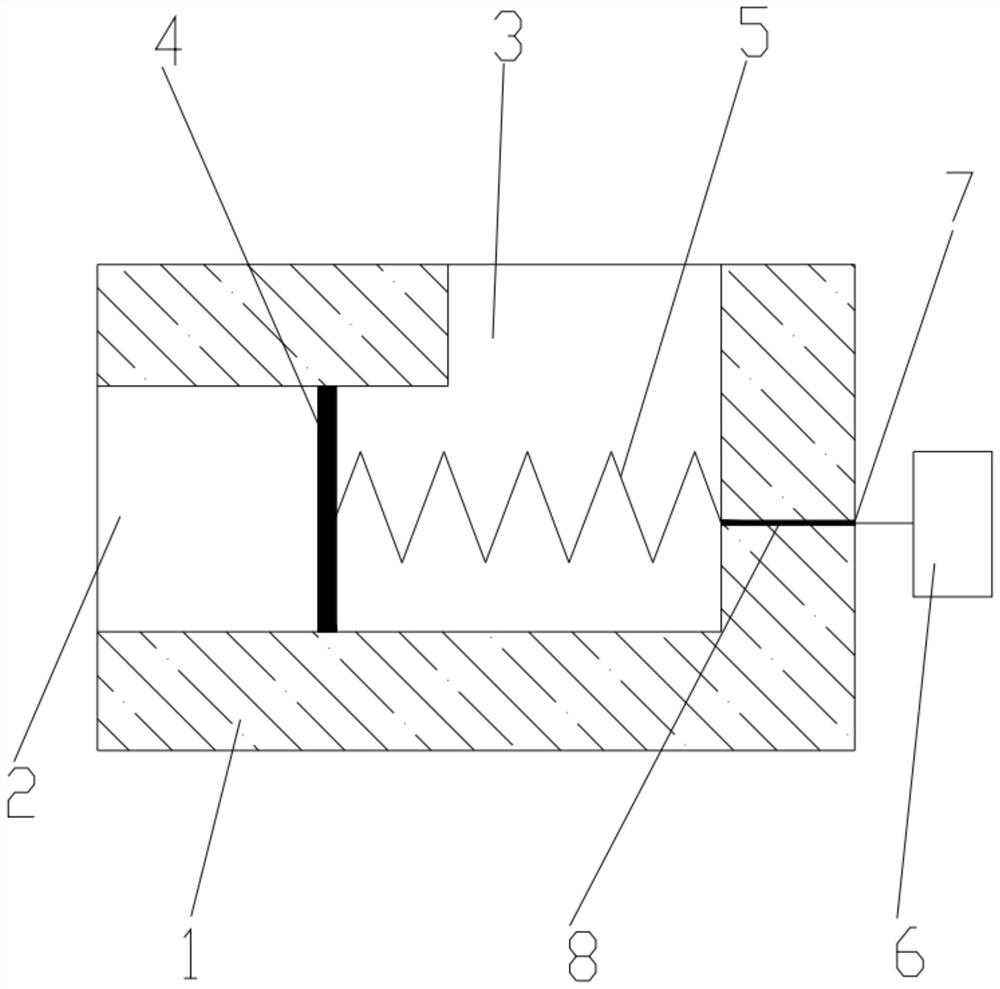

[0030] Such as Figure 2-3 As shown, a shape memory alloy isolation valve shown in this embodiment includes a valve body 1 with a channel inside, a channel inlet 2 and a channel outlet 3 are respectively provided at the front and rear ends of the channel, and a channel is provided in the channel The partitioned isolation diaphragm 4 is provided with a spring 5 on the side of the isolation diaphragm 4 close to the channel outlet 3, the material of the spring 5 is a shape memory alloy, and the other end of the spring 5 is connected to the inner wall of the valve body 1; In the structure, the isolation diaphragm 4 can block the flow of fluid in the channel and play the role of isolation. At this time, the isolation valve is in a closed state. Due to the physical characteristics of the shape memory alloy, the spring 5 has a shape memory effect. When the spring 5 is heated , the physical properties of the shape memory alloy can cause the spring 5 to deform, the spring 5 extends for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com