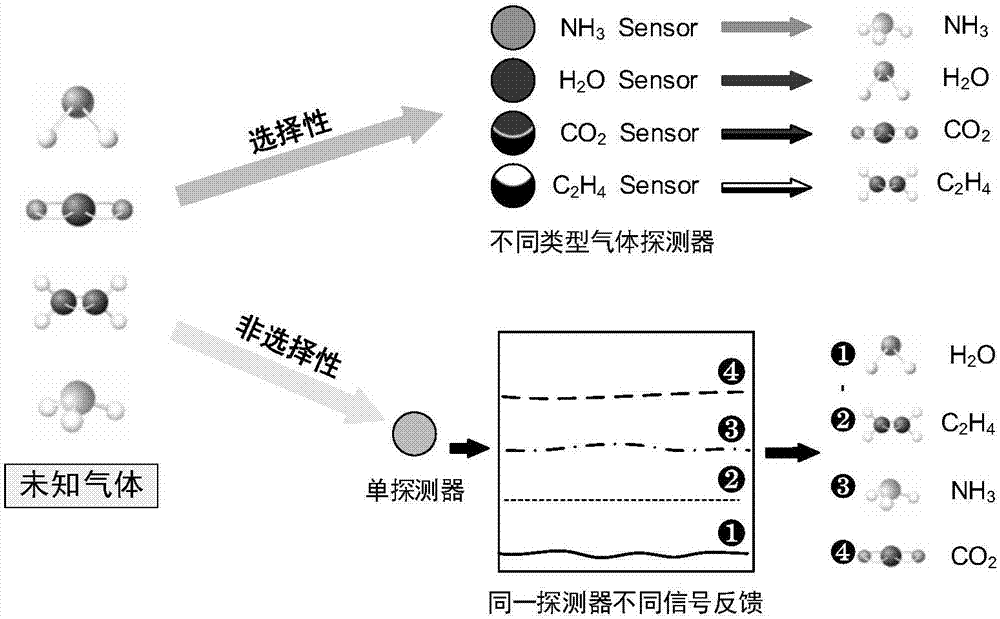

Non-selective fire gas detection device based on viscosity properties

A non-selective, detection device technology, used in measurement devices, flow characteristics, instruments, etc., can solve the problem of difficult to accurately identify the type of leaking gas, and achieve the effect of mild operating conditions, fast identification process, and accurate detection and identification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

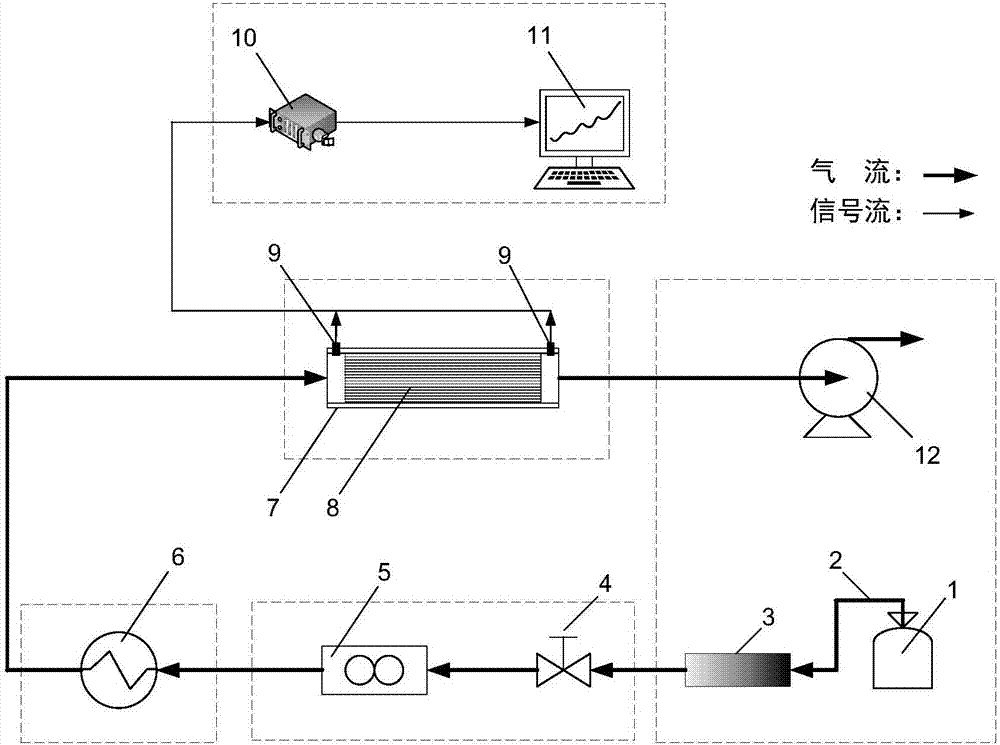

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] see figure 2 As shown, the non-selective fire gas detection device based on viscosity properties of the present invention is composed of 5 units of sampling, flow rate control, constant temperature control, detection and identification, and data recording and analysis, specifically comprising: the gas storage bag 1 for the sample to be tested, the sampling unit Pipe 2, filter and dryer 3, flow regulating valve 4, flow meter 5, constant temperature heater 6, sleeve pipe 7, porous medium 8, gas micro pressure difference sensor 9, data collector 10, microcomputer 11 and explosion-proof vacuum pump 12 . Wherein, the sampling tube 2 may be a copper tube with an inner diameter of 6 mm and an outer diameter of 8 mm, and the casing 7 may be a silicone tube with an inner diameter of 8 mm and an outer diameter of 14 mm.

[0025] During the detection process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com