Hydrophobic solid microspheres containing epidermal growth factors and preparation method and application of microspheres

A technology of epidermal growth factor and solid, applied in skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of maintaining EGF activity and not solving for a long time, and achieves simple preparation process, no three wastes, and easy use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

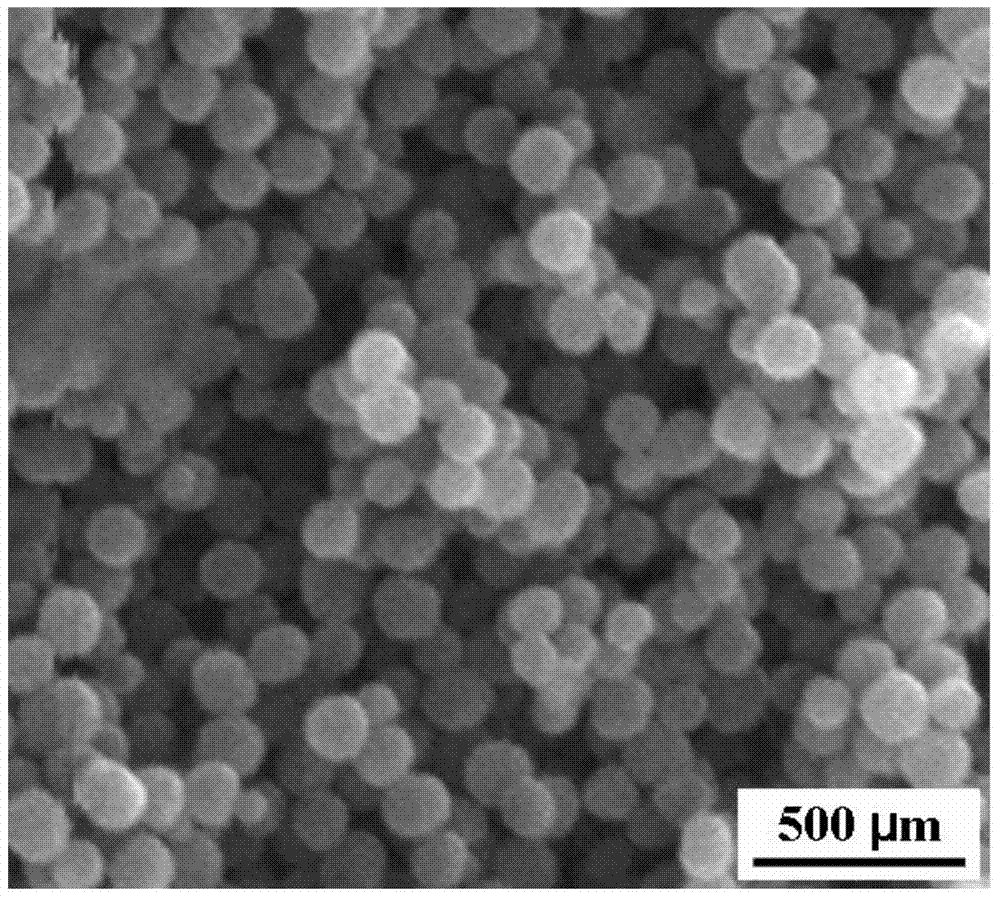

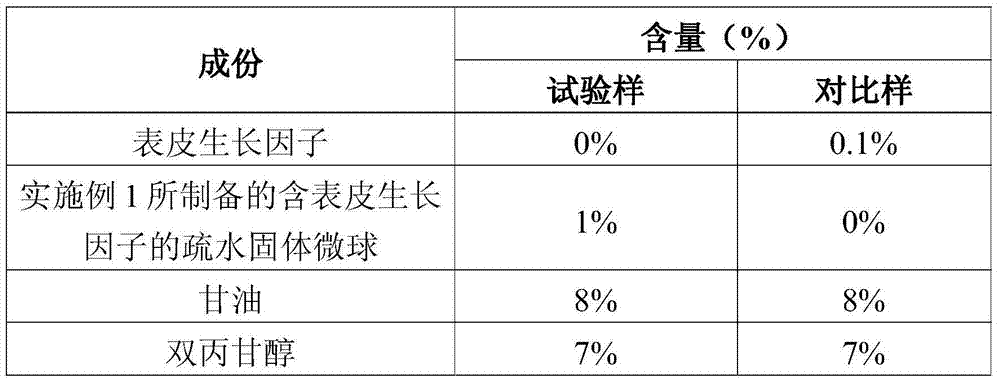

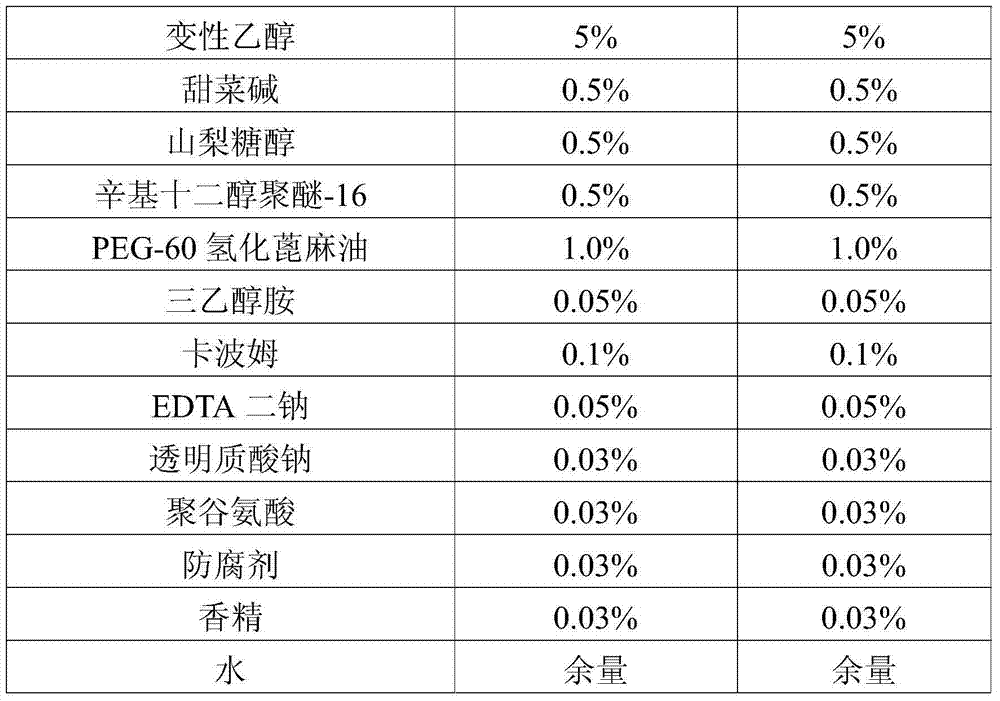

[0033] Add 10 g of polyethylene glycol (PEG-2000, white solid, melting point 51±2°C) into 100 mL of deionized water, stir at 400 rpm at 0°C until completely dissolved, freeze at -5°C and then lyophilize. After ball milling at -10°C, pass through a 115-mesh sieve (125 μm) to obtain polyethylene glycol porous microspheres.

[0034] At 0°C, mix 1 g of polyethylene glycol porous microspheres and 0.1 g of epidermal growth factor powder (purchased from Sigma; name: EGF Epidermal cell growth factor; property: lyophilized powder, BioReagent, suitable for cell culture; CAS number: 62229-50-9) into a three-dimensional mixer, first stirred at a low speed of 600rpm for 1min, and then stirred at a high speed of 1200rpm for 1min to obtain polyethylene glycol porous microspheres containing epidermal growth factor.

[0035] At 0°C, spread 1g of polyethylene glycol porous microspheres containing epidermal growth factor on the vibrating conveyor belt, and melt paraffin (section paraffin, pathol...

Embodiment 2

[0038] Add 10g of polyethylene glycol (PEG-4000, white solid, melting point 55±2°C) into 200mL of deionized water, stir at 300rpm at 5°C until completely dissolved, freeze at -80°C and then lyophilize. After ball milling at -20°C, pass through a 115-mesh sieve (125 μm) to obtain polyethylene glycol porous microspheres.

[0039] At 5°C, mix 1 g of polyethylene glycol porous microspheres and 0.2 g of epidermal growth factor powder (purchased from Sigma; name: EGF Epidermal cell growth factor; property: lyophilized powder, BioReagent, suitable for cell culture; CAS number: 62229-50-9) into a three-dimensional mixer, first stirred at a low speed of 500rpm for 2 minutes, and then stirred at a high speed of 2000rpm for 3 minutes to obtain polyethylene glycol porous microspheres containing epidermal growth factor.

[0040] At 5°C, spread 1g of polyethylene glycol porous microspheres containing epidermal growth factor on a vibrating conveyor belt, and melt paraffin (section paraffin, ...

Embodiment 3

[0042] Add 10g of polyethylene glycol (PEG-6000, white solid, melting point 57±2°C) into 400mL of deionized water, stir at 200rpm at 15°C until completely dissolved, freeze at -65°C and then lyophilize. After ball milling at -15°C, pass through a 115-mesh sieve (125 μm) to obtain polyethylene glycol porous microspheres.

[0043] At 15°C, 1 g of polyethylene glycol porous microspheres and 0.1 g of epidermal growth factor powder (purchased from Sigma; name: EGF Epidermal cell growth factor; properties: lyophilized powder, BioReagent, suitable for cell culture; CAS number: 62229-50-9) into a three-dimensional mixer, first stirred at a low speed of 300rpm for 4 minutes, and then stirred at a high speed of 2500rpm for 4 minutes to obtain polyethylene glycol porous microspheres containing epidermal growth factor.

[0044] Spread 1g of polyethylene glycol porous microspheres containing epidermal growth factor on a vibrating conveyor belt at 15°C, and melt paraffin (section paraffin, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com